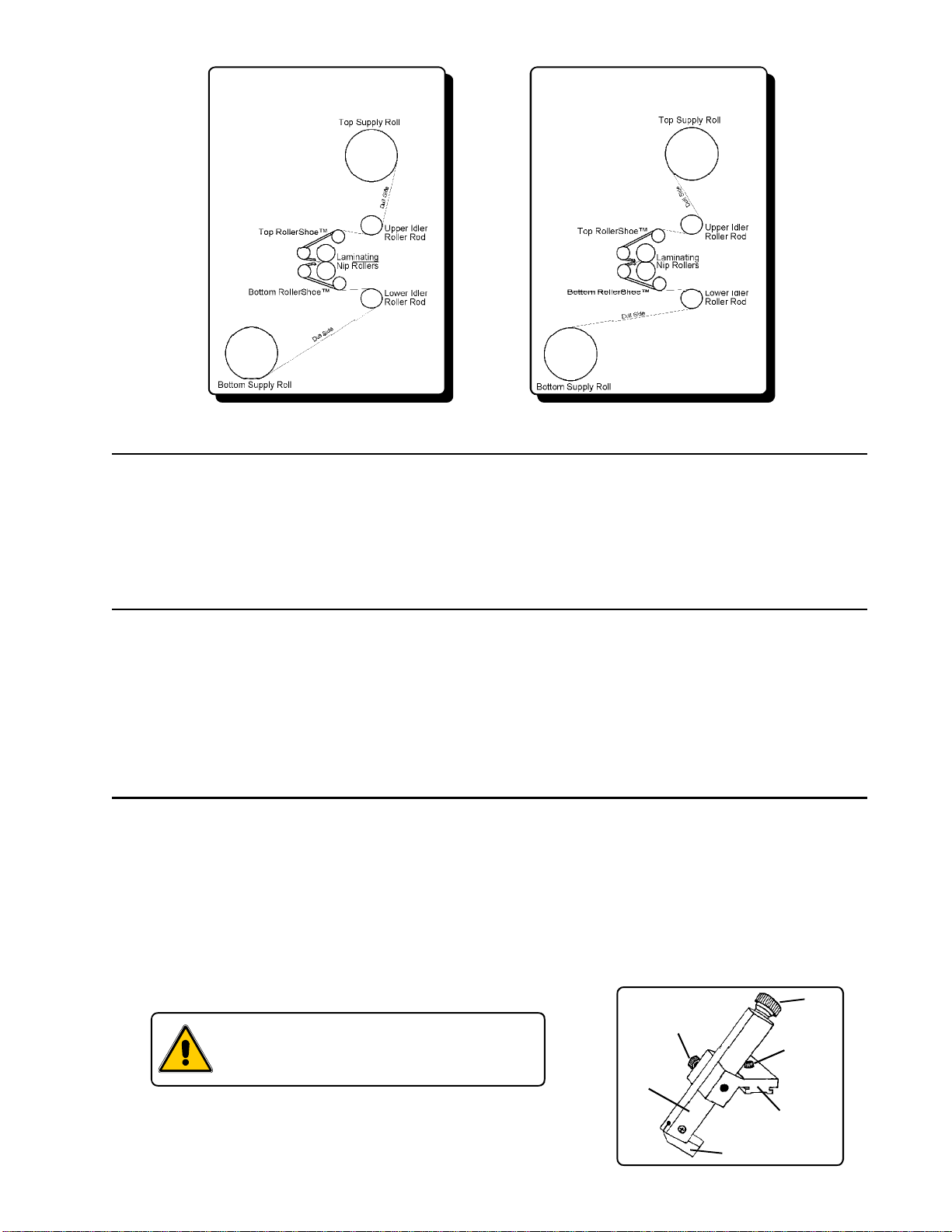

7. Set the FORWARD/REVERSE switch to the FORWARD position.

8.Turnthe MOTOR CONTROL ON/OFF switchtotheON position.

9.Turn the MOTORCONTROLknob far enoughtosufficiently pull afeedcard into thelaminator.

10. Feed the feed card between the RollerShoes™ and into the front rollers.

11.After the laminatoris properly threaded andthe poster board hasexited the rear ofthe laminator, makeany

necessary adjustments.

VIII. Coating Mount Board...

TheFinisher 2700 is capable ofapplyinganadhesive coating to mount boardthathasnot previous been coated.

1.Loada roll of adhesive, withthelinerwoundto the outside, onto thetopmandrelinthe same manner as with

laminatingfilm.

2. If the mount board is the same width as the roll of adhesive it is not necessary to load anything onto the

bottommandrel. If the mount boardisnarrower than the adhesive,loada roll of paperorfilmonto the bottom

mandrelto keep the adhesivefromaccumulating on the rollers andheatshoes. Thread as for laminatingfilm.

3. Select the MOUNT position on the right side of your laminator.

4.Turn the HEATED ROLLERS andtheTOPAND BOTTOM HEAT switches totheONpositions. The heated

rollersarenecessaryonlyduringwarm-upandmaybe turned off for most applications when operating tempera-

tureisreached.

5.Set the temperature toapproximately 200°F, depending uponthe type of adhesiveused. The Finisher2700

will take approximately 10 minutes to reach operating temperature. The roller and shoe temperatures are

indicated on the LCD displays on the control panel.

6.Feed the uncoated mountboard into the laminatorbehind a leader board. Theleaderboard will prevent the

compressionof the leading edge ofyourmount board.

7. Youmay coat subsequentboards now, one directlybehind the other, sothat the board infront becomes the

leaderboard. We recommend thatyou coat a sufficientsupply of mount boardinone session so you’llhave it

readyforfuture use.

IX. Mounting & Laminating...

Preparing your print for mounting:

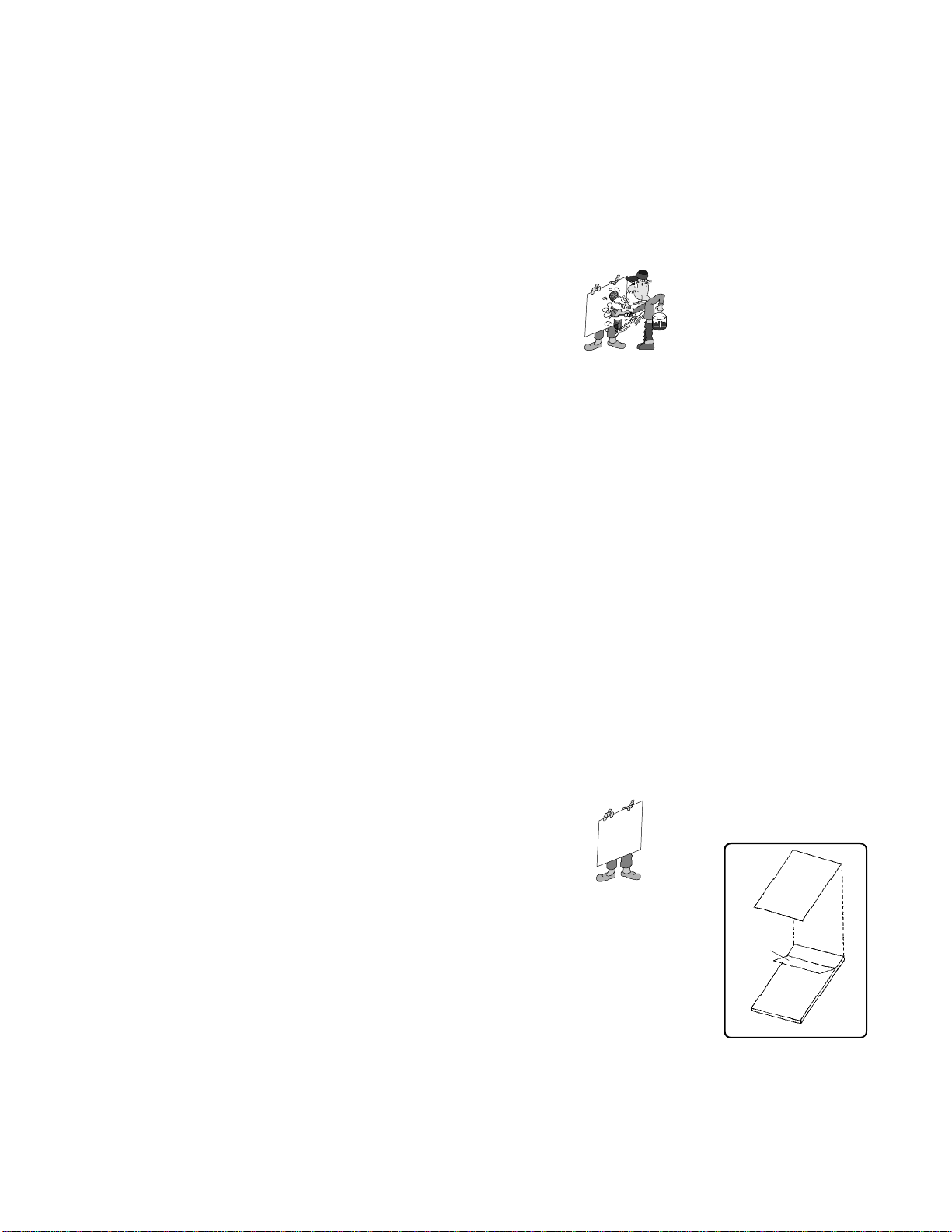

1. Peel back about 4” of the release liner on your precoated, low-tack mount board.

2. Align the top edge of your print with the top edge of the mount board (see Figure 4).

Mounting your Print:

1. Be sure all laminator parts (i.e. safety shield, feed table, etc.) are in their proper

positionsand the laminatingfilmis loaded correctly (See page5 for film loading

instructions).

2.Select the MOUNTpositionusing the PRESSURE

PRINT

MOUNT

BOARD

RELEASE

LINER

Figure 4

3. Turn the HEATED ROLLERS switch and the TOP & BOTTOM HEAT switches to the ON positions. The

heated rollers are necessary only during warm-up and may be turned off for most applications when operat-

ing temperature is reached.

8

abcoffice 800-658-8788 www.abcoffice.com