1 Product Description

Advanced sensor with dual digital displays for use with plastic and glass fiber optic assemblies

• Best in class response speeds of: 10 µs, 15 µs, 50 µs, 250 µs, 500 µs, 1000 µs and

2000 µs allow the operator to optimize for fast response, long distance

applications, or noisy environments.

• Outstanding color contrast sensitivity; detects 32 levels of gray scale from black to

white

• Choose from IR or one of 4 visible beam colors: red, blue, green and white.

Depending on the beam color and fiber, the sensor reliably detects the toughest

color mark contrasts

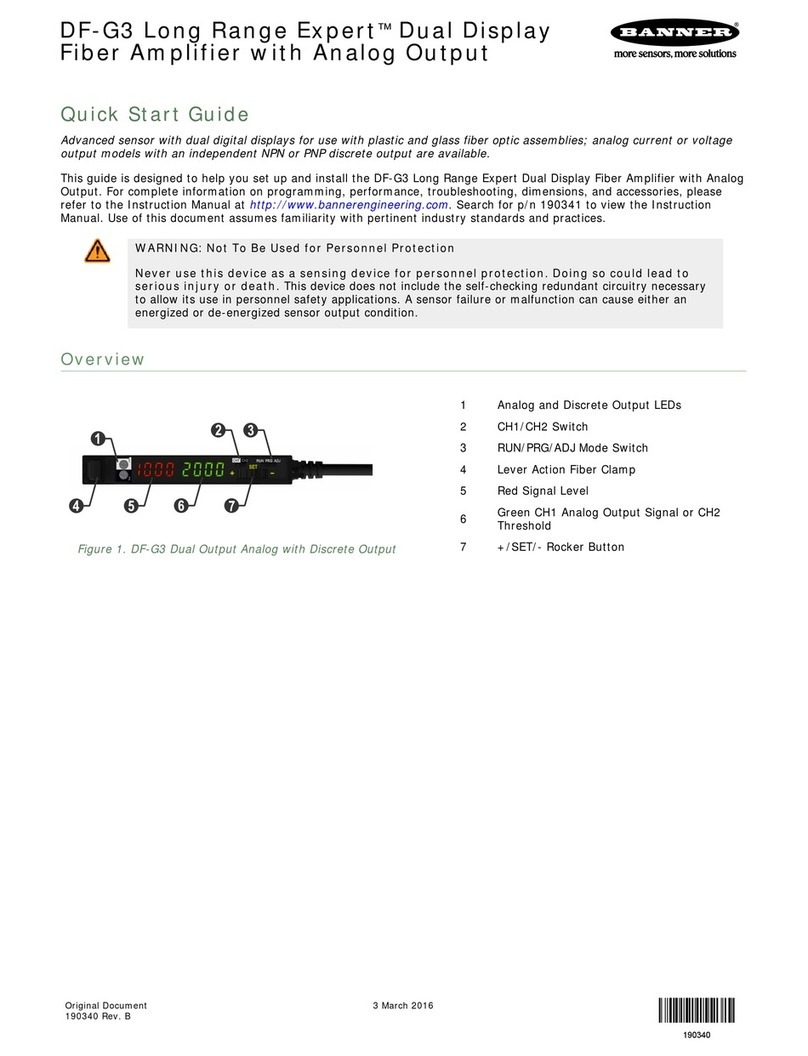

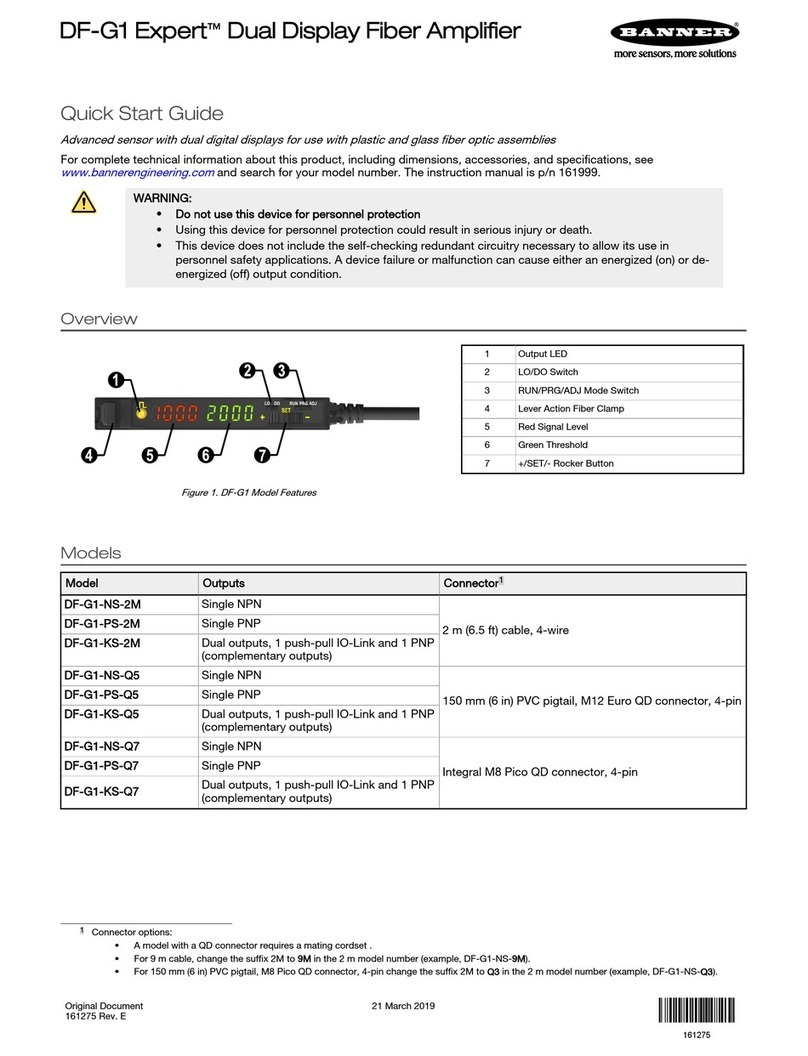

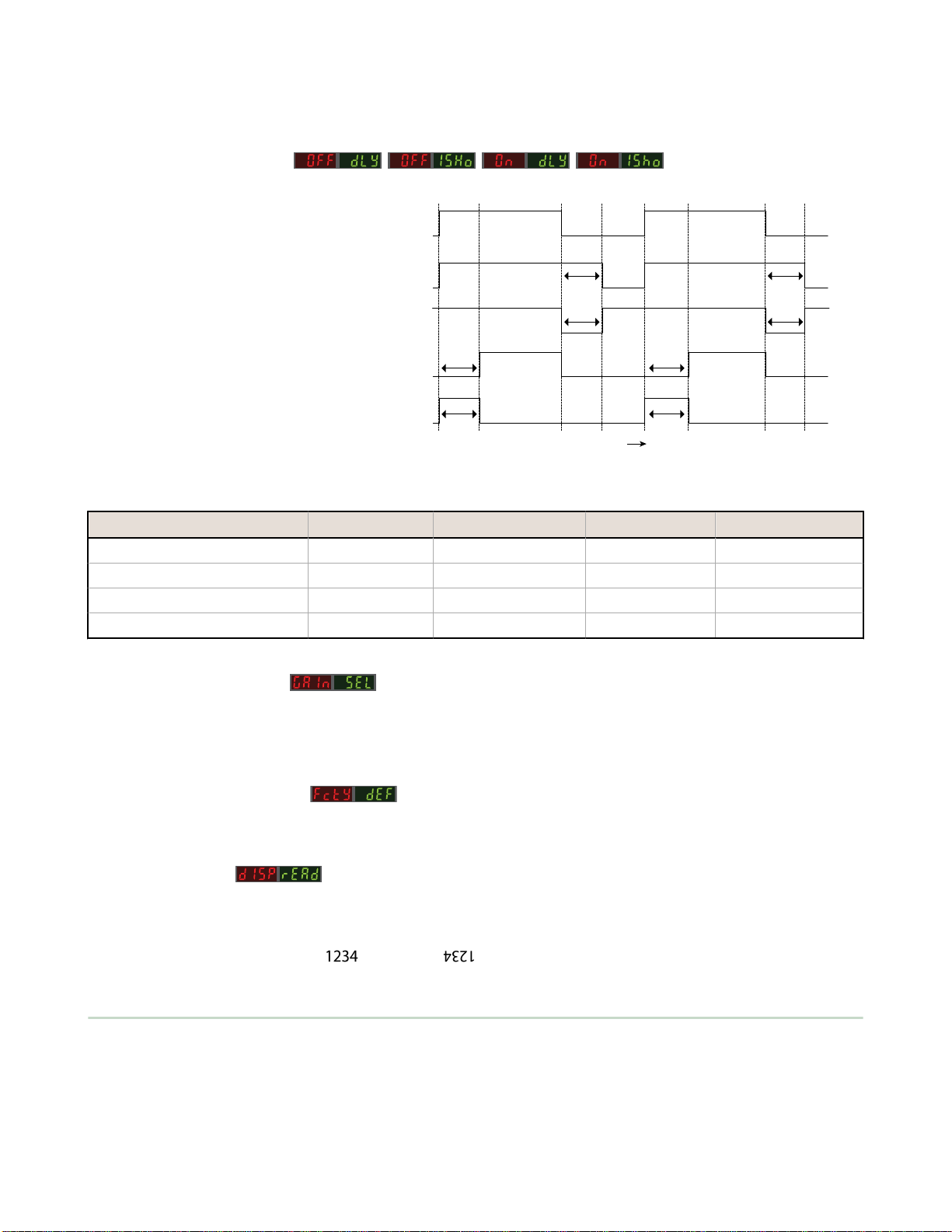

• Easy to read dual digital displays show both signal level and threshold

simultaneously

• Lever action fiber clamp provides stable, reliable, and trouble-free fiber clamping

• Simple user interface ensures easy sensor set-up and programming via displays

and switches/buttons or remote input teach wire

•Expert TEACH and SET methods ensure optimal gain and threshold for all

applications, especially for high speed or low contrast applications

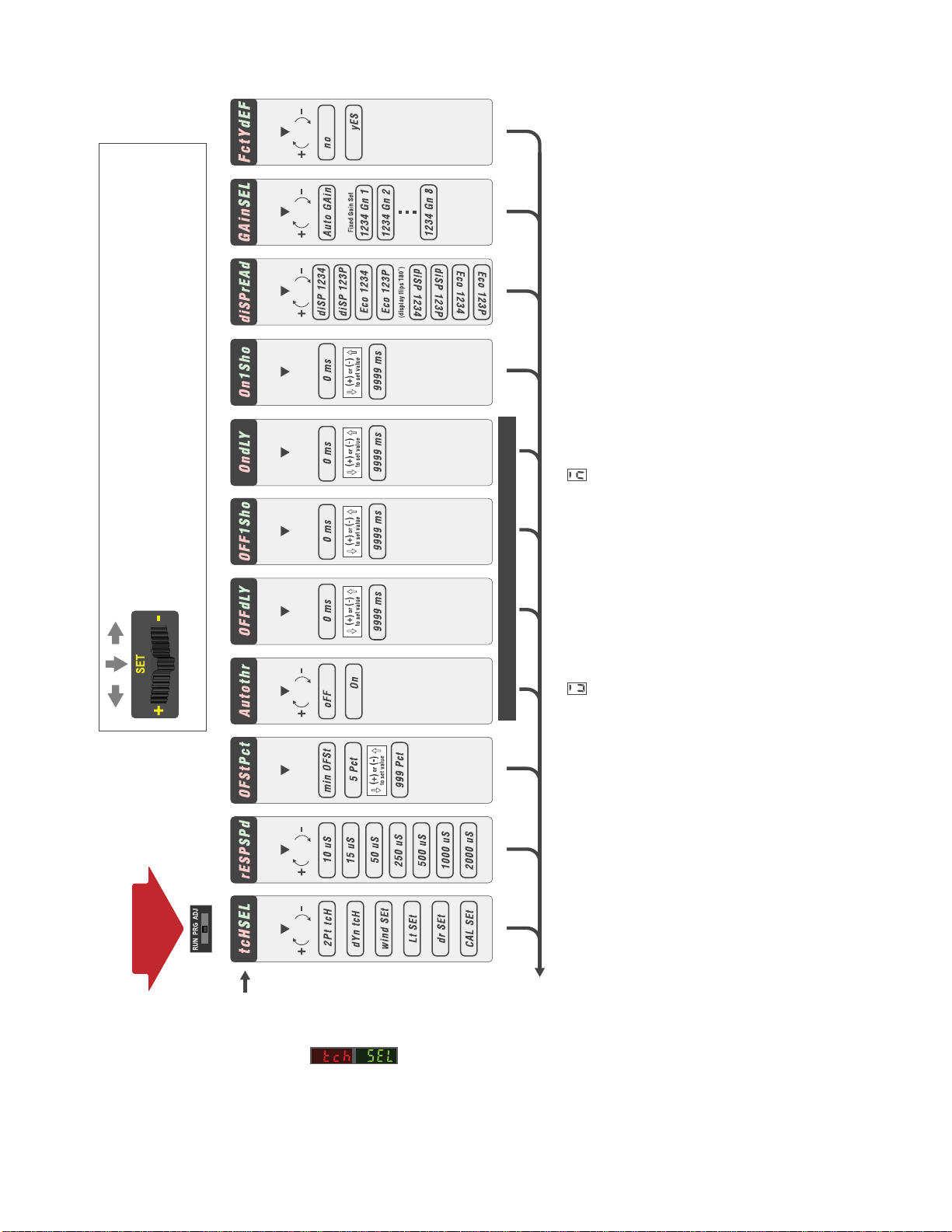

• User has full control over all operating parameters: threshold, Light Operate or

Dark Operate, output timing functions, gain level, and response speed

• Thermally stable electronics shorten start-up time and maintain signal stability

during operation

• ECO (economy) display mode reduces amplifier power consumption by 25%

• Cross talk avoidance algorithm allows two sensors to operate in close proximity for

many applications

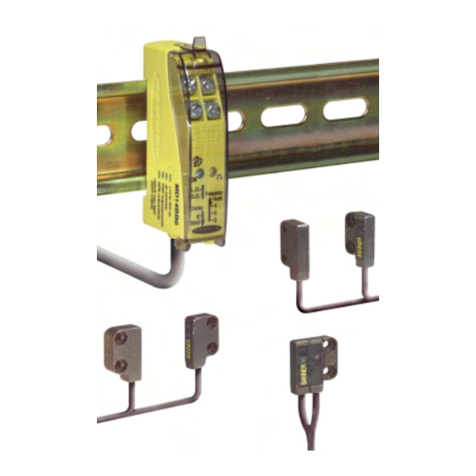

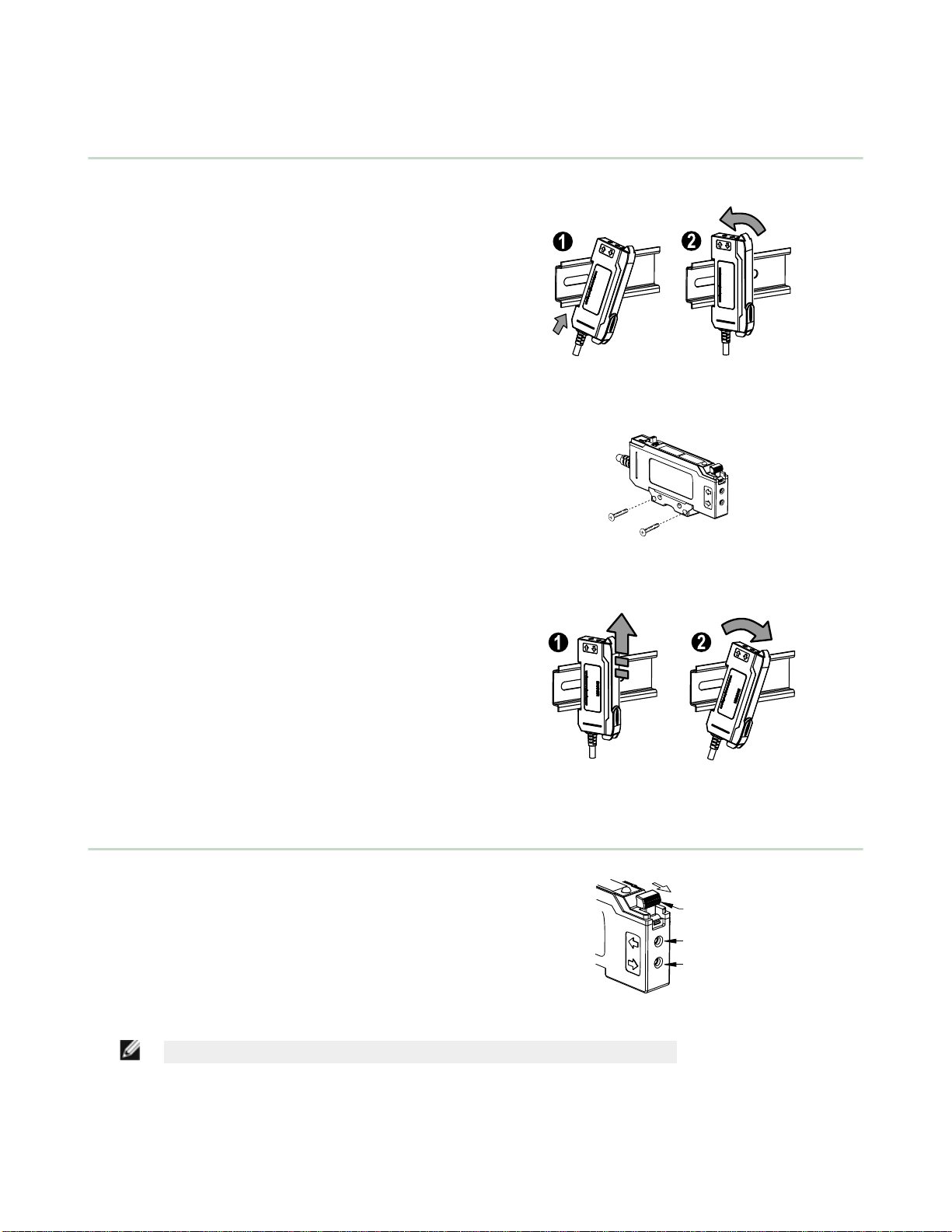

• Sleek 10 mm wide housing mounts to 35 mm DIN rail

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to

serious injury or death. This device does not include the self-checking redundant circuitry necessary

to allow its use in personnel safety applications. A sensor failure or malfunction can cause either an

energized or de-energized sensor output condition.

1.1 Models

Model Sensing Beam Color Reference Sensing Range1Outputs Connector2

DF-G2-NS-2M Visible Red 1100 mm Single NPN

2 m (6.5 ft) cable, 4-wire

DF-G2-PS-2M Single PNP

DF-G2W-NS-2M Broad Spectrum White 550 mm Single NPN

DF-G2W-PS-2M Single PNP

DF-G2G-NS-2M Visible Green 660 mm Single NPN

DF-G2G-PS-2M Single PNP

DF-G2B-NS-2M Visible Blue 770 mm Single NPN

DF-G2B-PS-2M Single PNP

DF-G2IR-NS-2M Infrared 2100 mm Single NPN

DF-G2IR-PS-2M Single PNP

1Excess gain = 1, Long Range response speed, opposed mode sensing. PIT46U plastic fiber used for visible LED models, IT.83.3ST5M6 glass fiber

used for IR model

2Connector options:

• A model with a QD connector requires a mating cordset (see Quick-Disconnect Cordsets on page 29)

• For 9 m cable, change the suffix 2M to 9M in the 2 m model number (example, DF-G2-NS-9M)

• For 150 mm (6 in) PVC pigtail, M8 Pico QD connector, 4-pin change the suffix 2M to Q3 in the 2 m model number (example, DF-G2-NS-

Q3)

• For 150 mm (6 in) PVC pigtail, M12 Euro QD connector, 4-pin change the suffix 2M to Q5 in the 2 m model number (example, DF-G2-

NS-Q5)

• For integral M8 Pico QD connector, 4-pin change the suffix 2M to Q7 in the 2 m model number (example, DF-G2-NS-Q7)

DF-G2 High Speed Expert™Dual Display Fiber Amplifier

www.bannerengineering.com - Tel: 763.544.3164 3