Specifications

Sensing Beam

660 nm visible red

Supply Voltage

NPN/PNP models: 10 to 30 V dc Class 2 (10% maximum ripple)

IO-Link models: 18 to 30 V dc (10% maximum ripple)

Power and Current Consumption (exclusive of load)

Standard display mode: 960 mW, Current consumption < 40 mA at

24 V dc

ECO display mode: 720 mW, Current consumption < 30 mA at 24 V

dc

Supply Protection Circuitry

Protected against reverse polarity and transient overvoltages

Delay at Power-Up

500 milliseconds maximum; outputs do not conduct during this time

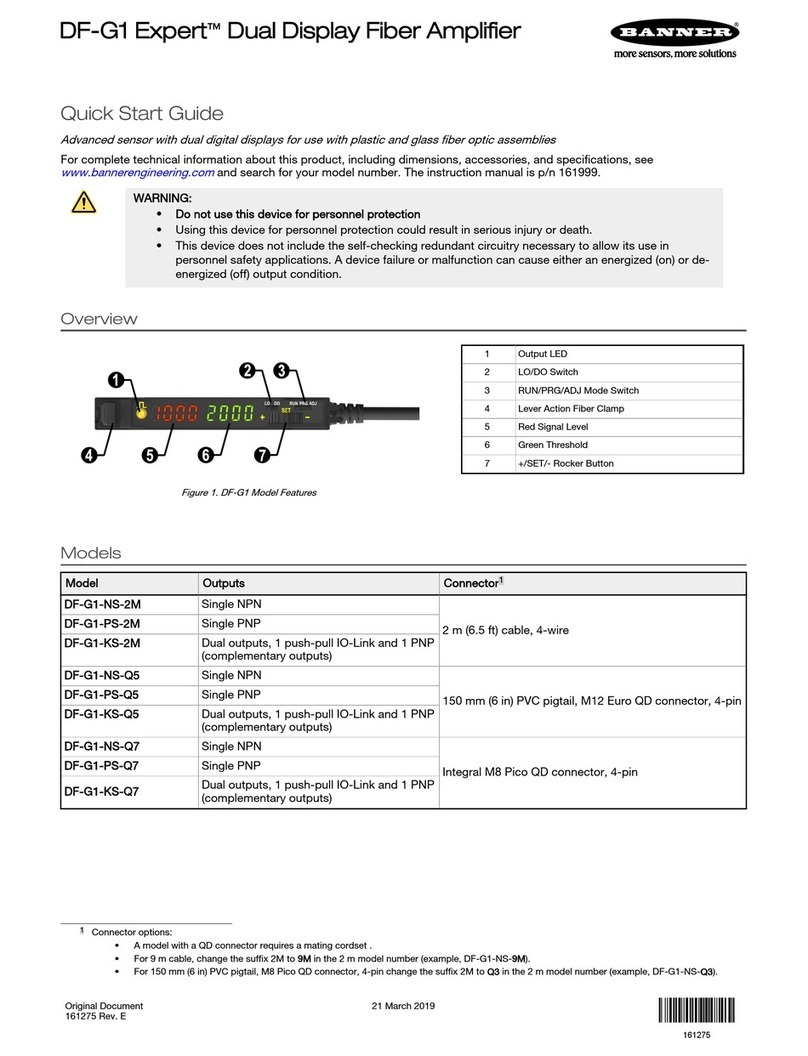

Output Configuration

NPN/PNP models: 1 current sinking (NPN) or 1 current sourcing

(PNP) output, depending on model

IO-Link models: 1 push-pull and 1 PNP (complementary outputs)

Required Overcurrent Protection

WARNING: Electrical connections must be

made by qualified personnel in accordance

with local and national electrical codes and

regulations.

Overcurrent protection is required to be provided by end product

application per the supplied table.

Overcurrent protection may be provided with external fusing or via

Current Limiting, Class 2 Power Supply.

Supply wiring leads < 24 AWG shall not be spliced.

For additional product support, go to http://

www.bannerengineering.com.

Supply Wiring Required Overcurrent Protection

20 5.0 Amps

22 3.0 Amps

24 2.0 Amps

26 1.0 Amps

28 0.8 Amps

30 0.5 Amps

Output Rating

100 mA maximum load (derate 1 mA per °C above 30 °C)

OFF-state leakage current: NPN/PNP models: < 5 μA at 30 V dc;

IO-Link models: < 50 μA at 30 V dc

ON-state saturation voltage: NPN: < 1.5 V; PNP /IO-Link: < 2 V

Output Protection

Protected against output short-circuit, continuous overload, transient

overvoltages, and false pulse on power-up

Output Response Time

High Speed: 200 µs; Standard: 500 µs; Long Range: 2 ms; Extra Long

Range: 5 ms

Repeatability

High Speed: 66 µs, Standard/Long Range/Extra Long Range: 100 µs

Construction

Black ABS/polycarbonate alloy (UL94 V-0 rated) housing, clear

polycarbonate cover

Connections

PVC-jacketed 2 m or 9 m (6.5 ft. or 30 ft.) 4-wire integral cable; or

integral 4-pin M8/Pico-style quick disconnect; or 150 mm (6 in.) cable

with a 4-pin M12/Euro-style quick disconnect; or 150 mm (6 in.) cable

with a 4-pin M8/Pico-style quick disconnect.

Environmental Rating

IEC IP50, NEMA 1

Operating Conditions

Temperature: −10 °C to +55 °C (+14 °F to +131 °F)

Storage Temperature: −20 °C to +85 °C (−4 °F to +185 °F)

Humidity: 90% at +60 °C maximum relative humidity (non-

condensing)

IO-Link Interface

Supports Smart Sensor Profile: Yes

Baud Rate: 38,400 bps (COM2)

Process Data Width: 16 bits

IODD files: Provide all programming options of top panel interface,

plus additional functionality, see the DF-G1 Manual (P/N 161999)

Certifications

Industrial

Control

Equipment

3TJJ

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following

the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture

which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty

does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR

TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any

obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

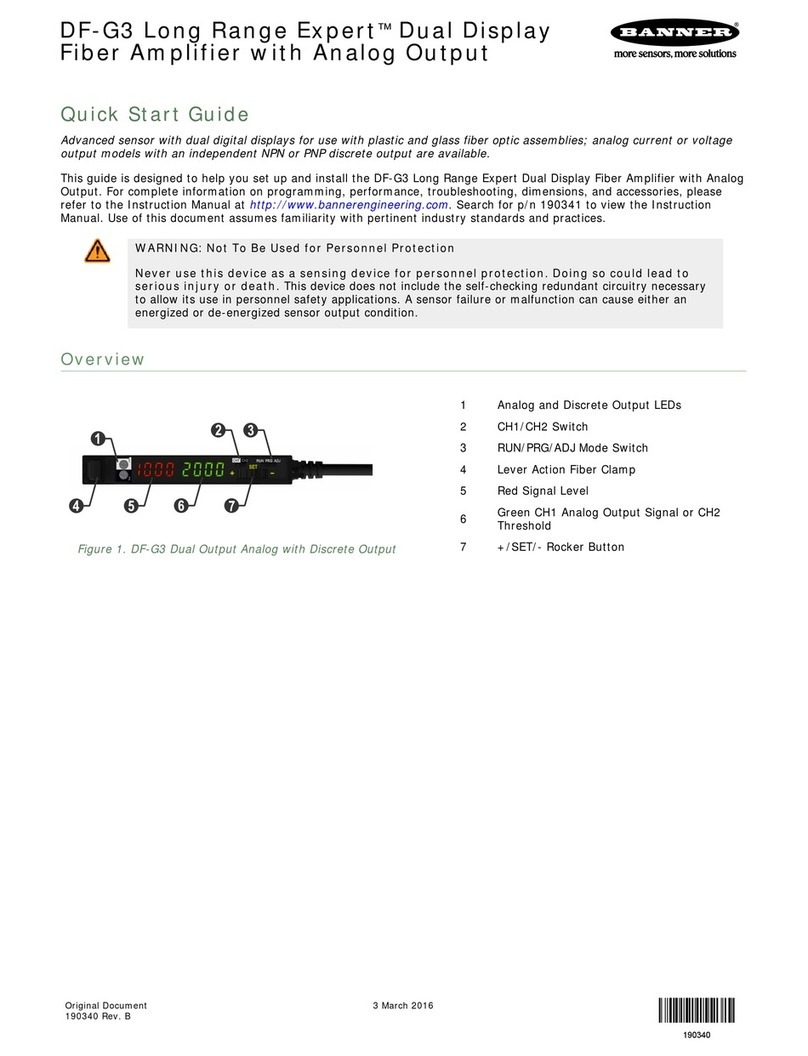

DF-G1 Expert™Dual Display Fiber Amplifier

www.bannerengineering.com - Tel: +1-763-544-3164