Building Automation Products, Inc., 750 North Royal Avenue, Gays Mills, WI 54631 USA

T

el:+1-608-735-4800 • Fax+1-608-735-4804 • E-mail:

[email protected] • Web:www

.bapihvac.com

Specications subject to change without notice.

1 of 4

Installation & Operating Instructions

rev. 08/21/1728173_ins_CO2_Duct

CO2 Duct and Rough Service Sensor

The BAPI CO2 Duct Sensor is an accurate and reliable way

of incorporating demand controlled ventilation. It measures

CO2 in ranges of 0 to 2,000, 0 to 5,000, 0 to 10,000 and 0

to 50,000 ppm with a eld selectable output of 0 to 5 or 0 to

10 VDC.

The Single Beam (ACD) unit has been optimized for

periodically unoccupied areas and features automatic

background calibration over a long time period to reduce

drift. The Dual Channel (DCD) “24/7” unit has been

optimized for continuously occupied areas and features a

3-point calibration process.

Barometric pressure changes from altitude or weather

can affect CO2 sensors, even putting them outside of their

specied accuracy. The BAPI unit has a built-in Barometric

pressure sensor that continuously compensates the output

for accurate readings despite the weather or altitude.

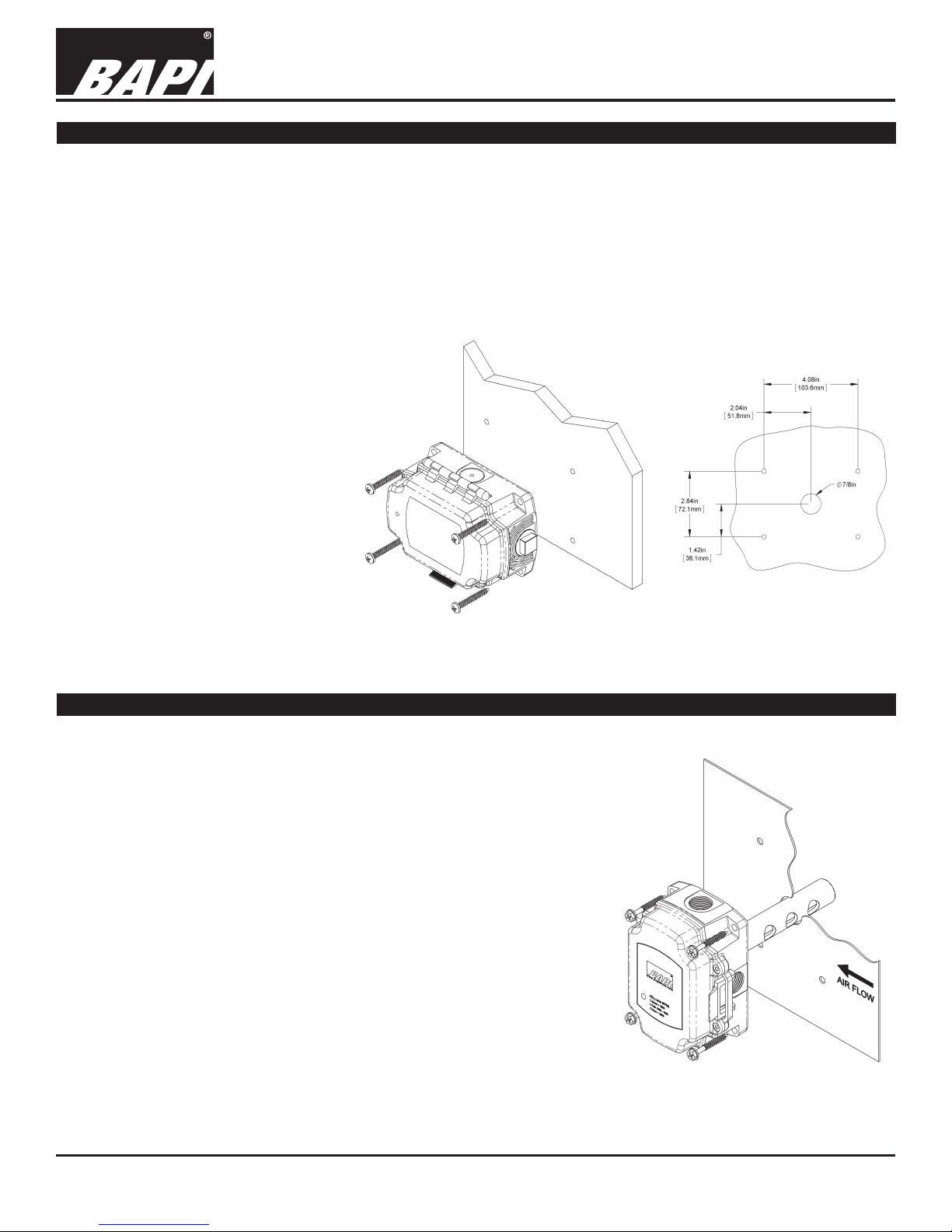

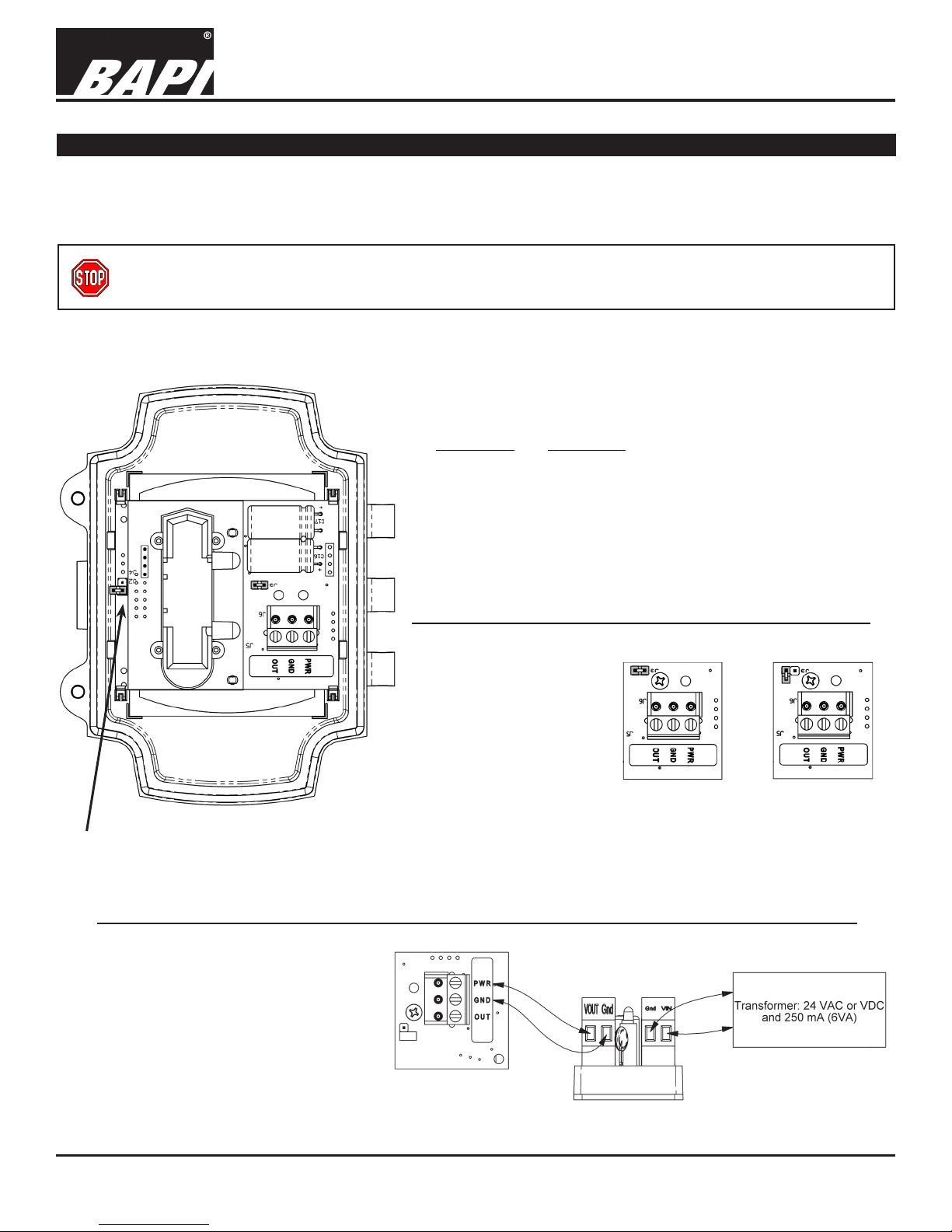

The Duct unit samples duct air using an aspiration tube.

The Rough Service unit features a ventilated BAPI-Box and

is ideal for areas such as outdoor air plenums, equipment

rooms, attics, green houses and warehouses. Optional

indication of the CO2 level as “Good, Fair or Poor” is

available as a 3-color LED for 0 to 2,000 ppm range units.

Identication and Overview

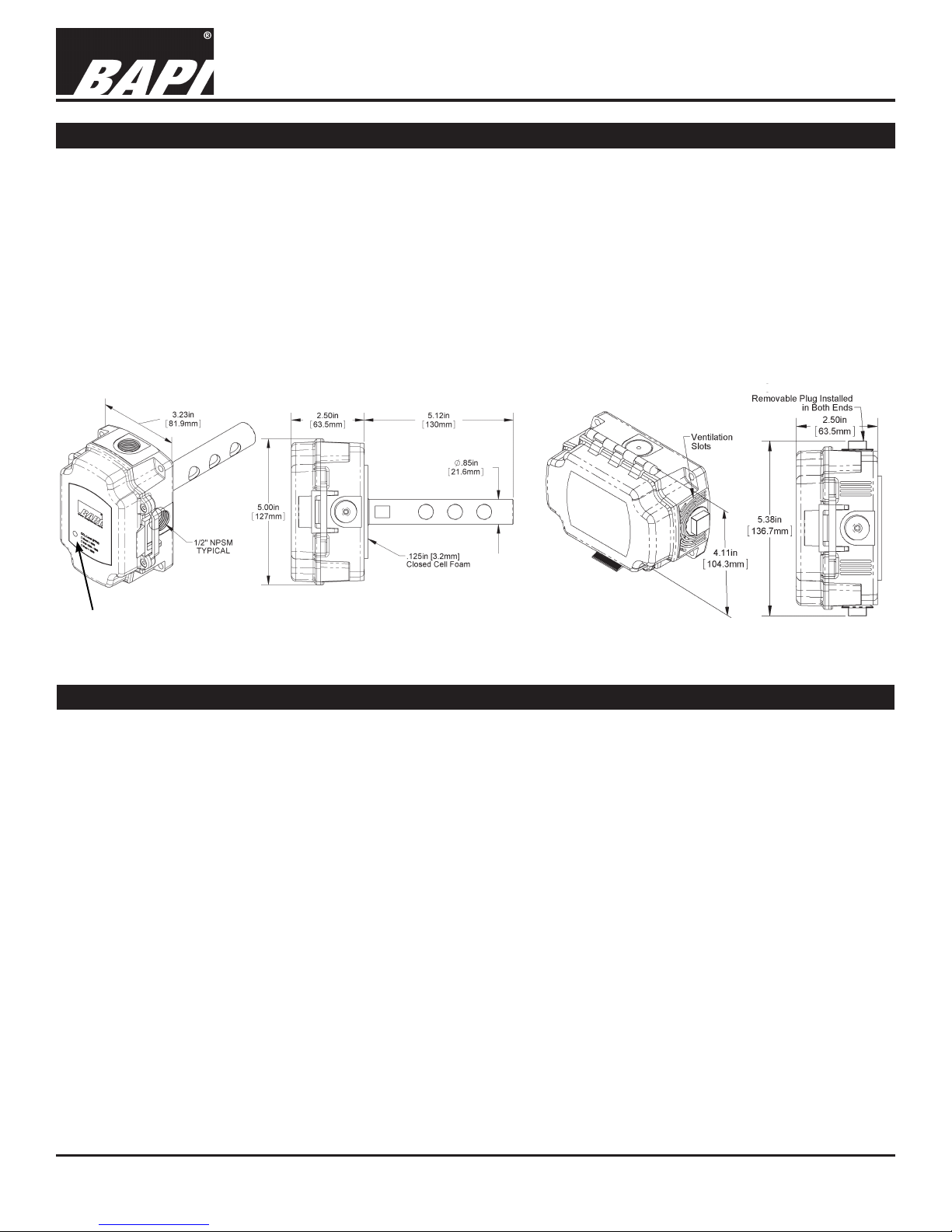

Fig. 1: Duct CO2 Sensor

Three-color

LED Fig. 2: Rough Service CO2 Sensor

Specications

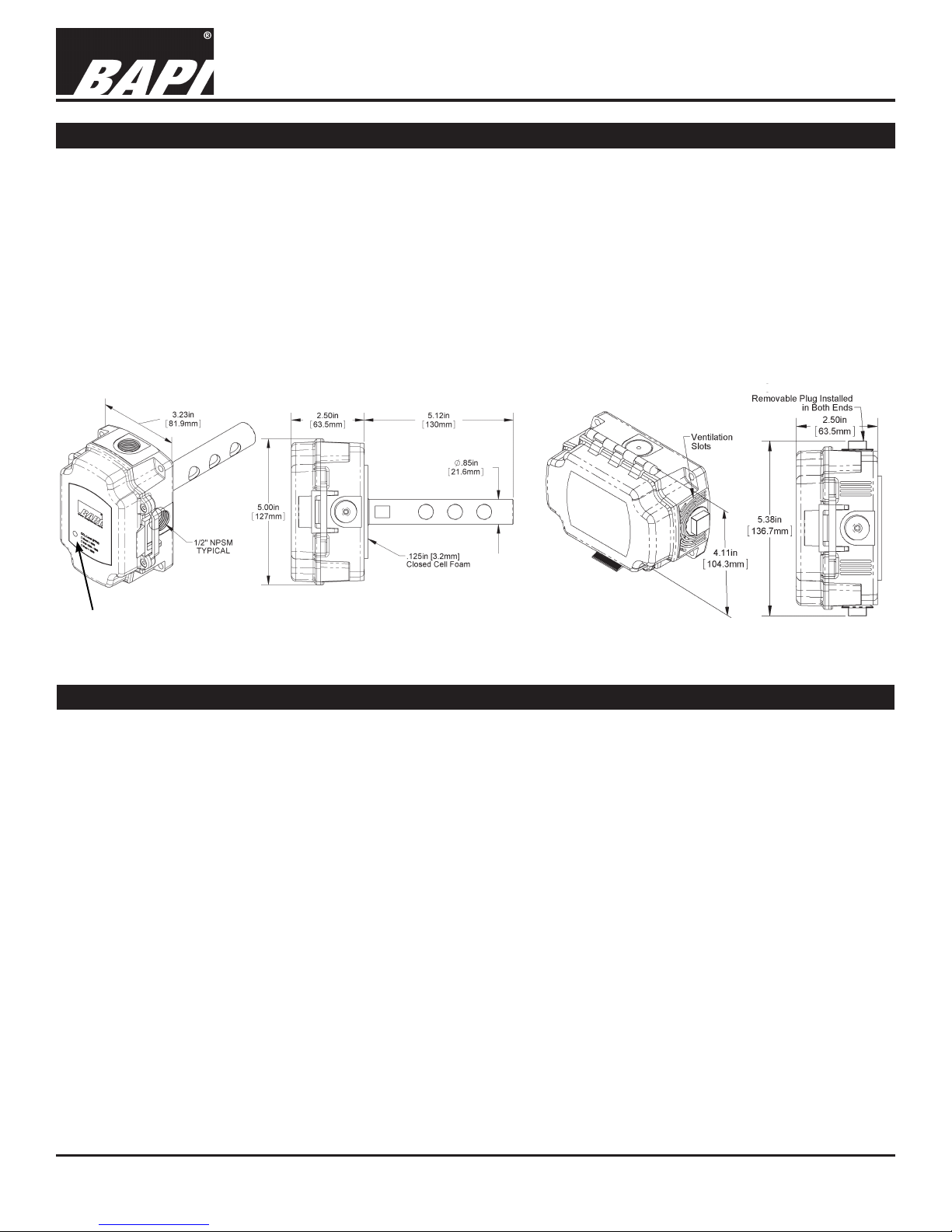

Power:

12 to 24 VDC, 240mA

18 to 24 VAC, 12 VA Peak

CO2 Sensing Elements:

Single Beam Non-Dispersive Infrared (NDIR)

or Dual Channel NDIR for “24/7” Model

Selectable Output:

0 to 5 VDC or 0 to 10 VDC

Termination: 3 Terminals, 16 to 22 AWG

Wiring: 2 Pair

Operating Environment:

32 to 122°F (0 to 50°C)

0 to 95%RH non-condensing

Enclosure Material:

Polycarbonate, UL94 V-O

CO2 Detection Range:

0 to 2,000, 0 to 5,000, 0 to 10,000 and 0 to 50,000 ppm

Start-Up Time: 10 Minutes

Response Time:

Less Than 5 Minutes (after Start-Up Time)

CO2 Accuracy:

(Automatic Background Calib. Single Channel Model)

400 to 1,250 ppm: ±30ppm or 3% of reading,

whichever is greater

1,250 to 2,000 ppm: ±5% of reading + 30ppm

CO2 Accuracy:

(“24/7” Dual Channel Model)

75ppm or 10% of reading (whichever is greater)

CO2 Drift Stability (DCD “24/7” Units):

<5% of full scale over life of product.

Optional 3-Color LED (0 to 2,000 ppm range only):

Good, Green < 1,000 PPM CO2

Fair, Orange = 1,000 to 1,500 PPM CO2

Poor, Red > 1,500 PPM CO2

Certications: RoHS

Warranty Period:

5 Years from manufacture date