BAQ kaloMAX Manual

3 General handling

Power switch / fuses

The power switch and the fuses ( 2 x T 1 A ) are located at the back side of the

unit between power connector and power switch.

Specimen holder

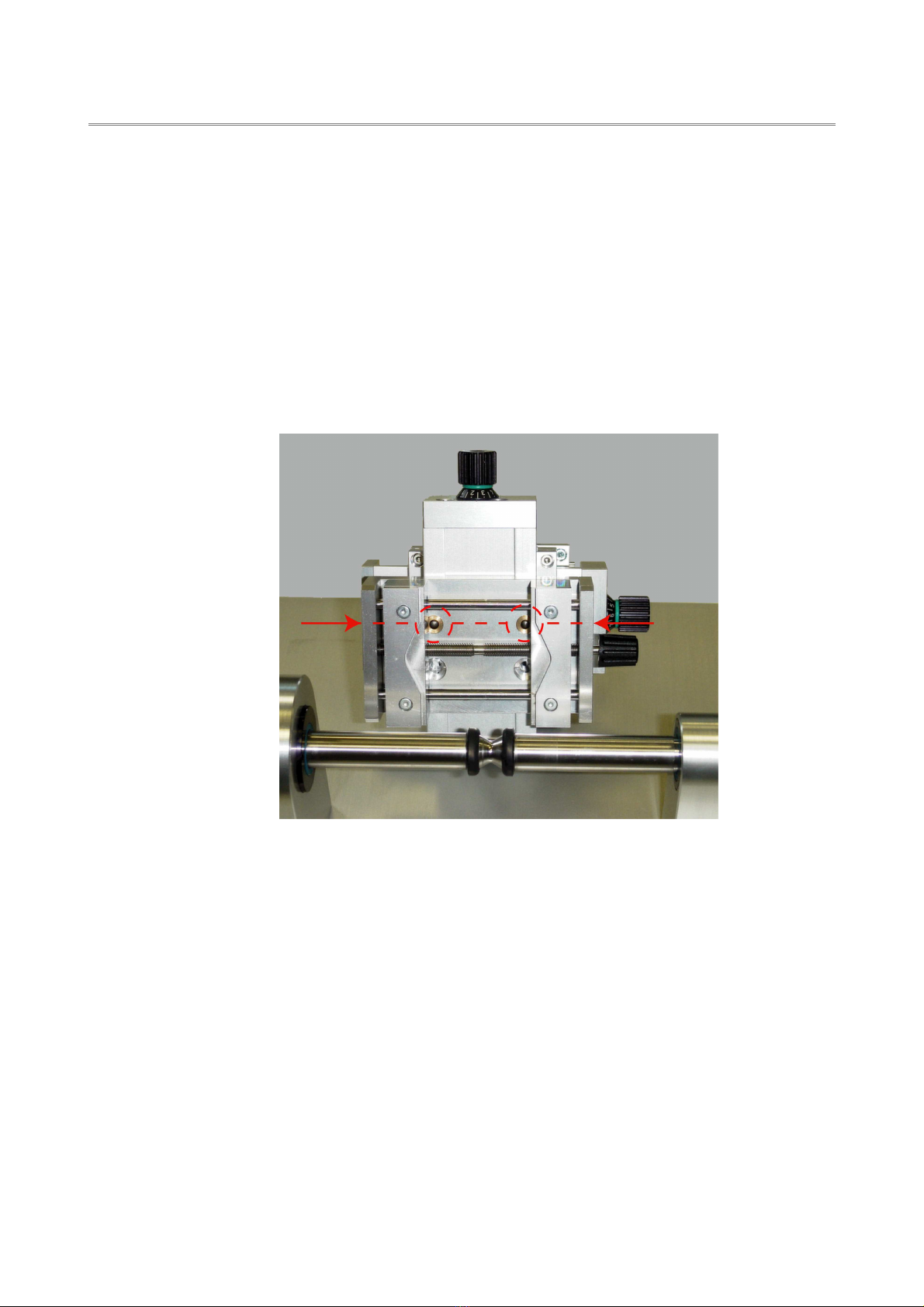

The samples are clamped into a small vice. The upper part of the vice jaws can

be turned to fit round or straight samples. This parts can be replaced in case of

damage.

Compound table

The specimen holder is mounted to a compound table with a movement range

of 25 x 25 mm.

Movable stand

The adjustment to different ball diameters or sample thickness is done by

moving the whole unit of specimen holder and compound table. To move the

unit, the fixing screws at the back side have to be loosened.

LED readouts

The LED readouts show the actual values for the number of revolutions (rpm),

the grinding period and the selected program.

After power up, the last parameters are active.

When the motor is started, the remaining grinding time will be displayed

continually.

Buttons

The 'START'-button starts the grinding procedure using the active parameter for

revolutions and grinding period.

The 'STOP'-button stops the grinding. The motor stops immediately.

The 'ENTER'-button is used to set up a new program.

By means of the ↑↓ buttons beneath the readouts for revolutions and grinding

period, the corresponding values can be changed stepwise.

When any parameter is changed, the program number is set to '-'. A test run can

be done by pressing the start button.

Page 5