Bend-Tech Dragon A400 User manual

A400

Part 1 of 1

Plasma Cutting Guide

Revision 3 | English ©2020 Bend-Tech LLC

ii Bend-Tech Dragon A400

Plasma Cutting Guide

©2020 Bend-Tech LLC

All rights reserved. The information in this manual is subject to change without notice.

Bend-Tech LLC strives to produce the most complete and accurate information regarding

its products. We are constantly working to improve and advance our products to increase

performance, user satisfaction and experience. Bend-Tech LLC assumes no responsibility for

errors or omissions regarding this manual. Bend-Tech LLC assumes no liability for damages

resulting from the use of the information contained in this publication.

iiiBend-Tech Dragon A400 Plasma Cutting Guide

Dragon A400

Plasma Cutting Guide

Revision 3

English

Original Instructions

July 2020

Bend-Tech, LLC

729 Prospect Ave.

Osceola, WI 54020 USA

(651) 257-8715

www.bend-tech.com

iv Bend-Tech Dragon A400

Plasma Cutting Guide

Covering Bend-Tech Dragon

Bend-Tech, LLC provides a limited warranty on all new Dragon machines that are

manufactured directly or under license by Bend-Tech, LLC, and sold by Bend-Tech, LLC or its

approved distributors.

Warranty Coverage

Each Bend-Tech Dragon machine is warrantied by the manufacturer against defects in material

workmanship for 12-months. The warranty period commences upon delivery of the Dragon

machine to the customer’s facility.

Repair or Replacement Only

The Manufacturer’s sole liability, and the Customer’s exclusive remedy under this warranty

shall be limited to repairing or replacing the defective part. Repair or replacement of parts

is at the sole discretion of the manufacturer. The Customer is responsible for warranty parts

installation. Bend-Tech does not provide warranty service labor.

Limits

This warranty does not cover components subject to wear due to normal use of the machine

such as belts, lights, tooling etc. This warranty is void if Bend-Tech, LLC has determined any

failure is the result of mishandling, abuse, misuse, improper installation, improper storage,

Software

Dragon software is covered by a 2-year maintenance plan from the purchase date of the

Dragon A400 machine. After the 2-year maintenance plan is expired, the Customer can

purchase a maintenance plan. A maintenance plan will ensure the customer always has

the newest version of Dragon software. The maintenance plan is critical to keeping Dragon

software updated with the newest capabilities possible, and is critical to the servicing of the

machine. Bend-Tech, LLC will contact the Customer regarding updates to the maintenance

plan within 1-month of expiration. Contact Bend-Tech Support to ensure software is up to date:

Limited Warranty

vBend-Tech Dragon A400 Plasma Cutting Guide

Any questions or concerns regarding this manual can be directed to Bend-Tech, LLC

representatives via the Dragon website, www.bend-tech.com. Click Contact in the menu bar for

communication options and send your comments to the Dragon Customer Service department.

Online Resources

• https://www.youtube.com/user/bendtech2020

• http://www.bend-tech.com/wiki7

• http://www.bend-tech.com

• https://www.facebook.com/2020ssi

• https://www.instagram.com/bend_tech

Customer Service

Congratulations on your purchase of the world’s best CNC plasma tube and pipe cutting

machine, the Dragon A400. Bend-Tech, LLC places great pride in customer satisfaction and it

our support is a key factor in your success.

Contact Us

You can contact Bend-Tech, LLC customer service at 651-257-8715. Our support hours are

mailing address is: Bend-Tech LLC, 729 Prospect Ave., Osceola, WI 54020, U.S.A..

Customer Satisfaction Commitment

vi Bend-Tech Dragon A400

Plasma Cutting Guide

This manual contains important statements that are called out from the regular text with an

associated signal word: “Danger,” “Warning,” “Caution,” or “Note.” Each of these signal words

is accompanied by its own icon. These signal words and icons indicate the severity of the

condition and the warning. The machine operator should familiarize themselves with these

warnings and read the statements before operating the machine.

Denitions & Examples

Danger

Danger indicates a serious condition that could cause severe injury or death to the operator or

bystanders if the instructions are not followed.

Warning

A Warning indicates there is a possibility for minor injury if the instructions are not followed

correctly.

! Danger !

Exceeding the material weight limit of the Dragon A400 can result in serious injury

to the operator and/or bystanders.

! Warning !

Due to the extreme temperatures that result from the plasma cutting process, parts

cooled in water in the parts catcher can still be extremely hot. Always use caution

when handling newly-cut parts.

Warnings

Example

Example

viiBend-Tech Dragon A400 Plasma Cutting Guide

Caution

Caution warns the operator that minor injury or machine damage could occur if instructions are

being performed.

Note

! Caution !

the Dragon A400.

Water Cooling system greatly reduces smoke and vapor emitted by the machine.

Bend-Tech recommends use of the Water Cooling system whenever possible.

Example

Example

viii Bend-Tech Dragon A400

Plasma Cutting Guide

Glossary

Glossary

A400

Indicates machine with 400-lb weight limit.

Axis

Bend-Tech 7X

Machine design software - CAD.

BOB

Breakout Board.

Material Support Lifter

The Material Support Lifter supports

material to reduce sag.

Chuck

Located on the Trolley, the Chuck

holds the material so it can be moved

forward, backward and rotated.

Control Box

Connects Dragon Software Suite

to the Dragon A400.

Coolant Tray

Cools cut parts as they are produced.

Drive Belt

The X Motor uses the Drive Belt to power the

Trolley along the Rail. The Drive Belt is mounted

stationary along the length of the machine.

Drive Belt Pulley

Located on the X Motor, it works in

conjunction with the Drive Belt to

power the Trolley along the Rail.

E-Stop

Emergency stop.

ESS

Ethernet Smooth Stepper (Control Board).

Ethernet

System for connecting multiple

computers via a Local Area Network.

Front Gate

The Gate supports the material at the

front of the machine. It consists of two

sets of self-centering roller jaws.

Gate Lead Screw

Controls operation and adjustment of the Gate.

Interface

Any particular screen display generated

by Bend-Tech software.

Mach3

Machine driver software.

Parts Catcher

The parts catcher is placed at the front of

the machine to catch parts as they are cut.

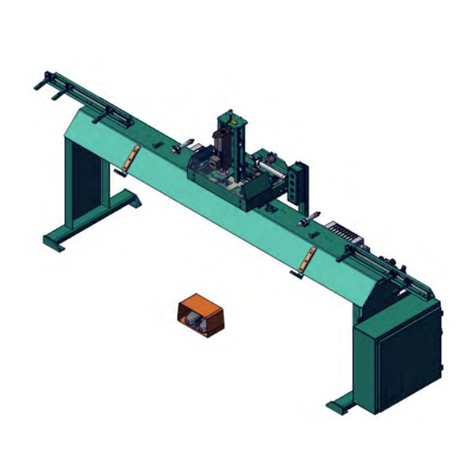

Rail

The Rail is the main structure of the Dragon

A400. The Trolley rides on the Rail.

Tail

The Tail is located at the opposite end of

the Head of the machine. The Tail arrives

pre-assembled. The X Axis homing sensor,

Drive Belt Adjustment Block and E-Stop

are located at the Tail of the machine.

Toolhead

Operates the Marker, Engraver and Torch.

Trolley

The Trolley rides on the Rail, and carries

the Chuck forward and backward along

the length of the Rail Support Beam.

ixBend-Tech Dragon A400 Plasma Cutting Guide

Contents

Contents

Limited Warranty .....................iv

Customer Service.................... v

Customer Satisfaction

Commitment............................. v

Warnings ..................................vi

Glossary ..................................viii

Contents...................................ix

01

Consumables.......................... 11

Overview .........................11

Consumables in Order of Assembly.....11

Consumables Parts List ............. 12

Inspecting and Changing

Consumables ..................... 12

Nozzle........................ 12

Electrode. . . . . . . . . . . . . . . . . . . . . . 12

Swirl Ring ..................... 13

Retaining Cap.................. 13

Shield Cap .................... 14

Signs that Consumables Need

Replacing ........................ 14

Signs of a Bad Electrode ......... 14

Signs of a Bad Nozzle ........... 14

Maximizing Consumables ........... 15

Normal vs. Fine Cut Consumables.. 15

Cutting Speed.................. 15

Gas Supply .................... 15

Torch Mounting ................. 16

Cut Settings ................... 16

Kerf Width..................... 16

Torch Maintenance .............. 17

Cut Charts ....................... 18

Cutting Speed ................. 18

02

Cutting Charts......................... 19

Before Using these Charts........... 19

45 AMP: Mild Steel................. 20

65 AMP: Mild Steel................. 21

85 AMP: Mild Steel................. 22

Additional Cutting Feed Rates for

65/85 Amp: Mild Steel............ 23

03

Troubleshooting ..................... 25

Diagnosing Cutting Issues ........... 25

Cope at Both Ends of the Tube are

not the Same Rotation ........... 25

Cut Quality Issues. . . . . . . . . . . . . . . 26

xBend-Tech Dragon A400

Plasma Cutting Guide

Contents

Round Holes are Coming Out Oval . 26

Machine Cutting and then Returning to

Previous Engraving. . . . . . . . . . . . . . 26

Material....................... 26

Jagged Cuts ................... 27

Torch Not Firing ................ 27

Torch Colliding with Material....... 27

04

Plasma System Gas Supply .. 29

Plasma System Gas/Air Supply ....... 29

11Bend-Tech Dragon A400 Plasma Cutting Guide

Consumables

01

01

Consumables

Overview

Bend-Tech recommends reading the Hypertherm Operator Manual (or operator manual for

whatever brand plasma cutting machine is being used with the Dragon machine) and using

the consumables recommended for mechanized cutting. The Hypertherm unit comes with

shielded consumables. Shielded consumables protect the nozzle and minimize any damage

that can result from slag during the piercing process. Bend-Tech recommends using shielded

consumables with the Dragon A400 whenever possible.

Ensure plasma machine settings are correct for the type of cutting being performed.

Consumables will typically last 3-5 hours of “arc on” time in a mechanized cutting setting.

Consumable life can vary depending on the type of cutting being performed, quality of air

supply, machine settings, type of material being cut and numerous other factors. It is important

to inspect consumables on a regular basis.

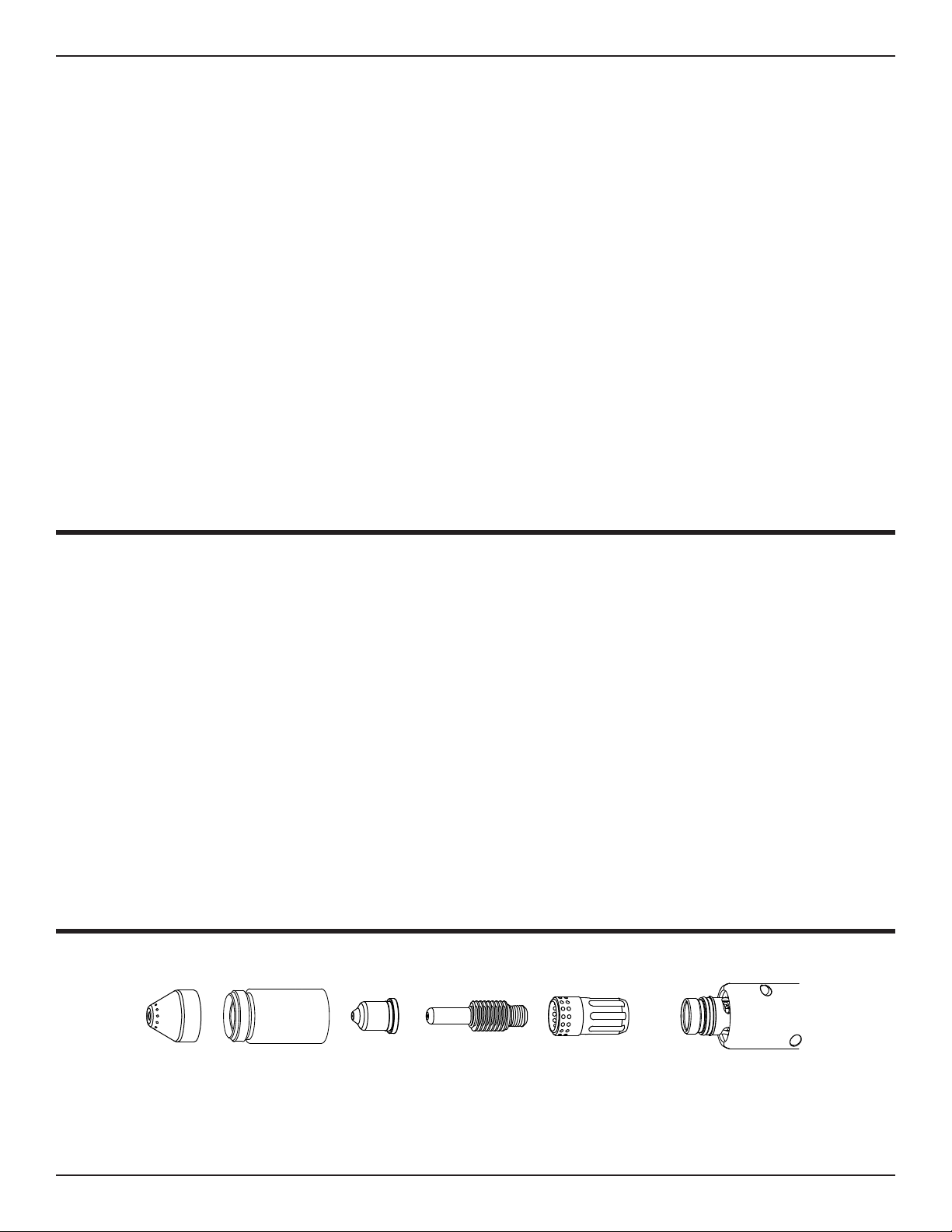

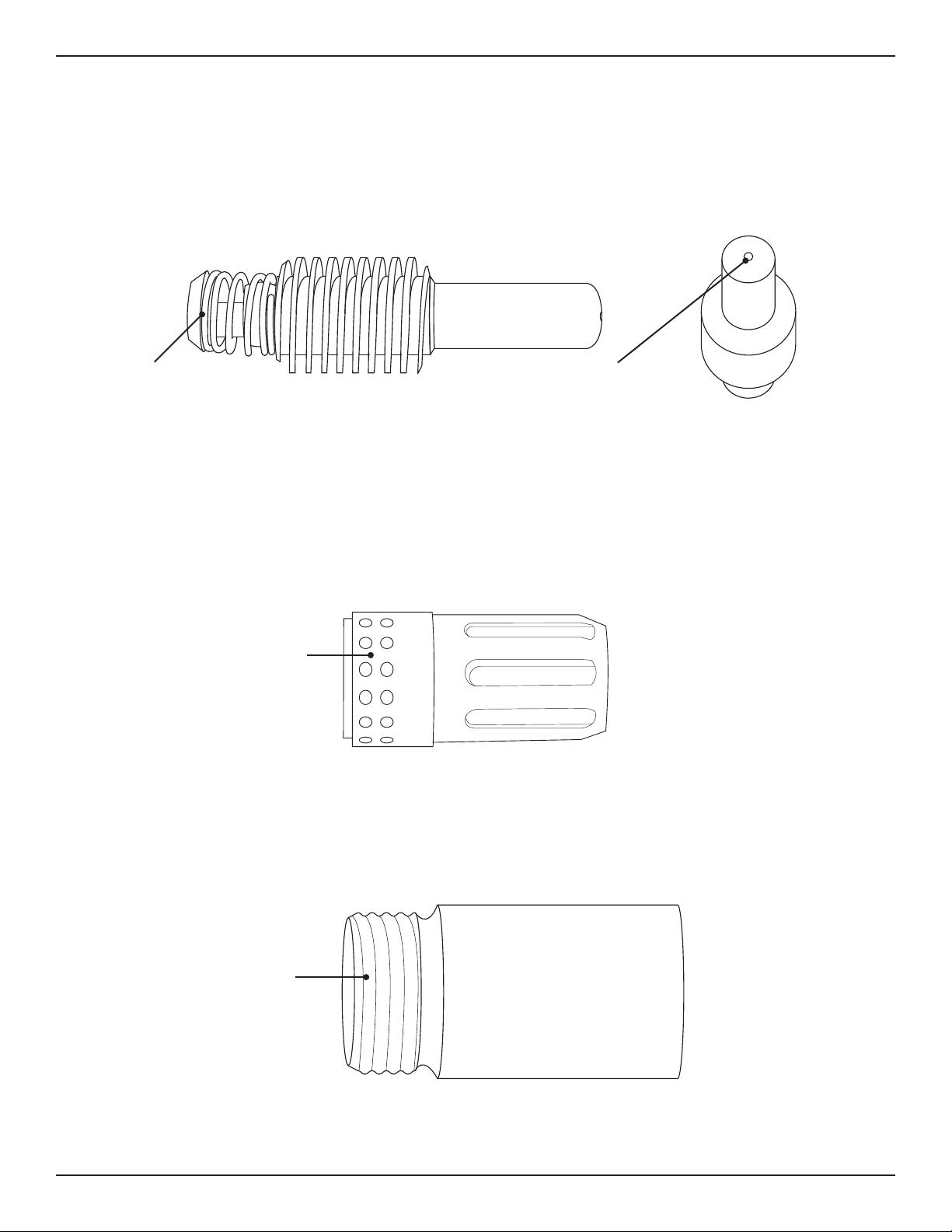

Consumables in Order of Assembly

Shield

Retaining Cap Nozzle Electrode Swirl Ring

12 Bend-Tech Dragon A400

Plasma Cutting Guide

Consumables

01

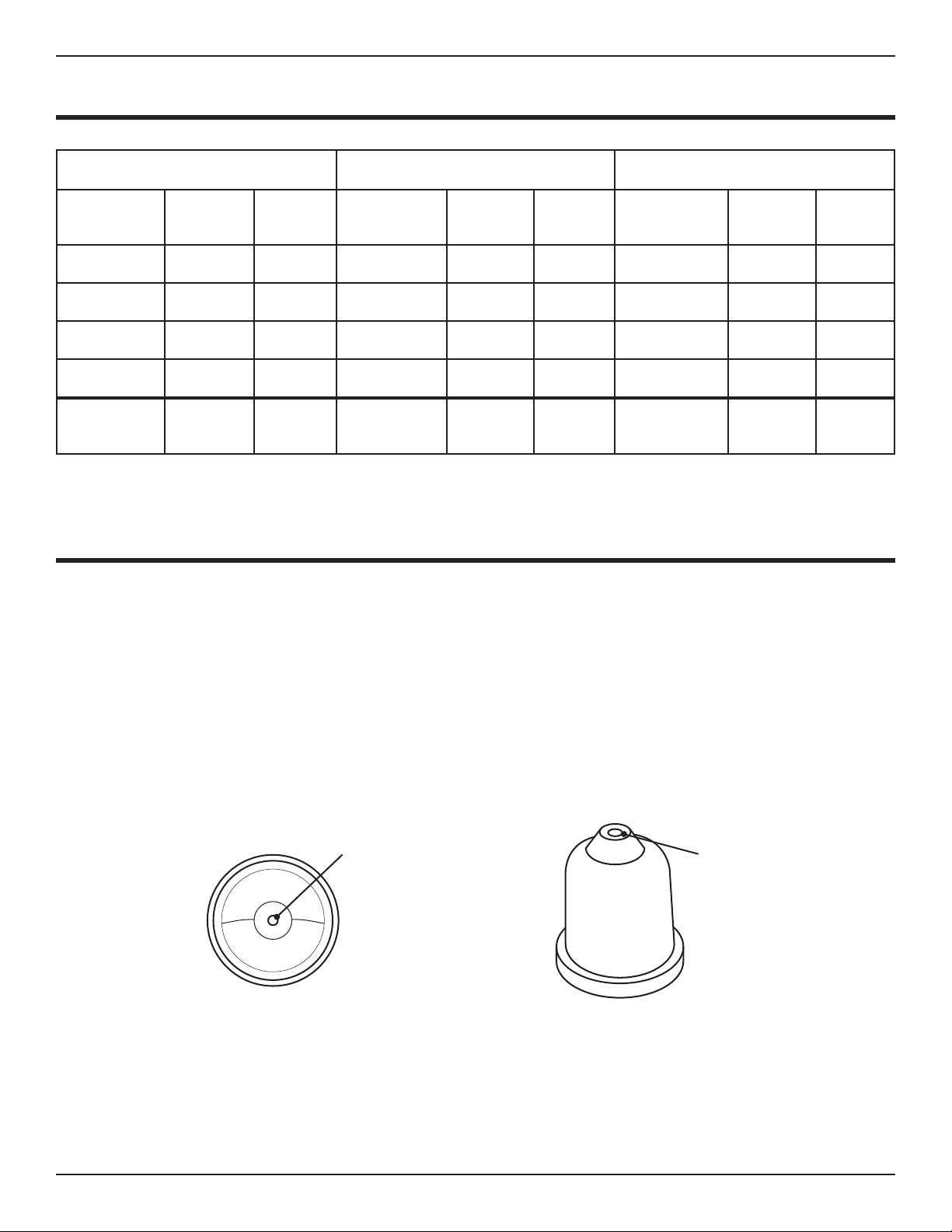

Consumables Parts List

Inspecting and Changing Consumables

It is recommended the Operator change the electrode and nozzle at the same time. This

Nozzle

an uneven cut. Often the Operator can conduct a visual inspection of the nozzle to determine

if it is worn out. Also check the cuts for excessive slag and dross. Inspect the nozzle to ensure

it is free of slag. Inspect the inside of the nozzle for out of round or inconsistencies, nicks or

Electrode

The Operator can determine electrode life by measuring pit depth. Pit depth is the distance

from the surface of the copper electrode piece to the halfnium located at the center of the

Check for dross build up

both inside and outside

of Nozzle.

Check to see if

Nozzle opening is out

of round.

45 Amp Consumables 65 Amp Consumables 85 Amp Consumables

Components Standard Fine Cut Components Standard Fine Cut Components Standard Fine Cut

Nozzle 220941 220930 Nozzle 220819 220930 Nozzle 220816 220930

Electrode 220842 220842 Electrode 220842 220842 Electrode 220842 220842

Shield 220817 220948 Shield 220817 220948 Shield 220817 220948

Swirl Ring 220857 220857 Swirl Ring 220857 220857 Swirl Ring 220857 220857

Retaining

Cap 220854 220854 Retaining

Cap 220854 220854 Retaining

Cap 220854 220854

13Bend-Tech Dragon A400 Plasma Cutting Guide

Consumables

01

deteriorate as the Torch is used. Once pit depth reaches .040-.045 in. the electrode and nozzle

should be replaced. To determine pit depth, measure the distance from the surface of the

electrode to the bottom of the pit of the electrode. Use a quality pit depth gauge. Follow the

manufacturer’s recommendations for pit depth.

In the case of a spring electrode ensure the spring is intact and moves freely.

Swirl Ring

Inspect the swirl ring for cracks, deformations and clogged holes. The swirl ring does not wear

like the electrode and nozzle, but it can become cracked from heat cycling or from some sort

of physical damage. The swirl ring will only need to be replaced if there is evidence of physical

damage.

Retaining Cap

Ensure the retaining cap is free of slag and not cracked, and that the threads are intact. Dirt

can damage the retaining cap threads. Heat can damage the retaining cap.

Make sure spring is

intact and moves freely.

Pit depth measured

here.

Make sure the swirl

ring has no cracks or

deformations, and that

the holes are clear.

Make sure the threads

are clean and intact.

14 Bend-Tech Dragon A400

Plasma Cutting Guide

Consumables

01

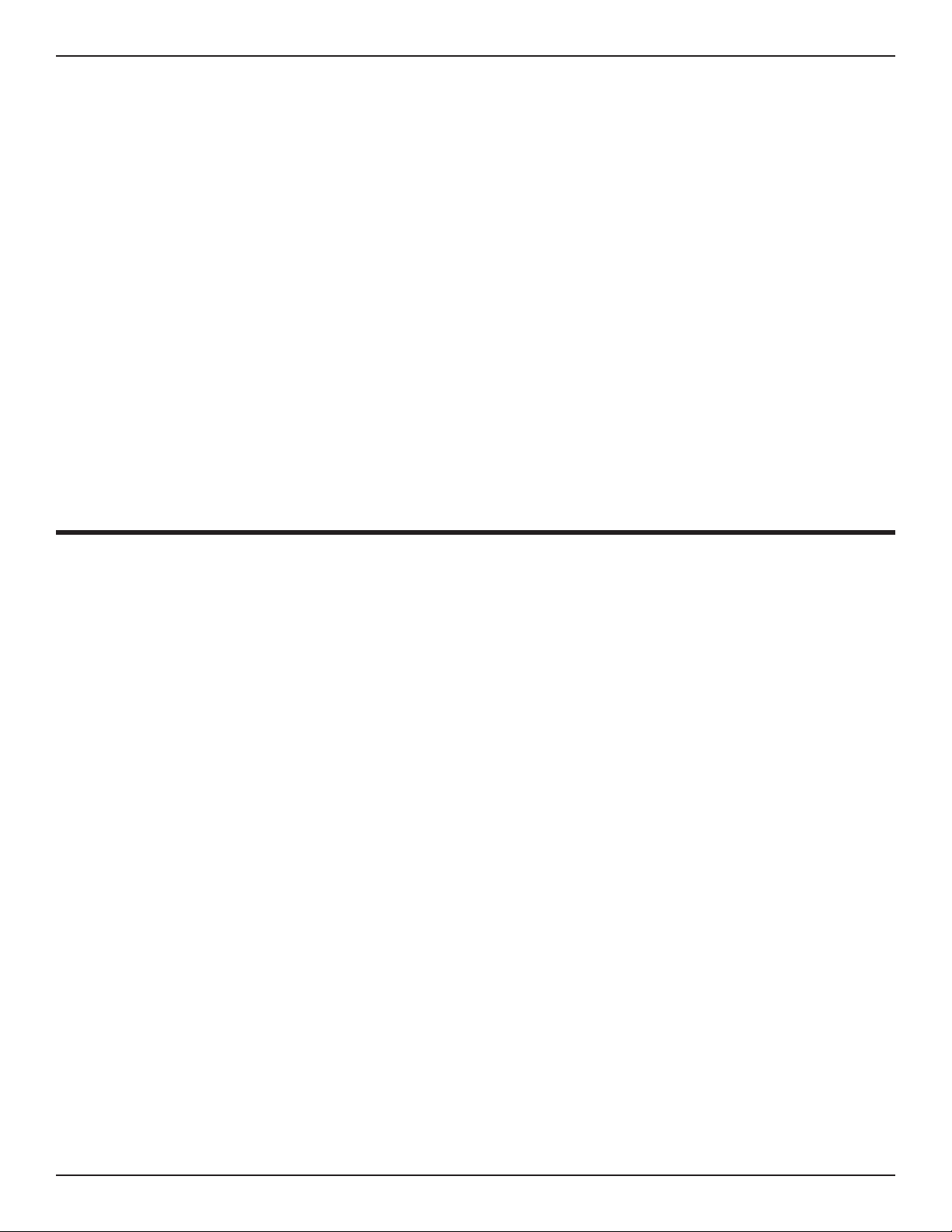

Shield Cap

Inspect the shield cap to ensure all of the holes are clean and not plugged. If the shield cap

cannot vent gas properly it will result in uneven or imprecise cuts. The shield cap will only need

to be replaced if there is evidence of physical damage and/or if hole is out of round. If there is

spatter on the Shield it may still be usable. However, it may also be an indication that the Torch

is set too close to the material, especially in regard to materials thinner than .25 in. Typically

the shield cap will last up to 15-times as long as the electrode and nozzle.

Signs that Consumables Need Replacing

Signs of a Bad Electrode

• Torch not cutting at required speed

• Green discoloration of the arc

• Excessive dross

•

Signs of a Bad Nozzle

• Kerf too wide

• Operator needs to slow the Torch down because the Torch is not cutting well at desired

speed

• Oblong holes

Do not judge consumables by their color. Staining or discoloration do not necessarily

indicate worn consumables.

Make sure the opening

is not out of round.

Check that the holes are

clean.

15Bend-Tech Dragon A400 Plasma Cutting Guide

Consumables

01

Maximizing Consumables

Normal vs. Fine Cut Consumables

For most fabricators normal consumables will perform excellent when used in the Dragon

• Fine cut consumables will perform more intricate cuts and produce sharper corners and

angles when used with thinner gauge metals.

•

consumables.

•

torch clean for best results.

• Refer to the cutting charts in this manual vs. the ones provided by Hypertherm. The Dragon

Cutting Speed

• Ensure cutting speed is set properly for the material thickness and amperage being used.

• Cutting too slow will result in a larger kerf. Cutting too slow will also cause the arc to start to

travel out to the sides of the material as it looks for ground. This can damage the shield.

• Cutting too fast, or cutting too high, can cause slag to build up on the consumables

because the plasma arc will not be able to force the slag through the kerf.

Gas Supply

•

pressure will cause rapid deterioration of the electrode.

• It is important to keep the air supply for the plasma system clean and free of moisture and

oil.

Recommended gas pressure setting for Hypertherm units is 90-135 psi.

16 Bend-Tech Dragon A400

Plasma Cutting Guide

Consumables

01

Torch Mounting

• Torch collision can cause physical damage to the consumables. Torch collision can damage

the Torch and lead to complete Torch replacement. Always ensure Torch height is set

correctly. Ensure Torch is mounted on the machine correctly.

• Ensure the Torch is tight in the Toolhead and not vibrating during the cutting process. If

the Torch is not secured properly and moves even slightly during the cutting process it can

result in poor cut quality.

Cut Settings

• Best cut quality is usually achieved when amperage is set to 95-percent of the nozzle’s

rating. If the amperage is too low the cut will be sloppy. If the amperage is too high it will

shorten the nozzle lifespan.

• Ensure the Torch does not pierce too low. Optimum pierce height is 1.5 to 2-times the cut

height. Piercing too low can cause molten metal to spatter on the nozzle and shield.

• Program Lead-in and Lead-out properly to avoid stretching the arc. If the Torch tries to arc

and it is not centered over the material the arc will cut into the sidewall of the nozzle and

damage it.

• Moving the Torch to the right results in the squarest cuts. The majority of swirl rings spin the

plasma stream clockwise. However, Torch cutting direction depends on the project and the

cut desired by the Operator.

• Ensure the consumables match the amperage set for the plasma cutting machine.

Kerf Width

Kerf is the width of the material that is removed during the plasma cutting process. The

Operator can adjust Kerf Width settings in Bend-Tech Dragon software in Tube Library >

Machine > Basic Settings > Kerf Width.

• Bend-Tech recommends setting Kerf Width at 0.06. However, for most accurate cutting, it

is recommended that the Operator make a test cut and measure the Kerf Width and adjust

the Kerf Width setting accordingly.

17Bend-Tech Dragon A400 Plasma Cutting Guide

Consumables

01

Torch Maintenance

• Bend-Tech recommends the Operator keep a log of Torch consumables. Record the

lifespan of consumables as well as amperage, material thickness and type of material. A

log will help the Operator keep track of consumables and optimize their lifespan.

• When assembling the Torch it is important that all the consumables are assembled properly,

use o-ring lubricant. Apply just enough to make the o-ring shiny. Do not use grease - this

can cause uncontrolled arcing within the Torch and ultimately Torch failure.

• Keep Torch consumables clean. Remove any excess slag, dirt or grease and wipe clean

with electronic contact cleaner or hydrogen peroxide on a regular basis.

18 Bend-Tech Dragon A400

Plasma Cutting Guide

Consumables

01

Cut Charts

Cutting Speed

High-speed dross Cutting speed too fast - arc

is lagging behind. Usually

to remove.

Low-speed dross Cutting speed too low - arc

jumping ahead. Large droplets

that are easier to remove than

high-speed but not ideal

Top spatter Cutting speed too fast

Select the appropriate settings for:

• Material type

• Material Thickness

• Desired cut quality

• Productivity goals

• Type of gas being used

• Gas pressure

• Torch distance or arc voltage

• Cutting speed

• Consumables being used

19Bend-Tech Dragon A400 Plasma Cutting Guide

Cutting Charts

02

02

Cutting Charts

Before Using these Charts

The cutting charts in this guide have been compiled based on Hypertherm recommended

settings as well as Bend-Tech experience in using and testing the Dragon A400. Bend-Tech

is providing these charts as a baseline. These settings may need to be adjusted based on

Operator preference to optimize machine performance.

The Dragon A400 is programmed with preset cut values. These values are a baseline that

will get the Operator up and running. Cut settings can be adjusted in the Tube Library in the

Machine, Lead In/Out and NRC interfaces.

20 Bend-Tech Dragon A400

Plasma Cutting Guide

Cutting Charts

02

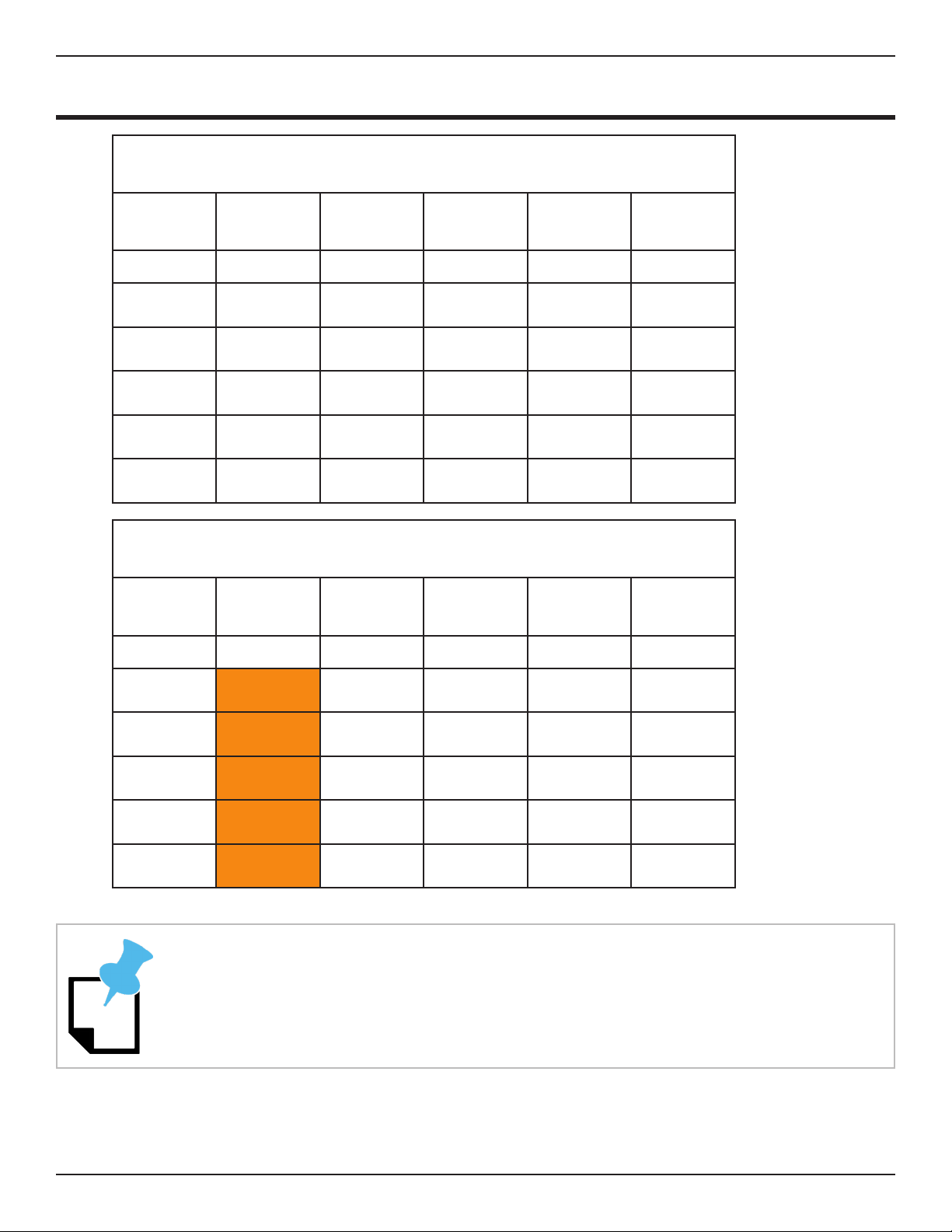

45 AMP: Mild Steel

45 Amp: Mild Steel

Material

Thickness

Cutting

Height

Pierce

Height

Dwell

Time

Cutting

Feed Rate Cutting

(in.) (in.) (in.) (sec) (ipm) AMPs

0.0625 0.06 0.09 0 80 30-34

0.125 0.07 0.1 0 65 32-36

0.1875 0.08 0.11 0 50 35-40

0.25 0.09 0.12 0.25 35 42-45

0.375 0.09 0.12 0.5 25 45

45 Amp: Mild Steel - Fine Cut Consumables

Material

Thickness

Cutting

Height

Pierce

Height

Dwell

Time

Cutting

Feed Rate Cutting

(in.) (in.) (in.) (sec) (ipm) AMPs

0.0625 0.05 0.09 0 80 30-34

0.125 0.06 0.1 0 65 32-36

0.1875 0.07 0.11 0 50 35-40

0.25 0.08 0.12 0.25 35 42-45

0.375 0.08 0.12 0.5 25 45

Re-do the Torch Mount when changing between ne cut consumables and regular

consumables.

Other manuals for Dragon A400

14

Table of contents

Other Bend-Tech Industrial Equipment manuals

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon mAchines User manual

Bend-Tech

Bend-Tech Dragon A400 Installation and operation manual

Bend-Tech

Bend-Tech Dragon User manual

Bend-Tech

Bend-Tech DRAGON A150 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon mAchines User manual