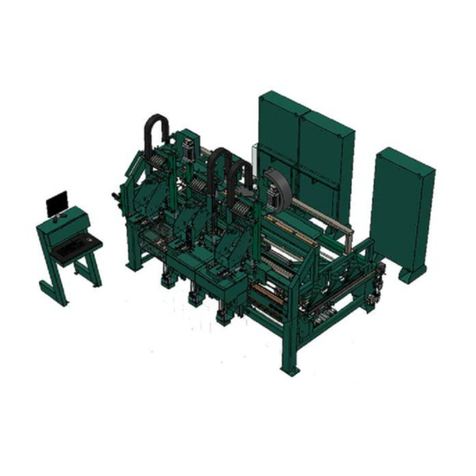

965X Operation Manual

Table of Contents

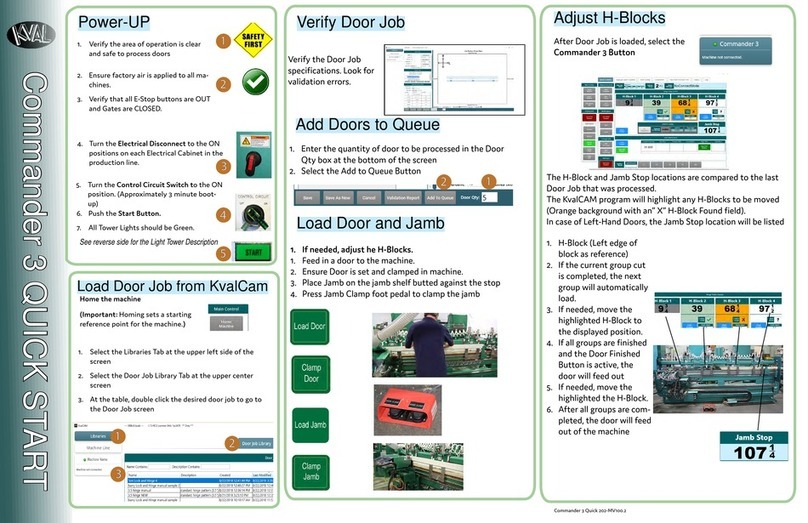

Step 5: Load the Jamb..........................................................................2-7

Step 6: Align and Clamp the Jamb .......................................................2-8

Step 7: Start Sequence.........................................................................2-8

Step 8: Next Group, Next Job, or End Process ....................................2-9

Powering Operations for the 965X........................................... 2-10

How to Power Up the 965X ................................................................2-10

Home the 965X.................................................................................. 2-11

How to Power Down ...........................................................................2-11

About Emergency Stops.....................................................................2-12

To Resume Normal Operation after an E-Stop ...................................2-12

Other Safety Controls .........................................................................2-12

About the Computer Setting ...............................................................2-12

About Machine Status Feedback............................................. 2-13

About the 965X interface Screens ........................................... 2-14

Screen Tabs........................................................................................2-14

About the Main Control Screen................................................ 2-15

Machine Controls Section........................................................ 2-16

About the Main Control Section..........................................................2-17

About the Sequence Control Section..................................................2-18

About Jamb Clamp and Jamb Stop Section .......................................2-19

About Speed Control ..........................................................................2-19

About the Jamb Support Selection .....................................................2-20

About the Jamb Support Blocks .........................................................2-20

Job Parameters and Task Section ........................................... 2-21

About the Top Bar ...............................................................................2-22

Jamb Specs........................................................................................2-22

Current Group.....................................................................................2-22

Status Message..................................................................................2-22

About the Tasks Screen......................................................................2-23

Task Display to Jamb Cut Example ....................................................2-23

About the Task Box.............................................................................2-24

Fractional Display or Decimal Display ................................................2-24

About the Cut Icons ............................................................................2-25

About the Process Box .......................................................................2-25

About the Skip Cut Check Box ...........................................................2-25

How to Change the Jamb Reference Display.....................................2-26

About Rollover Parameter Information ...............................................2-26

About Timers.......................................................................................2-27

About the Manual Servo Control Screen ................................. 2-28

Manual Axis Head Movement Direction..............................................2-28