Bard 8403-096 Owner's manual

Page 1 of 6

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 7960-902

Supersedes: NEW

Date: 3-1-21

8403-096 Carbon Dioxide Transmitter

(Dwyer®CDT-2N40-LCD-RLY 002 Sensor)

SUPPLEMENTAL INSTRUCTIONS

Series CDT Wall Mount Carbon Dioxide Temperature

Transmitters accurately monitor the CO2 concentration and

temperature in schools, ofce buildings, and other indoor

environments to help achieve LEED® certication. For

increased sensor life, a single-beam dual-wavelength non-

dispersive infrared (NDIR) sensor is used to automatically

correct the measurement in both occupied and unoccupied

buildings against aging effects. The single-beam dual-

wavelength sensor technology provides the highest level

of accuracy compared to Automatic Baseline Correction

methods, which can unintentionally shift the calibration

based on CO2 levels and barometric pressure conditions. In

order to achieve a higher level of accuracy, the Series CDT

includes digital barometric pressure adjustment and the

ability to eld-calibrate the sensor.

Universal outputs allow users to select the transmitter

output to be 4-20 mA, 0-5 VDC, or 0-10 VDC to work with

virtually any building management controller. An optional

relay with user adjustable set points can be used to control

exhaust fans, open actuated windows or dampers, or signal

a light or horn.

For applications that require visual indication, the Series

CDT can be ordered with an integral LCD display, Model

A-449 or Model A-449A remote LCD display that can plug

into the mini-connector port on the side of the transmitter.

The CDT can be congured to display temperature only,

CO2 only or CO2 and temperature together. Push buttons

are standard on the transmitters for access to the menu

structure, but the transmitter can be ordered without the

buttons. To prevent tampering, the action of the buttons

can be locked out using an internal dip switch selection.

Menu items that can be accessed include: engineering

units, relay output set points, display conguration,

transmitter output scaling, ambient barometric pressure

and eld calibration of the transmitter.

Single-beam dual-wavelength sensor advantages:

• Automatically corrects for aging effects in occupied

and unoccupied buildings*

- Perfect for hospitals and manufacturing plants

that are occupied 24 hours per day

• Measures actual unltered light intensity directly

- Eliminates error from incorrect assumptions of

gas concentration in theoretical logic assumption

methods

* For buildings occupied 24 hours per day, it is

recommended that calibration be veried every 6 to 12

months depending on application.

Manual 7960-902

Page 2 of 6

SPECIFICATIONS

Sensor: Single beam, dual-wavelength NDIR.

Range: CO2: 0 to 2000 or Oto 5000 PPM (depending on

model); Temperature: 32 to 122°F (0 to 50°C).

Accuracy: CO2: ±40 PPM ±3% of reading; Temperature:

±1°C @ 25°C.

Temperature Dependence: ±8 PPM/°C at 1100 PPM.

Non-Linearity: 16 PPM.

Pressure Dependence: 0.13% of reading per mm of Hg.

Response Time: 2 min for 99% step change.

Temperature Limits: 32 to 122°F (0 to 50°C).

Humidity Limits: 10 to 95% RH (non-condensing).

Power Requirements: 16-35 VDC or 19-28 VAC.

Power Consumption: Average: 2 w; Peak: 3.75 w.

Output: Current: 4-20 mA (max. 500 O); Voltage: 0-5

VDC or 0-10 VDC (min. 500 O); Relay: SPST NO rated

2A@ 30 VDC; RTD or thermistor per r-t curves on page 6

(depending on model).

Weight: 4.4 oz (125 g).

Agency Approvals: CE.

INSTALLATION

Disconnect power supply before

installation to prevent electrical shock and

equipment damage.

Make sure all connections are in accordance with the job

wiring diagram and in accordance with national and local

electrical codes. Use copper conductors only.

Use electrostatic discharge precautions

(e.g., use of wrist straps) during

installation and wiring to prevent

equipment damage.

Avoid locations where severe shock or

vibration, excessive moisture or corrosive

fumes are present.

Do not exceed ratings of this device,

permanent damage not covered by

warranty may result.

Upon powering the transmitter, the

rmware version will ash on the display. A

warm up period of 30 minutes is required

for the transmitter to adjust to the current

CO2 concentration.

Self calibration feature of the transmitter

requires exposure to normal outdoor

equivalent carbon dioxide level once every

30 days.

MOUNTING

1. Push tab on top and bottom of cover and lift cover

from back plate (see Figure 1).

2. Select the mounting location, away from diffusers,

lights or any external inuences.

3. Mount transmitter on a vertical surface to a standard

electrical box using the two #6 M2C type screws

provided.

FIGURE 1

Removal of Cover from Back Plate

WIRING

Use maximum 18 AWG wire for wiring to terminals. Refer

to Figure 4 for wiring information.

DIP SWITCH SETTINGS

To access the DIP switch, remove the cover of the unit as

shown in Figure 2. The DIP switch is located on the back

of the circuit board.

FIGURE 2

Diagram of Circuit Board

DIP Switch

FIGURE 3

DIP Switches

4. Pull wires through sub base hole and make necessary

connections.

5. Reattach cover to base plate.

Manual 7960-902

Page 3 of 6

DIP Switch Position 1: CO2 Output Selection

ON: Output set to voltage output

OFF: Output set to current output

DIP Switch Position 2: Temperature Output Selection

ON: Output set to voltage output

OFF: Output set to current output

DIP Switch Positions 3 & 4: Current or Voltage Output

Range Selection

Output Range DIP Switch 3

Position

DIP Switch 4

Position

2-10 V

4-20 mA ON OFF

0-10 V

0-20 mA OFF OFF

0-5 V

0-10 mA OFF ON

1-5 V

2-10 mA ON ON

DIP Switch Position 5: Menu Access

ON: Menu Enabled

OFF: Menu Disabled

CURRENT/VOLTAGE OUTPUT

On the Series CDT, the transmitter may be wired for

current or voltage output for both carbon dioxide and

temperature. The transmitter can be powered with either

16-35 VDC or 19-28 VAC. Wire the transmitter according

to Figure 4.

Optional relay can be used as either a dry

contact or low voltage switched circuit up

to 2 A at 30 VDC

FIGURE 4

Active Output Wiring Diagram

POWER

SUPPLY TEMP

RECEIVER

CO2

RECEIVER

REMOTE DISPLAY

For models that are ordered without an integral LCD

display, remote display Model A-449 can be used to

display the temperature, and carbon dioxide. The mini

USB plug of the remote display plugs into the receptor on

the side of the housing. After a short warm up time, the

display will begin to show the current temperature and

carbon dioxide measurements unless congured by the

user to show only temperature or only carbon dioxide.

EDITING MENU PARAMETERS

Before any adjustment can be made to the transmitter,

the Menu Lockout Dip Switch must be set to the “On”

position (See Figure 3)

ACCESSING MENU PARAMETERS

Step 1: To enter the menu structure, press Up button and

Down button simultaneously for 5 seconds (display

will show RON parameter).

Step 2: Press Up button or Down button to cycle between

menu items.

Step 3: Press Enter to edit the value for the displayed

menu item (SET will appear on display).

Step 4: Press Up button or Down button to adjust the

value of the menu item. Step 5: Press Enter

button to save the changes (SET will disappear).

Step 6: Repeat Steps 2 through 5 for each of the

parameters.

Step 7: To exit the menu at any time, press and hold Up

button and Down button simultaneously for 5

seconds or wait 10 seconds without pushing any

buttons.

FIGURE 5

Side View of Transmitter

Manual 7960-902

Page 4 of 6

MENU DESCRIPTIONS

RON Relay on set point

Sets the CO2 concentration which the optional relay

is energized.

ROF Relay off set point

Sets the CO2 concentration which the optional

relay is de-energized. Setting value lower than

RON provides direct action for detecting high

concentrations of CO2. Setting value higher than

RON provides indirect action for detecting low

concentrations of CO2. Up button and Down button

on the LCD display will be lit to indicate when the

relay is energized.

Low limit: 0 PPM

Factory setting: 950 PPM

High limit: 2000/5000 PPM

(depending on model)

DSP Display conguration

Determines the LCD display conguration during

normal operation. The LCD display can indicate

the CO2 concentration, temperature and CO2

concentration.

CT CO2 concentration and temperature

C CO2 concentration only

T Temperature only

UNI Units selection

Temperature and barometric pressure

measurements can be displayed in US engineering

units or SI engineering units. The factory default is

to display US engineering units.

US units °F for temperature and in Hg for

barometric pressure

SI units °C for temperature and hPa for barometric

pressure

COL CO2 low output range

Sets the CO2 concentration for the lowest output

(4 mA or O VDC).

Low limit: 0 PPM

Factory setting: 0 PPM

High limit: 2000/5000 PPM (depending on model)

COH CO2 high output range

Sets the CO2 concentration for the highest output

(20 mA, 5 VDC or 1O VDC). When COH is set above

COL, the transmitter is direct acting and the output

will increase with an increase in CO2 level. When

COH is below COL, the transmitter is reverse acting

and the output will increase with a decrease in CO2

level.

Low limit: 0 PPM

Factory setting: 2000/5000 PPM (depending on

model)

High limit: 2000/5000 PPM (depending on model)

AAC Average Atmospheric Carbon Dioxide value

Sets the value at which the sensors automatic

background calibration will reference. Factory

setting derived from research from the National

Oceanic and Atmospheric Administration (NOAA).

Low limit: 200 PPM

Factory setting: Current NOAA value

High limit: 9999 PPM

TOL Temperature low output range (Series CDT with

active temperature only)

Sets the temperature for the lowest output (4 mA or

O VDC).

Low limit: 32.0°F/0.0°C

Factory setting: 32.0°F/0.0°C

High limit: 122.0°F/150.0°C

TOH Temperature high output range (Series CDT with

active temperature only)

Sets the temperature for the highest output (20

mA, 5 VDC or 10 VDC). When TOH is set above

TOL, the transmitter is direct acting and the output

will increase with an increase in temperature. When

TOH is below TOL, the transmitter is reverse acting

and the output will increase with a decrease in

temperature.

Low limit: 32.0°F/0.0°C

Factory setting: 122.0°F/150.0°C

High limit: 122.0°F/150.0°C

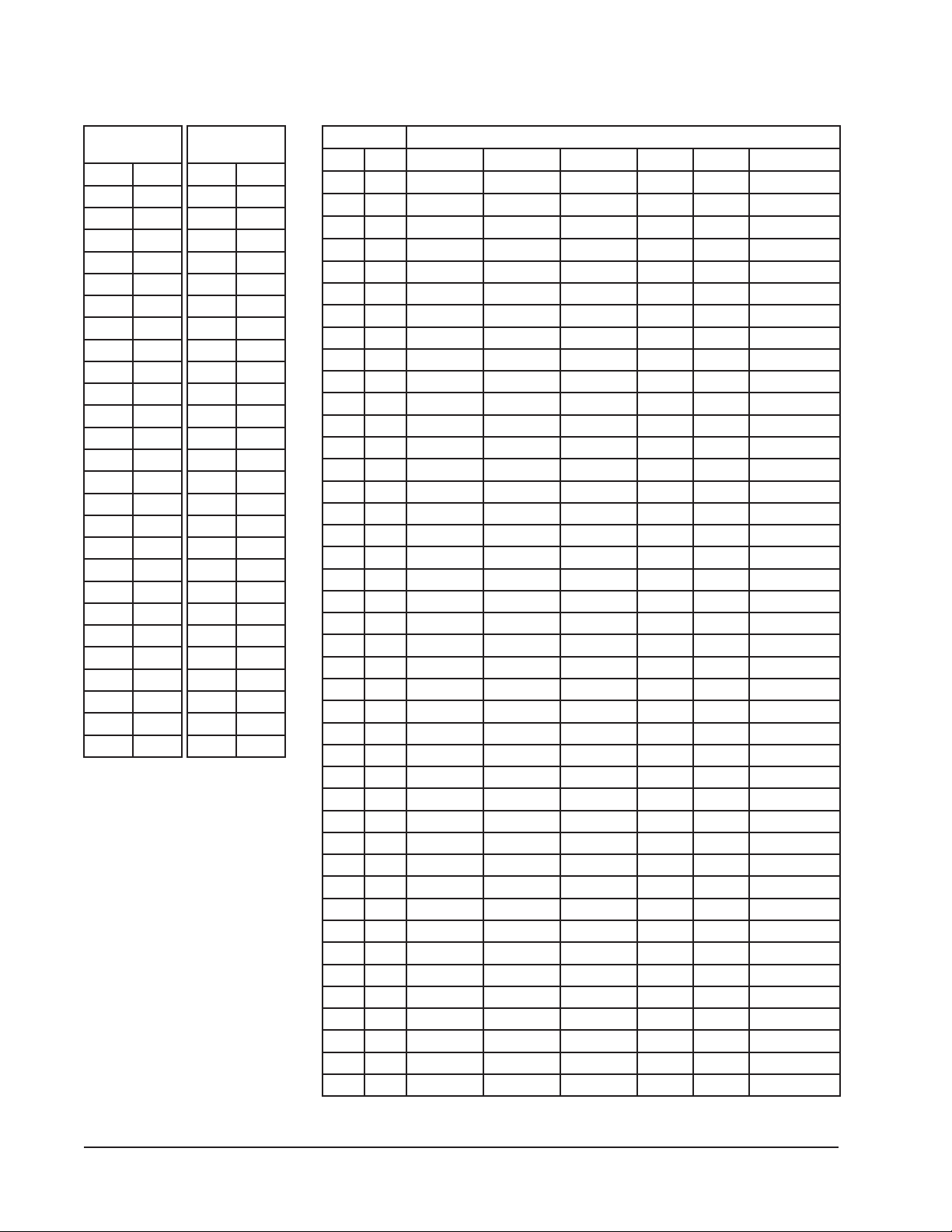

BAR Barometric pressure

Sets the typical barometric pressure for the

location where the transmitter is mounted. The

factory setting is for standard pressure at sea

level. Adjusting the barometric pressure gives a

more accurate measurement, especially at higher

elevations. Refer to the elevation charts in Table 1

for typical barometric pressures at a given elevation.

Low limit: 20.0 in Hg/677 hPa

Factory setting: 29.9 in Hg/1013 hPa

High limit: 32.0 in Hg/1084 hPa

CAL Calibration

Calibrates the carbon dioxide sensor to a known gas

value. Read CALIBRATING SENSOR below before

using this feature. Hold Enter button for 5 seconds.

RST Reset to Factory Defaults

Resets all menu settings lo their default value, and

clears zero and span.

YES: Press and hold -- button for several seconds to

reset settings

NO: Press -- button to exit this menu item without

resetting

Manual 7960-902

Page 5 of 6

CALIBRATING SENSOR

Step 1: Remove the cover as shown in Figure 1.

Step 2: Remove one of the gas nipple covers on the CO2

sensor and attach tubing from the gas pressure

regulator to the nipple (See Figure 6).

Step 3: Attach the terminal block accessory to the circuit

board so that the power wires line up with

terminals 1 and 2. Plug in the power supply to

power up the transmitter.

Step 4: Hold housing so that the sensor is in the vertical

plane as shown in Figure 6.

Step 5: Flow zero reference gas at 0.3 SLPM for 5

minutes.

Step 6: Press and hold the Up and Down buttons

simultaneously for 5 seconds to enter the menu

parameters. The display will show the “RON”

parameter.

Step 7: Press the Up or Down button to access the

calibration parameter menu which will display as

“CAL”.

Step 8: Press the Enter button. “SET” will then appear

on the display.

Step 9: Press the Down arrow for 3 seconds. All dashes

will appear on the display, then release the

button. Then after 10 seconds “SET” will

disappear.

Step 10: Exit the parameter menu by pressing and holding

the Up and Down buttons simultaneously for 5

seconds or wait 10 seconds.

Step 11: Flow the full scale reference gas at 0.3 SLPM for

5 minutes.

Step 12: Repeat steps 6 through 8.

Step 13: Press the Up arrow for 3 seconds. All dashes will

appear on the display, then release the button.

Then after 10 seconds “SET” will disappear.

FIGURE 6

Calibration

Step 14: Exit the parameter menu by pressing and holding

the Up and Down buttons simultaneously for 5

seconds or wait 10 seconds.

Step 15: Disconnect the power supply from the power

source and remove the terminal block from the

circuit board.

Step 16: Remove tubing from sensor and re-attach the gas

nipple cover to the sensor.

Step 17: Re-attach the cover to the back plate.

MAINTENANCE

Upon nal installation of the Series CDT, no routine

maintenance is required. The Series CDT are not eld

serviceable and should be returned if repair is needed.

Field repair should not be attempted and may void

warranty.

This symbol indicates waste electrical

products should not be disposed of

with household waste. Please recycle

where facilities exist. Check with your

Local Authority or retailer for recycling

advice.

Manual 7960-902

Page 6 of 6

TABLE 1

Elevation

US

Customary Units

ft in Hg

0 29.92

400 29.50

800 29.10

1200 28.69

1600 28.29

2000 27.90

2400 27.51

2800 27.13

3200 26.76

3600 26.39

4000 26.02

4400 25.66

4800 25.30

5200 24.95

5600 24.60

6000 24.26

6400 23.93

6800 23.60

7200 23.27

7600 22.94

8000 22.63

8400 22.31

8800 22.00

9200 21.70

9600 21.40

10000 21.40

SI

Units

m hPa

0 1013

100 1002

200 990

300 979

400 968

500 957

600 946

700 935

800 924

900 914

1000 904

1100 893

1200 883

1300 873

1400 863

1500 853

1600 844

1700 834

1800 824

1900 815

2000 806

2100 797

2200 787

2300 779

2400 770

2500 761

TABLE 2

Resistance vs. Temperature

Temperature Resistance Curves (in Ω)

°C °F A B C D E F

-55 -67.0 607800.00 963849.00 289154.70 78.32 783.2 2394000.00

-50 -58.0 441200.00 670166.00 201049.80 80.31 803.1 1646200.00

-45 -49.0 323600.00 471985.00 141595.50 82.29 822.9 1145800.00

-40 -40.0 239700.00 336479.00 100943.70 84.27 842.7 806800.00

-35 -31.0 179200.00 242681.00 72804.30 86.25 862.5 574400.00

-30 -22.0 135200.00 176974.00 53092.20 88.22 882.2 413400.00

-25 -13.0 102900.00 130421.00 39126.30 90.19 901.9 300400.00

-20 -4.0 78910.00 97081.00 29124.30 92.16 921.6 220600.00

-15 5.0 61020.00 72957.00 21887.10 94.12 941.2 163500.00

-10 14.0 47540.00 55329.00 16598.70 96.09 960.9 122280.00

-5 23.0 37310.00 42327.00 12698.10 98.04 980.4 92240.00

0 32.0 29490.00 32650.00 9795.00 100.00 1000.0 70160.00

5 41.0 23460.00 25392.00 7617.60 101.95 1019.5 53780.00

10 50.0 18780.00 19901.00 5970.30 103.90 1039.0 41560.00

15 59.0 15130.00 15712.00 4713.60 105.85 1058.5 32340.00

20 68.0 12260.00 12493.00 3747.90 107.79 1077.9 25360.00

25 77.0 10000.00 10000.00 3000.00 109.74 1097.4 20000.00

30 86.0 8194.00 8057.00 2417.10 111.67 1116.7 15892.00

35 95.0 6752.00 6531.00 1959.30 113.61 1136.1 12704.00

40 104.0 5592.00 5326.00 1597.80 115.54 1155.4 10216.00

45 113.0 4655.00 4368.00 1310.40 117.47 1174.7 8264.00

50 122.0 3893.00 3602.00 1080.60 119.40 1194.0 6722.00

55 131.0 3271.00 2986.00 895.80 121.32 1213.2 5498.00

60 140.0 2760.00 2488.00 746.40 123.24 1232.4 4520.00

65 149.0 2339.00 2083.00 624.90 125.16 1251.6 3734.00

70 158.0 1990.00 1752.00 525.60 127.08 1270.8 3100.00

75 167.0 1700.00 1480.00 444.00 128.99 1289.9 2586.00

80 176.0 1458.00 1255.00 376.50 130.90 1309.0 2166.00

85 185.0 1255.00 1070.00 321.00 132.80 1328.0 1822.60

90 194.0 1084.00 915.50 274.65 134.71 1347.1 1540.00

95 203.0 939.30 786.60 235.98 136.61 1366.1 1306.40

100 212.0 816.80 678.60 203.58 138.51 1385.1 1112.60

105 221.0 712.60 587.60 176.28 140.40 1404.0 951.00

110 230.0 623.60 510.60 153.18 142.29 1422.9 815.80

115 239.0 547.30 445.30 133.59 144.18 1441.8 702.20

120 248.0 481.80 389.60 116.88 146.07 1460.7 606.40

125 257.0 425.30 341.90 102.57 147.95 1479.5 525.60

130 266.0 376.40 301.00 90.30 149.83 1498.3 N/A

135 275.0 334.00 265.80 79.74 151.71 1517.1 N/A

140 284.0 297.20 235.30 70.59 153.58 1535.8 N/A

145 293.0 265.10 208.90 62.67 155.46 1554.6 N/A

150 302.0 237.00 186.10 55.83 157.33 1573.3 N/A

Table of contents