Macro Functions Guide Key

The table below should be used as a key on the following pages.

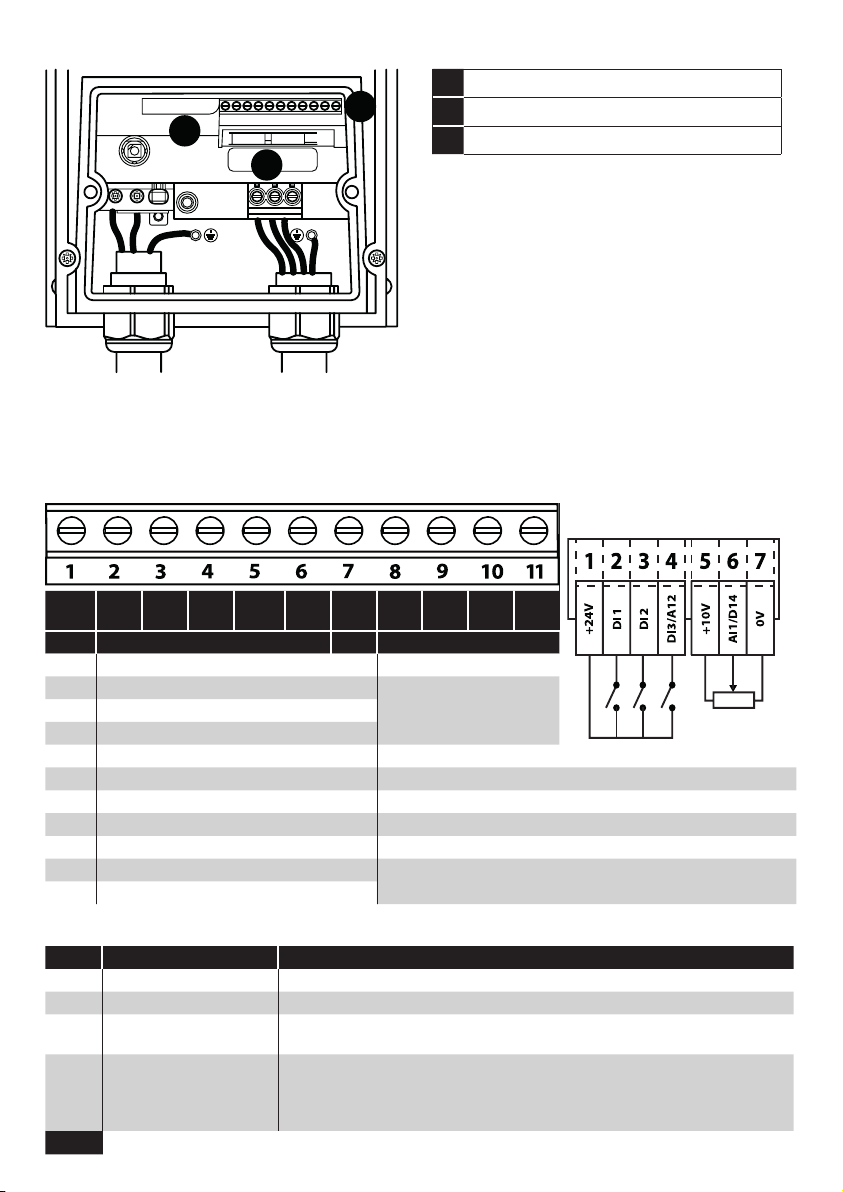

Function Explanation

STOP Latched Input, Open the contact to STOP the drive

RUN Latched input, Close the contact to Start, the drive will operate as long as the input is maintained

FWDLatched Input, selects the direction of motor rotation FORWARD

REVLatched Input, selects the direction of motor rotation REVERSE

RUN FWDLatched Input, Close to Run in the FORWARD direction, Open to STOP

RUN REVLatched Input, Close to Run in the REVERSE direction, Open to STOP

ENABLE Hardware Enable Input.

In Keypad Mode, P-31 determines whether the drive immediately starts, or the keypad start key must be

pressed.

In other modes, this input must be present before the start command is applied via the fieldbus interface.

STARTNormally Open, Rising Edge, Close momentarily to START the drive (NC STOP Input must be maintained)

^- START -^ Simultaneously applying both inputs momentarily will START the drive (NC STOP Input must be maintained)

STOPNormally Closed, Falling Edge, Open momentarily to STOP the drive

STARTFWDNormally Open, Rising Edge, Close momentarily to START the drive in the forward direction (NC STOP

Input must be maintained)

STARTREVNormally Open, Rising Edge, Close momentarily to START the drive in the reverse direction (NC STOP

Input must be maintained)

^-FAST STOP (P-24)-^

When both inputs are momentarily active simultaneously, the drive stops using Fast Stop Ramp Time P-24

FAST STOP(P-24)

Normally Closed, Falling Edge, Open momentarily to FAST STOP the drive using Fast Stop Ramp Time

P-24

E-TRIP Normally Closed, External Trip input. When the input opens momentarily, the drive trips showing

or depending on P-47 setting

Fire Mode Activates Fire Mode

Analog Input AI1 Analog Input 1, signal format selected using P-16

Analog Input AI2 Analog Input 2, signal format selected using P-47

AI1 REF Analog Input 1 provides the speed reference

AI2 REF Analog Input 2 provides the speed reference

P-xx REF Speed reference from the selected preset speed

PR-REF Preset speeds P-20 – P-23 are used for the speed reference, selected according to other digital input

status

PI-REF PI Control Speed Reference

PI FB Analog Input used to provide a Feedback signal to the internal PI controller

KPD REF Keypad Speed Reference selected

FB REF Selected speed reference from Fieldbus (Modbus RTU / CAN Open / Master depending on P-12

setting)

(NO) Input is Normally Open, Close momentarily to activate the function

(NC) Input is Normally Closed, Open momentarily to activate the function

INC SPDNormally Open, Rising Edge, Close momentarily to increase the motor speed by value in P-20

DEC SPD

Normally Open, Rising Edge, Close momentarily to decrease the motor speed by value in P-20