Black Ridge T100 User manual

1 2

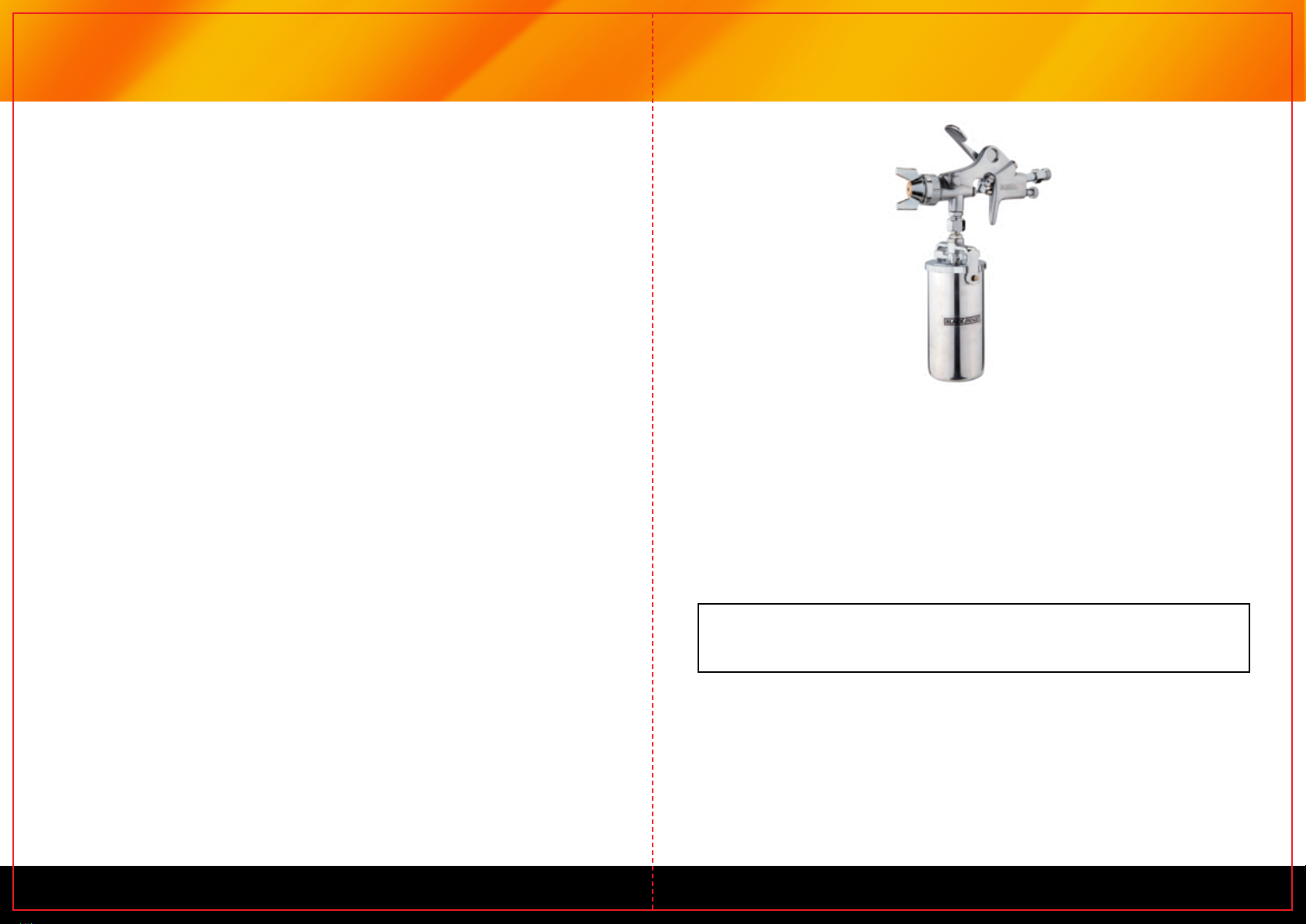

Model: T100

Standard Nozzle: 1.5mm

Max Operating Pressure: 50 PSI (3.45 BAR)

Minimum Air Consumption: 65 LPM

Fluid Delivery: 0.16-0.24 LPM

Painting Fan: 160-200mm (at distance of 10”)

Cup Size: 200ml

Air Inlet: 1/4”

• Toxic vapors produced by spraying certain materials can create intoxication

and serious damage to health. Always wear protective eyewear, gloves and

a respirator to prevent the toxic vapor hazard or solvent and paint coming into

contact with your eyes and skin.

• Never use oxygen, combustible or any other bottled gas as a power source

as it may cause an explosion and serious personal injury.

• Fluid and solvent can be highly flammable or combustible. Use in a well

ventilated work area and avoid any ignition sources, such as smoking, open

flames and similar hazards.

WARRANTY

This product is guaranteed against defects for a period of 12 months from date of

purchase. This warranty is provided by Super Cheap Auto Pty Ltd ACN 085 395

124 (Supercheap Auto) of 751 Gympie Rd Lawnton QLD 4501 Ph (07) 3482 7500.

Supercheap Auto will offer a repair, replacement product or store credit if the product

is assessed as being defective during the warranty period.

To claim under this warranty, take this product to the Front Service Desk of your nearest

Supercheap Auto store. For store locations, visit www.supercheapauto.com.au (AUS)

or www.supercheapauto.co.nz (NZ). You will need your receipt or proof of purchase.

Additional information may be requested of you to process your claim. Should you not

be able to provide proof of purchase with a receipt or a bank statement, identification

showing your name, address and signature may be required to process your claim.

This product may need to be sent to the manufacturer to assess the defect before

determining any claim. Faults or defects caused by product modification, misuse and

abuse, normal wear and tear or failure to follow user instructions are not covered under

this warranty.

Our goods come with guarantees that cannot be excluded under the Australian

Consumer Law. You are entitled to a replacement or refund for a major failure and

for compensation for any other reasonably foreseeable loss or damage. You are also

entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

Any expenses incurred relating to the return of this product to store will normally have

to be paid by you. For more information contact your nearest Supercheap Auto store.

The benefits to the consumer given by this warranty are in addition to other rights and

remedies of the Australian Consumer Law in relation to the goods and services to

which this warranty relates.

3 43 4

• Disconnect tool from air supply hose before attempting maintenance and

when not in use.

• Use clean, dry, and regulated compressed air rated at 40-70 PSI. Never

exceed the maximum operating pressure of 50 PSI.

• Never use homogenate (homogeneous) hydrocarbon solvent, which can

chemically react with aluminum and zinc parts.

• Never point gun at yourself or any other person at any time.

• Never modify this tool for any applications. Only use parts, nozzles and

accessories recommended by manufacturers.

• Put a small amount of thinner into the paint cup.

• Attach the paint cup to the gun and attach to the air line.

• Flush the gun’s fluid system out with thinner before attempting to paint.

• Empty thinner and clean paint cup.

• Pour paint into cup, test spray onto a piece of scrap and adjust fluid output

and pattern as desired.

When filling or refilling the material, disconnect your gun from the

air supply to avoid accidental spillage or spraying.

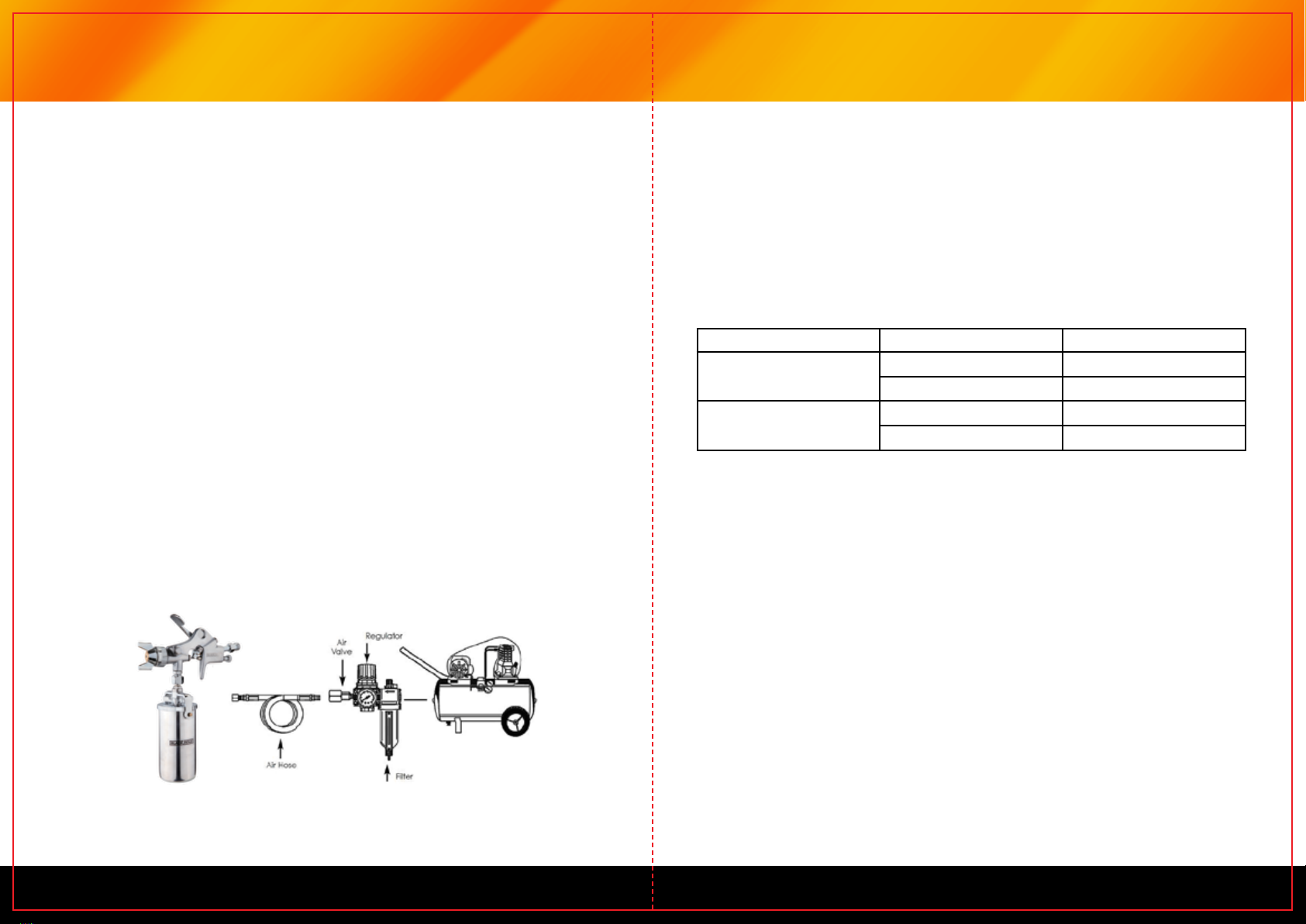

(for best results you should incorporate

an air regulator with filter).

Thin paint to manufacturer’s specification to ensure a good finish.

• Set the appropriate distance of 6” to 12” from the gun to the work piece,

relevant to the atomisation pressure and work demand.

• Keep the gun perpendicular to the surface of the work piece at all times, and

move the gun in a straight and horizontal line.

The desired pattern, volume of fluid output and fine atomisation can easily be

obtained by tuning the fan adjusting knob, air adjusting knob and fluid adjusting

knob.

Fan adjusting knob Turn right. Pattern is round.

Turn left. Pattern is fan.

Needle adjusting knob Turn right. Decrease fluid output.

Turn left. Increase fluid output.

• Pour remaining paint into another container and then clean paint cup and

air nozzle. Spray a small amount of thinner to clean the passage. Incomplete

cleaning will cause an adverse pattern shape. Clean thoroughly, immediately

after use.

• Clean other sections with a cloth soaked with thinner.

• Ensure paint passages have been completely cleaned before disassembly.

• Remove fluid nozzle after removing fluid needle set or while keeping fluid

needle pulled, in order to protect seat section.

Never use wire or other hard objects to clear the nozzle and clean

the fluid needle. This will cause damage to the components. Never immerse

the whole gun into solvent such as thinner as it will damage the air nozzle, fluid

nozzle and needle.

3 45 6

Air enters between the

fluid nozzle and tapered

seat of the gun body.

Remove the fluid nozzle

and clean the seat.

Replace if damaged.

Fluttering

Air is suctioned from fluid

needle packaging.

Tighten fluid needle

packaging.

Crescent

Paint build up on air nozzle

partially clogs horn holes.

Air pressure from each

horn is different.

Remove obstructions from

horn holes. Do not use

metal objects to clean

horn holes.

Inclined

Paint build up on the

periphery of the fluid

nozzle hole or centre hole

of air nozzle damaged.

Remove obstructions or

replace if necessary.

Loose fluid nozzle. Remove fluid nozzle, clean

and replace.

Paint viscosity too low. Add paint to increase

viscosity.

Split

Fluid output too high. Adjust the needle

adjustable knob or fan

adjustable knob.

Paint viscosity too high. Add thinner to reduce

viscosity.

Heavy

Fluid output too low. Adjust the needle

adjustable knob or fan

adjustable knob.

Fluid nozzle and fluid

needle seat are not seating

properly.

Clean or replace fluid

nozzle and fluid needle set.

Spit

The first-stage travel of

trigger (when only air

discharges) decreases.

Replace fluid nozzle and

fluid needle set.

Paint build-up inside air

nozzle set.

Clean air nozzle set.

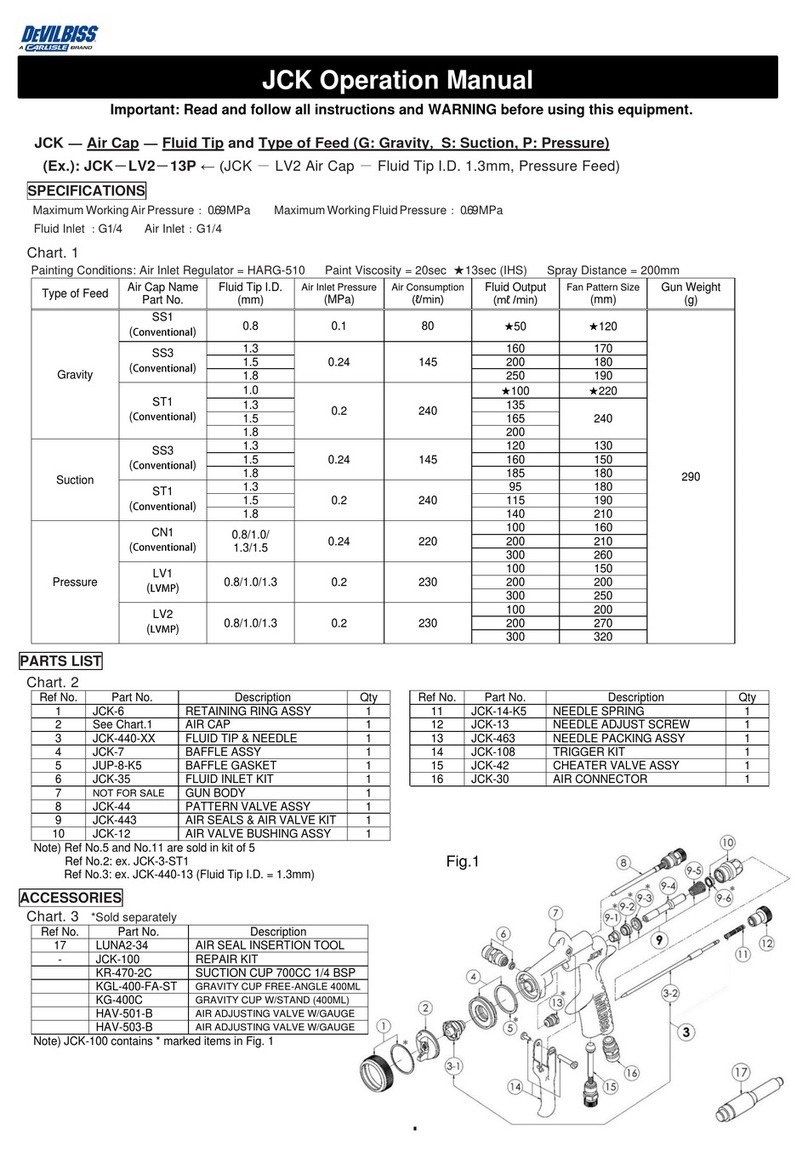

1 Sealing Screw 1 14 O-ring 6.0x1.5 1

2 Air Valve Sealing

Screw

1 15 Pattern Adj. Seat 1

3 Air Valve Stem 1 16 Pattern Adj. Spring 1

4 Air Valve Spring 1 17 Needle Sealing Screw 1

5 O-ring 5.0*1.8 1 18 Material Passage

Connector

1

6 Air Joint 1 19 Connector Screw 1

7 Needle Adj. Seat 1 20 Connector Nut 1

8 Throw-out Lever 1 21 Hexagon Nut 1

9 Needle Spring 1 22 Material Tube 1

10 Needle Adj. Knob 1 23 Material Tube 1

11 Trigger Pin 1 24 Sealing Gasket 1

12 Opening Stopper 3.5 1 25 Sealing Gasket 6

13 O-ring 3.5x1.8 1

3 45 6

NOTE:

When spray painting consider the size of the job and the size of your air

compressor being used. When spray painting large jobs like a fence or car, a Belt

Drive Air compressor is recommended. Always refer to the duty cycle of your air

compressor before spray painting.

Table of contents

Other Black Ridge Paint Sprayer manuals