barfield DC400 User manual

Copyright © 2020 Barfield Inc. All Rights Reserved.

DC400 &

DC400A

Adapter Module

USER INSTRUCTION SUPPLEMENT

M/N: DC400 & DC400A

P/N: 101-00802

Doc. P/N: 61-101-00802.EF1

Revision J

September 4, 2020

_________________________________________

MOD C, used with

DC400 or DC400A

P/N 101-00800 or P/N 101-00850

Digital DC Fuel Quantity Test Sets

For

KING AIR MODELS

100, A100, B100, 200, B200 / GT / GTi,

250, 300, 350 / 350i, 360, C90,

C90A / B / GT / GTi / GTx, E90, F90

and

BEECHCRAFT C99

61-101-00802.EF1 Revision J Page | ii

Corporate Headquarters

4101 Northwest 29thStreet

Miami, Florida 33142

www.barfieldinc.com

Email: [email protected]

Barfield Inc. Confidential and Proprietary Information.

This document and all the information contained herein is the sole property of Barfield Inc.

No intellectual property rights are granted by the delivery of this document or the disclosure of its content.

This entire document is proprietary information and shall not be reproduced or disclosed to a third party

without the express written consent of Barfield Inc.

This document and its content shall not be used for any purpose other than that for which it is supplied.

61-101-00802.EF1 Revision J Page | iii

CONTACT INFORMATION

Users are requested to notify the manufacturer of any discrepancy, omission, or error found in

this manual. Inquiries should include specific questions and reference the publication title,

number, chapter, page, figure, paragraph, and effective date.

Please send comments to:

TECHNICAL CUSTOMER SUPPORT - GSTE

BARFIELD, INC.

P.O. BOX 025367

MIAMI, FL 33102-5367

USA

Telephone: (305) 894-5400

(800) 321-1039

Fax: (305) 894-5401

Email: techsupport.gste@barfieldinc.com

61-101-00802.EF1 Revision J Page | iv

MAINTENANCE AND REPAIR INFORMATION

The manufacturer of this equipment does not recommend the user to attempt any maintenance

or repair. In case of malfunction, contact the manufacturer to obtain the list of approved repair

facilities worldwide, ensuring that this equipment will be serviced using proper procedures and

certified instruments.

BARFIELD PRODUCT SUPPORT DIVISION

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Email gsesales@barfieldinc.com

Shipping Address:

Barfield, Inc.

4101 NW 29th Street

Miami, Florida 33142

USA

Mailing Address:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

61-101-00802.EF1 Revision J Page | v

REVISION RECORD

REV.

ECO #

REV. DATE

DESCRIPTION OF CHANGE

A

N/A

March 11, 2003

Initial Release.

B

260-00617

May 19, 2003

For MOD C or later releases of Adapter Module.

C

260-00677

September 15, 2006

Changes are reflected in the company logo,

company contact information, unit figures and

listed part 101-00814 to 101-00829. Previous

instruction supplements did not show or mention

the modified version to the original 101-00814

adapter cable.

D

260-00729

January 22, 2009

Updated Company Logo.

E

260-00779

April 29, 2010

Added List of Approved Repair Facilities and

Recertification Information (page vii).

F

260-00788

September 15, 2010

Updated aircraft models, table data and test set

connector options. Added notes for accuracy of

procedures.

G

260-00812

April 16, 2012

Revised 101-00831 references. Added section 5

System Wiring Integrity Test. Moved Probes

Bench Test to Chapter 3.

H

260-00973

June 4, 2013

Corrected Step #s, Table and Figure references

In Section 5.

I

260-01076

January 7, 2015

Updated Barfield logos.

J

260-01274

September 4, 2020

Complete revision.

61-101-00802.EF1 Revision J Page | vi

TABLE OF CONTENTS

Contact Information / Recertification

Maintenance & Repair Information

Revision Record

Table of Contents

PAGE

GENERAL INFORMATION ............................................................................................1

1. APPLICABILITY.............................................................................................................. 1

2. CAPABILITIES................................................................................................................ 1

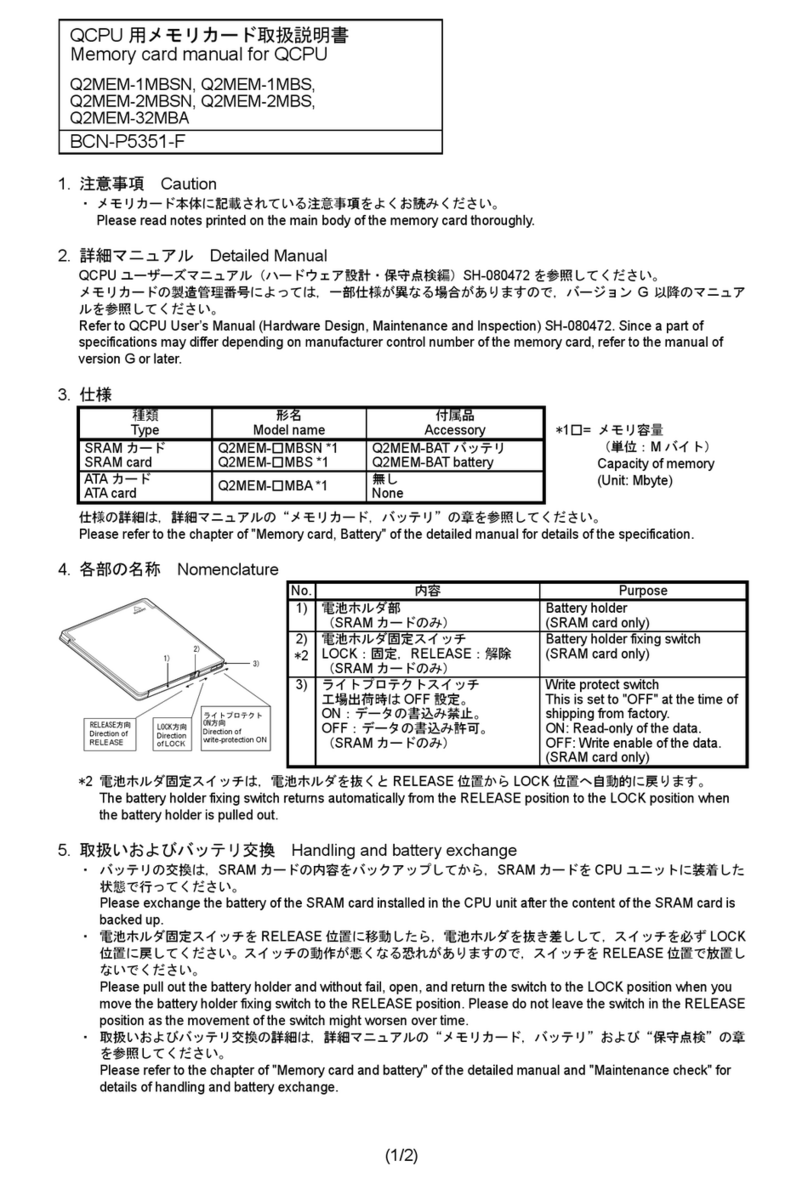

3. PANEL CONTROLS........................................................................................................ 1

4. AIRCRAFT SYSTEM DESCRIPTION.............................................................................. 1

6. PRECAUTIONS .............................................................................................................. 2

7. PRELIMINARY................................................................................................................ 2

8. DISCLAIMER .................................................................................................................. 2

9. RECERTIFICATION........................................................................................................ 3

CHAPTER 1: OPERATION ............................................................................................4

1. INSULATION MEASUREMENT TEST............................................................................. 4

2. CAPACITANCE MEASUREMENT TEST......................................................................... 7

3. INDICATOR TEST..........................................................................................................10

4. PREFERRED CALIBRATION TEST...............................................................................14

5. SYSTEM WIRING INTEGRITY TEST.............................................................................16

CHAPTER 2: ALTERNATE TESTS..............................................................................21

1. PROBES BENCH TEST .................................................................................................21

2. INDICATOR BENCH TEST.............................................................................................26

3. ALTERNATE CALIBRATION (WET TANKS)..................................................................29

61-101-00802.EF1 Revision J Page | 1

GENERAL INFORMATION

1. APPLICABILITY

This manual is one of a family of manuals, each developed to address an individual Adapter

Module especially designed for the DC400 / DC400A Digital Fuel Quantity Test Sets. It

contains complete instructions for the maintenance, inspection, testing, troubleshooting, and

calibration of the Gull Airborne and Ragen Data Fuel Quantity Systems.

At the time of this writing, these aircraft include:

A. C90 S/N LJ-575, LJ-586 through LJ-1062

B. C90A / B / GT / GTi / GTx S/N LJ-1063 and after

C. C99 S/N U-50, U-165 and after

D. E90 S/N LW-17, LW-69 and after

E. F90 S/N LA-1 thru LA-225

F. F90-1 S/N LA-226 and after

G. A100 / B100 S/N B-152, B-156 and after, BE-2 and after

H. 200 All 200, 200C, 200CT and 200T

I. B200 / GT / GTi, 250 All

J. 300 All 300 and 300C

K. 350 / 350i, 360 All

2. CAPABILITIES

(1) Complete testing of fuel quantity system.

(2) Testing of individual fuel probes.

(3) Testing of indicators.

(4) Dry and wet tank calibration.

3. PANEL CONTROLS

(1) Refer to the User Instruction Manual, Doc. 56-101-00800, for information on the DC400,

Fuel Quantity Test Set.

(2) Refer to the User Instruction Manual, Doc. 56-101-00850, for information on the

DC400A, Fuel Quantity Test Set.

(3) Refer to Aircraft Maintenance Manual for description for description of the aircraft fuel

quantity system.

4. AIRCRAFT SYSTEM DESCRIPTION

Refer to the Aircraft Maintenance Manual for specific procedures and maintenance practices.

61-101-00802.EF1 Revision J Page | 2

5. REQUIRED EQUIPMENT (OR EQUIVALENT)

QTY

P/N

EQUIPMENT NAME

DESCRIPTION

1

101-00800 or

101-00850

DC400 / DC400A, Digital Fuel

Quantity Test Set

Test Set (T/S)

1

101-00802

Fuel Quantity Adapter Module

All Beech King Air Series

1

101-00814 or

101-00829

Probe Adapter Cable

Rectangular or Circular

Connector

1

101-01012

Discrete Level Interface

Test leads, banana plug to

alligator clip pair

1

101-00817 or

101-00831*

Adapter cable

Circular to D Style or

D Style to Circular

1

101-01010*

Banana Lead Pair

1

28 VDC Power Supply

Note*: Item(s) not included with T/S; available as separate purchase.

6. PRECAUTIONS

(1) Refer to Aircraft Maintenance manual for proper fueling and defueling procedures.

Observe all safety precautions.

(2) Refer to the Aircraft Maintenance manual for location of the system components and

instructions for removal and replacement.

(3) Ensure fuel quantity circuit breakers are open and they remain open while aircraft and

test set connections are broken or made.

(4) Ensure power remains OFF unless otherwise specified.

7. PRELIMINARY

(1) To ensure the integrity of all system components, perform the Insulation, Capacitance

tests first. Then, perform one of the Indicator tests (System or Bench) and, if necessary,

the Probe Bench test. These tests will provide an effective means for troubleshooting the

system.

(2) After performing an indicator test and before returning the aircraft to service, calibrate

the aircraft fuel quantity system using the Preferred (or Alternate) Calibration Test.

(3) Failure to calibrate the system could result in an inaccurate fuel quantity indication.

8. DISCLAIMER

BARFIELD, INC., neither a vendor nor supplier of fuel quantity indicating systems or an

airframe manufacturer, has no control over testing and calibration values and procedures.

The Aircraft Maintenance Manual must be the first source of information regarding testing

and calibration values and procedures, taking precedence over this manual. A variant

between actual values and procedures and those recommended in this manual may exist.

However, the information presented here is correct to the best of our knowledge at the time

of publication and is presented for reference only.

61-101-00802.EF1 Revision J Page | 3

9. RECERTIFICATION

Barfield Adapter Module, P/N 101-00802, has a one-year recertification requirement.

Qualified technicians in a shop equipped with the necessary tooling, facilities, and Barfield-

approved procedures must perform the maintenance required by this unit. Please, refer to

the Maintenance and Repair Information for approved repair facilities.

61-101-00802.EF1 Revision J Page | 4

CHAPTER 1: OPERATION

1. INSULATION MEASUREMENT TEST

Note: Refer to Precautions and Preliminary in General Information section.

Note: This test may be performed with either wet or dry tanks.

A. Aircraft Preparation

(1) Disconnect aircraft battery.

CAUTION: WHEN LOWERING OR RAISING PILOT FUEL PANEL, ENSURE

AIRCRAFT BATTERY IS DISCONNECTED.

(2) Gain access to applicable Indicator.

(3) Open the circuit breakers.

CAUTION: WHEN BREAKING OR MAKING INDICATOR CONNECTIONS,

ENSURE APPLICABLE CIRCUIT BREAKER(S) ARE OPEN.

(4) Disconnect aircraft wiring plug at the indicator.

B. Test Set Preparation

(1) Set T/S ON / OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to IND AMP.

(3) Set the INSULATION / SYSTEM switch to INSULATION.

(4) Rotate the INS TEST POINTS switch to LO-Z / GND.

C. Connecting Test Set

(1) Connect T/S as per Figure 1 or Figure 2 and the following steps.

Note: Figure 1 depicts using Adapter Cable P/N 101-00831 for conversion to systems

with circular style connectors.

(2) Do NOT connect T/S IND connector.

(3) Connect T/S ACFT connector to aircraft wiring plug.

Figure 1 Insulation Test (with 101-00831 Adapter)

Aircraft Wiring

Do not connect

61-101-00802.EF1 Revision J Page | 5

Figure 2 Insulation Test

D. Insulation Test

(1) Set T/S ON / OFF switch to ON.

(2) Allow time for the T/S display to stabilize.

Note: On those occasions when display stabilization cannot be achieved, take the

reading after being performing this Test for 30 seconds. If this value is in the

acceptable range, then consider that the Aircraft system has passed this test.

(3) Verify that the T/S reading is less than 50 nS.

Note: The display reading is in nS (nano Siemens). To get an equivalent MΩ

(megaohms) measurement, divide 1000 by the T/S display reading.

T/S DISPLAY READING

EQUIVALENT MΩ

1.

Less than 1

1000

1.

500

2.

200

5.

100

10.

050

20.

020

50.

010

100.

005

200.

002

500.

001

1,000.

000

Greater than 1,000

Table 1 Conductance to Megaohm Conversion

(4) Rotate the INS TEST POINTS switch through each remaining position.

(5) Allow T/S to stabilize.

(6) Verify T/S reading is less than 50 nS at every position except SIG / RTN.

(7) With switch rotated to SIG / RTN, verify T/S reading of “1”.

Aircraft Wiring

Do not connect

61-101-00802.EF1 Revision J Page | 6

(8) Connect aircraft battery.

(9) Close circuit breakers.

(10) Set aircraft fuel panel select switch to AUX / NAC and hold (if applicable).

a. The battery switch must be in the ON position for all airplanes except the model

C90 / C90A / B / GT / GTi / GTx.

b. The fuel quantity select relay or switch shorts the signal lead to return lead of MAIN

/ TOTAL or AUX / NAC that is not selected.

c. Due to continuity through diodes inside the probe, a short on RTN / GND shows as

a short on SIG / GND.

(11) Rotate INS TEST POINTS switch through remaining positions.

(12) Allow T/S to stabilize.

(13) Verify T/S reading is less than 50 nS at each position except SIG / RTN.

(14) With switch rotated to SIG / RTN, verify a T/S reading of “1”.

(15) Return fuel panel select switch to MAIN / TOTAL.

a. If a test does not comply with specification, repeat test to verify readings.

b. If wrong reading remains, isolate fault by referring to aircraft wiring drawings and

disconnecting probes and / or the aircraft wiring at connecting junctions.

(16) This completes the Insulation Measurement Test.

(17) Set T/S ON / OFF switch to OFF.

Note: If testing the opposite side, repeat procedure.

E. Disconnecting/Reconfiguring

(1) Open circuit breakers and turn battery switch OFF (if applicable).

CAUTION: WHEN LOWERING OR RAISING THE FUEL PANEL, ENSURE

AIRCRAFT BATTERY IS DISCONNECTED.

(2) Disconnect T/S from the aircraft wiring.

(3) Reconnect aircraft wiring plug to Indicator.

(4) Return the aircraft to its original configuration.

61-101-00802.EF1 Revision J Page | 7

2. CAPACITANCE MEASUREMENT TEST

Note: Refer to Precautions and Preliminary in General Information section.

Note: This test must be performed with tanks drained or full.

A. Aircraft Preparation

(1) Disconnect aircraft battery.

CAUTION: WHEN LOWERING OR RAISING PILOT FUEL PANEL, ENSURE

AIRCRAFT BATTERY IS DISCONNECTED.

(2) Gain access to applicable Indicator.

(3) Open the circuit breakers.

CAUTION: WHEN BREAKING OR MAKING INDICATOR CONNECTIONS,

ENSURE APPLICABLECIRCUIT BREAKER(S) ARE OPEN.

(4) Disconnect aircraft wiring plug at the indicator.

B. Test Set Preparation

(1) Set T/S ON / OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to PROBE(S).

(3) Set the INSULATION / SYSTEM switch to SYSTEM.

(4) Set the MAIN / TOT-AUX / NAC switch to MAIN / TOT.

(5) Set the 200 (pF) / 1000 (pF) switch to 200 (pF) for empty capacitance and 1000 (pF)

for full capacitance.

C. Connecting Test Set

(1) Connect T/S as per Figure 3 or Figure 4 and the following steps.

Note: Figure 3 depicts the use of Adapter cable P/N 101-00831 for conversion to

systems with circular style connectors.

(2) Do NOT connect T/S IND connector.

(3) Connect T/S ACFT connector to aircraft wiring plug.

Figure 3 Capacitance Test (with P/N 101-00831 Adapter)

Aircraft Wiring

Do not connect

61-101-00802.EF1 Revision J Page | 8

Figure 4 Capacitance Test

D. Test

Note: If the CONTINUITY light is illuminated it means that the DC400/A Oscillator Circuit

is overloaded. The most probable cause is a short circuit on the LO-Z wire.

(1) Set the T/S ON / OFF switch to ON.

(2) Set the aircraft fuel panel select switch to MAIN or TOTAL.

(3) Push and hold the T/S PRESS TO READ CAP (pF) pushbutton.

(4) Verify that the tanks’ value is within tolerances as specified in Table 2 (Tank

Capacitance Empty) or Table 3 (Tank Capacitance Full).

Note: The values depicted in Table 2 and Table 3 are valid as of this publication’s

release date and provided as reference. Refer to the Aircraft Maintenance

manual for test values.

Aircraft Wiring

Do not connect

61-101-00802.EF1 Revision J Page | 9

C90, C90A / B / GT / GTi / GTx & C99

Aircraft Type

Total

Nacelle Only

Min.

Nom.

Max.

Min.

Nom.

Max.

C90, C90 / B / GT /GTi / GTx

151.5

164.8

177.0

57.3

63.3

69.3

C99

147.5

160.4

173.0

53.3

58.7

64.0

E90, A100, B100 with 100-380006-15 & -17 Integral Tank Units

Aircraft Type

Main

Aux Only

Min.

Nom.

Max.

Min.

Nom.

Max.

E90

166.2

184.1

201.9

29.1

32.0

35.2

A100 / B100

162.2

179.7

197.1

29.1

32.0

35.2

200

161.0

182.7

204.04

53.5

59.4

65.3

Aircraft with 100-380006-93, -121, -179 & -95, -123, -181 Tank Units

Aircraft Type

Total

Nacelle Only

Min.

Nom.

Max.

Min.

Nom.

Max.

E90

159.1

175.8

192.5

29.1

32.2

35.2

F90, A100 / B100

155.1

171.4

187.7

29.1

32.2

35.2

200, 250, 300 / 350i, 360

154.0

170.2

186.3

53.5

59.4

65.3

Table 2 Empty Tank Capacitance

C90, C90A / B / GT / GTi / GTx & C99

Aircraft Type

Total

Nacelle Only

Min.

Nom.

Max.

Min.

Nom.

Max.

C90, C90 / B / GT /GTi / GTx

224.6

249.5

274.5

79.3

88.1

96.9

C99

219.4

243.7

268.0

74.1

82.3

90.5

E90, A100, B100 with 100-380006-15 & -17 Integral Tank Units

Aircraft Type

Main

Aux Only

Min.

Nom.

Max.

Min.

Nom.

Max.

E90

241.4

268.2

295.0

46.2

51.3

56.4

A100 / B100

236.2

262.4

288.6

46.2

51.3

56.4

200

233.9

259.9

285.9

87.5

97.2

106.9

Aircraft with 100-380006-93, -121, -179 & -95, -123, -181 Tank Units

Aircraft Type

Total

Nacelle Only

Min.

Nom.

Max.

Min.

Nom.

Max.

E90

236.0

262.2

288.4

46.2

51.3

56.4

F90, A100 / B100

230.7

256.4

282.0

46.2

51.3

56.4

200, 250, 300, 350 / 350i, 360

228.5

253.9

279.2

87.5

97.2

106.9

Table 3 Full Tank Capacitance

(5) Release pushbutton.

(6) Connect aircraft battery.

(7) Close circuit breakers.

(8) Set the aircraft fuel panel select switch to AUX / NAC and hold (if applicable).

a. The battery switch must be in the ON position for all airplanes except the model

C90 / C90A / B / GT / GTi / GTx.

61-101-00802.EF1 Revision J Page | 10

(9) Push and hold the PRESS TO READ CAP (pF) pushbutton.

(10) Verify the tanks’ value is within tolerances as specified in Table 2 (Empty) and Table

3 (Full).

Note: Verify that capacitance is within specifications. If a test in not within

specification, isolate the fault by referencing the aircraft wiring schematics and

disconnecting the probes and / or the aircraft wiring at connecting junctions.

(11) Set the T/S ON / OFF switch to OFF.

Note: If testing the opposite side, repeat procedure.

E. Disconnecting/Reconfiguring

(1) Open circuit breakers and turn battery switch OFF (if applicable).

CAUTION: WHEN LOWERING OR RAISING THE FUEL PANEL, ENSURE

AIRCRAFT BATTERY IS DISCONNECTED.

(2) Disconnect T/S from the aircraft wiring.

(3) Reconnect aircraft wiring plug to Indicator.

(4) Return the aircraft to its original configuration.

3. INDICATOR TEST

Note: Refer to Precautions and Preliminary in General Information section.

Note: Failure to calibrate the system after performing the indicator test will result in an

inaccurate fuel quantity readings.

Note: The Indicator Bench Test (see Chapter 2, Section 2. INDICATOR BENCH TEST)

may be performed in place of the Indicator Test.

A. Aircraft Preparation

(1) Disconnect aircraft battery.

CAUTION: WHEN RAISING OR LOWERING THE PILOT FUEL PANEL, ENSURE

AIRCRAFT BATTERY IS DISCONNECTED.

(2) Gain access to applicable Indicator.

(3) Ensure applicable fuel quantity circuit breakers are open.

(4) Break connection between Indicator and aircraft wiring plug.

B. Test Set Preparation

(1) Set T/S ON / OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(3) Set the INSULATION / SYSTEM switch to SYSTEM.

(4) Set the MAIN / TOT-AUX / NAC switch to MAIN / TOT.

(5) Set the 200 (pF) / 1000 (pF) switch to 200 (pF).

61-101-00802.EF1 Revision J Page | 11

C. Connecting Test Set

(1) Connect T/S as per Figure 5 or Figure 6 and the following steps.

Note: Figure 5 depicts the use of Adapter cable P/N 101-00831 for conversion to

systems with circular style connectors.

(2) Connect T/S IND connector to Indicator.

(3) Connect T/S ACFT connector to aircraft wiring plug.

Figure 5 Indicator Test (With 101-00831 Adapter)

Figure 6 Indicator Test

D. Test

(1) Set the T/S ON / OFF switch to ON.

(2) Set the CAP SIM (pF) 100’s to 1. Set 10’s thumbwheels to 8.

Aircraft Wiring

Aircraft Wiring

61-101-00802.EF1 Revision J Page | 12

(3) Press and hold PRESS TO READ CAP (pF) pushbutton while adjusting CAP SIM

(pF) control knob to obtain a T/S reading of 189.0 pF.

(4) Rotate the TEST FUNCTION switch to IND AMP.

(5) Connect the aircraft battery.

(6) Close the circuit breakers.

(7) Turn the aircraft battery ON / OFF switch ON.

CAUTION: DO NOT TAP BEZEL OF INSTRUMENT TO VIBRATE. TO REMOVE

FRICTION, GENTLY TAP ADJACENT PANEL OR REAR HOUSING

OF INDICATOR BEFORE TAKING READINGS.

(8) Verify that the indicator reads zero lbs.

(9) If reading is not zero, adjust EMP 1/E 1.

(10) If the indicator will not give a zero reading, replace the indicator.

(11) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(12) Set the 200 (pF) / 1000 (pF) switch to 1000 (pF).

(13) Set CAP SIM (pF) 100’s thumbwheel to 2. Set the 10’s thumbwheel to 7.

(14) Push and hold the PRESS TO READ CAP (pF) pushbutton while adjusting CAP SIM

(pF) control knob to obtain a T/S reading of 273 pF.

(15) Release the pushbutton.

(16) Rotate the TEST FUNCTION switch to IND AMP.

(17) Verify the indicator reads 1200 lbs.

(18) If the indicator does not show 1200 lbs, adjust FULL.

(19) If the indicator still does not read 1200 lbs, replace indicator.

(20) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(21) Set the 200 (pF) / 1000 (pF) switch to 200 (pF).

(22) Set the CAP SIM (pF) 100’s thumbwheel to “-”. Set the 10’s thumbwheel as follows:

a. If testing E90, F90, A100 or B100 series aircraft, set 10’s to “3”.

b. If testing C90, C90A / B / GT / GTi / GTx, C99, 200, 250, 300, 350 / 350i, or 360,

set 10’s to “6”.

(23) Push and hold the PRESS TO READ CAP (pF) pushbutton while adjusting CAP SIM

(pF) control knobs and verify as follows:

a. If testing E90, F90, A100 or B100 aircrafts, T/S display shows 31.0 pF.

b. If testing C90, C90A / B / GT / GTi / GTx, C99, 200, 250, 300 , 350 / 350i or 360,

T/S display shows 60.0 pF.

(24) Release pushbutton.

(25) Set the MAIN / TOT-AUX / NAC switch to AUX / NAC.

(26) Rotate TEST FUNCTION switch to IND AMP.

(27) Verify the indicator reads 0 lbs.

(28) If reading is not 0 lbs., adjust the indicator using the EMP 2 / E 2.

(29) If the indicator still does not read 0, replace the indicator.

61-101-00802.EF1 Revision J Page | 13

(30) Repeat steps D.2 through D.29 until an accurate gage adjustment is obtained.

(31) Set the MAIN / TOT –AUX / NAC switch to MAIN / TOT.

(32) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(33) Set the 200 (pF) / 1000 (pF) switch to 1000 (pF).

(34) Set the CAP SIM (pF) 100’s thumbwheel to 2. Set the 10’s thumbwheel to 1.

(35) Press and hold the PRESS TO READ CAP (pF) pushbutton while adjusting the CAP

SIM (pF) control knob to obtain a T/S reading of 210 pF.

(36) Rotate the TEST FUNCTION switch to IND AMP.

(37) Verify the indicator reads 300 ± 35 lbs.

(38) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(39) Set the CAP SIM (pF) 100’s thumbwheel to “2”. Set the 10’s thumbwheel to “3.”

(40) Press and hold the PRESS TO READ CAP (pF) pushbutton while adjusting the CAP

SIM (pF) control knob to obtain a test display of 231 pF.

(41) Rotate the TEST FUNCTION switch to IND AMP.

(42) Verify the indicator reads 600 ± 35 lbs.

(43) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(44) Set the CAP SIM (pF) 100’s thumbwheels to “2”. Set the 10’s thumbwheel to “5”.

(45) Press and hold the PRESS TO READ CAP (pF) pushbutton while adjusting CAP SIM

(pF) control knob to obtain a T/S display of 252 pF.

(46) Rotate the TEST FUNCTION switch to IND AMP.

(47) Verify the indicator reads 900 ± 35 lbs.

(48) Set the T/S ON / OFF switch to OFF.

E. Disconnecting/Reconfiguring

(1) Open the circuit breakers, turn the battery switch OFF.

CAUTION: WHEN RAISING OR LOWERING THE PILOT FUEL PANEL, ENSURE

AIRCRAFT BATTERY IS DISCONNECTED.

(2) Disconnect T/S from the aircraft wiring.

(3) Disconnect T/S from the Indicator.

(4) Reconnect aircraft wiring plug to Indicator.

(5) Return the aircraft to its original configuration.

61-101-00802.EF1 Revision J Page | 14

4. PREFERRED CALIBRATION TEST

Note: Refer to Precautions and Preliminary in General Information section.

Note: When draining facilities are not readily available, the Alternate Calibration Procedure

(see Chapter 2, section 3. ALTERNATE CALIBRATION (WET TANKS)) may be

used as a temporary measure.

Note: The preferred calibration is done with dry tanks. This method is the most accurate

for calibration since the indicator zero reading is set to the actual empty tank

condition. A capacitance value, applied to the system by the T/S, is substituted for

an equivalent quantity of fuel in the tanks. The Indicator is adjusted to read the

substituted fuel quantity.

A. Aircraft Preparation

CAUTION: REFER TO THE AIRCRAFT MAINTENACE MANUAL FOR PROPER

DEFUELING AND FUELING PROCEDURES. OBSERVE ALL SAFETY

PRECAUTIONS.

(1) Ensure aircraft is defueled. Drain pumps.

(2) Disconnect aircraft battery.

CAUTION: WHEN RAISING OR LOWERING THE PILOT FUEL PANEL, ENSURE

AIRCRAFT BATTERY IS DISCONNECTED.

(3) Gain access to applicable Indicator.

(4) Open the circuit breakers.

(5) Disconnect aircraft wiring plug at the indicator.

B. Test Set Preparation

(1) Ensure T/S ON / OFF switch is OFF.

(2) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(3) Set the INSULATION / SYSTEM switch to SYSTEM.

(4) Set the MAIN / TOT-AUX / NAC switch to MAIN / TOT.

(5) Set the 200 (pF) / 1000 (pF) switch to 200 (pF).

(6) Set the CAP SIM (pF) 100’s thumbwheels to “-“. Set the 10’s to “9”.

C. Connecting Test Set

(1) Connect the T/S as shown in either Figure 5 or Figure 6 and the following steps.

Note: Figure 5 depicts using Adapter Cable 101-00831 for conversion to systems with

circular style connectors.

(2) Connect T/S IND connector to Indicator.

(3) Connect T/S ACFT connector to aircraft wiring plug.

D. Test

(1) Set T/S ON / OFF switch is ON.

(2) Press and hold PRESS TO READ CAP (pF) pushbutton while adjusting CAP SIM

(pF) control knob to obtain a T/S reading according to Table 4.

Other manuals for DC400

1

This manual suits for next models

1

Table of contents

Other barfield Control Unit manuals

Popular Control Unit manuals by other brands

Fike

Fike FAV Installation and maintenance instructions

gefran

gefran R-CPU300 Installation and operation manual

Land Pride

Land Pride 380-137A Assembly instructions

Moso

Moso LDP Series Operation guide

VSI

VSI 9000 Series Installation, operation and maintenance manual

schmersal

schmersal PDM-IOP-4CC-IOP operating instructions

TC Electronic

TC Electronic DB4 MKII Operation manual

Accutron

Accutron PRO TECHNICAL/OPERATION MANUAL

Hitachi

Hitachi RU-1000VR operating instructions

Mitsubishi Electric

Mitsubishi Electric Q2MEM-1MBSN manual

D-Link

D-Link DMC-1002 Quick installation guide

RLE Technologies

RLE Technologies SeaHawk LDZB6 quick start guide