Fike FAV User manual

SOLUTIONS

Fire Protection

Explosion Protection

Overpressure Protection

Pressure Activation

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Explosion Isolation

Valve - FAV

EXPLOSION PROTECTION SYSTEMS

Doc. 8.8503.00.9

Rev. April, 2018

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 2

COPYRIGHT INFORMATION

© Copyright 2017, Fike Corporation. All rights reserved. Printed in Europe.

This document may not be reproduced, in whole or in part, by any means without the prior written consent of Fike. All

Fike documentation and hardware are copyrighted with all rights reserved.

TRADEMARKS

Fikeis a registered trademark of Fike. All other trademarks, trade names or company names referenced herein are

the property of their respective owners.

ERRORS AND OMISSIONS

While every precaution has been taken during the preparation of this document to ensure the accuracy of its content,

Fike assumes no responsibility whatsoever for errors or omissions.

Fike reserves the right to change product designs or specifications without obligation and without further notice in

accordance with our policy of continuing product and system improvement.

READER QUESTIONS AND RESPONSES

If you have any questions regarding the information contained in this document, or if you have any other enquiries

regarding Fike products, please call Fike Europe Product Support at 0032 14 21 00 31.

Fike encourages input from our distributors and end users on how we can improve this manual and even the product

itself. Please direct all calls of this nature to Fike Europe Product Support at 0032 14 21 00 31. Any communication

received becomes the property of Fike.

TERMS AND CONDITIONS OF SALE

Because of the many and varied circumstances and extreme conditions under which Fike’s products are used, and

because Fike has no control over this actual use, Fike makes no warranties based on the contents of this document.

FIKE MAKES NO IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A SPECIFIC PURPOSE. Refer to

www.fike.com/terms-conditions for Fike’s full TERMS AND CONDITIONS OF SALE.

TERMS OF USE

Do not alter, modify, copy, or otherwise misappropriate any Fike product, whether in whole or in part. Fike assumes

no responsibility for any losses incurred by you or third parties arising from such alteration, modification, copy or

otherwise misappropriation of Fike products.

Do not use any Fike products for any application for which it is not intended. Fike shall not be in any way liable for any

damages or losses incurred by you or third parties arising from the use of any Fike product for which the product is not

intended by Fike.

You should install and use the Fike products described in this document within the range specified by Fike, especially

with respect to the product application, maximum ratings, operating supply voltage range, installation and other

product characteristics. Fike shall have no liability for malfunctions or damages arising out of the use of Fike products

beyond such specified ranges.

You should install and use the Fike products described in this document in compliance with all applicable laws,

standards, and regulations in the country of installation. Fike assumes no liability for damages or losses occurring as a

result of your noncompliance with regionally applicable laws and regulations.

It is the responsibility of the buyer or distributor of Fike products, who distributes, disposes of, or otherwise places the

product with a third party, to notify such third party in advance of the contents and conditions set forth in this

document. Fike assumes no responsibility for any losses incurred by you or third parties as a result of unauthorised

use of Fike products.

QUALITY NOTICE

Fike has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and review

our documentation to assure the highest quality in all respects.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 1

TABLE OF CONTENTS

Section Page No.

1. INTRODUCTION .......................................................................................................................................................... 2

1.1. Scope................................................................................................................................................................. 2

2. WARNINGS.................................................................................................................................................................. 4

3. FAST ACTING VALVE.................................................................................................................................................... 5

3.1. Description ........................................................................................................................................................ 5

3.2. Identification ..................................................................................................................................................... 6

3.3. Composing Parts ............................................................................................................................................... 7

3.4. Dimensions........................................................................................................................................................ 8

4. VALVE ACTUATOR ASSEMBLY SAFETY PROCEDURES................................................................................................ 10

5. FAST ACTING VALVE INSTALLATION ......................................................................................................................... 11

5.1. Mechanical Installation ................................................................................................................................... 11

5.2. Electrical installation ....................................................................................................................................... 12

5.2.1. Electrical scheme open/close module (Optional)....................................................................................... 12

5.2.2. Position indicators piston ........................................................................................................................... 12

5.3. Valve Actuator Assembly Installation Procedure ............................................................................................ 13

5.4. Valve Actuator Assembly Removal Procedure ................................................................................................ 13

6. VALVE REFURBISHMENT........................................................................................................................................... 14

6.1. Valve Actuator Assembly Handling Warning................................................................................................... 14

6.2. FAV Maintenance............................................................................................................................................ 14

6.2.1. Actuating Cylinder Rebuild ......................................................................................................................... 14

6.2.2. Gate Damper Replacement (DN50 –DN200 FAV) ...................................................................................... 14

6.2.3. Gate Damper Replacement (DN250 –DN500 FAV) .................................................................................... 15

6.3. Roll Pin Replacement ...................................................................................................................................... 15

6.4. Flange O-Ring Replacement ............................................................................................................................ 15

6.5. Flange to FAV Assembly .................................................................................................................................. 16

6.6. Muffler Seal Replacement............................................................................................................................... 16

6.7. Refurbish Kits .................................................................................................................................................. 16

7. SCHEDULED MAINTENANCE ..................................................................................................................................... 18

7.1. Every Three (3) Months................................................................................................................................... 18

7.2. Every Ten (10) Years........................................................................................................................................ 18

7.2.1. Service Environment................................................................................................................................... 18

8. DE-COMMISSIONING PROCEDURE / CHECK-LIST ..................................................................................................... 19

9. REPAIR AND RETURN AUTHORISATION.................................................................................................................... 20

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 2

Scope

This document is intended to provide information and assist with the maintenance of Fike Europe Fast Acting Valves

(FAV). Individuals should read this manual carefully. Specific sections will be of particular interest depending upon

specific responsibilities. This information shall be used in conjunction with the drawings and additional information

provided for the specific application.

Fike Explosion Isolation Concept

The risk of an industrial explosion occurs in many stages of production, transport, and storage of combustible dusts

and gases. Apart from all the known preventive measures to avoid conditions, in which explosions may occur, a large

number of constructive protection measures can be taken.

Protective techniques are classified into explosion venting, suppression and isolation.

Explosion venting and explosion suppression are designed to protect process vessels from overpressurisation.

Explosion isolation is intended to keep explosions from spreading throughout a process. By isolating the explosion, the

effect of an explosion is limited to the equipment where the explosion initially occurred.

Responsive mechanical explosion isolation systems, commonly referred to as Fast Acting valves (FAV), are designed to

act upon the detection at the incipient stage of combustion by mechanically isolating the combustion and preventing

flame propagation.

The Fike Explosion Isolation System proceeds through 3 basic sequences to provide successful activation: detection,

initiation and closure of the valve. The Fike Fast Acting valve is the critical element in the sequence of successful

explosion isolation. The rapid closure provides the physical barrier which prevents flame propagation beyond the

isolating valve location.

Refer to Fike documents X.2.32.01-x Fast Acting Valve - FAV, X.2.66.01-x FAV Reload Kit, and X.2.26.01-x Valve

Actuator Assembly for detailed information.

Definitions

FAV:Fast Acting Valve

Explosion: The propagation of a flame in a premixed dispersion of combustible gases, dusts, mists or mixtures of

these, in a gaseous oxidant such as air in a closed or substantially closed vessel.

Deflagration: Explosions which propagate because of heat transfer and having two distinctive and separate parts - a

pressure wave and a flame. The deflagration type of explosion is generally referred to as a combustion reaction where

the flame front burns into the unburned material at a velocity lower than the speed of sound. The Fike hardware is

designed to provide protection against deflagrations only, not against detonations unless otherwise specified.

Explosion sensor: Device that is responsive to the changes of environmental parameters such as pressure caused by a

developing explosion.

Activation pressure Pa:That pressure threshold, above the pressure at ignition of the reactants (Pi), at which a

detection of the explosion is deemed to have occurred.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 3

Explosion detector: Device or arrangement of apparatus, containing one or more explosion sensors, that responds to

a developing explosion by providing an explosion detection signal.

Response time: The time necessary for actuation of the system after a detection of an explosion.

Active Explosion Isolation System: A system which is designed to be activated by a sensor/or a control and indicating

equipment (CIE) and stop explosions from travelling through pipelines or limit destructive effects of the explosion.

Actuator: Initiating device, typically a gas generator (Valve Actuator Assembly –GCA).

Control and indicating Equipment (CIE): Equipment which records and monitors the signals transmitted by explosion

pressure sensors / detectors spark and flame, temperature and other safety sensors. Depending on configuration, by

interrogation and interpretation of the detector / sensor data the CIE selectively controls the actuation of Suppressors,

extinguishing barriers, fast closing isolation valves, process equipment shut down, water spray or extinguishing

release, and all audible and visual alarms. The CIE must be constructed according to special specifications.

Explosion Protection System Controller (EPSC): Fike equivalent name for CIE.

Armed: the EPSC is active and will process a detection signal.

Disarmed: the EPSC is inactive and will not process a detection signal.

Shutdown: Disarm action followed by the discharging of the capacitors of a CIE/EPSC. Consequently, the power to fire

the actuator is no longer present. Therefore, shutdown is safer than DISARM. Shutdown must be used during

maintenance to an area of plant, where people can enter the protected volume. Shutdown also guarantees a safe

state of the circuitry for the operator or technician for maintenance or measurements.

Fike Service Sign:

The sections marked with this icon require specialist assistance.

ONLY CERTIFIED FIELD SERVICE ENGINEERS SHALL PERFORM THE ACTIONS DESCRIBED IN THESE MARKED SECTIONS.

Service Qualifications

The information contained in this document is provided for reference purposes only. For further product information

or ordering replacement parts, please contact your local Fike Branch Office or Representative (details of which can be

found on the back page) or Fike Product Support by calling 816-229-3405 (fax: 816-229-0314) or Fike Europe Product

Support at +32 14 21 00 31 (fax: +32 14 21 07 43).

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 4

WARNING: ISOLATION SYSTEM PARTS ARE NOT DESIGNED TO BE EXPOSED TO VIBRATIONS. FOR MORE DETAILS OR

IN CASE OF DOUBT CONTACT FIKE.

WARNING: ONLY QUALIFIED FIKE PERSONNEL HAVE THE AUTHORITY TO INSTALL / REMOVE ACTUATORS.

WARNING: IN MANY COUNTRIES THE TRANSPORT, STORAGE AND USE OF ACTUATORS ARE CONTROLLED BY

GOVERNMENT RULES AND OFFICES. THE LOCAL AUTHORITIES MUST BE CONSULTED BEFORE

TRANSPORT, USE OR INSTALLATION OF THESE DEVICES AND THE RELEVANT PERMITS OBTAINED

WARNING: ACTUATORS ARE PYROTECHNIC DEVICES THAT CAN CAUSE BODILY INJURY AND / OR EQUIPMENT

DAMAGE IF NOT HANDLED CORRECTLY. ONLY AUTHORIZED PERSONS SHALL WORK WITH THESE DEVICES

AND MUST BE FAMILIAR WITH AND UNDERSTAND THE RELEVANT PROCEDURES.

WARNING: TO PREVENT POSSIBLE INJURY, THE ACTUATOR MUST BE DISCONNECTED AND SHUNTED WHENEVER

PERFORMING ANY OF THE REFURBISHMENT AND REBUILD PROCEDURES.

WARNING: IN NORMAL CIRCUMSTANCES, ACTUATORS ARE THE LAST PART TO BE INSTALLED AND MAY ONLY BE

INSTALLED WHEN EQUIPMENT AND SYSTEM HAVE BEEN CHECKED.

WARNING: ALL MAINTENANCE WORK SHOULD BE EXECUTED BY CERTIFIED FIELD SERVICE ENGINEERS.

ONLY COMPONENTS SUPPLIED BY FIKE i.e. RELOAD KITS, SPARE PARTS ETC., SHOULD BE USED TO

REFURBISH THE CONTAINERS.

FIKE SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES TO FIKE ASSEMBLIES, COMPONENT PARTS

OR HARM TO PERSONNEL IF WORK TO THE FIKE EQUIPMENT IS CARRIED OUT BY NONE FIKE CERTIFIED

ENGINEERS.

THE SECTIONS MARKED WITH THIS ICON REQUIRE SPECIALIST ASSISTANCE. PLEASE CONTACT FIKE FOR

INFORMATION, ASSISTANCE OR SERVICE TRAINING PROGRAMS.

WARNING: FOR THE USE OF THE EQUIPMENT ON DUST, IGNITION HAZARDS RELATED TO STATIC ELECTRICITY NEEDS

NO ADDITIONAL MEASURES. THE ATEX APPROVALS DOES NOT COVER GASES.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 5

The Fike Mechanical Explosion Isolation system typically comprises an EPC controller, explosion pressure detectors of

type UC2 and explosion isolation valves (EIV or FAV) eventually combined with chemically isolation containers

depending the nature of the explosion hazard. Explosion isolation system as a protection system, suitable for use on

process equipment containing dust atmospheres without external hazardous gas atmosphere areas.

The Fike Explosion Isolations Valves are designed to act upon the detection at the incipient stage of a combustion, and

mechanically isolate the combustion. The system suitable for dust –air mixtures with a deflagration index or

equivalent Kst less than 330 bar*m*s-1 (DN50-DN250) or 200 bar*m*s-1 (DN300-DN400) and maximum explosion

overpressure Pmax <12 barg.

The following valve sizes are covered: DN50, DN80, DN100, DN150, DN200, DN250, DN300, DN350, DN400

Minimum distances Xmin and Maximum distances Xmax of the valve in meters from protected vessel.

Protection method for connected

Containment

Venting or suppression

Pmax, Pred max

12 barg

3-4 barg

DN of the isolation valve in mm

Xmin

Xmax

Xmin

Xmax

50 to 100

To be

calculated by

IsolCalc.

75 x Dia

To be

calculated by

IsolCalc.

75 x Dia

150 to 250

50 x Dia

50 x Dia

300 to 400

1.5 x Xmin

2 x Xmin

On detection of an incipient explosion, the CIE (control and indicating equipment) activates the explosion isolation

system and initiates alarm systems. Control and detection of the combustion may be done by one of the following

devices in combination with CIE type EPC.

The FAV is in compliance with: EN 1127-1, EN 13463-1:2009 & EN 15089:2009.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 6

To identify the FAV and order replacement parts, the FAV and its driving container have been permanently labeled.

The FAV is tagged with a name sticker (fig. 1).

Figure 1 - Sticker Fast Acting Valve (FAV)

The CE name plate on the valve body contains among other following information: Model, Serial No, Size and Date of

Manuf. (fig. 2).

Figure 2 - Valve Identification Plate

Figure 3 shows the pinch point sticker (on the valve body) a warning against pinching or injury.

Figure 3 - Pinch Point Warning

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 7

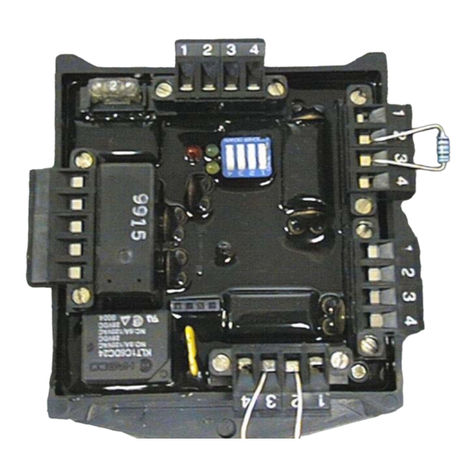

Table 1 - Composing parts

Figure 4 - FAV composing parts

N°

Description

Junction box (with Valve Actuator

Assembly inside)

Exhaust valve (muffler)

Roll pin plug

Gate damper

Bottom cover plate

Upper end cap

Cylinder

Lower end cap

Flange

FAV identification plate

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 8

Figure 5 - Dimensions

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 9

Table 2 - Dimensions different sizes FAV

Valve

Size

Valve

Actuator

Assembly

Qty

ANSI

bolting

Bolt

diameter

Max.

torque

(Nm)

ID

(mm)

BC

(mm)

A

(mm)

B

(mm)

C

(mm)

D

(mm)

Weight

(kg)

DIN

Bolting

2”

1

150

5/8 –11 UNC

190

50.8

120.6

165

786

112

122

45

DN50

PN10/16

M16 x 2

195

50.8

120.6

3”

1

150

5/8 –11 UNC

190

78.6

180.0

229

994

111

238

80

DN80

PN10/16

M16 x 2

195

82.5

180.0

4”

1

150

5/8 –11 UNC

190

101.6

180.0

229

994

111

238

80

DN100

PN10/16

M16 x 2

195

101.6

180.0

5”

1

150

¾ - 10UNC

360

131.7

210.0

285

1271

126

329

80

DN125

PN10/16

M20 x 2.5

380

152.4

240.0

6”

1

150

¾ -10 UNC

360

152.4

241.4

285

1271

126

329

100

DN150

PN10/16

M20 x 2.5

380

152.4

240.0

8”

2

150

¾ -10 UNC

360

202.7

298.4

343

1481

126

405

180

DN200

PN16

M20 x 2.5

380

203.2

295.0

10”

2

150

7/8 –9 UNC

640

254.0

361.9

406

1679

126

483

220

DN250

PN16

M24

660

254.0

355.0

12”

2

150

7/8 -9 UNC

640

304.8

410.0

533

1924

195

608

350

DN300

PN16

M24

660

304.8

410.0

14”

2

150

1 –8 UNC

809

356.0

476.2

584

2209

209

692

450

DN350

PN16

M24

617

356.0

470.0

16”

2

150

1 –8 UNC

809

356.0

476.2

635

2350

209

784

500

DN400

PN16

M27

960

406.4

525.0

20”

2

150

1 1/8 -8UNC

1426

406.4

635.0

777

2939

210

942

700

DN500

PN16

M30

1200

492.0

650.0

REMARK: Valve sizes DN125 and DN500 are outside the ATEX certification and do not bear CE marking. Therefore

these sizes may not be installed within the EU.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 10

WARNING: To prevent possible injury, the Valve Actuator Assembly must be disconnected and shunted when

performing any of the following procedures.

WARNING: Valve Actuator Assemblies are thermo chemical devices that can cause bodily injury and equipment

damage when improperly handled. All persons who may work with or come in contact with Valve Actuator Assemblies

in any way shall read and understand the Valve Actuator Assembly Safety Procedures in this document.

Valve Actuator Assemblies employed in the Fike Explosion Protection System must be respected for their very fast

response and the possibility of accidental initiation.

NOTICE: When Valve Actuator Assemblies are handled in accordance with all proper safety practices, accidental

initiation should not occur. The Valve Actuator Assembly will not fire at current less than 0.2 Amps.

•Valve Actuator Assembly leads shall remain shunted at all times when electrically disconnected from the

protection system and during Valve Actuator Assembly installation and removal.

•Always wear an electrically grounded wrist strap or other approved device when handling unpackaged

Valve Actuator Assemblies.

•Always wear approved eye protection when handling or installing Valve Actuator Assemblies.

•Never handle or have on your person more than one unpackaged Valve Actuator Assembly at any time.

•Never handle Valve Actuator Assemblies while wearing static producing clothes or shoes.

•Remove the Valve Actuator Assembly from the shipping container only when installing into the FAV.

•Always handle the Valve Actuator Assembly by the wires and never by the threaded discharge end or

case.

•The discharge end of the Valve Actuator Assembly shall be pointed down, away from the body and to the

rear.

•Never expose Valve Actuator Assemblies to high heat sources. Exposure of Valve Actuator Assemblies to

temperatures over 130°F may reduce the service life.

•Never check Valve Actuator Assembly continuity with any type of ohm meter or other unapproved

device. Use only a Fike approved device.

•The device shall display a label marked “Approved device for measuring Valve Actuator Assembly

continuity”.

•If a Valve Actuator Assembly is suspected of being defective, contact Fike. Refer to the Repair and Return

Authorization section of this document for the return procedure.

•Never install Valve Actuator Assemblies if ground faults are present in the system.

•Never install Valve Actuator Assemblies if voltage is present on the conduit or equipment.

•Never install Valve Actuator Assemblies if radio transmitters are being used in nearby areas.

•Always hold the leads carefully so there is no tension where the leads connect to the case.

•Lead wires shall be straightened, as required, by hand. The leads shall not be thrown, waved in the air or

uncoiled by snapping like a whip.

•Secure leads tightly in one hand just above the housing and draw the other hand across the leads to

straighten.

•Do not allow the shunt to be removed from the leads.

•Connect Valve Actuator Assembly leads only after the Valve Actuator Assembly has been installed into a

properly secured FAV.

•Refer to the Electrical Control Panel Manual (E06-051) for electrical connections.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 11

•During connection of the Valve Actuator Assembly to the terminal strip, the Valve Actuator Assembly

shall remain shunted until all Valve Actuator Assemblies are connected to the appropriate terminals.

The valve shall be positioned according to figure 6: The valve can be mounted from an upright vertical position to a

horizontal position. It shall not be mounted at an angle below a horizontal position.

Figure 6 - Valve orientation options

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 12

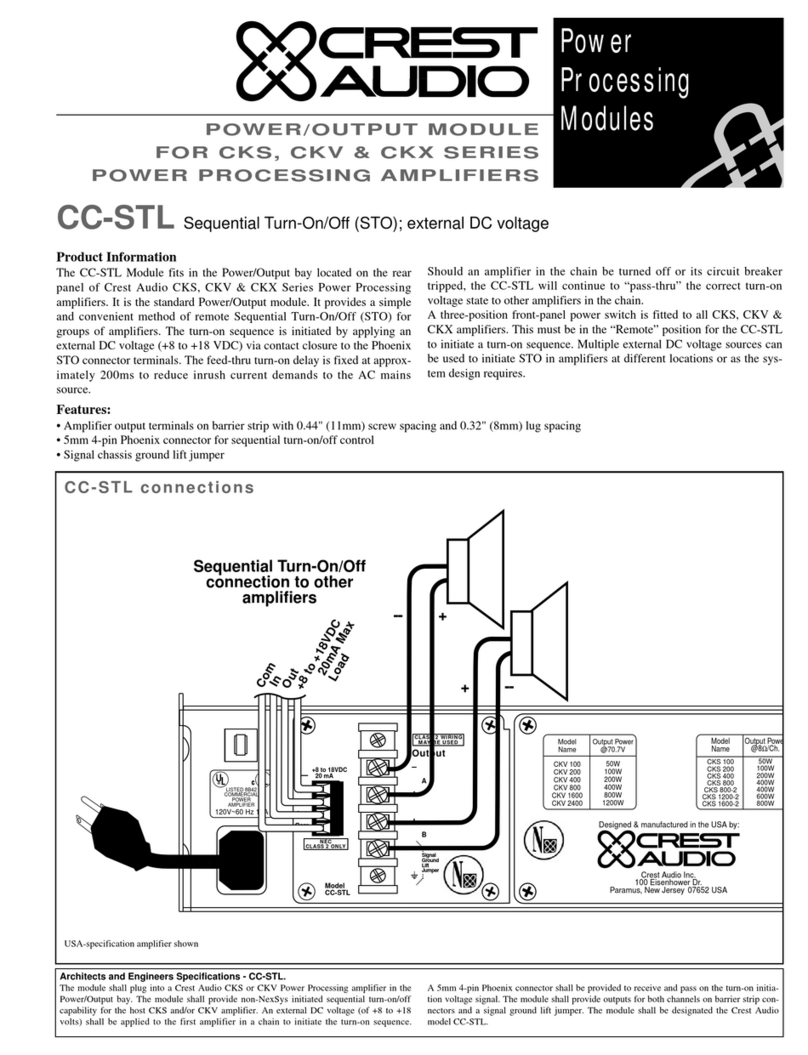

Figure 7 - Electrical scheme open/close module

The magnetic switches detect the opening and close position of the magnetic ring which is connected on the piston.

Hereby, the system (PLC) can check if the valve is open or close.

Figure 8 - Position indicator piston

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 13

Step 1: Verify the control panel “Armed/Disabled” switch is in the “Disabled” position and sufficient time (15

minutes) has been allowed for capacitors in the system to dissipate their charge before proceeding.

Step 2: Verify that the power is off at the control panel and all electrical charges have been dissipated.

Step 3: Refer to the EPC Manual (doc. n° E06-051-X) for the remainder of this procedure. Also refer to Fike document

X.2.26.01-x Valve Actuator Assembly.

Step 1: Place the control panel “Armed/Disabled” switch in the “Disabled” position and allow sufficient time (15

minutes) for capacitors in the system to dissipate their charge before proceeding.

Step 2: Open the cover of the electrical connection junction box, remove the Valve Actuator Assembly lead wires

from the screw terminals and immediately shunt the lead wires by twisting them together securely.

Step 3: Use care not to pinch or penetrate the insulation on the Valve Actuator Assembly lead wires, disconnect and

remove the conduit on the Valve Actuator Assembly mounting boss.

Step 4: Remove the Valve Actuator Assembly leads from the conduit and remove the Valve Actuator Assembly from

the Valve Actuator Assembly housing. If the Valve Actuator Assembly has not been activated, handle with

care and follow all Valve Actuator Assembly Safety Procedures per Section 4.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 14

WARNING: To prevent possible injury, the Valve Actuator Assembly shall be disconnected, shunted and removed

from the FAV when performing any of the following procedures.

Step 1: Remove the two (2) muffler assemblies from the base of the FAV actuating cylinder.

Step 2: With the FAV in the closed position (down), remove the nuts and lock washers at the upper end of the

actuating cylinder.

Step 3: Remove the upper end cap.

Step 4: Remove the actuating cylinder from the assembly.

Step 5: Remove the cylinder seals from the grooves of the upper and lower end caps.

Step 6: Clean Valve Actuator Assembly debris from the cylinder, piston and piston o-ring using a clean wiper.

Step 7: Remove the corrosion inhibitor pads from the piston and replace.

Step 8: Apply new vacuum grease to the cylinder, piston and piston o-ring.

Step 9: Install new cylinder seals into the upper and lower end caps.

Step 10: Reassemble the components and torque the bolts/nuts, in a star pattern, to the value specified in Table 2.

Step 1: Thread a 1/2" NPT pipe plug in one of the muffler ports and attach shop air to the other port.

Step 2: Using shop air at a pressure of 3-4 barg, raise the gate to the full open position.

Step 3: With the FAV in the open (up) position, remove the bolts retaining the housing bottom.

Step 4: Remove the gate damper and use a light to inspect the gate to flange areas. If the flange o-rings have been

damaged the flanges will have to be removed and the o-rings replaced. Refer to Section 6.4 for this

procedure.

Step 5: Remove the corrosion inhibitor pads from the piston and replace.

Step 6: Insert a new gate damper in the lower housing.

Step 7: Remove excess gasket sealer from the housing and housing bottom and apply new gasket sealer (vacuum

grease) to the sealing surface of the housing bottom.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 15

Step 8: Assemble the housing bottom to the housing and torque the bolts/nuts, in a star pattern, to the value

specified in Table 2.

Step 1: Thread a 1/2" NPT pipe plug in one of the muffler ports and attach shop air to the other port.

Step 2: Using shop air at a pressure of 3-4 barg, raise the gate to the full open position.

Step 3: With the FAV in the open (up) position, remove the nuts retaining the housing bottom.

Step 4: Remove the housing bottom and gate damper and use a light to inspect the gate to flange areas. If the flange

o-rings have been damaged the flanges will have to be removed and the o-rings replaced. Refer to Section 6.4

for this procedure.

Step 5: Remove the gate damper from the housing bottom and thoroughly clean the housing bottom internal surface

using a solvent. Allow the solvent to dry completely.

Step 6: Remove the corrosion inhibitor pads from the piston and replace.

Step 7: The replacement gate damper has been shipped with an adhesive strip. The application temperature range

for the adhesive is 20°C to 35°C. Remove the release paper from the new damper and center it on the

housing bottom.

Step 8: Apply pressure on the top surface of the damper to provide a uniform bond. At room temperature full bond

strength occurs in 72 hours. At a temperature of 65°C full bond strength occurs in 1 hour.

Step 9: Apply new gasket sealer (vacuum grease) to the sealing surface of the housing bottom.

Step 10: Assemble the housing bottom to the housing and torque the bolts/nuts, in a star pattern, to the value

specified in Table 2.

Step 1: Remove the roll pin access plugs or covers from both sides of the upper FAV housing. Using a punch and

hammer, remove the roll pin from the gate and piston rod assembly.

Step 2: With the slit of the new roll pin oriented to the top or bottom of the FAV, use a punch and hammer to insert

it into the assembly. Replace the roll pin access plugs or covers.

NOTE: Flanges using a dovetail feature on the outside diameter of the o-ring groove do not require an adhesive.

Remove the existing o-ring, clean the groove and press the o-ring into the groove to seat.

Step 1: If o-rings need replacing remove the pre assembly screws from the flanges.

Step 2: Remove the flanges from the FAV assembly. Keep the flange shims with each flange to maintain proper

assembly clearances.

Step 3: Remove the o-rings and all adhesive from the grooves. Clean the grooves using a clean wiper and alcohol or

acetone.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 16

Step 4: Apply new gasket sealer (vacuum grease) to the O-Rings. Place the o-rings in the grooves and press into place

to seat.

Step 5: Turn each flange over, with the o-ring down, and place on a clean flat surface.

Step 1: Using shop air move the gate to the open (up) position.

Step 2: Place the original Shims on each Flange.

Step 3: Assemble the Flanges to the FAV. Do not fully tighten the cap screws.

Step 4: Align the bore of each flange with the bore of the gate and torque the cap screws in one-third increments in a

crisscross fashion.

Step 5: Using shop air, actuate the gate in both directions ten (10) times, to insure free movement. Pressure required

will vary with valve size and flange bolts/nuts, in a star pattern compression.

Step 1: Remove the outlet from the body of the muffler assemblies located on the lower end cap of the actuating

cylinder.

Step 2: Remove the ring and the seals from the body of the mufflers.

Step 3: Remove debris from the inside of the muffler bodies using a clean wiper.

Step 4: Insert new seals into the bodies.

Step 5: Insert the metal rings into the bodies. The curved surface of the ring should be placed on the seal surface.

Step 6: Assemble the outlets to the bodies and torque to 13.5 Nm. Excessive torque will damage the seals and allow

moisture to enter the assembly.

Refer to Fike document X.2.66.01-x FAV Reload Parts for contents of Refurbish Kits.

Contact your local Fike representative for information on availability, prices and delivery times.

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 17

Doc. 8.8503.00.9

Rev. April, 2018

PAGE / 18

All system components should be thoroughly inspected by factory trained personnel. Following are specific

requirements. Additional maintenance may be required depending on process and environmental conditions.

•Visually inspect the system.

•Cycle the gate in both directions ten (10) times, to insure free movement using shop air.

•Inspect the Valve Actuator Assembly area for evidence of deterioration.

•Refurbish the FAV system per specific instructions contained in this manual.

•Replace the Valve Actuator Assembly.

The ten (10) year replacement of the Valve Actuator Assembly is based on the combined shelf and service lives of the

Valve Actuator Assembly. Replacement may be required sooner under the conditions described below.

The combined shelf and service lives of the Valve Actuator Assembly is ten (10) years from the date of manufacture,

provided the Valve Actuator Assembly has not been exposed to temperatures less than -40°C or greater than 60°C.

Other Fike Control Unit manuals

Fike

Fike Lantronix XPort 10-2627 Operating instructions

Fike

Fike 55-043 User manual

Fike

Fike FIK-M500M User manual

Fike

Fike TWINFLEX SRM 100-0010 User manual

Fike

Fike MICROMIST 10-2340 User manual

Fike

Fike P Service manual

Fike

Fike FIK-IM-10 User manual

Fike

Fike TWINFLEX IRM 100-0011 User manual

Fike

Fike 55-046 User manual

Fike

Fike FIK-RVM User manual

Popular Control Unit manuals by other brands

Marshall Excelsior

Marshall Excelsior ME980-905 installation instructions

Visual Productions

Visual Productions IoCore2 user manual

GEM

GEM 711 Installation, operating and maintenance instructions

tams elektronik

tams elektronik LED Control Basic manual

Velleman

Velleman K8095 Assembly manual

Modentic

Modentic HPV-40AT user manual