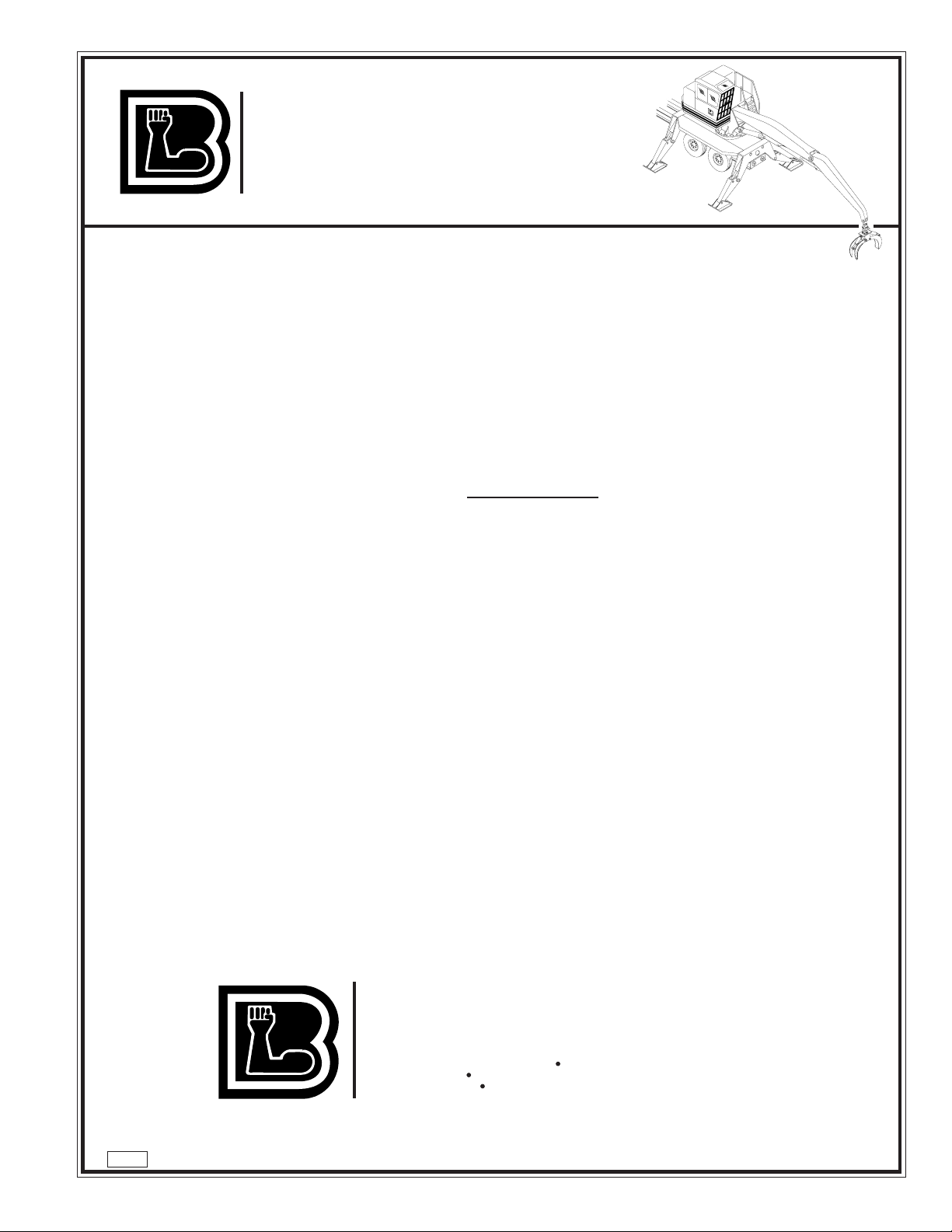

BARKO LOADERS 295 User manual

The information and illustrations in this manual have

been approved as accurate at the time of printing.

However, the manual may contain information on

options not present on your loader. The right is

reserved by Barko Hydraulics,LLC to make changes

and improvements in it's product at anytime without

notice or obligation.

BARKO

LOADERS

295 Articulated Carrier

SERVICE MANUAL

Machine

Serial Number

013112

NOTE: The Grapple Service and Installation Information is not included in this manual. See separate

Grapple Service and Installation manual which accompanies all grapples from the factory.

BARKO

HYDRAULICS,LLC

mailing: PO Box 16227, Duluth, MN 55816 shipping: 1 Banks Avenue, Superior, WI 54880

phone: 715-392-5641 fax: 715-392-3931

OPERATORS: 800-00030 PARTS: 800-00091 SERVICE: 800-00158

TABLE OF CONTENTS

INTRODUCTION ........................................................ 3

Introduction ......................................................... 4

Abbreviations and Symbols ................................. 5

Hydraulic Pressure Warning Sheet ...................... 6

Warranty .............................................................. 7

Know Your Machine ............................................. 8

Safety Summary ................................................. 9

Fire Prevention .................................................... 14

Model Description ................................................ 15

MAINTENANCE ......................................................... 16

A. Preventive Maintenance .................................... 16

Safety While Servicing ........................................ 17

Preventive Maintenance ...................................... 18

Special New-Machine Instructions ....................... 18

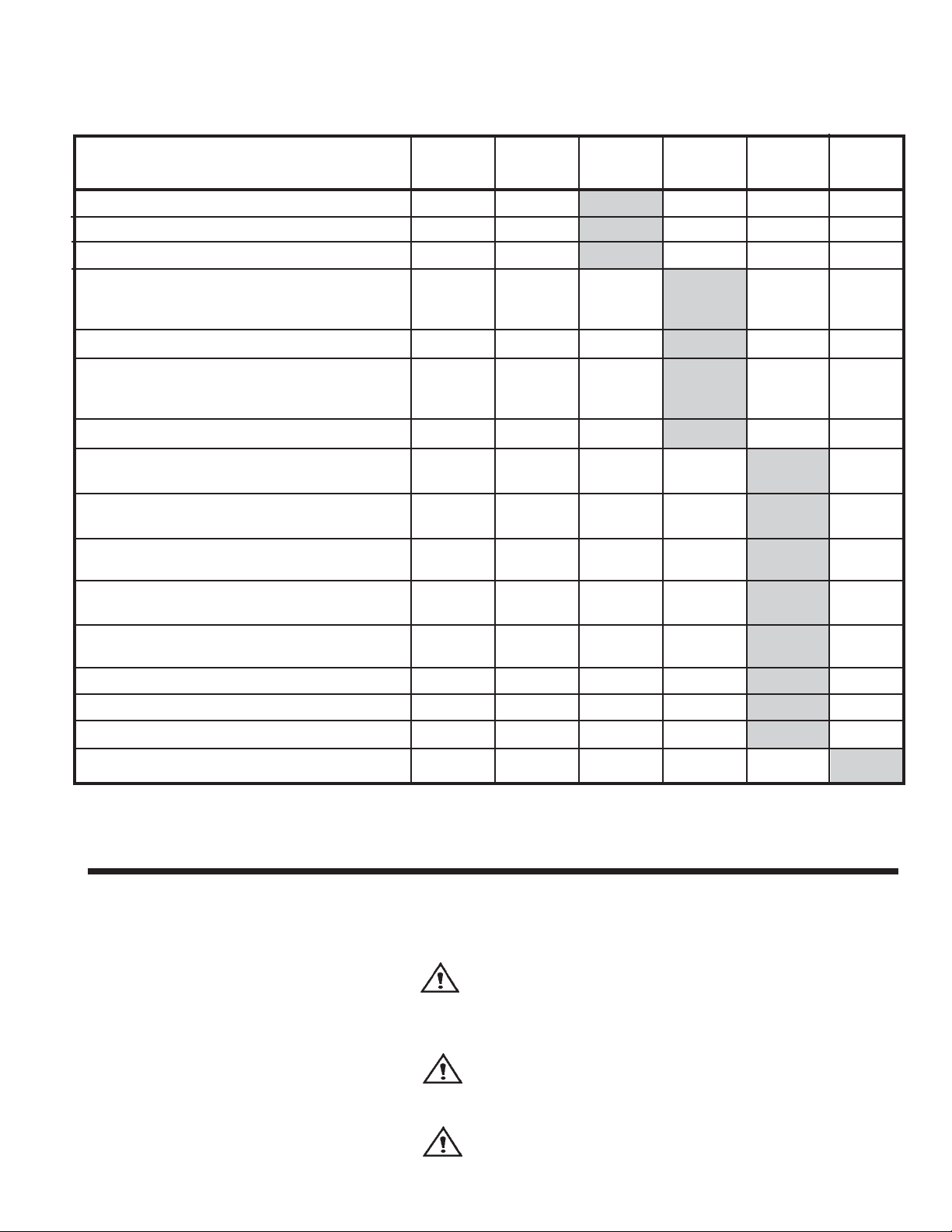

Service Schedule ................................................ 19

Tires .................................................................... 20

Lubrication Points ................................................ 21

Fluid Specifications ............................................. 22

Special Torque Specifications ............................. 24

General Torque Specifications ............................. 25

B. Hydraulic System .............................................. 26

Hydraulic Pressure Settings (295 AC) .................. 27

Machine Function Speeds ................................... 27

Hydraulic Pressure Adj (V30D-95/95) ................... 28

Piston Pump Adjustments ................................ 28

K170 Upper Valve Bank Adjustments ............... 30

K170 Steering/Travel Valve Bank Adjustments 31

L90 Stabilizer Valve Bank Adjustments ............ 32

L90 Lower Valve Bank Adjustments ................. 33

Hydraulic Pressure Adj (AA11V-095) ................... 34

Hydraulic Reservoir Maintenance ......................... 35

Hydraulic Filter Maintenance................................ 36

Eliminating Air From The System ........................ 37

Hydraulic Fittings, Hoses & Tubing ...................... 38

Hydraulic Cylinder Maintenance ........................... 39

Hydraulic Collector Maintenance .......................... 41

Danfoss Drive Motor Maintenance (OMV800) ...... 43

F12 Swing Motor Maintenance ............................. 46

Swing Motor Gearbox Maintenance (G6/08) ......... 50

C. Electrical System Maintenance ........................ 51

Electrical System Maintenance ........................... 52

Electrical System Description .......................... 52

Electrical System Inspection ............................ 52

Battery Disconnect Switch ............................... 52

Using an Extra Battery to Start Machine .......... 53

Installing a New Battery.................................... 54

Alternator Drive Belt Adjustment ...................... 54

Alternator Maintenance ..................................... 54

Trouble Shooting the Electrical System ............ 56

Air Conditioner Maintenance ................................ 57

Refrigerant ........................................................ 57

Checking/Adding Refrigerant ............................ 58

Running the Unit as Preventive Maintenance ... 59

Fresh-Air Intake Filter ....................................... 59

Receiver/Dryer Installation................................ 59

Condenser Installation ...................................... 59

Air Conditioner Trouble Shooting ...................... 59

Air Conditioner Charging ................................... 61

D. Power Unit Maintenance ................................... 65

Engine Maintenance ............................................ 66

Pump Drive Maintenance ..................................... 67

Two, Three and Four Pad Pump Drives ............ 67

Single Pad Pump Drives .................................. 70

Disconnect Clutch (optional) ............................. 70

Air Cleaner Maintenance ...................................... 71

E. Structural Maintenance ..................................... 75

Turntable Bearing Maintenance ........................... 76

TROUBLE SHOOTING .............................................. 80

Engine .............................................................. 81

Hydraulic System ............................................. 82

Electrical System ............................................. 83

Machine Operations ......................................... 84

DECALS .................................................................... 85

page 3

295 AC

800-00158

Introduction

page 4

295 AC

800-00158

INTRODUCTION

Your Barko Loader has been designed and manufactured with high quality materials and care in workmanship.

This manual is intended as a permanent reference to aid professional operator's in their work, and should be

available for use at any time. If the loader is not equipped with this manual, ask your supervisor to obtain one

for you.

Understand the correct servicing procedures before servicing the loader. It is important to know the correct

operating and servicing procedures of the loader and all safety precautions to prevent the possibility of

property damage and/or personal injury or death.

As a professional, trained operator, you are responsible for safety, both your own and that of your co-workers.

Your knowledge and use of all safety practices and correct servicing procedures in this manual, and your

good judgement, can be a major factor in preventing some of the thousands of injuries and deaths caused by

industrial accidents each year.

A professional operator should also be familiar with the information contained in other applicable sources such

as American National Standards, SAE, OSHA, etc.

ADDITIONAL INFORMATION:

Logging Safety Resource Guide (APA, 95-A-1) is available from the American Pulpwood Association. This

guide lists sources of videotapes, slide programs, movies, and publications on various aspects of logging

safety.

DON'T FORGET - SAFETY FIRST!

Loader

Model No.

Serial No.

Engine

Model No.

Serial No.

The machine serial number plate is located on the

front of the platform near the ladder.

NOTE: Information in this manual is current at the time of printing. Barko Hydraulics reserves the right to

make changes and improvements to it's products and manuals at any time without notice or

obligation.

REFERENCEINFORMATION

All requests for information, service or spare parts

should include loader serial number. For more

information contact:

Barko Hydraulics,LLC

P.O. Box 16227

One Banks Avenue

Duluth, MN 55816

Phone: 715-392-5641

Fax: 715-392-3931

Website: www.barko.com

Email: [email protected]

page 5

295 AC

800-00158

ABBREVIATIONS AND SYMBOLS

EXPLANATIONS OF OTHER OCCURRENCES IN THIS MANUAL:

- In a parts list, when there are item numbers with empty spaces (no description or part number), these

parts have been previously deleted from that parts list and are not recorded anywhere.

- In a parts list, when there are items with no part number and a dotted line (----) is in the part number

space, this means that the part number is not sold separately or is not available at this time.

- When references to "right hand" or "left hand" are used in this manual, it is done from the operator's seat

in the forward operating position.

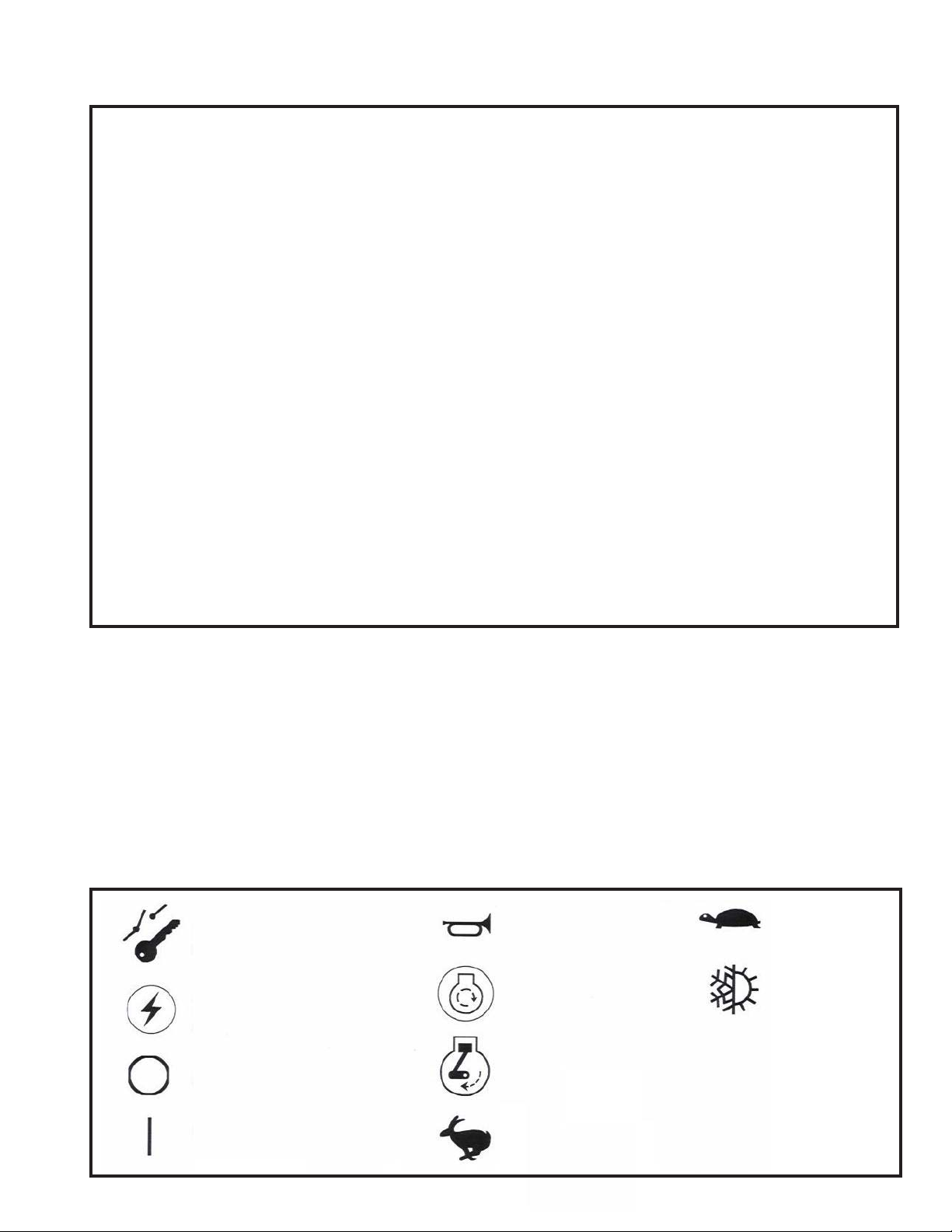

SYMBOLS USED ON MACHINE

Ignition

Key Switch

Power On

(Accessory)

Power Off

Power On

Horn

Starter

Engine

RPM

Faster

Slower

Air

Conditioner

a/c = air conditioner

AC = Articulated Carrier (Art. Car.)

adj. = adjust or adjusting

appl. = application

AR = As Required

assy = assembly

BC = Back of Cab

b/m = bill of material

brg. = bearing

CAR = Carrier

coll. = collector

cond. = conditioner

CRL = Crawler

cyl. = cylinder

dia. = diameter

dwg. = drawing

Ft. Lbs. = Foot Pounds

gal. = gallon

HRT = Hydrostatic Rough Terrain carrier

ill. or illus. = illustration

In. Lbs. = Inch Pounds

incl. = includes or including

j.s. = joystick

Lbs. = pounds

LH (lh) = left hand

mtg. = mounting

N/A = Not Applicable

no. = number

NSS = Not Sold Separately

opt. = optional

pg. = page

qt. = quart

RH (rh) = right hand

sec. = secondary

see sep. ill. = see separate illustration (means:

located elsewhere in manual)

SE = Stationary Electric

SER or SR = Stationary Electric Remote

s/n = serial number

str. = straight

swhd = saw head

TM = Truck Mount

w/ = with

page 6

295 AC

800-00158

WARNING

BARKO HYDRAULICS, LLC

Raising hydraulic pressure on

this machine above the factory

approved settings may cause

death, severe injury or property

damage and will void the

warranty.

The consequences of increasing hydraulic pressure are

serious. The function of the relief valves is to provide a

fuse action to protect the machine and the operator from

overloading. When overloaded, the machine can

become stressed to a level where parts fracture causing

death, severe injury or property damage. This is an

extremely dangerous practice.

Accordingly, you are advised that the pressure settings

of this machine are limited to the factory approved

settings. Pressures in excess of these settings render

each and all Barko warranties null and void and

constitute an obvious misuse and abuse of our product.

HYDRAULIC PRESSURE WARNING SHEET

page 7

295 AC

800-00158

BARKO HYDRAULICS, LLC

WARRANTY

BARKO HYDRAULICS, L.L.C. ("Barko") warrants to the Distributor and/or original Buyer each new hydraulic

knuckle boom loader, feller buncher or other product in BARKO HYDRAULICS Equipment Group including attachments

and accessories thereto, ("Product") sold by BARKO to be free from defects in material and workmanship under normal

use, maintenance and service.

BARKO will cause any major structural component of a BARKO product covered by this warranty which proves to be

defective in material or workmanship under normal use, maintenance and service within three (3) years ) or 6,000

hours, whichever occurs first from first day in service, provided first day in service is not later than one (1) year from

delivery to Distributor and/or original Buyer or other user, to be replaced without charge with a new or repaired part, at

BARKO election. BARKO also will cause the labor to remove any such defective part and to install the new or repaired

part to be provided without charge to the owner of said BARKO product. The parts and labor to meet this warranty will

be furnished by designated BARKO distributor.

BARKO will cause all other parts of product covered by this warranty which proves to be defective in material or

workmanship under normal use, maintenance and service within one (1 ) year or 2,000 hours, whichever occurs first

from first day in service, provided first day in service is not later than one (1) year from delivery to Distributor and/or

original Buyer or other user, to be replaced, without charge, with a new or repaired part, at BARKO election. BARKO

also will cause the labor to remove any such defective part and to install the new or repaired part to be provided without

charge to the owner of said BARKO product. The parts and labor to meet this warranty will be furnished by BARKO

designated distributor.

BARKO warrants all service parts purchased from BARKO and used on a BARKO manufactured unit, to be free

from defects in material and workmanship under normal use, maintenance and service for a period of six (6) months or

1,000 hours, whichever occurs first. BARKO will cause any such part which proves to be defective to be replaced with a

new or repaired part at BARKO election on a parts only basis.

Proof of any defect must be submitted to BARKO within ten (10) days from the date on which the defect was

discovered and any claim submitted within thirty (30) days after repair work is completed.

BARKO warranty does not cover:

1 Defects, damage or deterioration due to normal use, wear, tear, exposure, storage or corrosion.

2. Normal maintenance service, including replacement of filters, oil, seals and the like.

3. Damage due to failure to maintain or use the BARKO product or part according to manuals, schedules or good

practice.

4. Damage caused by abuse of equipment or parts by overloading, misapplication, improper operation or use,

installation of unapproved accessories or unauthorized alterations.

5. Damage resulting from repairs made in an unauthorized manner or installation of components not authorized by

BARKO.

6. The labor to remove and reinstall a defective replacement part after the expiration of the warranty period applicable

to the product in which part is located.

7. Overtime labor premiums.

8. Transportation of the BARKO product to the distributor's service facility or transportation of the distributor's service-

man to the product's location.

9. Vendor components not manufactured by BARKO, such as engines, transmissions and components, Tires, batteries

or other parts normally warrantied and serviced by the manufacturer. The warranty of the respective manufacturers

of these components shall apply.

The Buyer accepts this warranty and the limitations and disclaimers set forth herein as part of the purchase of the

BARKO product or part to which this warranty applies.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED, STATUTORY, WRITTEN OR

ORAL, AND THERE IS NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

Remedies available to any person claiming under this warranty are exclusive and expressly limited to obtaining the

parts and the labor, where applicable, in accordance with terms of this warranty.

BARKO liability for losses, damages or expenses of any kind arising from the design, manufacture or sale of the

product covered by this warranty, whether based on warranty, negligence, contract, tort or otherwise, is limited to an

amount not exceeding the cost of correcting the defects as herein provided, and, at the expiration of the applicable

warranty period, all such liability shall terminate.

BARKO shall in no event be liable for incidental, consequential or special damages to losses of use of the BARKO

product, a loss or damage to property other than the BARKO product, a loss of profits or other commercial loss, or any

special or consequential damages (except liability for consequential damages which by law may not be disclaimed).

Revised 2/98

page 8

295 AC

800-00158

KNOW YOUR MACHINE

The following is a list of ten important safety precautions and warnings you should read through and

understand before operating or servicing your machine.

1. Don't assume that because you know the control functions of other similar machinery, that you

can run and/or service the Barko Loader. All machines differ in some ways, and these

differences must be noted and acknowledged. Read this manual thoroughly and understand all

safety, operating, and servicing procedures before using the loader.

2. Know how to put your machine in a zero energy state for purposes of inspection, maintenance,

or repair.

3. Clear operating area of all obstacles and personnel before operating loader.

4. Never approach power lines with any part of the machine or load! Current in a high voltage

power line may arc some distance to jump from the wire to a nearby "ground". KEEP WELL

CLEAR!

5. Allow only the operator on the machine. Keep riders off. Riders on machine are subject to injury

such as being struck by foreign objects and being thrown off the machine. Riders also obstruct

the operator's view, resulting in the machine being operated in an unsafe manner.

6. Never use a boom or attachment for a work platform or personnel carrier. Serious injury or death

may result.

7. When machine is not operating or when leaving cab, boom and attachment must be lowered to

the ground. Failure to do so may allow boom or attachment to move, causing property damage,

injury, or death.

8. Do not tamper with any hydraulic line when it is pressurized. Escaping fluid under pressure can

penetrate the skin, causing serious injury. Relieve pressure before unhooking hydraulic or other

lines. Tighten all connections before applying pressure. Keep hands and body away from

pinholes and nozzles which eject fluids under high pressure. Use a piece of cardboard to search

for leaks.

If any fluid is injected into the skin, it must be surgically removed within a few hours by a doctor

familiar with this type of injury or gangrene may result.

9. Under no circumstances should any modifications be made to Barko machinery without factory

authorization. Any modifications may void the warranty. This machine was designed to do a

specific job and alterations could result in property damage, injury or death.

10. Replace any safety decals that are faded, torn, missing, illegible, or otherwise damaged. See your

machine's Parts Manual for decal kits applicable to your machine and for locations of all decals.

Don't stop here - read on.

page 9

295 AC

800-00158

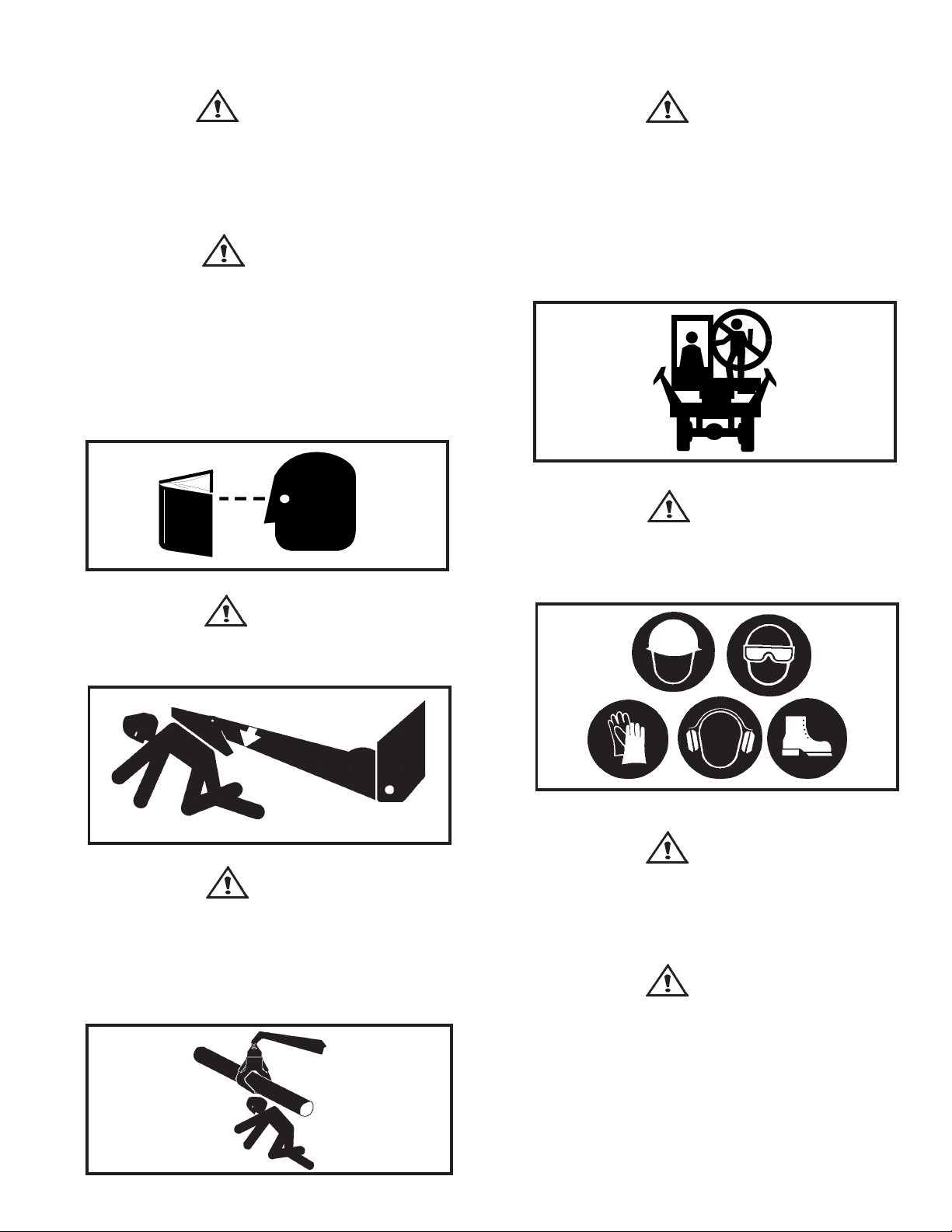

SAFETY SUMMARY

Failure to follow safety precautions in this manual can result in death, severe personal injury and/or property damage.

Carefully read safety precautions below and within this manual. Heed all decals on machine.

DANGER - Indicates an immediate hazard which WILL result in severe personal injury or death.

WARNING - Indicates a hazard or unsafe practice which COULD result in severe personal injury or death.

CAUTION - Indicates a hazard or unsafe practice which could result in minor personal injury or property

damage.

DANGER

Never let anyone in or near pivot area of an

articulated machine.

WARNING

Combustible and flammable fluids can cause

death or severe injury. Do not smoke or permit

open flames near fuels or hydraulic fluids. Do not

fill the tanks to capacity - allow room for fluid

expansion. Do not remove the fuel cap or refuel

while engine is hot, running or without proper

ventilation. Never use fuel for cleaning purposes.

Clean up any fluid spills immediately.

WARNING

An unstable machine can cause death, severe

injury, or property damage. Do not operate

machine without lowering stabilizers on firm,

level ground.

WARNING

Be extra careful when traveling on a slope, near

ditches, congested areas or over rough ground.

The danger of tipping is always present. Know

your machine's capabilities.

WARNING

Always lower boom to ground and shut down

engine before leaving cab. If necessary to work

on machine with lifted boom, securely support

machine and attachment.

DANGER

Never approach power lines with any part of the

machine. Current in a high voltage line may arc

some distance to jump from the wire to a nearby

"ground". KEEP WELL CLEAR!

DANGER

Do not operate machine during electrical storms.

page 10

295 AC

800-00158

WARNING

Do not operate or work on machine until you:

- Read and understand machine manuals, safety

decals, employer work rules, and applicable

government regulations.

- Are trained and qualified in safe machine

operation and maintenance.

- Consult supervisor to explain any unclear

instructions and warnings.

- Contact Barko to replace lost manuals.

DANGER

Moving stabilizers will cause death or severe

injury. Stand clear. Operate stabilizers only

when personnel are clear.

SAFETY SUMMARY CONTINUED...

WARNING

If machine malfunctions during operation, stop

machine motion as quickly as possible, lower

boom to the ground and shut down the machine.

Service or repair the machine as needed before

running or operating again.

WARNING

Allow only the operator on the machine. Keep

riders off. Riders on machine are subject to death

or injury from being struck by foreign objects and

being thrown from machine. Riders also obstruct

the operator's view, resulting in machine being

operated in an unsafe manner.

Never use a boom attachment for a work platform

or personnel carrier.

WARNING

Ensure that tire pressure is within rated limits to

prevent personal injury or damage to machine.

DANGER

Falling boom or load will cause death or severe

injury. Stay clear if boom or load are not

grounded.

Clear all persons from area of operation and

machine movement. Never move boom or loads

over the heads of other persons.

WARNING

Wear required personal protective equipment at

all times to help prevent personal injury. Do not

wear loose fitting clothing or personal articles,

loose or uncovered long hair, or jewelry.

WARNING

When using a Slasher Saw Attachment, be sure to

get proper informational manuals from Slasher

manufacturer. Read and understand those

manuals before using this machine for Slasher

purposes.

page 11

295 AC

800-00158

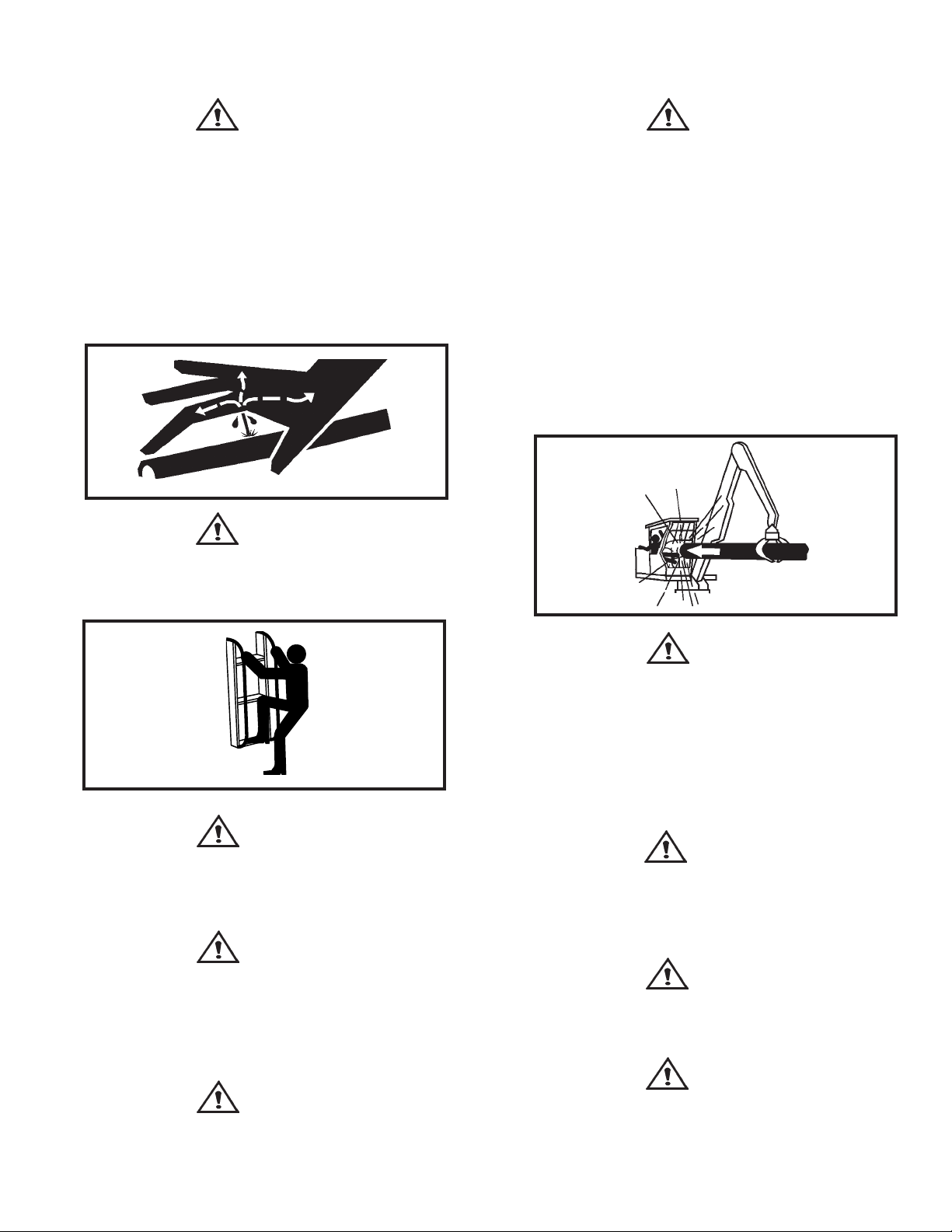

WARNING

Improper load handling and/or hydraulic pressure

loss can cause load to impact cab guard,

resulting in death or severe injury.

- Do not rely on guard alone for personal

protection. Use safe and proper load

handling techniques.

- Do not operate machine with damaged or

unsecured guard or cab.

- Do not repair damaged guard. Replace with

factory-authorized guard.

- Do not modify guard without factory

authorization.

- Do not operate before conducting Pre-Start

Maintenance Inspection. Check hydraulic

components for leaks, loose fittings or

damage.

WARNING

High pressure hydraulic fluid can penetrate skin

causing death, gangrene or other severe injury.

Seek immediate medical help to remove fluid.

- Keep hands and body away from areas

ejecting fluid. Use piece of cardboard to

check for leaks. Wear proper hand and eye

protection.

- Relieve hydraulic pressure before loosening

any hydraulic connections.

- Tighten all hydraulic connections before

applying hydraulic pressure.

WARNING

Always maintain 3-point contact with handles and

steps when mounting or dismounting. Never

jump on or off machine. Do not rush. Walk, do

not run.

WARNING

Mechanically connected controls will cause

movement of components at all times - even if

pump or engine is not operating. Always be

certain that boom and attachment are properly

supported or resting on firm ground before

stopping engine to minimize chance of

accidental movements of components causing

death, severe injury or property damage.

WARNING

Grease all boom, cylinder, and turntable bearing/

pinion points daily.

WARNING

Transparent material such as safety glass must be

replaced when it is cracked or broken, or when

vision is obscured due to scratches.

WARNING

Loose or overtorqued bolts can cause death,

severe injury, or property damage. Maintain

proper bolt torque. Visually check bolts daily.

Check torque every 50 hours.

WARNING

Remove or secure all personal or maintenance

items such as lunch buckets, chains, shovels,

tools, etc., before moving or operating machine.

WARNING

Replace any safety decals that are faded, torn,

missing, illegible, or otherwise damaged.

SAFETY SUMMARY CONTINUED...

WARNING

Make sure that all walking and climbing surfaces

of machine are free of dirt, debris, water, grease,

oil, and snow. Do not leave loose tools or rags

on machine. Replace all non-skid material that is

torn, missing or damaged.

page 12

295 AC

800-00158

WARNING

Any unauthorized welding, alterations, additions

or modifications made to Barko machinery will

void warranty. This machine was designed to do

a specific job and alterations could result in

death, severe injury or property damage.

If Barko-authorized welding must be done, first

disconnect battery, electronic throttle, and radio,

or electrical and structural damage may occur.

WARNING

Hot and pressurized fluid can cause severe burns.

Let system cool before removing any caps. Then

remove caps slowly.

WARNING

If this machine is equipped with electric motor

driven Auxiliary Oil Cooler, be sure battery is

disconnected before going near cooler fan. If

battery is not disconnected, fan may come on at

any time causing severe injury.

WARNING

Hot exhaust pipe can cause severe burns. Do not

touch exhaust pipe when hot, or when engine is

running.

CAUTION

Use only hydraulic fluid in hydraulic oil reservoir.

Use only diesel fuel in fuel reservoir.

Other fluids will cause machine damage.

SAFETY SUMMARY CONTINUED...

DANGER

Improper electrical connections will cause battery

explosion, combustion or electrical component

damage, and may result in death or severe injury.

This is a 12 volt negative ground electrical

system.

WARNING

Always wear seat belt when operating or running

machine.

CAUTION

Check the Air Cleaner Assembly daily for cracks,

loose clamps, or any other damage. If debris is

able to bypass the Air Cleaner for any reason, it

can damage the engine.

WARNING

Maintain all components of Muffler Assembly to

meet noise and exhaust standards.

WARNING

Improper machine transport can cause death,

severe injury or property damage.

Before transporting:

- Lower and secure boom/attachment.

- Raise stabilizers.

- Shut down machine to a zero energy state.

page 13

295 AC

800-00158

WARNING

Use caution when checking items beyond your

reach. Use an approved safety ladder.

SAFETY SUMMARY CONTINUED...

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to

the State of California to cause cancer, birth defects, and other

reproductive harm.

WARNING

Do not exceed 15 PSI nozzle pressure when

drying parts with compressed air. Do not direct

compressed air against human skin. Serious

injury could result.

WARNING

Older air conditioning equipment may contain R-

12, a substance which harms public health and

environment by destroying ozone in the upper

atmosphere. To remove R-12 from the air

conditioning system, use service equipment

certified to meet the requirements of S.A.E. J2209

or J1990.

WARNING

On machines equipped with an accumulator,

release all pressure before working on the

system. After service work is done, repressurize

the accumulator(s) to the proper specification.

page 14

295 AC

800-00158

FIRE PREVENTION

This machine may have several components which are at high temperatures under normal operating conditions, such

as the engine, exhaust system, brake system and transmission.

Clean the machine often. High pressure washing of the machine is suggested every 1000 hours (or 6 months) and

always after a spill.

The following list of hazards provides information which will help to prevent fires:

WARNING

Always keep a fire extinguisher

and first aid kit where they can be

easily reached in case of fire and

keep these items properly

maintained.

Operating personnel should be

instructed on what to do in case

of fire and be required to

demonstrate how to use fire

extinguisher and fire suppression

equipment.

Any portable fire extinguisher or

fire suppression system carried

on the machine that has been

used, should be recharged or

replaced before the machine

resumes operating. Fire

extinguisher manufacturers

recommended service intervals

should be followed.

WARNING

Allow machine to cool down by

idling the engine for a while

before shut-down. Many engine

and transmission fires start after

shut-down.

WARNING

Before adding fuel, shut down

the engine and allow it to cool.

Never smoke while handling fuel

or working on either the fuel or

the hydraulic system.

WARNING

Do not use the machine in areas

with explosive dust or gases that

can be ignited by arcs, sparks,

hot components, or exhaust

fumes.

WARNING

Daily inspect the machine for

flammable debris, removing any

twigs, leaves, straw, rags, fluid

spills or leaks, dirt or grime. Pay

special attention to areas such as

the engine, engine cooling

system, exhaust system, battery,

electrical connections, brake

systems, transmission/drivetrain,

fuel system and hydraulic system.

Clean as often as necessary to

help prevent overheating and

combustion.

WARNING

The electrical system (battery,

electrical connections, etc.) can

be a source of arcs or sparks if

damaged or incorrectly

maintained. Daily inspect all

electrical wiring and connections

for damage. Keep the battery

terminals clean and tight. Replace

or repair any damaged part. Use

proper battery connection and

disconnection procedures.

WARNING

Daily inspect all fuel and

hydraulic oil tubes, hoses, and

fittings for damage and leakage.

Tighten or replace as necessary.

Always clean fluid spills.

WARNING

Do not use ether or starting fluids

on diesel engines with glow

plugs. These starting aids can

explode and injure bystanders.

WARNING

Before doing welding of any kind,

clean machine and disconnect

battery cables. Cover rubber

hoses, battery, and other

flammable parts. Never ground

an arc welder or electrical

accessories through turntable or

boom bearings as arcing may

occur causing bearing damage.

Do not weld on any structural

member unless specifically

authorized by Barko

Hydraulics. Any unauthorized

welding or welding procedures

will void the warranty, and may

cause structural damage.

WARNING

Read the Engine Manual that

comes with every machine for

complete engine operating and

engine safety instructions.

page 15

295 AC

800-00158

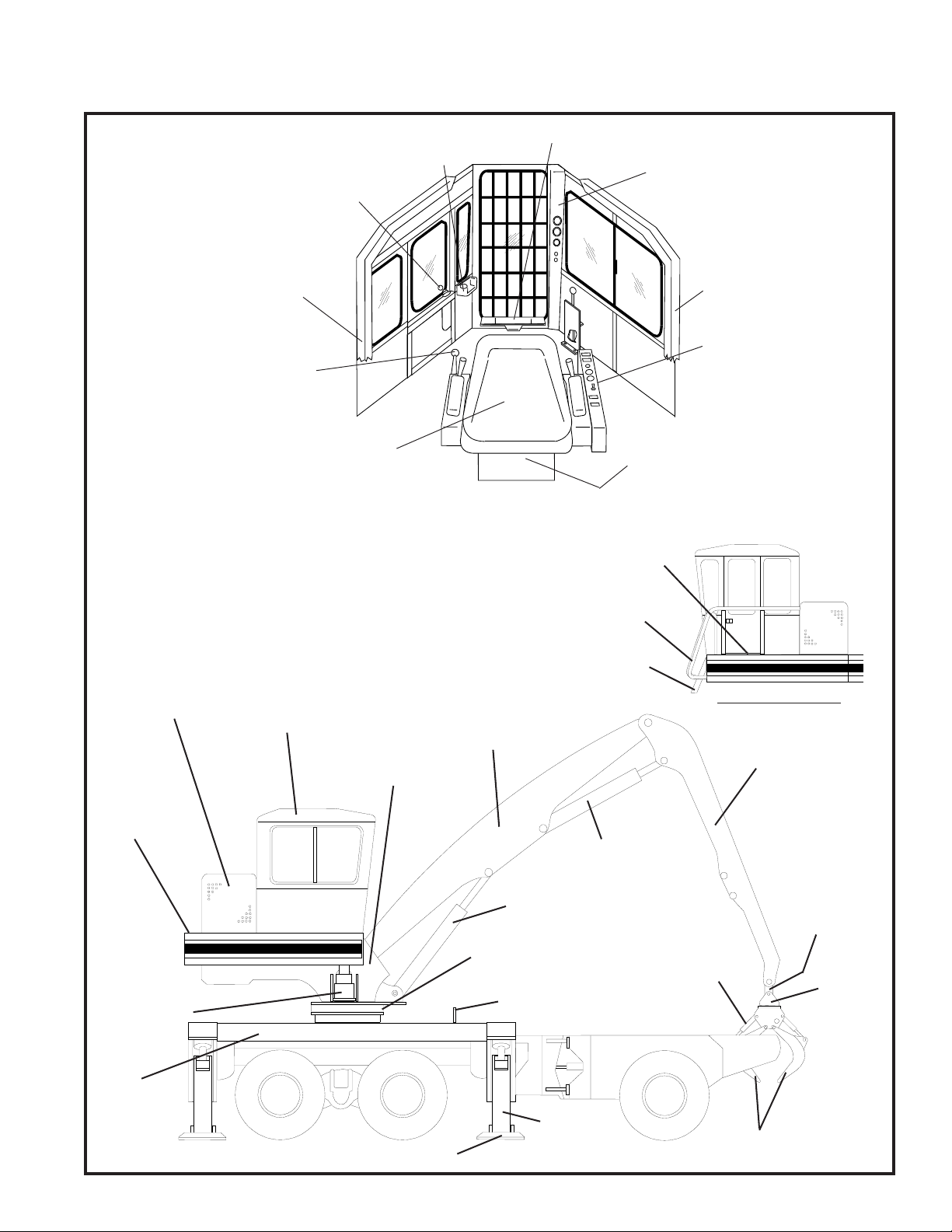

Stick Boom

Cylinder

Main

Boom

Platform/Control Deck

Hydraulic Oil Reservoir,

Shrouding, Power Unit

& Pumps

Main Boom

Cylinder

Turntable Bearing

Lower

(subframe)

Swing Motor

Gearbox

Stabilizer

Leg and

Cylinder

Stabilizer Pad

Grapple

Rotator

Grapple

Arms

Grapple

Cylinders

Counterweight

Cab

Head

Assembly

MODEL DESCRIPTION

Stick Boom

Grapple

Hanger

Operator's Seat

with Seatbelt

Heater/Air Conditioner

(located under and behind the seat

with attached ducting)

Heater/Air

Conditioner Ducting

(not shown attached

to unit)

Instrument Panel

(seat mounted)

Instrument Panel (wall

mounted)

Cup and

Thermos Holder

Door Handle

Swing Pedal

Servo Lever

(lifts entire armrest,

shutting off servo)

Heater/Air

Conditioner Ducting

(not shown attached

to unit)

Ladder

Handrails

LEFT SIDE VIEW

Transmission

Shift Lever

page 16

295 AC

800-00158

Maintenance

A. PREVENTIVE MAINTENANCE

Maintenance

page 17

295 AC

800-00158

The following maintenance section gives suggested guidelines for operational maintenance on your machine. It is

not intended for use as a service manual.

In severe conditions (extreme dust, heat, cold, humidity, etc.) you will need to service your machine more often.

Your experience will dictate a more severe servicing program.

Safety while servicing your machine is your responsibility. Only qualified and authorized personnel should be

permitted to maintain, repair, adjust and inspect machine.

Read and understand warnings and safety precautions in Safety Summary and elsewhere in this manual before

doing any service on machine. The following precautions should be used as a reminder to safe servicing.

SAFETY WHILE SERVICING

REMEMBER: SAFETY FIRST!

WARNING

Always shut down the machine and lower the boom

and attachment to the ground before working on the

machine. If necessary to work on a lifted boom or

attachment, securely support the boom and

attachment so that they cannot move or fall in any

way.

WARNING

Don't leave loose tools and rags on the

machine. Ensure that all walking and climbing

surfaces are clean.

WARNING

Handle fuel carefully. Do not smoke while filling

fuel tank or working near fuel.

Refer to Fluid Specifications whenever

replacing oils, fluids, or filling fuel tank.

WARNING

Do not weld on any structural member unless

specifically authorized by Barko Hydraulics. Any

unauthorized welding or welding procedures will

void the warranty, and may cause death, severe

injury, property damage or structural damage to the

machine.

WARNING

Do not support the machine on cinder blocks,

hollow tiles, or props that may crumble under a

load. Do not work under a machine that is

supported solely by a jack.

CAUTION

Check the Hour Meter regularly to determine when

the machine needs periodic maintenance. Use the

intervals on the Service Schedule except when

operating in extreme conditions; then shorter

intervals must be used.

WARNING

Under no circumstances should any modifications

be made to Barko machinery without factory

authorization. Any modifications may void the

warranty. This machine was designed to do a

specific job and alterations could result in death,

severe injury or property damage.

WARNING

Relieve all hydraulic pressure before breaking any

hydraulic connection, opening the reservoir access

cover, or performing any maintenance on the

machine.

- Lower boom to ground.

- Shut down machine to a zero energy state.

- Remove key from ignition.

- Disengage servo lever.

- Allow machine to cool.

- Relieve all hydraulic pressure.

- Disconnect battery using battery disconnect switch.

- Remove, block or guard against body contact with all

other sources of hazardous pressure, temperature,

electricity, or machine motion.

- Ensure machine, boom or attachment are not

supported on props that may collapse. Ensure boom

and attachment are grounded.

BEFORE INSPECTION OR MAINTENANCE:

page 18

295 AC

800-00158

Preventive maintenance is really just a simple matter of common sense. If you keep any piece of mechanical

equipment clean and properly lubricated, and promptly replace any worn or damaged parts, you are going to "prevent"

deterioration and promote long life and safe, productive service. The only other requisite to such a program is the

regular scheduling of such maintenance.

Obviously, when you are operating under severe job conditions, such as a dusty job site, in extreme heat or cold, a long

operating day, or extremely heavy loads, the recommended intervals in the schedule should be shortened.

The suggested schedule on the following page is designed to be just a reminder of what should be done. For detailed

instructions on each item, consult the Table of Contents for where each is located in this manual.

AFTER THE FIRST 50 HOURS OF OPERATION OF A NEW MACHINE

A new machine needs a special maintenance procedure after the first 50 hours of operation.

1. Do a complete inspection of the loader. Rectify any problems, replace any damaged parts.

2. Check torque (retorque if necessary):

- Turntable Bearing Mounting Bolts

- Mounting Bolts/Nuts on major machine components (gearboxes, motors, pumps, booms,

attachment, turntable bearing, lower assembly, tires, etc.)

3. Change all filter elements.

4. Change hydraulic oil in hydraulic oil reservoir.

5. Change gear fluid in swing motor gearbox.

Resume the normal maintenance intervals after this. See the Service Schedule for more information.

SPECIAL NEW-MACHINE INSTRUCTIONS

PREVENTIVE MAINTENANCE

WARNING

Instructions are necessary before doing service on loader. See

warnings and instructions both at the beginning and

throughout this manual. After doing service or making repairs

or adjustments always check function of loader.

Safety glasses or goggles are always needed for eye protection

from electric arcs, from shorts or welding, battery acid,

compressed springs, fluids under pressure, and flying debris

or loose material when engines are running or tools are used.

Use eye protection approved for type of welding. Failure to

obey warnings can cause death, severe injury or property

damage.

page 19

295 AC

800-00158

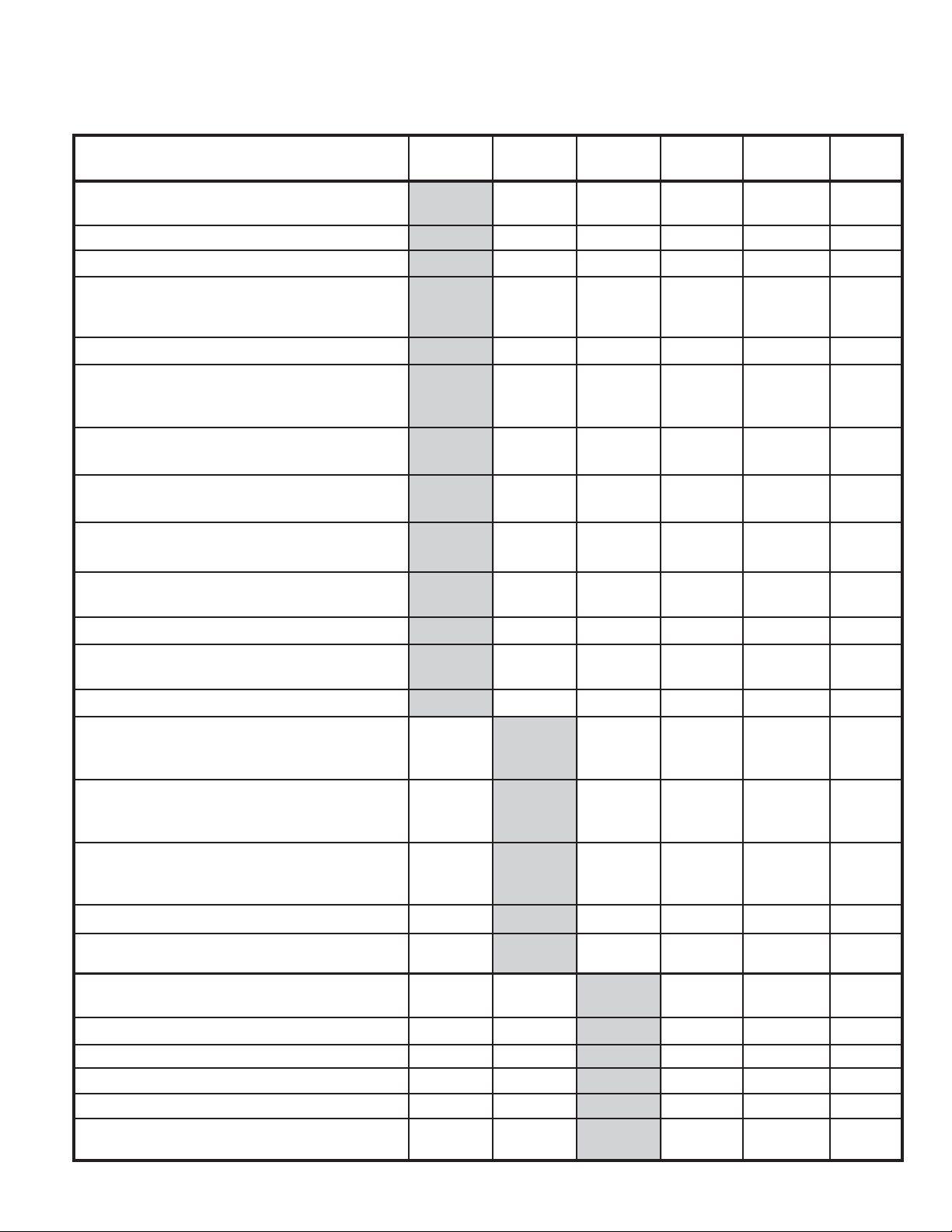

8 hours

Daily

SERVICE REQUIRED

Fan and Drivebelts - Check for looseness

and wear. Tighten or replace as needed.

Operator's Platform - Clean area of debris,

tools, rags, water, ice, and snow.

Fuel Tank - Check level and fill if necessary.

Engine Crankcase Oil - Check level.

Engine Radiator - Check coolant level and

fill if necessary. Inspect exterior for dirt and

debris and clean if necessary.

Hoses, Connections, Cylinders - Inspect for

leaks and damage. Tighten, repair, or

replace parts if necessary.

Pump Drive - Check fluid level.

Swing Motor Gearbox - Check fluid level.

Engine Air Cleaner - Inspect & replace

element,if needed.

Hydraulic Reservoir - check level and quality

of oil.

Hydraulic Oil Reservoir - On new machines

the oil must be changed after the first 50 hours,

and then every 1000 hours after that.

Hydraulic Oil Filter - On new machines the

filter element should be replaced first at 50

hrs. and then at 400 hrs. thereafter.

Engine Shrouding - Clean and inspect.

SERVICE SCHEDULE

Fittings - Lubricate as shown on Lubrication

Points. Use a multi-purpose grease.

Bolts/Nuts - Visually inspect for wear or

damage.

Control Lever Linkage - Lubricate.

Bolts/Nuts - Check for proper

torque every 50 hours. Retorque if necessary.

Battery - Clean and coat posts with grease.

Check electrolyte level and fill if necessary.

Engine Oil Filter - Replace.

Hydraulic Oil Cooler and Radiator - Clean.

Hydraulic Oil Reservoir Breather - Replace.

Hydraulic Collector - Check mounting bolts.

Accumulators - Check pressure and maintain

at 900 PSI.

50 hours

Weekly

100 hours

Monthly

400 hours

2 Months

1000 hours

6 Months Yearly

Swing Motor Gearbox - On new machines

the fluid should be changed first at 50

hrs. and then every 400 hours thereafter.

page 20

295 AC

800-00158

Hydraulic Reservoir - Replace oil and clean

suction screens.

Entire Loader - Steam clean, inspect for

stress, wear, cracks, damage, and loose parts.

SERVICE REQUIRED

NOTE: Use the intervals on Service Schedule when operating in normal conditions. Service the

machine at shorter intervals when operating in very hot, cold, dusty, or humid conditions.

SERVICE SCHEDULE CONTINUED...

Pilot Filters in Valve Banks - Remove, inspect

and clean.

Air Conditioner Air Intake Filter - Replace.

8 hours

Daily

50 hours

Weekly

100 hours

Monthly

400 hours

2 Months

1000 hours

6 Months Yearly

Swing Motor Gearbox - Replace fluid. On new

machines the fluid should be changed first at 50

hrs. and then every 400 hours thereafter.

Tires - Check for correct pressure.

Axle Cradle Center Pivots - Lubricate.

Articulating Pivot Points - Lubricate.

Pump Drive - Replace fluid.

Planetary Axle - Drain and fill with lubricant.

Replace seals. Refer to Service Manual.

Drive Shaft Universal Joint - Lubricate.

Brakes - Adjust if necessary.

Wheel Bearings - Clean and inspect. Replace

if necessary. Pack with grease.

Hydraulic Oil Filter - Replace elements every

400 hours, after initial change at 50 hours on a

new machine.

Transmission - Check fluid. Add if necessary.

Transmission - Change fluid (80-90 gear fluid).

Visually inspect the tires for proper inflation, and for cuts, gouges, blisters or tread separation.

Check the tire pressure. Make sure all tires are properly inflated.

WARNING

Improperly inflated tires can cause excessive heat buildup resulting in blowouts. Always

keep tires inflated to the proper pressure. Unexpected blowouts may cause severe injury or

death.

CAUTION

Over or under inflated tires can cause a drastic reduction in tire and rim life.

CAUTION

Keep the valve caps on to prevent dirt from entering the valves. Dirt will cause valve damage.

TIRES

Table of contents