Toavoidcrushingand

relatedinjuries:

NEVERwork on, under or

aroundaloadsupported

only by a crane.

Immediatelytransferthe

loadtoan appropriately

ratedenginestand.

!WARNING

!SAFETYMESSAGE!

Lift only on areas of the engine as specified by

thevehiclemanufacturer.

Be sure all tools and personnel are clear before

loweringload.

OPERATION

1. Load capacity should be coordinated with boom

extension and legs extension. Do not extend boom

extension beyond the marking that coordinate with

the legs extension.

2. Ensure application is compatible with product.

3.Secureenginetochain/sling hook assembly,ensuring

loadis centered.

4. Follow vehicle service manual recommendations to

remove engine. When ready to remove engine, turn

releasevalve clockwise untilfirm. Pump handleuntil

loadis high enough to clearvehicle.

5. Immediately upon removal and when clear of the

vehicle,lowertheloadtothelowestpracticalposition

byturning the release valve levercounter-clockwise

slowlyand carefully.

Note: Avoid rolling the loaded engine crane. To help

positionanenginestandifnecessary,moveonlyacross

smooth,level, seamless surfaces.

Before movingensure the load:

a. is lowered to the lowest practical position, but

alwaysbelow the center of gravity.

b.ispreventedfrom swinging and inadvertentshifting.

5. Position a suitable engine stand near the removed

engine, then immediately transfer the load to

appropriateenginesupportdevice(enginestand).

6.Checktoensurestandissecure before working on or

around.

BEFORE USE

1. Inspect crane before each use. Do not use if bent,

brokenorcrackedcomponentsare noted.Ensurethat

casters/wheelsandboommove freely. Check for and

tighten any loose assemblies.

2. Verify that the product and the application are com-

patible.

3. Before using this product, read the owner's manual

completely and familiarize yourself thoroughly with

the product and the hazards associated with its im-

properuse.

!WARNING

Study,understand,andfollowallinstructionsprovided

withandonthisdevicebeforeoperatingthisdevice.

Donotexceedratedcapacityforeachboomposition.

Use the device only on a hard, level surface.

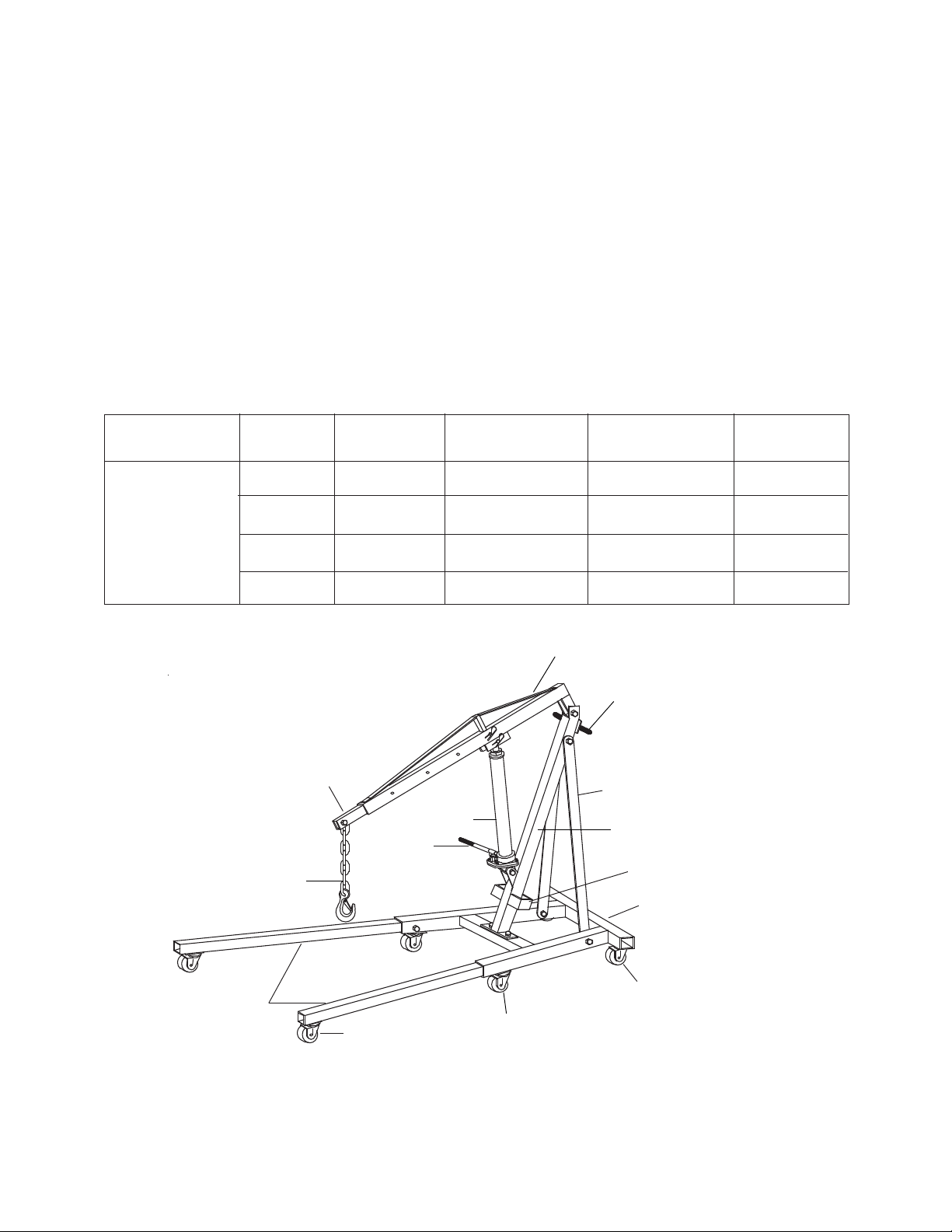

These engine cranes are intended to be used to lift

andlowerrated capacity automotive andlight truck

engines. It is an aid in the removal and installation

ofautomotive and light truck engines.

Onlyuse chains and slings with a capacity equal to

orgreater thanthat of the crane.

If loaded crane must be moved, make certain that

load is stable, is in lowest possible position and is

movedoverasmooth,hardlevelsurface.

Avoidshockloadscausedbythe rapid opening and

closingofreleasevalve.

Shock loads may cause the load to swing, causing

thecrane to flip violently, bend or break.

Ensuretheboomisfullylowered before checking or

adding fluid to the hydraulic unit.

Never extend boom extension beyond furthest

distance of leg extension.

Do not stand over loaded boom nor in its intended

lineoftravel.

Do not use adapters or accessories that are not

providedinitially.

Do not use the device for any purpose other than

that for which it is intended.

Do not modify this device.

Failure to heed these markings may result in

personalinjuryand/orpropertydamage.

4