10-5

®

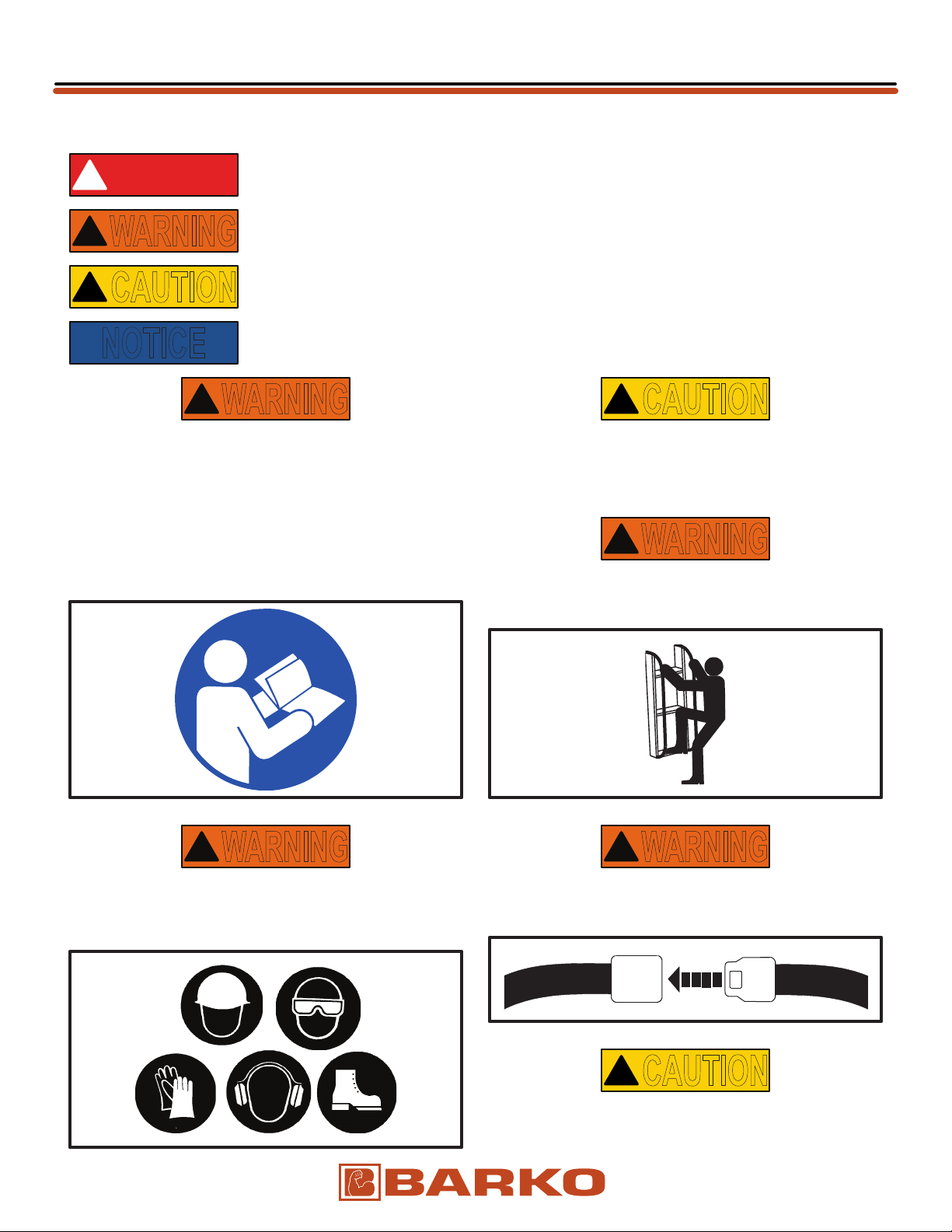

KNOW YOUR

The following is a list of 10 important safety precautions and warnings you

should read through and understand before operating or servicing your machine.

Don't assume that because you know the control functions of other similar machinery, that

you can run and/or service the BARKO machine. All machines differ in some ways, and these

differences must be noted and acknowledged. Read this manual thoroughly and understand all

safety, operating, and servicing procedures before using the machine.

Know how to put your machine in a zero energy state for purposes of inspection,

maintenance, or repair.

Clear operating area of all obstacles and personnel before operating machine.

Never approach power lines with any part of the machine or load! Current in a high voltage

power line may arc some distance to jump from the wire to a nearby "ground".

KEEP WELL CLEAR!

Allow only the operator on the machine. Keep riders off. Riders on machine are subject to

injury such as being struck by foreign objects and being thrown off the machine. Riders also

obstruct the operator's view, resulting in the machine being operated in an unsafe manner.

Never use a boom or attachment for a work platform or personnel carrier. Serious injury or

death may result.

When machine is not operating or when leaving cab, boom or lift arm and attachment must

be lowered to the ground. Failure to do so may allow boom or attachment to move, causing

property damage, injury, or death.

Do not tamper with any hydraulic line when it is pressurized. Escaping fluid under pressure

can penetrate the skin, causing serious injury. Relieve pressure before unhooking hydraulic or

other lines. Tighten all connections before applying pressure. Keep hands and body away from

pinholes and nozzles which eject fluids under high pressure. Use a piece of cardboard to search

for leaks.

If any fluid is injected into the skin, seek professional medical attention immediately!

Under no circumstances should any modifications be made to BARKO machinery without

factory authorization. Any modifications may void the warranty. This machine was designed to

do a specific job and alterations could result in property damage, injury or death.

Replace any safety decals that are faded, torn, missing, illegible, or otherwise damaged.

See your machine's Decals section for decal kits applicable to your machine and for locations of

all decals.

Don’t stop here, read on...

®

1.

2.

3.

4

5.

6.

7.

8.

9.

10.

06/19/2018

Updated

SERVICE