Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup.......................................................................11

1InstallingtheWheels......................................12

2InstallingtheSteeringWheel..........................12

3ChargingandConnectingtheBattery.............13

4CheckingtheAngleIndicator.........................14

5AdjustingTireAirPressure.............................14

6InstallingtheHoodLatch(CEOnly)................14

7InstallingtheExhaustGuard(CE

Only).............................................................16

8InstallingtheRollBar.....................................16

9InstallingtheFrontLiftArms...........................17

10InstallingtheCarrierFramestothe

CuttingUnits.................................................18

11MountingtheCuttingUnits...........................19

12MountingtheCuttingUnitDrive

Motors...........................................................20

13AdjustingtheLiftArms.................................21

14InstallingtheTipperRollerKit

(Optional)......................................................22

15ApplyingtheCEDecals...............................22

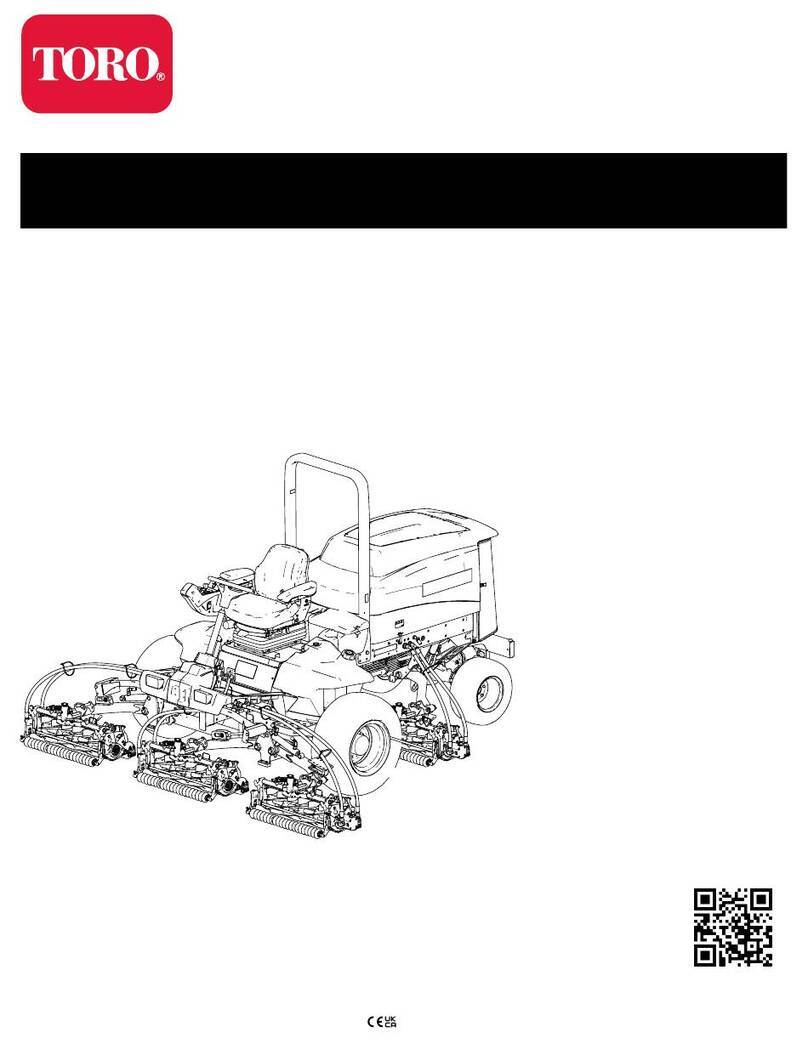

ProductOverview...................................................23

Controls...........................................................23

Specications..................................................25

Attachments/Accessories.................................25

BeforeOperation.................................................26

BeforeOperationSafety...................................26

PerformingDailyMaintenance..........................26

CheckingtheInterlockSystem..........................26

FillingtheFuelTank..........................................26

DuringOperation.................................................27

DuringOperationSafety...................................27

StartingtheEngine...........................................28

ShuttingOfftheEngine.....................................29

BleedingtheFuelSystem.................................29

CuttingGrasswiththeMachine........................29

ClipRate(ReelSpeed).....................................30

AdjustingReelSpeed.......................................31

OperatingTips.................................................31

AfterOperation....................................................32

AfterOperationSafety......................................32

AfterMowing....................................................32

IdentifyingtheTie-DownPoints........................32

HaulingtheMachine.........................................32

TowingtheMachine..........................................32

Maintenance...........................................................33

MaintenanceSafety..........................................33

RecommendedMaintenanceSchedule(s)...........33

DailyMaintenanceChecklist.............................35

Pre-MaintenanceProcedures..............................36

RemovingtheBatteryCover.............................36

OpeningtheHood............................................36

Lubrication..........................................................37

GreasingtheBearingsAndBushings................37

CheckingtheSealedBearings..........................39

EngineMaintenance...........................................40

EngineSafety...................................................40

ServicingtheAirCleaner..................................40

CheckingtheEngine-OilLevel..........................40

ChangingtheEngineOilandtheFilter..............41

FuelSystemMaintenance...................................42

ServicingtheFuelT ank.....................................42

InspectingtheFuelLinesand

Connections..................................................42

DrainingtheWaterSeparator...........................42

ChangingtheFuelFilterCanister......................43

BleedingAirfromtheInjectors..........................43

ElectricalSystemMaintenance...........................44

ElectricalSystemSafety...................................44

ServicingtheBattery.........................................44

ServicingtheFuses..........................................44

DriveSystemMaintenance..................................45

CheckingtheTirePressure...............................45

TorquingtheWheelNuts...................................45

AdjustingtheTractionDriveforNeutral.............45

CoolingSystemMaintenance..............................46

CoolingSystemSafety.....................................46

CheckingtheCoolingSystem...........................46

CleaningtheEngineCoolingSystem................46

BrakeMaintenance.............................................47

AdjustingtheParkingBrake..............................47

BeltMaintenance................................................48

ServicingtheEngineBelts................................48

ControlsSystemMaintenance.............................49

AdjustingtheThrottle........................................49

HydraulicSystemMaintenance...........................49

HydraulicSystemSafety...................................49

CheckingtheHydraulicLinesand

Hoses............................................................49

CheckingtheLeveloftheHydraulic

Fluid..............................................................49

HydraulicFluidSpecications...........................50

HydraulicFluidCapacity...................................50

ChangingtheHydraulicFluid............................50

ReplacingtheHydraulicFilter...........................51

CuttingUnitSystemMaintenance........................52

BladeSafety.....................................................52

CheckingtheReel-to-BedknifeContact............52

BacklappingtheCuttingUnits...........................52

Cleaning..............................................................54

WashingtheMachine.......................................54

Storage...................................................................54

StorageSafety..................................................54

PreparingtheTractionUnit...............................54

PreparingtheEngine........................................54

Troubleshooting......................................................56

UsingtheStandardControlModule

(SCM)...........................................................56

3