Barksdale BFS-30 N User manual

Art.-Nr.: 923-1938

Index ), .0.201

Specifications are subject to

changes without notice.

21

1. Installation

Operating of the BFS-30 N/L flow monitors and indicators is based on the movement of a

spring-loaded piston within a cylindrical tube. The instrument can be mounted in any position

in a system. Flow direction is from the lowest to the highest value, indicated on the scale. The

viscosity-compenstion is achieved by the combination of the spring and the calibrated orifice

inside the piston and guaranties high accuracy over a viscosity range up to 600 cSt.

The flow media must be free of particle contamination, otherwise the instruments will not func-

tion properly. Particularly magnetic particles may cause faults. We recommend the use of dirt

filters or magnetic filters. All non standard applications should be discussed with our technical

engineers.

The flow monitors must not be positioned in inductive or magnetic fields. Minimum distance

from iron parts: 10 mm.

All connection sizes comply with the R-standard (DIN 2999, part 1). Only suitable thread and

sealing material should be used for installation, otherwise the correct function of the equipment

may be affected.

To avoid the risk of measure faults, the upstream line should be 10 x D and the downstream

line 5 x D (where D = internal diameter of the tube).

The highest accuracy will be reached by mounting the flow monitors vertically, with flow direc-

tion from bottom to the top.

When screwing the fittings, take care of the max. lengh of the threads. Too long threads

may cause damage of the flow monitor.

(BFS-30-O:

When screwing the fittings, the flowmeter threads must be fixed with a spanner. Never

rotate the flowmeter connections inside the aluminum sleeve. This may cause leakage

or breaking of the glass.)

All model provided with a switch should be protected from electrical overload. Never exceed

the given maximum switch capacity, not even for short periods. The embedded reedswitch is

very sensitive for specifically inductive loads, which may occur at closing or opening and which

can up to 10 times the given nominal value of the coil. Use protecting relays or other precauti-

ons in such cases.

Our reedswitch are gold-rhodium-plated, which allow direct connecting to SPS-systems.

Operating Instructions Flow monitor Type BFS-30 N / L

and Flow monitor Type BFS-30-O

Barksdale GmbH

Dorn-Assenheimer Strasse 27

D-61203 Reichelsheim / Germany

Tel.: +49 - 60 35 - 9 49-0

Fax: +49 - 60 35 - 9 49-111 and 9 49-113

e-mail: [email protected]

www.barksdale.de

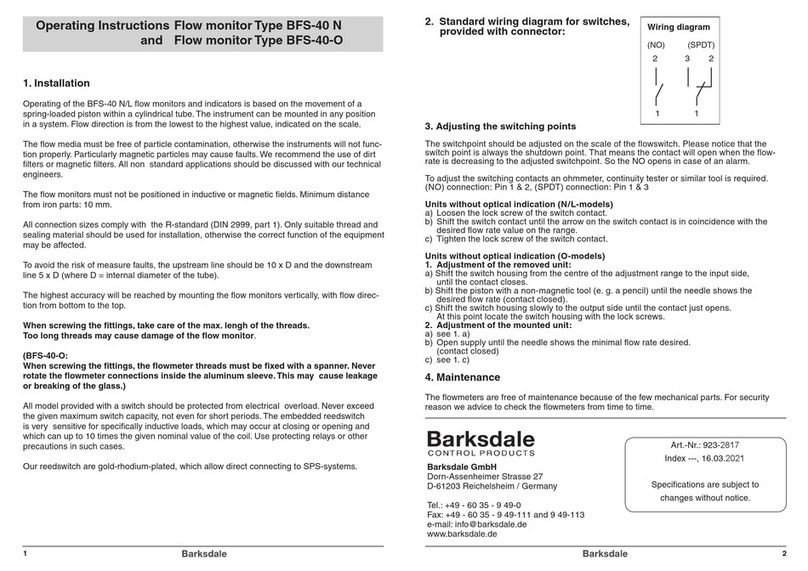

(NO) (SPDT)

Wiring diagram

23 2

11

2. Standard wiring diagram for switches,

provided with connector:

3. Adjusting the switching points

The switchpoint should be adjusted on the scale of the flowswitch. Please notice that the

switch point is always the shutdown point. That means the contact will open when the flow-

rate is decreasing to the adjusted switchpoint. So the NO opens in case of an alarm.

To adjust the switching contacts an ohmmeter, continuity tester or similar tool is required.

(NO) connection: Pin 1 & 2, (SPDT) connection: Pin 1 & 3

Units without optical indication (N/L-models)

a) Loosen the lock screw of the switch contact.

b) Shift the switch contact until the arrow on the switch contact is in coincidence with the

desired flow rate value on the range.

c) Tighten the lock screw of the switch contact.

Units without optical indication (O-models)

1. Adjustment of the removed unit:

a) Shift the switch housing from the centre of the adjustment range to the input side,

until the contact closes.

b) Shift the piston with a non-magnetic tool (e. g. a pencil) until the needle shows the

desired flow rate (contact closed).

c) Shift the switch housing slowly to the output side until the contact just opens.

At this point locate the switch housing with the lock screws.

2. Adjustment of the mounted unit:

a) see 1. a)

b) Open supply until the needle shows the minimal flow rate desired.

(contact closed)

c) see 1. c)

4. Maintenance

The flowmeters are free of maintenance because of the few mechanical parts. For security

reason we advice to check the flowmeters from time to time.

Operating data BFS-30-O

Pressure MS 250 bar

Pressure VA 300 bar

Pressure drop 0,02 - 0,4 bar

Temperatuer max. 120 °C

Electrical data*

Normally open 250 V - 3 A - 100 VA

Change over** 250 V - 1,5 A - 50 VA

Protection IP65

Materials brass stainl. steel

Housing brass 1.4571

Float brass 1.4571

Spring 1.4571 1.4571

Seals Perbunan, Viton or EPDM

Accuracy ±10% of FS

Electrical connection acc. to DIN 43650 or with 1 m cable

6. Technical data:

Operating data BFS-30-N BFS-30-L

Pressure MS / MS with GL 250 bar / 100 bar 300 bar / 100 bar

Pressure VA 300 bar 350 bar

Pressure drop 0,02 - 0,4 bar 0,02 - 0,2 bar

Temperature max. 120 °C 120 °C

Electrical data*

Normally open 250 V - 3 A - 100 VA 230 V - 3 A - 60 VA

Change over** 250 V - 1,5 A - 50 VA 250 V - 1,5 A - 50 VA

Protection IP65 IP65

Materials brass stainl. steel brass stainl. steel

Housing brass 1.4571 brass 1.4571

Float brass 1.4571 brass 1.4571

Spring 1.4571 1.4571 1.4571 1.4571

Seals Perbunan, Viton or EPDM

Accuracy ±10% of FS ±10% of FS

Electrical connection acc. to DIN 43650 or with 1 m cable

43

Dimensions (in mm)

BFS-30-N / L

BFS-30-O

G

L

D

ø1

W

D

G

L

ø

W

D

(BFS-30-L)

* Data only for application in non explosive atmosphere

(G) G 1/4 G 1/2 G 3/4 G 1

(hex) 34 34 34 40

(ø) 40 40 40 40

(W) 76 76 76 76

(D) 21 21 21 17

(L) 152 152 152 130

Weight (g) 1590 1515 1430 1250

(G) G 1/4 G 1/2 G 3/4 G 1 1/2“

(hex) 34 34 34 40 27

(ø) 40 40 40 40 31

(W) 76 76 76 76 52

(D) 21 21 21 17 14

(L) 152 152 152 130 90

Weight (g) 1500 1425 1340 1160 350

hex

5. Switch versions for hazardous locations

As option there is an intrinsically safe approved version for G and D environments according to

ATEX regulations. These switches, marked with EEx ia label, must be operated with a certified

switch amplifier according to the applicable regulations.

Design conditions, approval data and instructions must be observed carefully. Installation and

operation must be performed by trained personnel only.

Approval data: Approved for: II 1 GD Ex ia IIB T6 Ga, Ex ia IIIC T100°C Da

Certificate-No.: ISSeP08ATEX016X/1

Electrical data for intrinsically safe application: Ui = 28 V Ci = 40 pF

Ii = 50 mA Li = 4 µH

** Minimum load: 3 VA

Contact rating for SPS-applications: 200 V, 1 A, 20 VA (Please request)

$OOFRQGXFWLYHSDUWVWKDWFDQEHFRPHGDQJHURXVO\FKDUJHGPXVWEHFRQQHFWHGDQGIHGLQWRWKH

HTXLSRWHQWLDOERQGLQJ,QVLGHWKHGHYLFHQRH[SORVLYHPL[WXUHJDVDLUGXVWDLURUK\EULGVPD\

RFFXUDWDQ\WLPH7KLVLVWREHJXDUDQWHHGE\WKHRSHUDWRU

This manual suits for next models

2

Other Barksdale Measuring Instrument manuals