Barksdale BNA 21 User manual

Operating Instructions

Bypass level indicator

1Intended Applications ................................................................................................... 2

2Safety Instructions......................................................................................................... 3

3Standards ....................................................................................................................... 4

4Warranty/Guaranty......................................................................................................... 4

5Principle of Operation ................................................................................................... 5

6Installation/Commissioning .......................................................................................... 6

7Maintenance ................................................................................................................. 10

8Technical Data.............................................................................................................. 11

9EU type examination certificate.................................................................................. 12

Barksdale GmbH

Dorn-Assenheimer Straße 27

D-61203 Reichelsheim

Phone: +49 (6035) 949-0

Fax: +49 (6035) 949-111 and 949-113

Internet: www.barksdale.de

1

14

Art. no.: 923-0664

Index G, 03.07.2019

Specifications are subject to

changes without notice!

Refer to data sheet for further

technical data.

Intended Applications

The Bypass Level Indicator (BNA) serves exclusively for indicating the level corresponding to that of

the connected tank. Control devices such as solenoid switches or remote indicators can be

additionally installed by Barksdale.

The manufacturer assumes the responsibility for correct execution of the equipment according to

the orderer's instructions. The orderer assumes the responsibility for the correct installation and use

of the equipment subject to the applicable national regulations.

DANGER

Read the operating instructions and the safety instructions carefully before using the Bypass

Level Indicator. Nonobservance may cause injuries to health or material damage.

Barksdale GmbH cannot be held liable for any damage resulting from incorrect use.

The Bypass Level Indicators (BNA) must not be used in situations in which lives depend on

proper functioning of the equipment.

The Bypass Level Indicator may only be used in the specified fields of application and with the

permissible data (see nameplate). The temperature ranges must be within the permissible limits.

The stated pressures and electrical load values must not be exceeded.

The orderer ensures that exothermic reactions or spontaneous gas-phase formation of the

medium are impossible.

Observe also the applicable national safety instructions for assembly, commissioning and

operation of the Bypass Level Indicator.

CAUTION

If the medium is water and there is a risk of icing the water must be discharged from the Bypass

Level Indicator (BNA) or heating must be provided to prevent damage to the float or the indicator

tube.

The maximum speed of the float caused by level changes must not exceed 1 m/s. If necessary a

suitable screen must be installed by the orderer in the connection to the tank.

NOTE

Unless agreed otherwise the Bypass Level Indicator (BNA) is designed for static operating

conditions. If any vibrations are to be expected, e.g. by pumps, compressors etc. the orderer

must provide for adequate vibration absorption.

The classification of ex devices is stated on the nameplate and the EC type examination certificate.

The designation II 1G Ex h IIC T6…T1 Ga permits use in potentially explosive gas atmosphere

outside the equipment in zone 0. Inside the equipment zone 0 is also permitted.

CAUTION

In ex areas the orderer must not use any plastic bypass level indicators (BNA) because

of the risk of electrostatic charging.

If the Bypass Level Indicator (BNA) is determined for use in potentially explosive

atmosphere, it must be checked whether the damper has been installed in the lower

flange. The BNA must be suitable for the intended use according to its nameplate.

In case of use in zone 0, the maximum process temperatures according to the

temperature class and the permissible pressure range in the tank of 0.8 to 1.1 bar

absolute in case of potentially explosive temperature must be observed. If the Bypass

Level Indicator (BNA) is used in a potentially explosive atmosphere outside the

permissible pressure range and temperature range in the tank mentioned above, the type

examination certificate serves only as a guideline.

Additional examinations for the specific operating conditions are recommended.

Safety Instructions

The safety instructions are intended to protect the user from dangerous situations and/or prevent

material damage.

In the operating instructions the seriousness of the potential risk is designated by the following

signal words:

DANGER

Refers to imminent danger to men.

Nonobservance may result in fatal injuries.

WARNING

Refers to a recognizable danger.

Nonobservance may result in fatal injuries, and destroy the equipment or plant parts.

CAUTION

Refers to a danger.

Nonobservance may result in minor injury and damage to the Bypass Level Indicator (BNA)

and/or the plant.

3

2

NOTE

Refers to important information essential to the user.

Disposal

The Bypass Level Indicator must be disposed of correctly in accordance with the local

regulations for electric/electronic equipment.

The Bypass Level Indicator must not be disposed of with the household garbage!

Standards

The standards applied during development, manufacture and configuration are listed in the CE

conformity and manufacturer's declaration.

Warranty/Guaranty

Warranty

Our scope of delivery and services is governed by the legal warranties and warranty periods.

Terms of guaranty

We guaranty for function and material of the Bypass Level Indicator under normal operating and

maintenance conditions in accordance with the statutory provisions.

Loss of guaranty

The agreed guaranty period will expire in case of:

incorrect use

modifications to the equipment

incorrect installation

incorrect handling or operation contrary to the provisions of these operating instructions

No liability is assumed for any damage resulting therefrom, or any consequential damage.

Principle of Operation

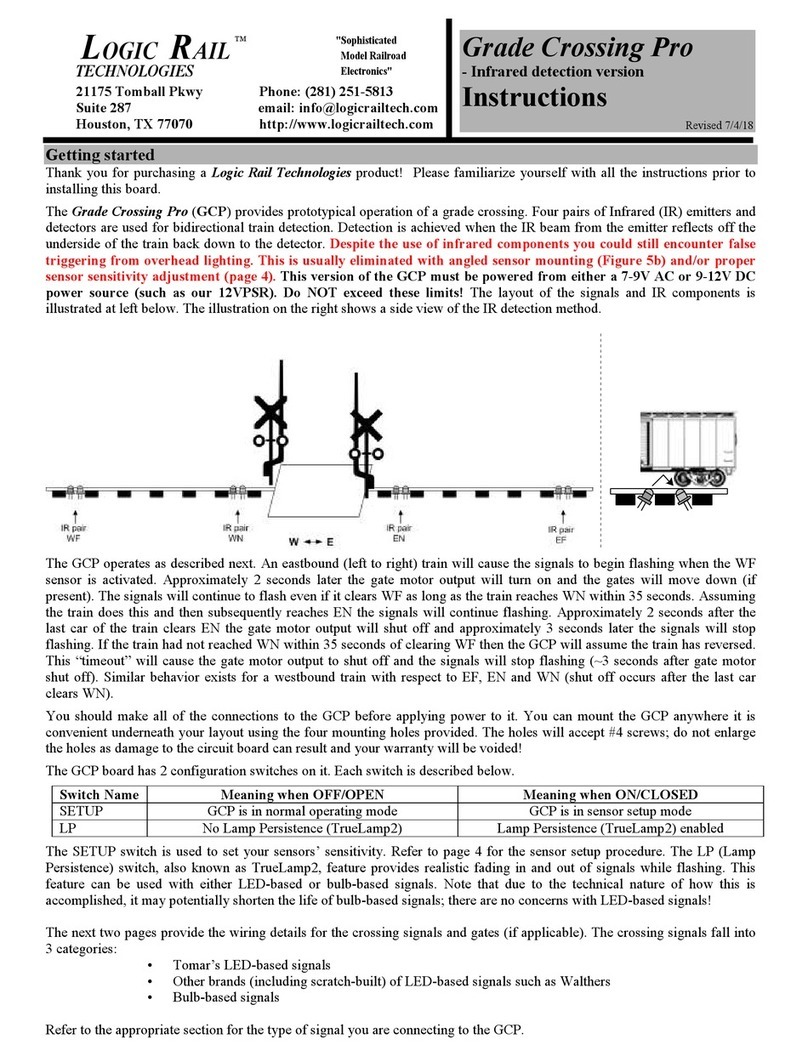

Figure 1: Sectional drawing BNA Figure 2:Detail - level indication BNA

The Bypass Level Indicator (BNA) works according to the principle of operation shown in figure 1.

The tank to be monitored (1/1) is connected with the Bypass Level Indicator (1/4) by two

connecting lines (1/2 and 1/3). The liquid to be measured is always at the same level in the tank

and in the Bypass Level Indicator.

The float (1/5) contains a magnetic system which acts on the one hand on the magnetic flags of

the indication bar (1/7) and on the other hand on the limit switches (1/8) or on the electric

transmitter (1/9).

5

4

Installation/Commissioning

DANGER

The electrical connection may only be made by trained expert staff!

Prior to any work on electrical components disconnect them from power supply.

NOTE

When the equipment is used in potentially explosive atmosphere chapter 0 „Intended

Applications“ must be observed!

If the Bypass Level Indicator (BNA) is determined for use in potentially explosive

atmosphere, it must be checked whether the damper has been installed in the lower

flange. The BNA must be suitable for the intended use according to its nameplate.

DANGER

In ex areas, only equipment which is in conformity with ATEX may be used.

EN 60079-14 must be observed.

The BNA-EX must be integrated in the potential equalisation system via the tubing during

installation.

Metallic process connection parts have to be included in the local potential equalization.

The Bypass Level Indicator type BNA-S../..EX…MA….has to be installed and used in

such a way that electrostatic charging from operation, maintenance or cleaning is

excluded.

NOTE

Before further steps are taken the orderer must check whether the operating conditions agreed in

the order are still valid. The equipment must be suitable for the intended purpose. This applies in

particular to:

the pressure, temperature, medium characteristics

the classification according to the Pressure Equipment Directive

possible additional loads

Mechanical installation

Bypass Level Indicators (BNA) are measuring devices. Perform all work on BNA with utmost care.

Check whether the Bypass Level Indicator (BNA) supplied is in conformity with your order

specification.

Check whether all parts are available and that the connection flanges of tank and indicator match.

The float has been packaged and attached to the outside of the Bypass Level Indicator (BNA).

Remove the bottom connection flange (1/10) from the BNA.

Insert the float into the BNA in such a way that the mark (Top) points up.

Attach the bottom connection flange with its gasket to the BNA.

Tighten all screws crosswise.

CAUTION

During erection of the Bypass Level Indicator (BNA) the float may be damaged by bumping.

Erect the Bypass Level Indicator (BNA) slowly and carefully.

CAUTION

Frozen fluids on or in the Bypass Level Indicator (BNA) may cause faults or total failure.

If no liquid process medium can be guaranteed at low outdoor temperatures (risk of fluid

freezing) the BNA must be protected against frost by suitable measures or emptied completely.

CAUTION

Thermal hazard from hot/cold surface of Bypass Level Indicator (BNA)

Do not touch the BNA with your bare hands. Wear protective gloves.

DANGER

Depressurize the system before carrying out any work on the Bypass Level Indicator (BNA)!

7

6

NOTE

Ensure that the flanges of the tank are accurately aligned with the flanges of the BNA.

Non-alignment of the flanges causes seizing or distortion of the BNA (1/4). The float (1/5) may

get jammed.

The principle of operation of the Bypass Level Indicator is based on the magnetic field principle.

No magnetic iron parts (e. g. screws, clamps etc.) must be used in the vicinity of the level tube.

Observe the data in chapter 8 „Technical Data“.

Install the BNA so that the nameplate (1/11) of the BNA (1/4) is located at the bottom.

Align all indication rotors (2/12) by means of a magnet or the enclosed float. All rotors must

show the colour white or silver;

white: makrolon, medium temperature up to 150 °C or aluminium, medium temperature up to 350 °C

silver: aluminium, medium temperature up to 200 °C

The maximum ambient temperature is 120 °C.

Ensure that all flange attachment screws, the vent plug (1/13) and the drain screw (1/14) are

tightened or closed properly.

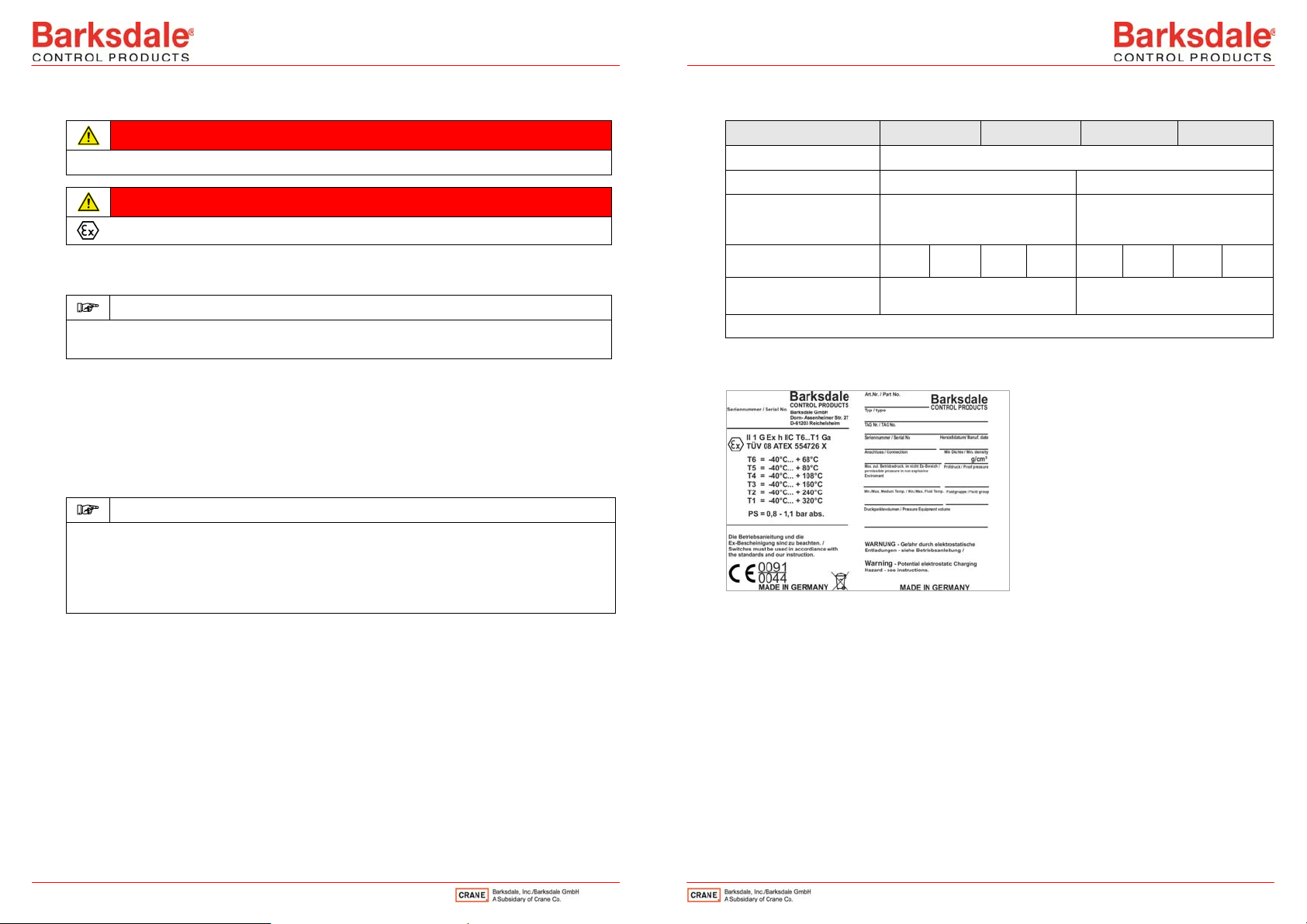

Torques for the screws:

Type Screw dimension Torque [Nm]

X1 M12 50

Plug G½, ½“ NPT 80

Fastening clamp 7 mm hexagon head 0.75

Electrical installation

DANGER

The orderer must ensure that all applicable regulations are observed in the event that electric

limit switches and remote indicators are used.

For further information about installation of the electric limit switches and remote indicators refer to

the corresponding installation and operating instructions.

Commissioning

The Bypass Level Indicators (BNA) are specially made for a specific application. The most

important data, such as flange, pressure, temperature and min. specific gravity of the float are

specified on the nameplate (1/11).

Check prior to commissioning whether the technical data according to the nameplate are in

agreement with the plant requirements.

Operating pressure and operating temperature of the plant must not exceed the data stated on the

nameplate of the Bypass Level Indicator. Exceeding the limit values will cause changes in the

behaviour and service life of the BNA. If the proof pressure is exceeded, functioning of the BNA is

no longer guaranteed and the BNA may be damaged.

Ensure that - dependent on the type of medium to be measured - the appropriate safety

precautions are taken.

Filling the Bypass Level Indicator

Slowly open the top valve (1/2a).

Slowly open the bottom valve (1/3b).

The liquid rises slowly in the BNA (1/4). The float (1/5) is lifted until the same level is reached in the

tank (1/1) and in the BNA.

Fully open the bottom valve (1/3b).

NOTE

For pressures above 40 bar a vented float (additional designation: -VAE) is used which is

provided with a small pressure compensation tube.

When using the VAE version take care that the temperature in the BNA and in the float rises

evenly and slowly. The use of vented floats should be discussed with the manufacturer

beforehand.

9

8

Maintenance

DANGER

Depressurize the system before carrying out any work on the Bypass Level Indicator (BNA)!

DANGER

Maintenance must not be performed in a potentially explosive atmosphere.

If the liquid to be measured contains dirt particles which may deposit in the bottom part of the BNA:

Determine the necessary time interval for cleaning.

NOTE

Coated Bypass Level Indicators must be checked regularly - at least every 12 months - for

damage to the coating.

Cleaning

Open the drain plug (1/14) or drain valve. Wash out the deposits.

If there are any encrustations, remove the top and bottom flange (dependent on the model).

Carefully remove the float.

Clean the BNA mechanically.

Check all flanges, discharge tubes and vent plugs for firm seat and tightness at regular

intervals.

Check the gaskets carefully. Replace graphite gaskets immediately when damaged.

NOTE

The orderer must ensure that the inspection intervals required for his plant are observed.

Indicators provided with a heating jacket covering the inner weld seams must be subjected to a

pressure chamber leak test at intervals to be specified by the operator. This is to recognize

corrosion-conditioned leaks of a weld seam exposed to the process medium, and to prevent that

process medium from entering the heating circuit.

8 Technical Data

BNA 21/22 BNA 31/36 BNA 41/42 BNA 45/46

Tube and flange material 1.4571

Float material 1.4571 or titanium 1.4571 or titanium

Media temperature range Max. -40°C…+ 150°C

(ex area according to ATEX

see certificate)

Max. -40°C…+ 320°C

(ex area according to ATEX

see certificate)

Process connection G1/2“ on the

side

G1/2“ on the

side

G1/2“ on the

side

G1/2“ on the

side

Maximum permissible

pressure

PN 16 PN 40

Refer to data sheets for further technical data, dimensions and options

Nameplate

For ex equipment (example)

.

11

10

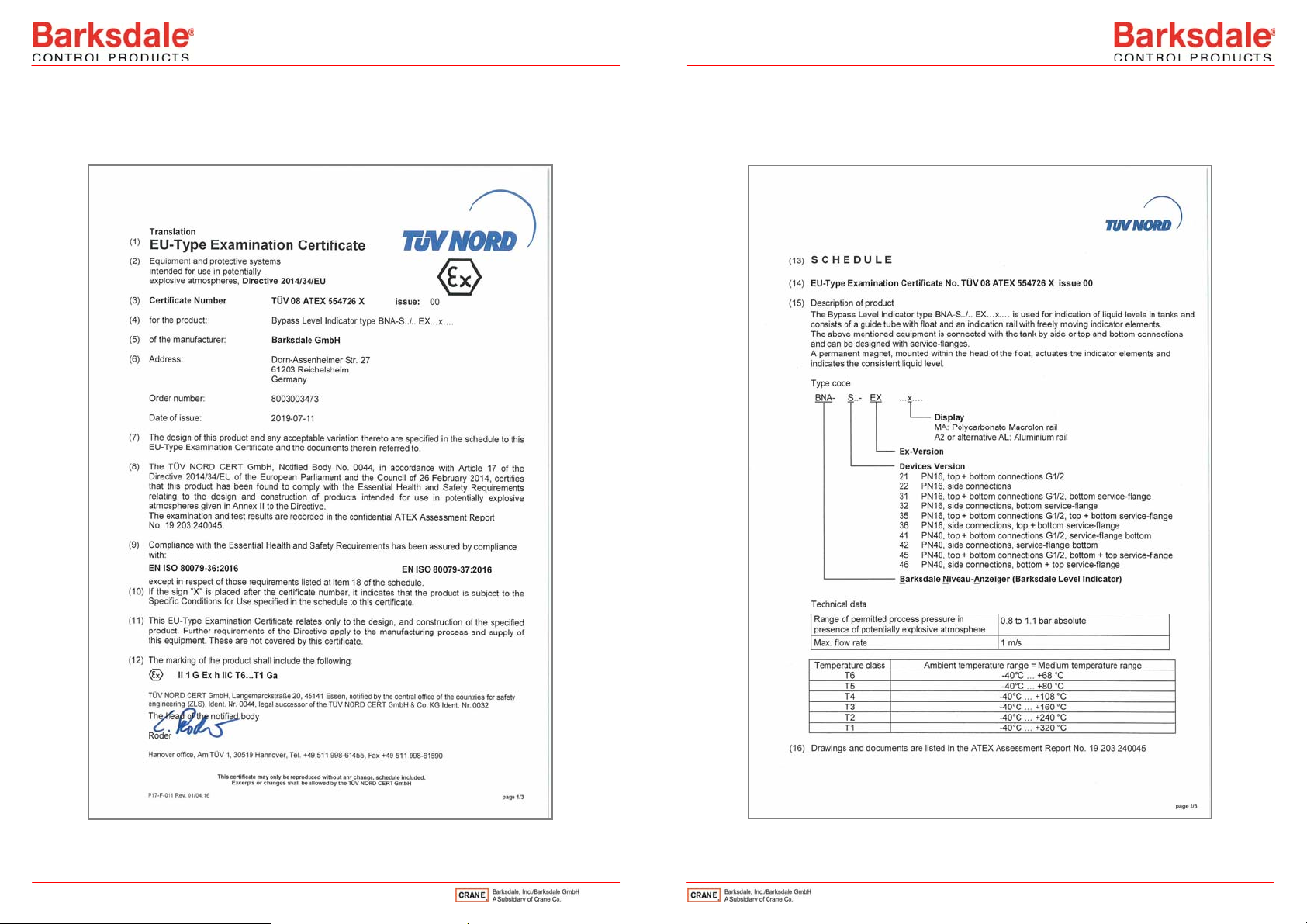

9 EU type examination certificate

Ex equipment: observe the EU type examination certificate

12 13

This manual suits for next models

7

Table of contents

Other Barksdale Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Eddyfi Technologies

Eddyfi Technologies GEKKO M2M Technical documentation

Schmidt

Schmidt Paper Schmidt PS8000 quick reference

Gemlogis

Gemlogis VISTA quick start guide

PCE Instruments

PCE Instruments PCE-DC 41 manual

CGOLDENWALL

CGOLDENWALL NDJ-5S user manual

southern electric

southern electric iplan user guide

Emerson Research

Emerson Research X-STREAM Series Instruction manual addendum

PCE Health and Fitness

PCE Health and Fitness PCE-HT 120 user manual

eXact

eXact idip quick start guide

PCB Piezotronics

PCB Piezotronics 356A36 Installation and operating manual

Gasmet

Gasmet GT5000 quick guide

Shimadzu

Shimadzu IRAffinity-1 instruction manual