Barnstead D14031 User manual

DIamond™TII

Type II water system

Operation Manual

Model No. Description Voltage

D14031 12 LPH 100V - 240V

D14041 24 LPH 100V - 240V

LT1403X8 • 10/05/06

Safety Information ..................................................................................................................................................................4

Alert Signals ....................................................................................................................................................................4

Warnings..........................................................................................................................................................................4

Introduction ..........................................................................................................................................................................6

Product Overview ............................................................................................................................................................6

General Usage ................................................................................................................................................................6

General Specifications............................................................................................................................................................7

Dimensions and Clearance Requirements......................................................................................................................7

Electrical Requirements ..................................................................................................................................................7

Feedwater Requirements ................................................................................................................................................7

DI Product Water ............................................................................................................................................................7

RO System ......................................................................................................................................................................8

RO Membrane Performance ..........................................................................................................................................8

Environmental Conditions................................................................................................................................................9

Declaration of Conformity................................................................................................................................................9

Unpacking ........................................................................................................................................................................10

Installation ........................................................................................................................................................................11

Locating Unit..................................................................................................................................................................11

Bench Mounting......................................................................................................................................................11

Wall Mounting ........................................................................................................................................................11

Installing the Control Panel in a Remote Location ........................................................................................................12

Component Installation..................................................................................................................................................13

UV Lamp Installation ..............................................................................................................................................13

Water Connection Details..............................................................................................................................................14

Push-to-Connect Fitting Tubing Installation ..........................................................................................................14

Push-to-Connect Fitting Tubing Removal ..............................................................................................................14

Tubing Adapter Fittings ..........................................................................................................................................15

Quick Disconnect Fittings ......................................................................................................................................16

Cartridge and Membrane Installation ............................................................................................................................17

Prefilter Installation..........................................................................................................................................17

MPS Cartridge Installation ..............................................................................................................................17

Carbon Filter Installation ................................................................................................................................18

RO Membrane Installation ..............................................................................................................................18

Cartridge Pack Installation ..............................................................................................................................20

Water Service Connections ..........................................................................................................................................21

Feedwater Connection ..........................................................................................................................................21

Atmospheric Drain..................................................................................................................................................21

Reservoir Connection ............................................................................................................................................21

Power Connections ......................................................................................................................................................22

Optional Accessories ....................................................................................................................................................22

Dispense Overflow Cutoff Float ............................................................................................................................23

Performing an Electronic Calibration Using the Optional N.I.S.T. Calibration Module ..........................................24

Manual Remote Dispenser and Accu DIspense™ Volumetric Remote Dispenser................................................24

Controls ................................................................................................................................................................................25

Control Panel ................................................................................................................................................................25

Buttons ........................................................................................................................................................................25

Initial Operation ....................................................................................................................................................................27

RO Membrane Rinse Up ..............................................................................................................................................27

System Sanitization Procedure ....................................................................................................................................27

Cartridge Pack Rinse Up ..............................................................................................................................................29

Operational Modes ........................................................................................................................................................29

Idle Mode................................................................................................................................................................29

Run Mode ..............................................................................................................................................................29

Standby Mode ........................................................................................................................................................30

2

Table of Contents

Flush Mode ............................................................................................................................................................30

Automatic Flush (RO Membrane) ..................................................................................................................30

Manual Flush (RO Membrane) ......................................................................................................................30

Normal Operation ..........................................................................................................................................................31

Dispensing Water ..........................................................................................................................................................31

Automatic Dispensing....................................................................................................................................................32

Reservoir Replenishment ..............................................................................................................................................32

User Settings ................................................................................................................................................................33

Setting the Displayed Language ............................................................................................................................33

Setting the Time and Date ....................................................................................................................................33

Setting the Low Product Purity Alarm ....................................................................................................................33

Setting the RO % Reject Alarm..............................................................................................................................34

Setting the Feedwater Chlorine Level....................................................................................................................34

Setting System Options ................................................................................................................................................35

Auto Standby Timer................................................................................................................................................35

Unit Under Counter ................................................................................................................................................35

Display Contrast ....................................................................................................................................................35

Set Units ................................................................................................................................................................36

Printer Attached......................................................................................................................................................36

Reservoir Type ......................................................................................................................................................37

Computer/Printer Setup ........................................................................................................................................................37

Connecting DIamond TII to Computer and Communicating Through the RS-232 Port Using Hyperterminal or Procomm ....37

Hyperterminal....................................................................................................................................................................37

Procomm ..........................................................................................................................................................................38

Connecting and Starting the Printer ........................................................................................................................................40

Maintenance and Servicing ..................................................................................................................................................40

System Sanitization ......................................................................................................................................................40

Prefilter Replacement ....................................................................................................................................................40

MPS Replacement ........................................................................................................................................................40

Carbon Replacement ....................................................................................................................................................41

Cartridge Pack Replacement ........................................................................................................................................41

RO Membrane Replacement ........................................................................................................................................42

0.2 Micron Final Filter Replacement ............................................................................................................................43

Fuse Replacement ........................................................................................................................................................44

UV Lamp Replacement ................................................................................................................................................44

Resetting Routine Timers ..............................................................................................................................................45

Prefilter, MPS, Carbon, Membrane and Cartridge Pack Timers ............................................................................45

Reservoir Vent Timer..............................................................................................................................................45

System UV Timer ..................................................................................................................................................46

Reservoir UV Timer................................................................................................................................................46

Sanitization Timer ..................................................................................................................................................46

Shutdown ......................................................................................................................................................................46

General Cleaning Instructions ......................................................................................................................................46

Troubleshooting ....................................................................................................................................................................47

System Alarms ..............................................................................................................................................................49

Routine Care ................................................................................................................................................................54

Replacement Parts ..............................................................................................................................................................55

Consumables ................................................................................................................................................................55

General Maintenance ....................................................................................................................................................56

Safety Stock ..................................................................................................................................................................56

Wiring Diagrams ..................................................................................................................................................................57

Ordering Procedures ............................................................................................................................................................59

One Year Limited Warranty ..................................................................................................................................................60

3

TABLE OF CONTENTS

Your Barnstead International DIamond TII Type II water

system has been designed with function, reliability, and

safety in mind. It is your responsibility to install it in con-

formance with local electrical codes. This manual con-

tains important safety information. You must carefully read

and understand the contents of this manual prior to the

use of this equipment. For safe operation, please pay

attention to the alert signals throughout the manual.

Water purification technology employs one or more of the

following: chemicals, electrical devices, mercury vapor

lamps, steam and heated vessels. Care should be taken

when installing, operating or servicing Barnstead

products. The specific safety notes pertinent to this

Barnstead product are listed below.

Warnings

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capacity.

2. Do not locate the DIamond TII directly over

equipment that requires electrical service.

Routine maintenance of this unit may involve

water spillage and subsequent electrical shock

hazard if improperly located.

3. Replace fuses with those of the same type and

rating.

4. Do not disassemble water lines or remove car-

tridges where spilled water could contact

equipment that requires electrical service.

Electrical shock hazard could result.

5. Power unit OFF before plugging in or unplug-

ging unit.

6. Disconnect from the power supply prior to main-

tenance and servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion may

result. This device contains components which

may ignite such materials.

4

Safety Information

Caution

Cautions alert you to a possibility of

damage to the equipment.

Warning

Warnings alert you to a possibility of

personal injury.

Note

Notes alert you to pertinent facts and

conditions.

Alert Signals

Note

The UV lamp contains mercury. If bro-

ken or no longer needed, do not dis-

pose of the UV lamp in the trash.

Recycle or dispose of the UV lamp as

hazardous waste.

2. Do not use in the presence of highly corrosive

substances such as bleach or acid baths; fire

may result.

3. This device is to be used with water feeds only.

Sanitizing agents must be used in compliance

with instructions in this manual. Failure to com-

ply with the above could result in explosion and

personal injury.

4. Avoid splashing cleaning solutions on clothing or

skin.

5. Ensure all piping connections are tight to avoid

chemical leakage.

6. Ensure adequate ventilation.

7. Carefully follow manufacturer’s safety

instructions on labels of chemical containers and

material safety data sheets.

8. This unit is equipped with an ultraviolet lamp.

Ultraviolet radiation is harmful to the eyes and

skin. Do not attempt to observe the lamp

directly.

9. Refer servicing to qualified personnel.

5

SAFETY INFORMATION

6

Introduction

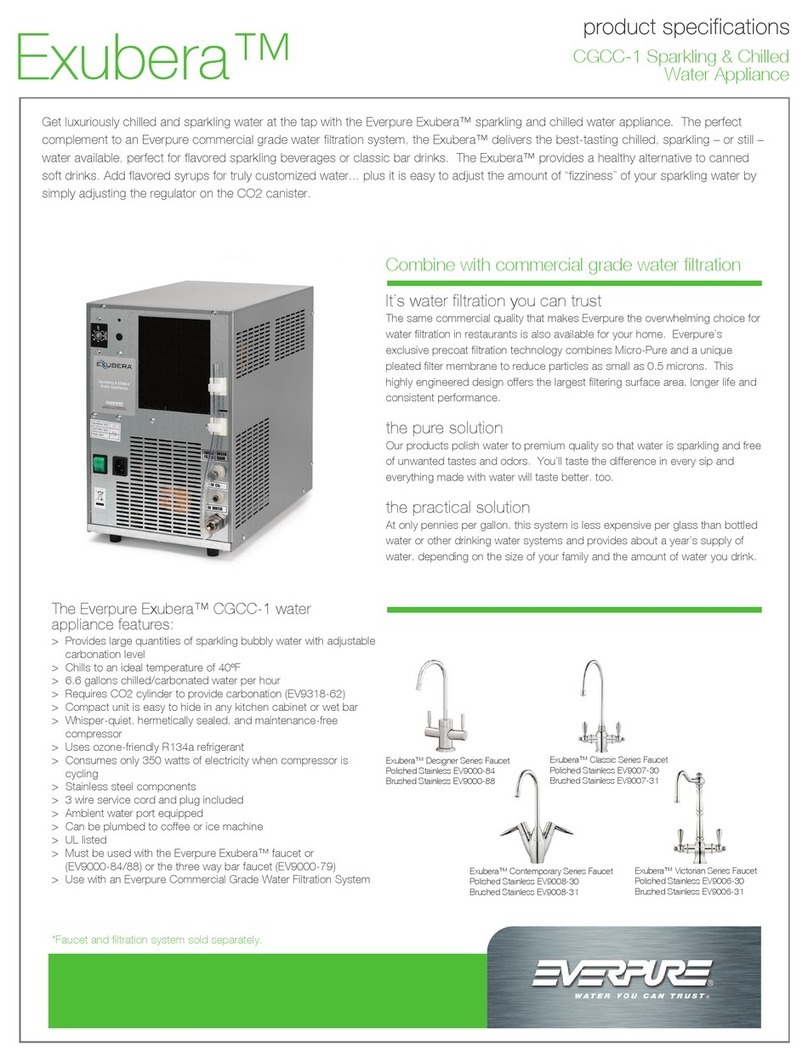

Product Overview

The Barnstead DIamond TII is a tap-fed water purification

system designed to be simple to use and to provide

reagent grade water that exceeds ASTM Type II, and

NCCLS/CAP Type I standards. It uses a thin film compos-

ite reverse osmosis membrane with pretreatment to pro-

duce RO water that is then polished using a two-stage

deionization process combined with UV oxidation and a

0.2 micron final filter.

The % of the rejection between incoming and reverse

osmosis product water is monitored and an indication is

provided to the user if the RO water quality is unaccept-

able. Incoming and RO pressure are provided by pres-

sure sensors located inside the unit. The DI water purity

is continuously sensed by a resistivity cell and displayed

on a graphical display.

RO operation is automatic and works independently of the

DI system to fill the external reservoir as determined by

sensors in the reservoir.

The DIamond TII is not shipped with pretreatment and DI

polishing cartridges or a final filter. These must be

ordered separately. The start-up kit containing these

components can be ordered using part number D502138

for all units.

The electronics can be verified and calibrated utilizing a

N.I.S.T. Traceable Calibration Module. See accessory

ordering information.

Please read the instructions carefully to ensure that you

receive maximum benefit from the DIamond TII. Also,

please fill out and return the enclosed warranty registra-

tion card as it will help us assure you of proper warranty

coverage.

General Usage

Do not use this product for anything other than its intend-

ed usage. If the equipment is used in a manner not speci-

fied by the manufacturer, the protection provided by the

equipment may be impaired.

7

Dimensions and Clearance Requirements

DIamond TII dimensions - 13.5" W X 18.5" D X 19.5" H (34.3 cm X 47.0 cm X 49.5 cm)

Clearances:

Sides - 9" (22.9 cm) minimum to allow for servicing

Above - 3" (7.6 cm) minimum for removal of top cover

Front - 4.75" (12.1 cm) minimum for opening front door

Electrical Requirements

The DIamond TII is equipped with two power cords and corresponding fuses taped to each power cord to be

plugged into a grounded electrical outlet of the appropriate voltage.

All models: 100-240 VAC +5% -10%, 47-63 Hz.

Feedwater Requirements1

Types1Tap (Potable)

Turbidity 1.0 N.T.U. maximum

Pressure Range 2 bar (30 psig) to 6.9 bar (100 psig)

Temperature Range 4-40°C (39-104°F)

Minimum Inlet Flow Requirements 100 lph

pH 3-10

TDS 600 (max. ppm as CaCO3)

Silt Density Index <5%

Free Chlorine <3 ppm

Langlier Saturation Index <1

Iron (total as Fe) <0.5 ppm

Silica <30 ppm

DI Product Water

Quality

Resistivity: ASTM Type II, NCCLS Type I >15 megohm/cm

TOC: <15 PPB

Flow Rate: up to 1 LPM with a new D3750 final filter

Bacteria: Less than 1 CFU/ml

Volumetric Dispense:

Accuracy: ±5%

Repeatability: ±3%

Feedwater suitability must be determined by a water analysis

General Specifications

1500 ppm NaCl feedwater solution @ 25°C

(77°F), @ 4.5 bar (65 psig), 15% recovery.

Flow rate and recovery will decrease with

lower water temperature and pressure.

Barnstead recommends the use of a hot

water mixing valve before the RO system for

water cooler than 15°C (59°F).

8

RO System

Model RO Product Flow Rate Recovery

D14031 12 lph ±15% (3.2 gph) 10-20%

D14041 24 lph ±15% (6.3 gph) 20-40%

RO Membrane Performance1

Rejection

Inorganic (minimum) >90%

Inorganic (typical) >95%

Particles >99%

Bacteria >99%

Organics (>300 MW) >99%

1500 ppm NaCl feedwater solution @ 25°C (77°F), @ 4.5 bar (65 psig), 15% recovery. Flow rate and recov-

ery will decrease with lower water temperature and pressure. Barnstead recommends the use of a hot water

mixing valve before the RO system for water cooler than 15°C (59°F).

GENERAL SPECIFICATIONS

9

Environmental Conditions

Operating: 15°C - 30°C; 20% - 80% relative humidity, non-condensing. Installation Category II

(overvoltage) in accordance with IEC 664. Pollution Degree 2 in accordance with IEC 664.

Altitude limit: 2,000 meters.

Storage: -25°C - 65°C; 10% to 85% relative humidity.

Declaration of Conformity

Barnstead International hereby declares under its sole responsibility that this product conforms with the tech-

nical requirements of the following standards:

EMC: EN 61000-3-2 Limits for harmonic current emissions

EN 61000-3-3 Limits for voltage fluctuations and flicker

EN 61326-1 Electrical equipment for measurement, control, and

laboratory use - EMC requirements; Part I: General

Requirements

Safety: EN 61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use;

Part I: General Requirements

per the provisions of the Electromagnetic Compatibility Directive 89/336/EEC, as amended by 92/31/EEC and

93/68/EEC, and per the provisions of the Low Voltage Directive 73/23/EEC, as amended by 93/68/EEC.

The authorized representative located within the European Community is:

Electrothermal Engineering Ltd.

419 Sutton Road

Southend On Sea

Essex SS2 5PH

United Kingdom

Copies of the Declaration of Conformity are available upon request.

GENERAL SPECIFICATIONS

10

Unpacking

Remove the unit from its shipping container and ensure that the

following items are removed from the packaging materials

before discarding:

1) DIamond TII unit

2) Approximately 6 ft. (1.83 m) of 1/4” (0.64 cm) O.D.

drain tubing (TU1190X12) with a 1/4” NPT fitting at one

end

3) Approximately 10 ft. (3.05 m) of 3/8” (0.95 cm) O.D.

feedwater tubing provided with a quick disconnect

insert on one end and a 1/4” NPT fitting on other end

(TU1119X7)

4) Two approximately 10 ft. of 3/8” O.D. tubes for fluidical-

ly connecting the unit to the storage reservoir. One tube

will have an integral shut-off connection (see Quick

Disconnect Fittings section of this manual)

5) For Model D14041 only: Membrane Reject 1 to

Membrane Feed 2 tube

6) North American power cord with attached (1.6 amp)

fuse bag (CRX72)

7) European power cord with attached (0.63 amp) fuse

bag (CRX70)

8) UV lamp (LMX13)

9) Hose barb fitting (05930BI) – Attached to unit dispens-

ing valve

10) Tube removal tool (AYX23)

11)Wall Bracket - Unit (BC1190X12)

12) Wall Bracket - Remote Display (BC1190X10)

13) Display Cable (WH1403X4)

14) Blank Display (DL1190X18)

15) Plug Adapter (CEX42)

16) If a DIamond TII storage reservoir (D14061, D14062,

D14063, D14064, D14071, D14072, D14073 or

D14074) is also purchased, see contents in separate

box.

Also required for installation: Customer-supplied fasteners to

mount unit and remote display.

11

Locating Unit

Locate storage reservoir approximately 5 ft. (1.52 m) from

the DIamond TII for electrical connections. See DIamond

TII storage reservoir manual or customer-supplied reser-

voir manual for mounting instructions. The outlet of

DIamond TII storage reservoir must be above or at

the same level as the inlet of the DIamond TII.

Bench Mounting

Place the DIamond TII on a bench top that is accessible

to electricity and an atmospherically vented drain.

Wall Mounting

Install the DIamond TII on a wall in a convenient location

that is accessible to an atmospherically vented drain and

electricity.

1. Locate the wall bracket packed separately from

the unit.

2. Using the wall bracket as a template, locate and

drill the mounting holes in the wall. A minimum

of four (customer-supplied) fasteners will be

required — two on the top and two on the bot-

tom.

3. Attach the wall bracket to the wall using cus-

tomer-supplied fasteners.

4. Remove the locking screws on each side of the

wall bracket.

5. Pull the two locking slides on each side of the

wall bracket out as far as they will go.

6. Hang the unit on the wall bracket by sliding the

mounting pins into the wall bracket slots.

7. Push the locking slides on each side of the wall

bracket in as far as they will go.

8. Replace the locking screws.

Installation

Note

Please refer to the “General

Specifications” section for clearance

requirements.

Warning

Do not locate the DIamond TII directly

over equipment that requires electrical

service. Routine maintenance of this

unit may involve water spillage and

subsequent electrical shock hazard if

improperly located.

NOTE

The outlet of DIamond TII storage

reservoir must be above or at the

same level as the inlet of the

DIamond TII.

********************

************************

Caution

Wall composition, condition and con-

struction, as well as fastener type,

must be considered when mounting

this unit. The mounting surface and

fasteners selected must be capable of

supporting a minimum of 150 lbs.(68

kg). Inadequate support and/or fasten-

ers may result in damage to mounting

surface and/or equipment. If you are

unsure of mounting surface composi-

tion, condition and construction or cor-

rect fasteners, consult your building

maintenance group or contractor.

12

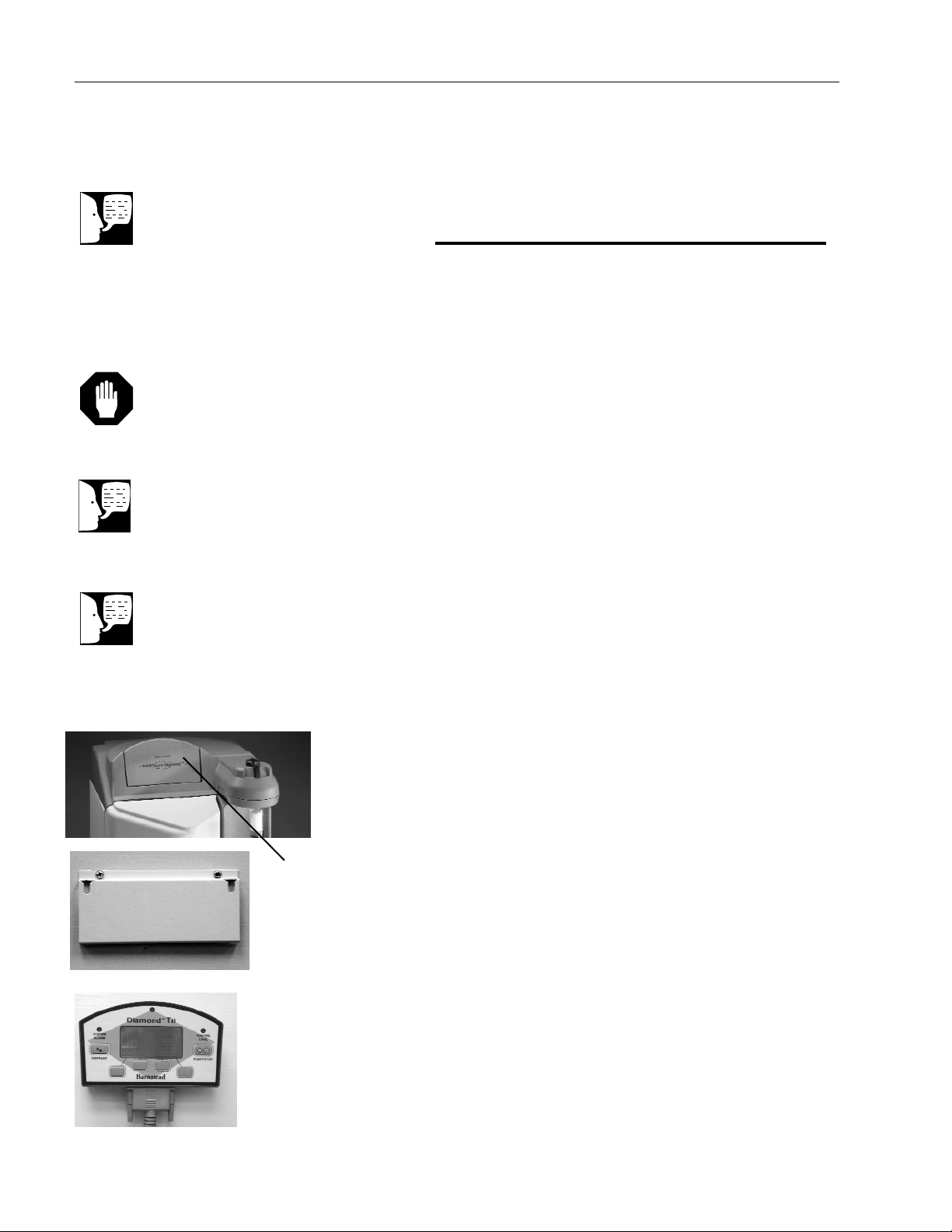

Installing the Control Panel in a

Remote Location (See Fig. 1)

For your convenience, the control panel can be removed

from the unit and mounted at a convenient location within

10 ft. (3.1 m.) of the unit. To remove the control panel

from the unit:

1. Turn the unit OFF and disconnect it from the

power supply.

2. Slide the control panel upward about 1/4” (0.64

cm) to 3/8” (0.95 cm) - (just enough to clear

connector on top cover), pull forward, and

remove. (The control panel fits tightly in the unit

so it may be difficult to remove.)

3. Replace the control panel with the blank panel

provided with the unit to protect the electrical

connector.

4. Using the display wall bracket as a template,

locate and drill the mounting holes in the wall. A

minimum of two (customer-supplied) fasteners

will be required. Attach the wall bracket to the

wall using the customer-supplied fasteners.

5. Locate the 25-pin connector on the left side of

the unit. Remove the protective cover and store

it for future use if the control panel is returned to

the top cover.

6. Locate the 10 ft. (3.1 m.) 25 pin M-F cable

included with the unit; attach the male end to

the 25 pin connector on the left side of the unit,

and the other end to the connector on the bot-

tom of the control panel.

7. Tighten the cable screws on each end to secure

the cable to the unit and control panel.

8. The control panel may now be mounted on the

wall.

9. An accessory bench mounting display bracket

(AY1367X2) can be used. Contact Barnstead

International to order.

INSTALLATION

Note

The removable control panel was not

designed to be repeatedly removed

from the unit, therefore, you may

experience difficulty when attempting

to remove it. It is therefore

recommended that the control panel

be permanently mounted in a remote

location or remain intact with the unit.

Caution

Repeated removal and replacement of

the control panel from the top cover

may eventually cause it to become

damaged.

Note

The protective cover on the rear side

panel display connector should remain

in place when the display is not

remotely located.

Blank panel

Control Panel Wall Mount Bracket

Figure 1: Mounting the

Control Panel

Note

Abracket is available that will allow

you to mount the control panel on the

bench. If bench mounting is desired,

please order bracket AY1367X2.

Control Panel Mounted in Remote Location

13

Component Installation

UV Lamp Installation (See Fig. 7)

Locate the UV chamber inside the left door of the

DIamond TII. Install the UV Lamp as follows:

1. Disconnect the power cord from the unit.

2. Access the left side of the unit by unlatching the

screw securing the door with a flathead screw-

driver. Open the door.

3. Remove the UV lamp from its packaging. DO

NOT TOUCH THE GLASS PORTION OF THE

LAMP! It is recommended that lint-free gloves

be worn when handling the lamp. The glass por-

tion must be free of fingerprints, perspiration,

etc. Even a light coating of perspiration will

reduce the effectiveness of the lamp. If the glass

portion of the lamp is touched, clean it with a

damp, lint-free cloth: use isopropyl alcohol as

required.

4. Remove black cap by sliding it off of UV cham-

ber.

5. Insert the lamp halfway into the UV lamp cham-

ber and plug it in, then fully insert the lamp into

the chamber, and replace black cap.

6. Make sure the UV lamp cable is tucked behind

the chamber before closing and relatching the

door.

7. Reset the UV lamp timer as directed in the

“Resetting Routine Timers” section of this manu-

al.

INSTALLATION

Caution

DO NOT TOUCH THE GLASS POR-

TION OF THE LAMP! It is recom-

mended that lint-free gloves be worn

when handling the lamp. The glass

portion must be free of fingerprints,

perspiration, etc. Even a light coating

of perspiration will reduce the effec-

tiveness of the lamp. If the glass por-

tion of the lamp is touched, clean it

with a damp, lint-free cloth: use

isopropyl alcohol as required.

Note

The UV lamp contains mercury. If

broken or no longer needed, do not

dispose of the UV lamp in the trash.

Recycle or dispose of the UV lamp as

hazardous waste.

14

Water Connection Details

Push-to-Connect Fitting Tubing

Installation (Refer to Fig. 2)

The following instructions will apply when you need to

attach a piece of tubing to your DIamond TII during instal-

lation, unless otherwise noted in the installation instruc-

tions. To make tubing connections:

1. Make sure the tubing is cut off reasonably

square and that no plastic burrs or ridges

are present.

2. Mark from end of tube an insertion length of 3/4”

(1.9 cm).

3. Wet the tube end with water and insert the tube

straight into the fitting until it bottoms out on the

interior shoulder and the insertion mark is no

longer visible.

Push-to-Connect Fitting Tubing Removal

(Refer to Fig. 3)

1. Using the tool provided (AYX23), push the collet

toward the body while pulling on the tubing to

release the tube.

INSTALLATION

COLLET

TUBING

TYPICAL

FITTING

3/4"

Insertion

Length

Figure 2

Tubing Installation

Note

For easier insertion, wet the end of

the tubing with water.

Note

Figure 2 and 3 will be used at the

connection to the atmospheric drain.

Figure 3

Tubing Removal

TUBE REMOVAL TOOL

TUBING

COLLET

TYPICAL FITTING

PLACE REMOVAL TOOL UP AGAINST

COLLET AND PUSH FORWARD WHILE

SIMULTANEOUSLY PULLING THE TUBE

BACK

PULL TUBING

15

Tubing Adapter Fittings

1. Completely disassemble the fitting. Refer to

Figure 4 to familiarize yourself with the names

of the component parts.

2. Make sure the tubing is cut off reasonably

square and that no plastic burrs or ridges are

present.

3. Place the grab ring and back-up ring in the hex

nut in the order and orientation shown in

Figure 4. Thread the nut onto the adapter. DO

NOT use the o-ring at this time.

4. Push the tubing through the nut until it bottoms

out in the adapter.

5. Remove the adapter nut and tubing. Place the

o-ring over the tubing. Be careful not to push

the back-up ring or grab ring further back on

the tubing when installing the o-ring.

6. Install the hex nut on the adapter and hand

tighten.

INSTALLATION

Figure 4: Typical Polypropylene Tubing Adapter Installation

Caution

Do not tighten tube fitting hex nut with

a wrench. Tight connections can be

easily made by hand.

16

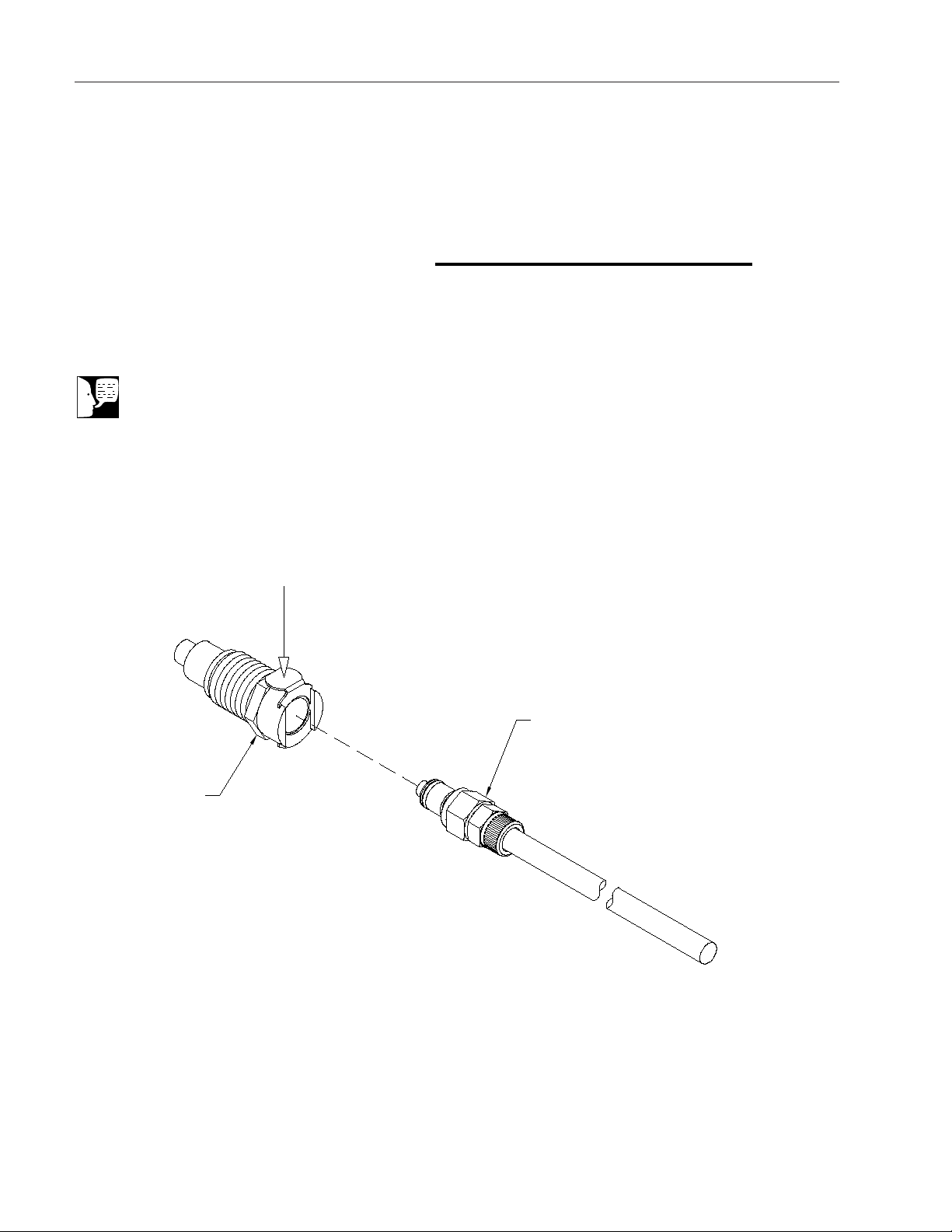

Quick Disconnect Fittings

These fittings are found on the water inlet. (See Fig. 5)

To insert the inlet tubing:

1. Press on the metal thumbpad on the coupling

body to ensure the fitting is open.

2. Wet the o-ring on the coupling insert and push

into the coupling body until you hear a click.

Gently pull on the tubing to ensure it is secure.

3. To remove, press the metal thumbpad to release

and pull coupling insert out.

INSTALLATION

Coupling Insert

Push down on thumbpad

to release coupling insert

Coupling Body

Figure 5: Quick Disconnect

Note

The quick disconnect fittings contain

valves and if not properly inserted

water will not flow.

17

Cartridge and Membrane

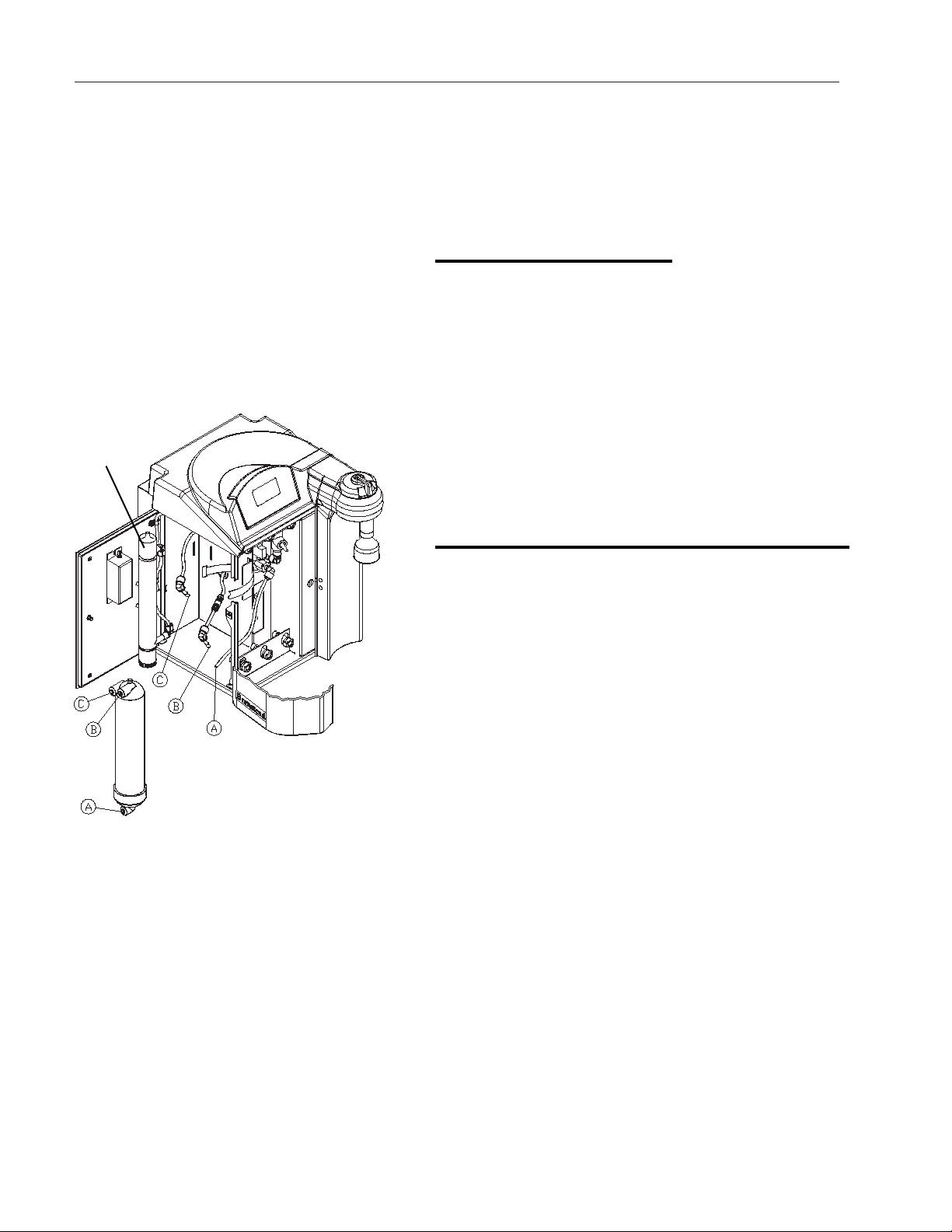

Installation (See Fig. 6)

Your DIamond TII has been shipped with one membrane

(for 12 lph unit) or two membranes (for 24 lph unit), that

you will install. The Startup Kit (D502138) includes a pre-

filter, MPS cartridge and carbon filter, and must be pur-

chased separately. To prepare your DIamond TII for opera-

tion, disconnect the unit from the power supply if connect-

ed.

Prefilter Installation

Particulates can damage your membranes, resulting in

premature membrane failure. Therefore, your DIamond TII

uses a prefilter to remove particulates from your feed

water. Install the prefilter as follows:

1. Open the front left door.

2. Remove the prefilter (Part Number D502113)

from its packaging and wet the o-rings with water.

3. Insert the prefilter upright into the left position

upper and lower quick disconnects and push until

firmly connected. For easier installation, connect

bottom first.

MPS Cartridge Installation

The MPS cartridge contains a slow dissolving anti-scalant

material. The anti-scalant material combines with water to

prevent scale buildup on the membrane surface.

Install the MPS cartridge as follows:

1. Remove the MPS cartridge (Part Number

D502114) from its packaging and wet the o-

rings with water.

2. Insert the MPS cartridge upright into the middle

position upper and lower quick disconnects and

push until firmly connected. For easier installa-

tion, connect bottom first.

INSTALLATION

Figure 6: Cartridge Installation

Prefilter

MPS cartridge

Carbon filter

Note

Figure 2 shows the correct

sequence of prefilter, MPS and

carbon filters. Cartridges must be

installed in the correct order to

operate properly.

Note

It will be important to replace

the MPS cartridge once the

material is half dissolved.

Carbon Filter Installation

Chlorine can also damage your membranes, resulting in

premature membrane failure. Therefore, your DIamond TII

uses an extruded carbon filter to remove chlorine from your

feed water.

Install the carbon filter as follows:

1. Remove the carbon filter (Part Number D502115)

from its packaging and wet the o-rings with water.

2. Insert the carbon filter straight into the right posi-

tion upper and lower quick disconnect and push

until firmly connected. For easier installation, con-

nect bottom first.

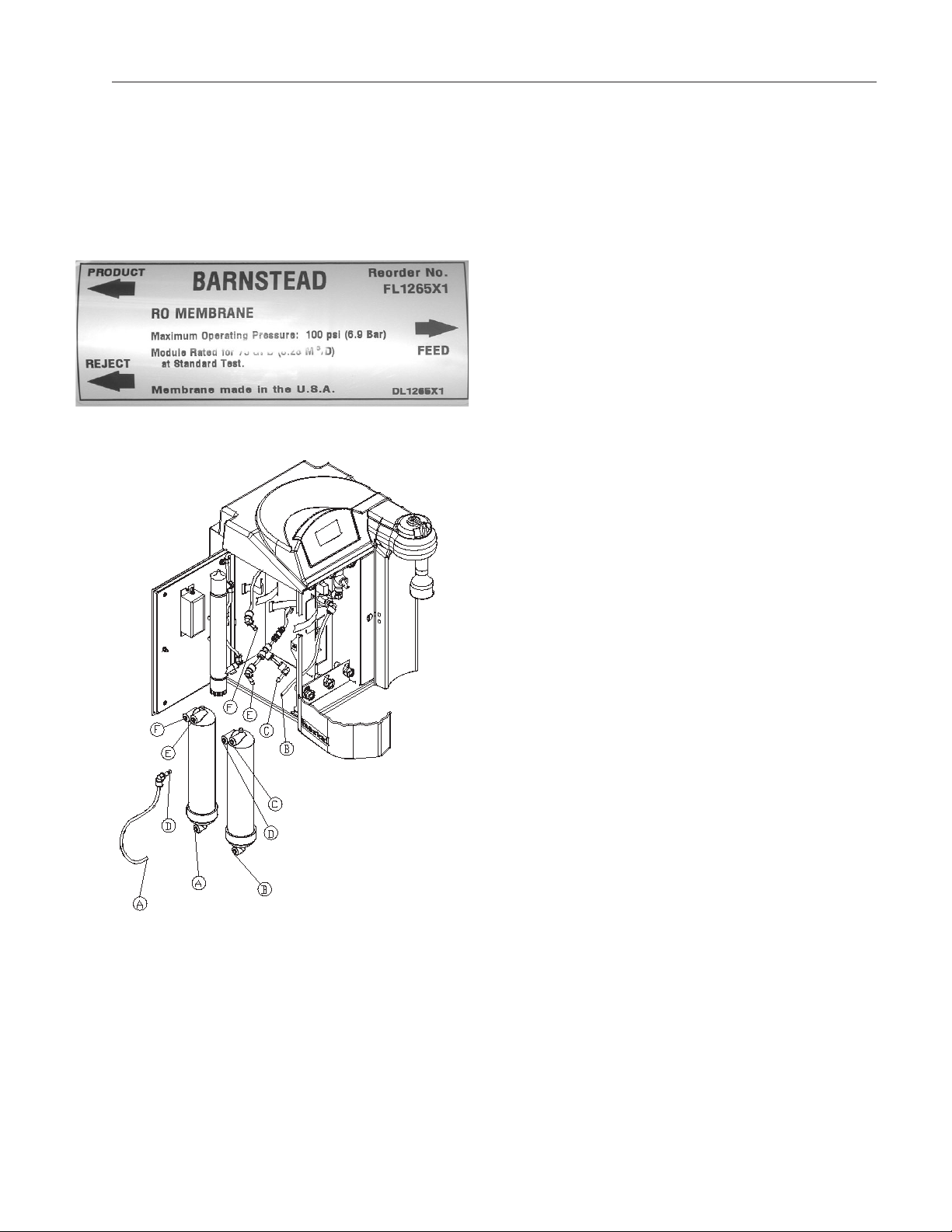

RO Membrane Installation (See Fig. 7 - 10)

12 LITER PER HOUR UNITS (1 MEMBRANE)

1. Remove the RO membrane from its packaging.

Note the location of the FEED, PRODUCT, and

REJECT connections on the membrane. The cor-

rect orientation for the installed membrane will be

vertical, with the Feed connection on the bottom.

See Figure 8.

2. Open the left side door on the DIamond TII.

3. Referencing Figure 7, locate the three unconnect-

ed tubes (two with elbows, one without) labeled

FEED (A), PRODUCT (B) and REJECT (C). Refer

to “Tubing Installation: Figure 2” and mark FEED

(A) tubing 3/4” (1.9 cm) from end.

4. Make FEED (A) connection by first wetting the

tube with water and pushing it firmly into the mem-

brane connector. See Figure 7.

5. Using the Velcro®strap secure the membrane into

the right most position against the bracket.

6. Make the PRODUCT (B) and REJECT (C) connec-

tions by first wetting the tube stem of the elbow

with water and pushing it firmly into the membrane

connector. See Figure 7.

INSTALLATION

Figure 7: 12 lph RO Membrane Installation

UV Lamp

Velcro®is a registered trademark of

Velcro Industries B.V. Ltd Liab Co. Netherlands

Castorweg 22-24 Curacao Netherlands Antilles

18

7. The door can remain open until the unit has

been operating and you have checked for possi-

ble water leaks at the membrane connections.

8. Rinse membrane per the instructions in the

“Initial Operation” section of this manual.

24 LITER PER HOUR UNITS (2 MEMBRANES)

1. Remove the RO membranes from their packag-

ing. Note the location of the FEED, PRODUCT,

and REJECT connections on the membrane.

See Figure 9. The correct orientation for the

installed membrane will be vertical with the

Feed connection on the bottom. See Figure 8.

2. Open the left side door on the Diamond TII.

3. Locate the four unconnected tubes (three with

elbows, one without) labeled FEED 1, PROD-

UCT, PRODUCT and REJECT 2. Refer to

“Tubing Installation: Figure 2” and mark FEED 1

tubing 3/4” (1.9 cm) from end.

4. Find the tube with the elbow labeled FEED 2

and REJECT 1 packaged with the unit. Refer to

“Tubing Installation: Figure 2” and mark FEED 2

end of the tube 3/4” (1.9 cm) from end.

5. Make FEED 2 (A) connection by first wetting the

tube with water and pushing it firmly into the

membrane connector. See Figure 9. Using the

Velcro®strap secure the membrane into the left

most position against the chassis walls. See

Figure 9.

6. Make the FEED 1 (B) connection by first wetting

the tube end and push firmly into the membrane

connector. Using the Velcro®strap secure the

membrane into the right most position against

the bracket. See Figure 9.

7. Make the PRODUCT (C) and REJECT 1 (D)

connections on right most membrane by first

wetting the tube stem of the elbow with water

and pushing it firmly into the connector. See

Figure 9.

INSTALLATION

Figure 8: Membrane Housing Label

Figure 9: 24 lph RO Membrane Installation

19

20

8. Make the PRODUCT (E) and REJECT 2 (F)

connections on left most membrane by first wet-

ting the tube stem of the elbow with water and

pushing it firmly into the connector. See Figure

9.

9. The door can remain open until the unit has

been operating and you have checked for possi-

ble water leaks at the membrane connections.

10. Rinse membranes per the instructions in the

“Initial Operation” section of this manual.

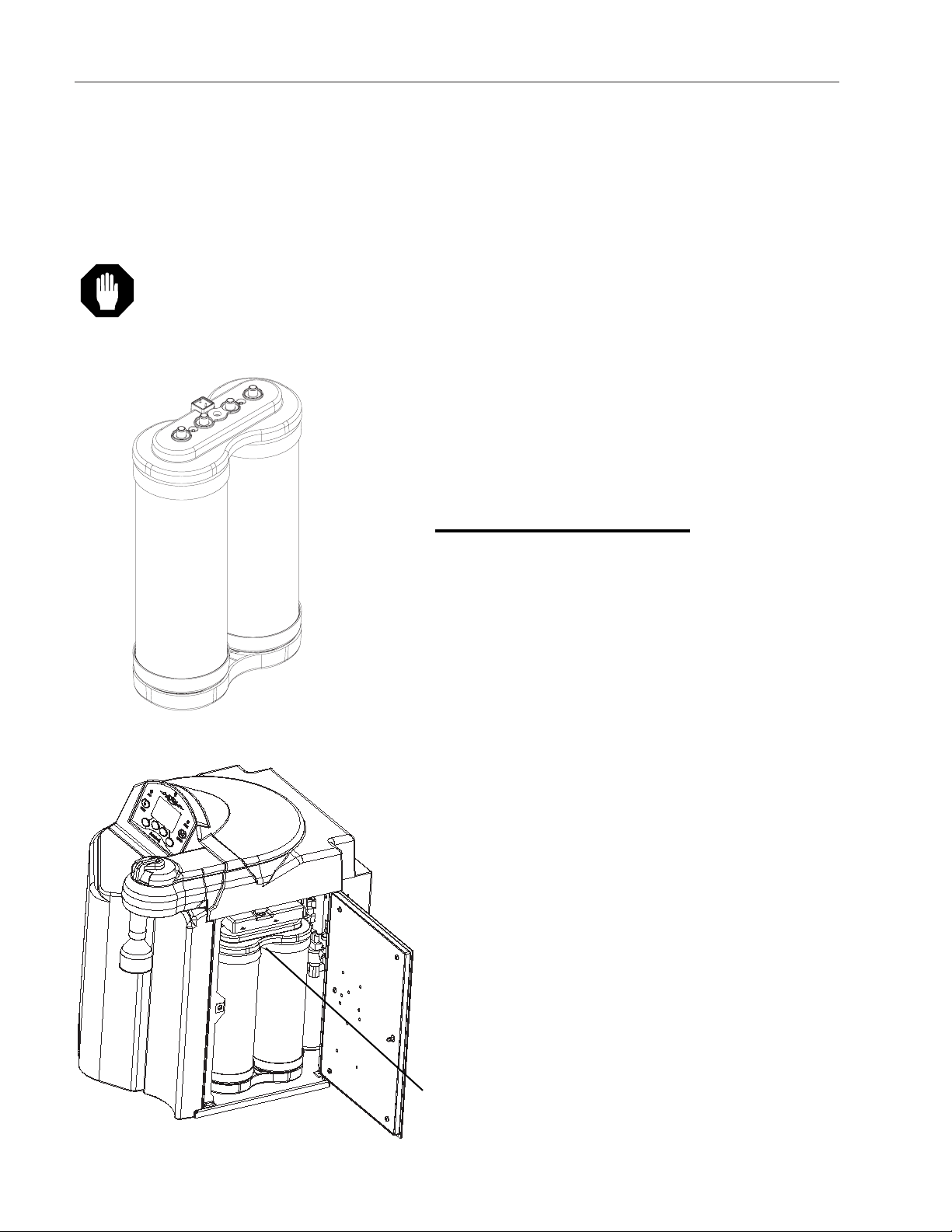

Cartridge Pack Installation

Cartridge packs will come bagged with four manifold

connection caps.

Each cartridge pack includes one 0.2 micron absolute

final filter.

1. Open right side door. Remove the four caps

from the top of the cartridge pack.

2. Verify that each of the four posts on the car-

tridge pack has an o-ring.

3. Lift unit manifold upward, insert cartridge pack

and align the pack so that it mates with the unit

manifold.

4. Lower unit manifold until it is flush with the top

of the cartridge pack.

5. Hand tighten wing head screw securely.

6. Close door.

7. DO NOT install the 0.2 micron filter and bell

assembly at this time.

INSTALLATION

Caution

Do not allow the DIamond TII to oper-

ate unless water is available to the

unit.

Figure 10: Dual Cartridge Pack

Figure 11: Cartridge Pack Installed

Note orientation of top cartridge

pack manifold

This manual suits for next models

3

Table of contents

Popular Water System manuals by other brands

Watts

Watts GTS450C Installation, operation and maintenance manual

Zip

Zip HydroTap G4 Installation and operating instructions

Watts

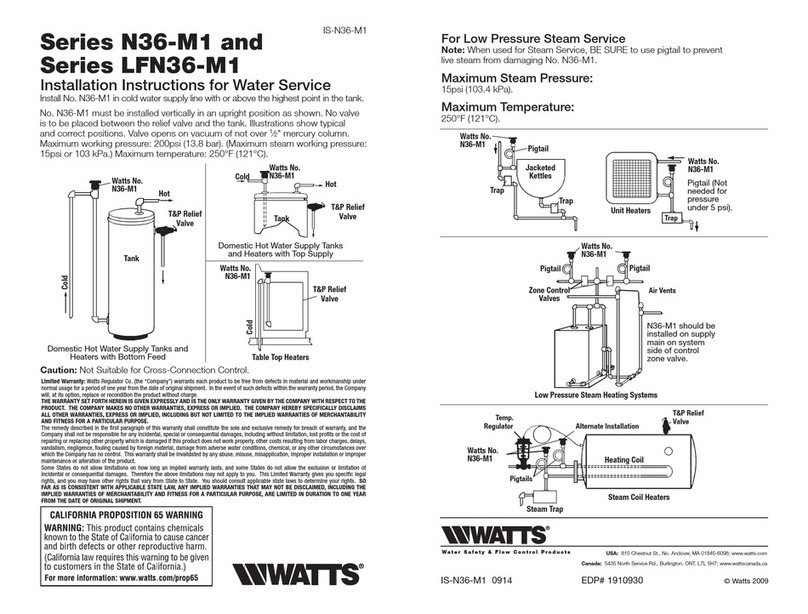

Watts Series N36-M1 installation instructions

AmeriWater

AmeriWater GRUNDFOS CHI Operation & maintenance manual

VacPak-It

VacPak-It SVC100 quick start guide

Technosmart

Technosmart Atmopure 320 manual