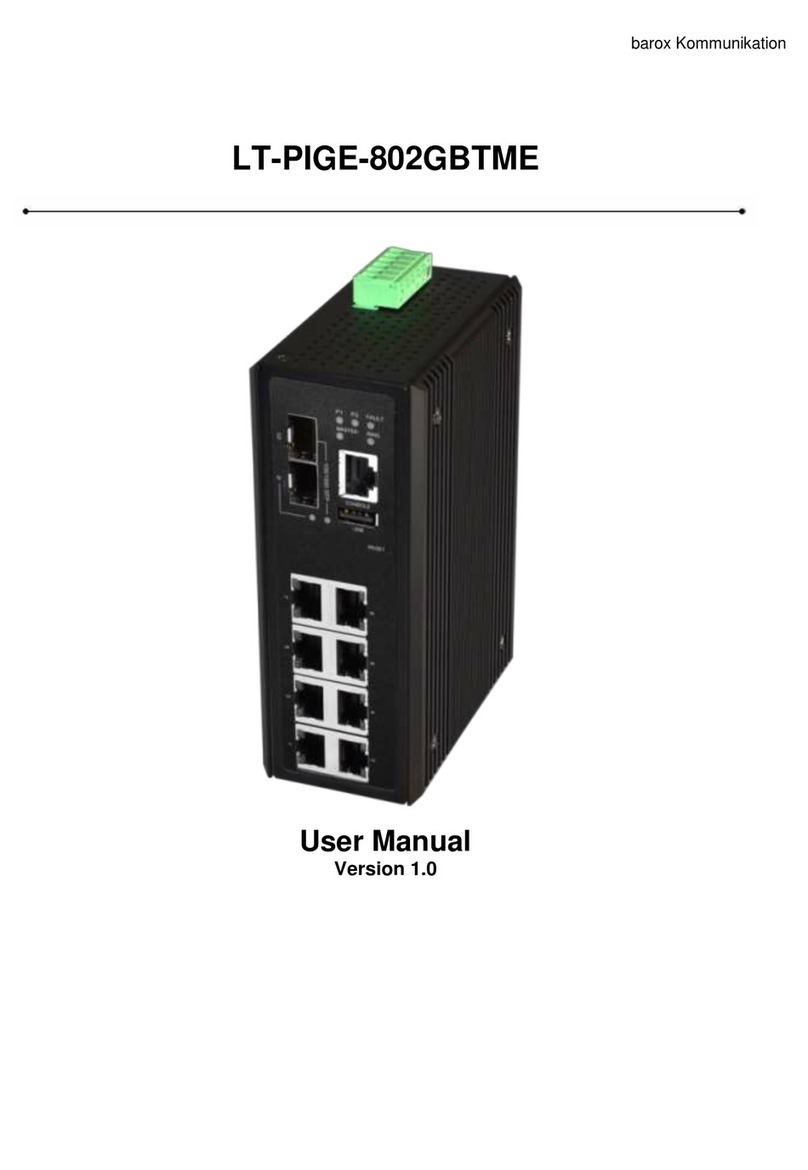

Barox LT-PIGE-804GBTME Series User manual

LT-PIGE-804GBTME

User Manual

Version 1.0

All Rights Reserved

This document contains information, which is protected by copyright. Reproduction, adaptation or

translation without prior permission is prohibited, except as allowed under the copyright laws.

Disclaimer

Barox Kommunikation provides this manual without warranty of any kind, expressed or implied,

including but not limited to the implied warranties of merchantability and fitness for a particular

purpose. Barox Kommunikation may make improvements and/or changes to the product and/or

specifications of the product described in this manual, without prior notice. Barox Kommunikation will

not be liable for any technical inaccuracies or typographical errors found in this guide. Changes are

periodically made to the information contained herein and will be incorporated into later versions of

the manual. The information contained is subject to change without prior notice.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class-A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy. It may cause harmful interference to radio communications if the equipment is not

installed and used in accordance with the instructions. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio/TV technician for help.

Caution: Any changes or modifications not expressly approved by the grantee of this device could void

the user's authority to operate the equipment.

CE Mark Warning

This is a Class-A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Industrial Ethernet Switches

Industrial Grade Gigabit Managed Ethernet Switches

User Manual

Version 1.0 (August 2015)

Contents

Overview.....................................................................................................................................................................1

Software Features...................................................................................................................................................1

Hardware Features .................................................................................................................................................2

Package Contents...................................................................................................................................................3

Safety Precaution....................................................................................................................................................3

Hardware Description.................................................................................................................................................4

Physical Dimensions...............................................................................................................................................4

Front Panel..............................................................................................................................................................5

Top View ................................................................................................................................................................. 5

LED Indicators.........................................................................................................................................................6

Ethernet Ports .........................................................................................................................................................7

Cabling....................................................................................................................................................................8

Wiring the Power Inputs........................................................................................................................................11

Wiring the Fault Alarm Contact.............................................................................................................................12

Mounting Installation.................................................................................................................................................13

DIN-Rail Mounting.................................................................................................................................................13

Wall Mounting .......................................................................................................................................................15

Hardware Installation................................................................................................................................................16

Installation Steps...................................................................................................................................................16

Trouble Shooting ......................................................................................................................................................17

Technical Specification.............................................................................................................................................18

1

Overview

This series is rated IP30 and installation by DIN Rail. Each unit of this industrial gigabit managed

Ethernet switch series has 8 IEEE 802.3at compliant ports (30W/port) and 4 dual-rate (100/1000) SFP

slots, suitable for applications that require high bandwidth and long distance communication.

In order to prevent unregulated voltage, this series provides high EFT and ESD protection. This also

allows it to function in harsh environments, as well as support power redundancy with a dual power

input design with reverse polarity protection. The built-in relay warning function alerts users about

occurring power failures.

With one model having an operating temperature of , and another with a wide operating temperature

of -40°C ~ 75°C, this series is designed to meet any needs for industrial automation, outdoor

application and harsh environments.

Software Features

Network Redundancy

STP, RSTP, MSTP, ITU-T G.8032 Ethernet Ring Protection Switch (ERPS) for network redundancy

Configuration

Web UI based management, Telnet, Serial Console, Cisco-like CLI, TFTP, SSH, SSL, SNMP

v1/v2c/v3, RMON, USB

Network Management

Qos, traffic classification QoS, Cos, bandwidth control for Ingress and Egress, broadcast storm

control, Diffserv

IEEE802.1Q VLAN, management VLAN supported

IGMP snooping v1/v2, IGMP filtering / throttling, IGMP query up to 256 group

DHCP Client/Server/Relay with Option 82

Internet Protocol Version 6 (IPv6)

PoE Status, Monitoring

RMON, MIB II, NTP/SNTP, uPnP, Modbus/TCP

Security Features

MAC based port security, static MAC address

Access Control List(ACL), 802.1X authentication, RADIUS

SNMP v3 encrypted authentication and access

PoE Ports Management

Port Status, Statistics, Monitoring

Auto powered device (PD) detection

Auto reset (cycle power to unresponsive PD)

2

PoE ports weekly power scheduling

Port Configuration

Port Status, Statistics, Monitoring, Mirroring, Security, and Rate Limiting, SFP DDM

Event Handling

Event notification by Email: Cold/Warm Start, Power Failure, Authentication, SNMP trap and

Fault Alarm Relay Output

Software Upgrade

TFTP, Web GUI, CLI

USB Port

Configuration Backup

Hardware Features

Interface & Performance

All Copper ports support auto MDI/MDI-X function

Embedded 8*10/100/1000Tx (PSE 30W/Port) and 4*100/1000 SFP Slots

Store-and-forward switching architecture

8K MAC Address Table

Supports 9.6Kbytes Jumbo Frame

2,000VDC Power line EFT protection & 6000VDC Ethernet ESD protection

Power Input

DC 48-55V redundant power

Operating Temperature

Standard operating temperature model: -10°C ~ 65°C

Extended operating temperature model (–T): -40°C ~ 75°C

Case/Installation

IP30 protection

Installation in pollution degree to environment

DIN-Rail and Wall mount design

3

Package Contents

1 - LT-PIGE-804GBTME: 12-port industrial PoE+ gigabit managed Ethernet switch, with

8*10/100/1000Tx (PSE 30W/Port) and 4*100/1000 SFP Slots

1 - User manual CD

2 - Wall mounting brackets and screws

1 - RJ45 to DB9 Serial Console cable

1 - DC cable - 18 AWG & DC jack 5.5x2.1mm

Safety Precaution

Attention

If the DC voltage is supplied by an external circuit, please use a protection device on the power supply

input. Supply by UL Listed industrial use power. The industrial Ethernet switch’s hardware specs, ports,

cabling information, and wiring installation will be described within this user manual.

4

Hardware Description

Physical Dimensions

Figure 2.1, below, shows the physical dimensions of LT-PIGE-804GBTME series: 12-port industrial

PoE+ gigabit managed Ethernet switch, with 8*10/100/1000Tx (PSE 30W/Port) and 4*100/1000 SFP

Slots.

(W x H x D) is 46mm x 142mm x 99mm

Figure 2.1: LT-PIGE-804GBTME Series Physical Dimensions

5

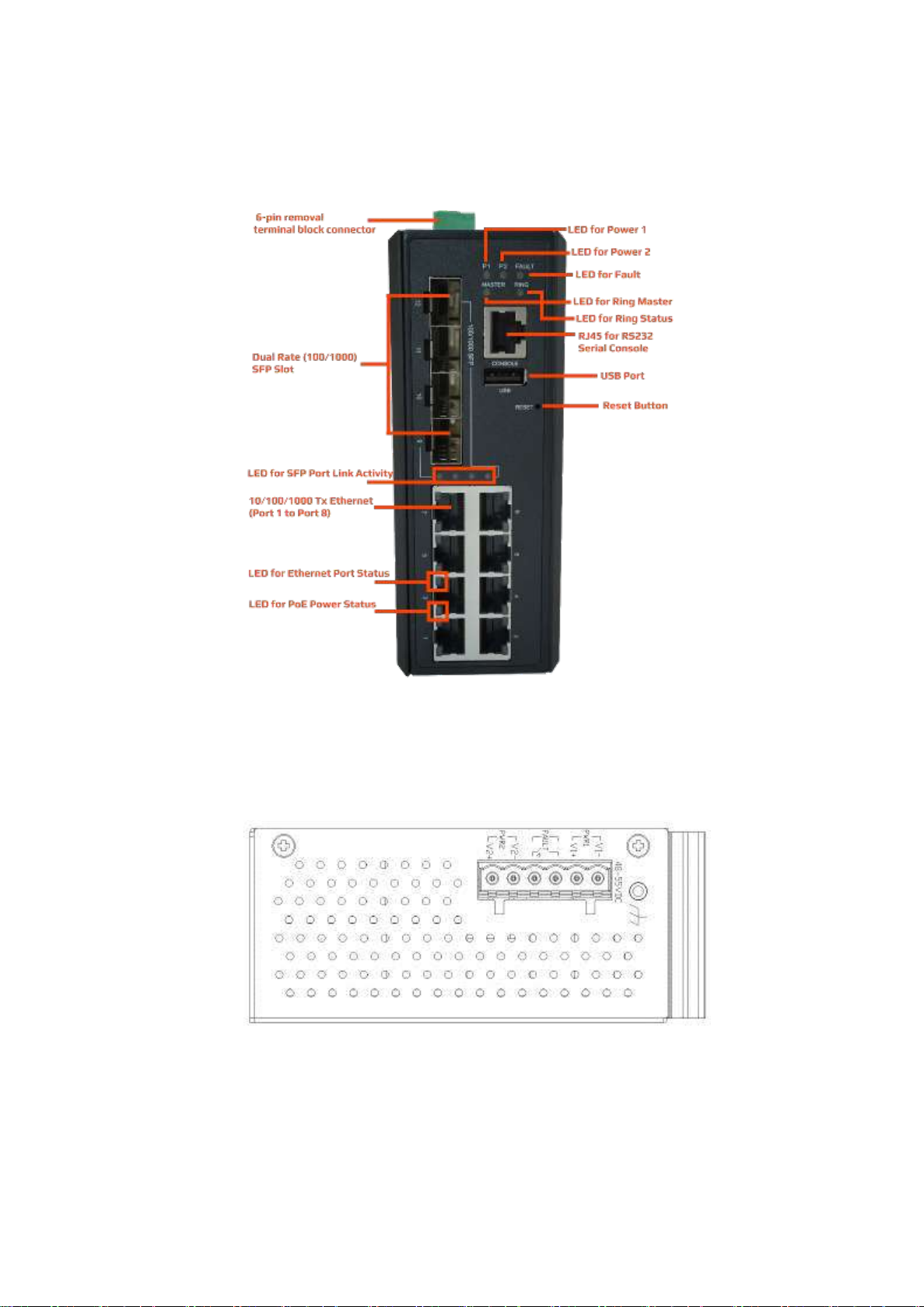

Front Panel

The front panel of the LT-PIGE-804GBTME series industrial PoE+ gigabit managed Ethernet switch is

shown below in Figure 2.2.

Figure 2.2: The Front Panel of LT-PIGE-804GBTME Series

Top View

Figure 2.3, below, shows the top panel of the LT-PIGE-804GBTME series switch that is equipped with

one 6-pin removal terminal block connector for dual DC power inputs (48-55VDC).

Figure 2.3: Top Panel View of LT-PIGE-804GBTME Series

6

LED Indicators

There are LED light indicators located on the front panel of the industrial Ethernet switch that display

the power status and network status. Each LED indicator has a different color and has its own specific

meaning, see below in Table 2.1.

LED

Color

Description

P1

Green

On

Power input 1 is active

Off

Power input 1 is inactive

P2

Green

On

Power input 2 is active

Off

Power input 2 is inactive

Fault

Green

On

System is ready

Off

System is booting

Red

On

Fault alarm event triggered

Off

Normal state

Master

Green

On

ERPS Owner Mode (Ring Master) is ready

Off

ERPS Owner Mode is not active

Ring

Green

On

Ring Network is active and works well

Flashing

Ring works abnormally or misconfigure

Off

Ring Network is not active

LINK/ACT

(SFP Port)

Green

On

Connected to network

Flashing

Networking is active with 1000Mbps

Off

Not connected to network

Amber

On

Connected to network

Flashing

Networking is active with 100Mbps

Off

Not connected to network

LAN Port 1-8

(Left LED)

Green

On

Connected to network, 10/100/1000Mbps

Flashing

Networking is active

Off

Not connected to network

LAN Port 1-8

(Right LED)

Green

On

The port is supplying power to the powered-device

Off

No powered-device attached or power supplying fails

Table 2.1: LED Indictors for LT-PIGE-804GBTME Series

7

Ethernet Ports

RJ-45 Ports(Auto MDI/MDIX)

The RJ-45 ports are auto-sensing for 10Base-T, 100Base-TX or 1000Base-T devices connections. Auto

MDI/MDIX means that the switch can connect to another switch or workstation without changing the

straight-through or crossover cabling. See the figures as below for straight-through and crossover

cabling schematics.

RJ-45 Pin Assignments (Table 2.2)

Table 2.2: RJ-45 Pin Assignments

Note: “+” and “-” signs represent the polarity of the wires that make up each wire pair.

All ports on this industrial Ethernet switch support automatic MDI/MDI-X operation. Users can use

straight-through cables (see Figure 2.4) for all network connections to PCs, servers, other switches or

hubs. With straight-through cable, pins 1, 2, 3, and 6, at one end of the cable, are connected straight

through to pins 1, 2, 3 and 6 at the other end of the cable. The table below (Table 2.3) shows the

10BASE-T, 100BASE-TX, 1000BASE-TX MDI and MDI-X port pin outs.

Table 2.3: Ethernet Signal Pin Outs

The following figures show the cabling schematics for straight-through and crossover.

Figure 2.4: Straight-Through Cable Schematic

Figure 2.5: Crossover Cable Schematic

8

The following figures show the 10,100, and 1000 Ethernet RJ-45 pin outs.

Figure 2.6: RJ45 Ethernet Port Pin Outs

Figure 2.7: Straight-Through Cable Schematic

Figure 2.8: Crossover Cable Schematic

Cabling

Use the four twisted-pair, category 5e, or the above cabling for RJ-45 port connections. The cable

between the switch and the link partner (switch, hub, workstation, etc.) must be less than 100 meters

(328 ft.) long.

The small form-factor pluggable (SFP) is a compact optical transceiver used in optical communications

for both telecommunication and data communication applications.

9

To connect the transceiver and LC cable, please follow below steps:

Step 1. Insert the SFP transceiver module into the SFP slot as shown below in Figure 2.9. Notice that

the triangle mark is at the bottom of the SFP slot. Figure 2.10 shows SFP transceiver module

was inserted.

Figure 2.9: Transceiver to the SFP Module

Figure 2.10: Transceiver Inserted

Step 2. Insert the fiber cable of the LC connector into the transceiver as shown below in Figure 2.11.

Figure 2.11: LC Connector to the Transceiver

10

To remove the LC connector from the transceiver, please follow the steps shown below:

Step 1. Press the upper side of the LC connector from the transceiver and pull it out to release as

shown below in Figure 2.12

Figure 2.12: Remove LC Connector

Step 2. Push down the metal clasp and pull the transceiver out by the plastic part as shown below in

Figure 2.13

Figure 2.13: Pull Out from the SFP Module

11

Wiring the Power Inputs

Please follow the below steps to insert the power wire.

Step 1. Insert the positive and negative wires into the PWR1 (V1+, V1-) and PWR2 (V2+, V2-) contacts

on the terminal block connector as shown below in Figure 2.14.

Figure 2.14: Power Terminal Block

Step 2. Tighten the wire-clamp screws to prevent the wires from loosening, as shown below in Figure

2.15.

Figure 2.15: Power Terminal Block

Note:

Only use copper conductors, 60/75°C, tighten to 5 lbs.

The wire gauge for the terminal block should range between 18~20 AWG.

12

Wiring the Fault Alarm Contact

The fault alarm contact is in the middle of the terminal block connector as the picture shows below in

Figure 2.16. By inserting the wires, it will detect the fault status including power failure or port link

failure (managed industrial switch only) and form a normally open circuit. An application example for

the fault alarm contact is shown below in Figure 2.16.

Figure 2.16: Wiring the Fault Alarm Contact

Note:

The wire gauge for the terminal block should range between 12 ~ 24 AWG.

If only using one power source, jumper Pin 1 to Pin 5 and Pin 2 to Pin 6 to eliminate power

fault alarm.

13

Mounting Installation

DIN-Rail Mounting

The DIN-Rail is pre-installed on the industrial Ethernet switch from the factory. If the DIN-Rail is not on

the industrial Ethernet switch, please see Figure 3.1 to learn how to install the DIN-Rail on the switch.

Figure 3.1: The Rear Side of the Switch and DIN-Rail Bracket

Follow the steps below to learn how to hang the industrial Ethernet switch.

Step 1. Use the screws to install the DIN-Rail bracket on the rear side of the industrial Ethernet

switch.

Step 2. To remove the DIN-Rail bracket, do the opposite from Step 1.

Step 3. After the DIN-Rail bracket is installed on the rear side of the switch, insert the top of the DIN-

Rail on to the track as shown below in Figure 3.2.

14

Figure 3.2: Insert the Switch on the DIN-Rail

Step 4. Lightly pull down the bracket on to the rail as shown below in Figure 3.3.

Figure 3.3: Stable the Switch on DIN-Rail

Step 5. Check if the bracket is mounted tightly on the rail.

Step 6. To remove the industrial Ethernet switch from the rail, do the opposite from the above steps.

15

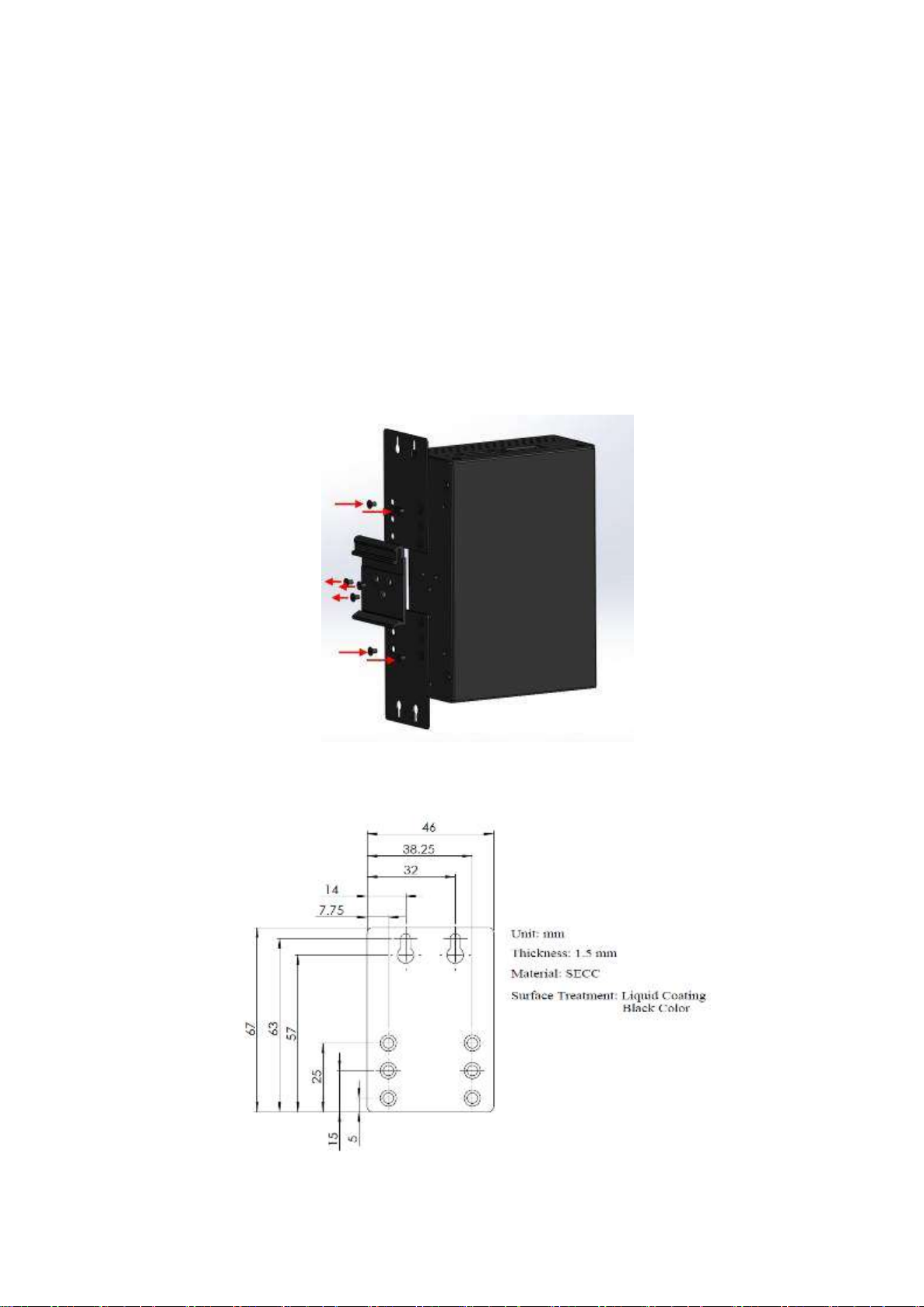

Wall Mounting

Follow the steps below to mount the industrial Ethernet switch using the wall mounting bracket as

shown below in Figure 3.4.

Step 1. Remove the DIN-Rail bracket from the industrial Ethernet switch by loosening the screws.

Step 2. Place the wall mounting brackets on the top and bottom of the industrial Ethernet switch.

Step 3. Use the screws to screw the wall mounting bracket on the industrial Ethernet switch.

Step 4. Use the hook holes at the corners of the wall mounting bracket to hang the industrial

Ethernet switch on the wall.

Step 5. To remove the wall mount bracket, do the opposite from the steps above.

Figure 3.4: Remove DIN-Rail Bracket from the Switch

Below, in Figure 3.5 are the dimensions of the wall mounting bracket.

Figure 3.5: Wall Mounting Bracket Dimensions

16

Hardware Installation

Installation Steps

This section will explain how to install LT-PIGE-804GBTME series: 12-port industrial PoE+ gigabit

managed Ethernet switch, with 8*10/100/1000Tx (PSE 30W/Port) and 4*100/1000 SFP Slots

Installation Steps

Step 1. Unpack the industrial Ethernet switch from the original packing box.

Step 2. Check if the DIN-Rail bracket is screwed on the industrial Ethernet switch.

If the DIN-Rail is not screwed on the industrial Ethernet switch, please refer to the DIN-Rail

Mounting section for DIN-Rail installation.

If you want to wall mount the industrial Ethernet switch, please refer to the Wall Mounting

section for wall mounting installation.

Step 3. To hang the industrial Ethernet switch on a DIN-Rail or wall, please refer to the Mounting

Installation section.

Step 4. Power on the industrial Ethernet switch and then the power LED light will turn on.

If you need help on how to wire power, please refer to the Wiring the Power Inputs section.

Please refer to the LED Indicators section for LED light indication.

Step 5. Prepare the twisted-pair, straight-through category 5 cable for Ethernet connection.

Step 6. Insert one side of the RJ-45 cable into switch’s Ethernet port and on the other side into the

networking device’s Ethernet port, e.g. switch PC or server. The Ethernet port’s (RJ-45) LED

on the industrial Ethernet switch will turn on when the cable is connected to the networking

device.

Please refer to the LED Indicators section for LED light indication.

Step 7. When all connections are set and the LED lights all show normal, the installation is complete.

Table of contents

Other Barox Switch manuals