BARRETO MANUFACTURING,

INC

.

EQUIPMENT

WARRANTY

Barreto Manufacturing, Inc. warrants all BARRETOequipment to be free of defects in material

and workmanship for a period of one (1) year. All BARRETO fuel components, fuel tank, cap,

lines & fittings are warranted for two (2) years. Warranty period begins on date of delivery to the

original user.

This warranty is in lieu of all other warranties, whether written or implied, and is limited to:

1. Replacement of parts returned to the dealer and/or factory and determined defective

upon inspection. (Replacement for parts to dealers shall be at dealer cost plus

shipping charges.)

2. Time for pick-up and/or delivery, transportation of service calls by dealers is

excluded. Manufacturer reserves the right to determine reasonable time

required for repair.

Warranty does not apply to damage caused by abuse or neglect. Time and materials

required for normal maintenance and service are also excluded from warranty coverage.

Engines, engine attached fuel tanks, engine accessories, batteries and tires are warranted by

the original manufacturer and are not covered by the Barreto Equipment Warranty.

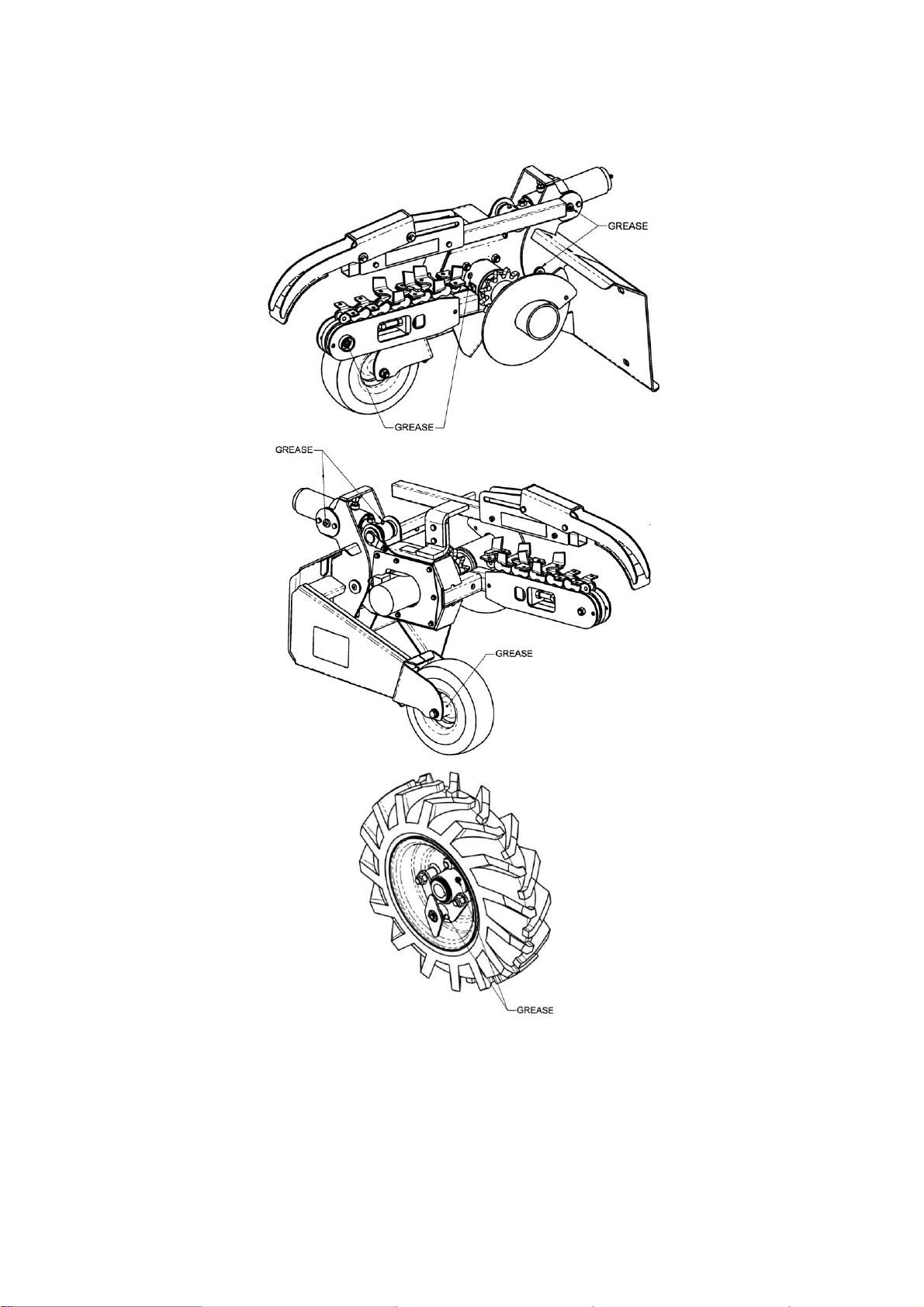

Wear parts such as dig chains, dig teeth, sprockets, chain rollers, bearings, bushings etc.

are excluded unless it can be determined that a defect has contributed to premature wear.

ROUTINE MAINTENANCE

Routinely check the condition and clean, tighten, repair, or replace as necessary the following:

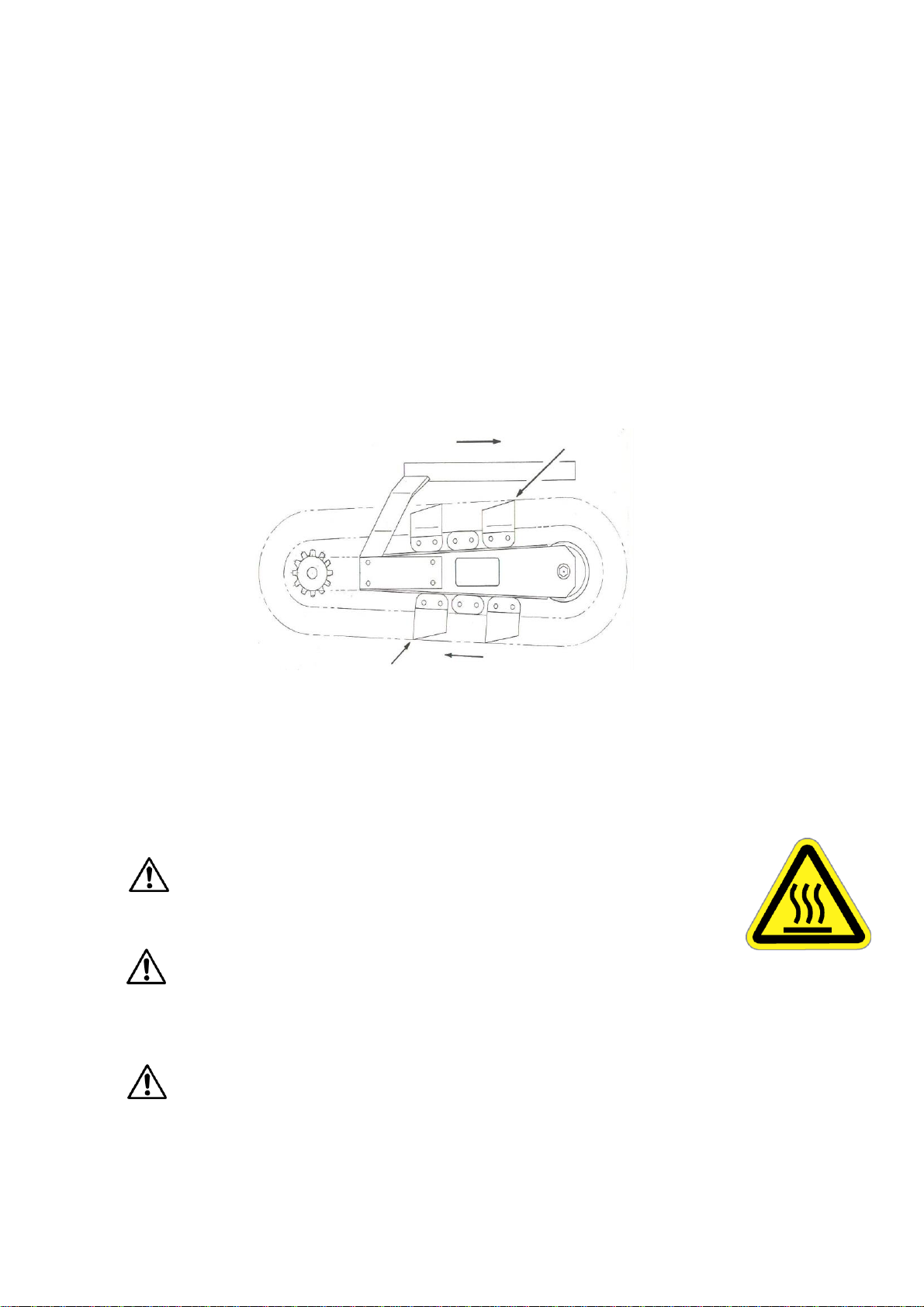

•Dig chain boom guard, muffler guard, hydraulic hoses and fittings

•Fuel lines, fasteners, Safety decals

Clean safety decals often using soap and water. Do not use abrasive cleaners or solvents such as

mineral spirits that may damage the decals. Replace any damaged (unreadable) or missing decals.

If you replace a machine part that has one or more decals affixed to it, replace the decals also.

Replacement parts and decals can be purchased from Barreto Manufacturing, Inc. When attaching

decals, the temperature of the mounting surface must be at least 40°F (5°C) and must be clean

and dry.

Service the engine according to the engine owner’s manual. Follow the directions for all aspects

of service including air filter change, oil level checking, filling, draining, disposal of engine oil,

disposal of petrol/gasoline, and off-season long-term storage.

Off-season long-term storage of the trencher can be at any ambient temperature.