Barrett WAM Arm User manual

WAMTM Arm

User’s Manual

Document: D1001

Version: AH.00

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 2 of 80

Table of Contents

TABLE OF CONTENTS...............................................................................................................1

TABLE OF CONTENTS...............................................................................................................2

LIST OF FIGURES........................................................................................................................4

LIST OF TABLES..........................................................................................................................5

LIST OF EQUATIONS .................................................................................................................5

1SYSTEM DESCRIPTION.....................................................................................................6

1.1 STANDARD WAM SYSTEM COMPONENTS......................................................................... 6

1.1.1 System Features........................................................................................................6

1.1.2 Documentation..........................................................................................................6

1.1.3 WAM Arm.................................................................................................................7

1.1.4 Tool-End Attachments ..............................................................................................8

1.1.5 Power Supply.......................................................................................................... 10

1.1.6 Safety Pendants.......................................................................................................10

1.1.7 Electrical Cables ....................................................................................................11

1.1.8 Control Software and Firmware.............................................................................11

1.1.9 Maintenance Kit .....................................................................................................11

1.2 SYSTEM OPTIONS ............................................................................................................ 13

1.2.1 WAM Wrist .............................................................................................................13

1.2.2 Passive Gimbals .....................................................................................................14

1.2.3 External WAM PC..................................................................................................15

1.2.4 Control Software/Firmware Upgrades...................................................................16

2SAFETY AND CAUTIONS.................................................................................................16

2.1 SAFETY INSTRUCTIONS ................................................................................................... 16

2.2 SAFETY SYSTEM:PENDANTS........................................................................................... 17

2.2.1 Safety States............................................................................................................17

2.2.2 Status Lights ...........................................................................................................17

2.3 HANDLING SAFETY FAULTS ............................................................................................ 18

3SYSTEM SETUP..................................................................................................................19

3.1 MOUNTING ...................................................................................................................... 19

3.2 GROUNDING .................................................................................................................... 20

3.3 INSTALLING THE EXTERNAL PC (OPTIONAL) .................................................................. 20

3.3.1 Physical Installation...............................................................................................20

3.3.2 Software installation...............................................................................................20

3.4 WAM WRIST (OPTIONAL) .............................................................................................. 20

3.5 SAFETY BOARD SETTINGS ............................................................................................... 22

3.6 ELECTRICAL CONNECTIONS ............................................................................................ 23

3.6.1 Power Source..........................................................................................................23

3.6.2 Pendants.................................................................................................................23

3.6.3 Communications.....................................................................................................24

3.7 POWER-UP SEQUENCE..................................................................................................... 24

3.8 CODE EXAMPLES............................................................................................................. 25

4PC & CONTROL SOFTWARE..........................................................................................26

4.1 LIBRARY OVERVIEW ....................................................................................................... 26

4.2 FILE SYSTEM LAYOUT..................................................................................................... 27

4.3 THE CONFIGURATION FILE (WAM.CONF)......................................................................... 27

4.4 OPERATING MODES......................................................................................................... 27

4.5 UPDATING FIRMWARE..................................................................................................... 28

4.5.1 Pucks™...................................................................................................................28

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 3 of 80

4.5.2 Safety Board........................................................................................................... 29

5WAM COMMANDS LIST.................................................................................................. 30

6WAM PROPERTIES LIST................................................................................................. 31

6.1 COMMON PROPERTIES..................................................................................................... 31

6.2 MOTOR PROPERTIES........................................................................................................ 36

6.3 SAFETY-MODULE PROPERTIES........................................................................................ 42

6.4 KEY TO PROPERTY TABLE............................................................................................... 45

7CANBUS COMMUNICATION SPECIFICATIONS....................................................... 46

7.1 DATA LINK SPECIFICATIONS ........................................................................................... 46

7.2 CANBUS TIMING ............................................................................................................ 46

7.3 ID SPECIFICATIONS ......................................................................................................... 46

7.3.1 Message IDs........................................................................................................... 46

7.3.2 Motor IDs and Groups........................................................................................... 46

7.4 CANBUS FRAME DATA PAYLOAD .................................................................................. 47

7.4.1 Standard CANbus Message Format....................................................................... 47

7.4.2 Exceptions .............................................................................................................. 47

7.5 FULL COMMUNICATION EXAMPLE .................................................................................. 48

8TROUBLESHOOTING....................................................................................................... 49

8.1 CHECKING THE ERROR LOG ............................................................................................ 49

8.2 COMMON PROBLEMS ...................................................................................................... 50

9THEORY OF OPERATION............................................................................................... 56

9.1 ELECTRONIC ARCHITECTURE .......................................................................................... 56

9.2 KINEMATICS,TRANSMISSION RATIOS,AND JOINT RANGES ............................................ 58

9.2.1 4 DOF and 7 DOF ................................................................................................. 58

9.2.2 4 DOF with Gimbals.............................................................................................. 66

9.2.3 Motor-to-Joint Transformations............................................................................. 68

APPENDIX A INTEGRATING A BARRETTHAND™ ................................................... 70

APPENDIX B TECHNICAL SPECIFICATIONS............................................................. 71

APPENDIX C FAQ ............................................................................................................... 74

APPENDIX D GLOSSARY.................................................................................................. 76

INDEX........................................................................................................................................... 79

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 4 of 80

List of Figures

FIGURE 1-WAM ARM ..................................................................................................................... 7

FIGURE 2-BLANK OUTER LINK ........................................................................................................ 8

FIGURE 3-END PLATES OF WRIST AND OUTER LINK........................................................................ 8

FIGURE 4–HAPTIC BALL .................................................................................................................. 9

FIGURE 5–TOOL PLATE ................................................................................................................... 9

FIGURE 6–CAN TERMINATION ........................................................................................................ 9

FIGURE 7–POWER SUPPLY ............................................................................................................. 10

FIGURE 8–SAFETY PENDANTS ....................................................................................................... 10

FIGURE 9–ELECTRICAL CABLES .................................................................................................... 11

FIGURE 10 –MAINTENANCE KIT ..................................................................................................... 12

FIGURE 11 –WAM WRIST .............................................................................................................. 13

FIGURE 12 –WRIST MAINTENANCE KIT.......................................................................................... 14

FIGURE 13 –GIMBALS OPTION........................................................................................................ 15

FIGURE 14 –EXTERNAL WAM PC.................................................................................................. 15

FIGURE 15 –BACK OF EXTERNAL WAM PC................................................................................... 15

FIGURE 16 –WAM WORKSPACE .................................................................................................... 16

FIGURE 17 –WAM RESPONSES TO ERRORS AND REQUESTS........................................................... 19

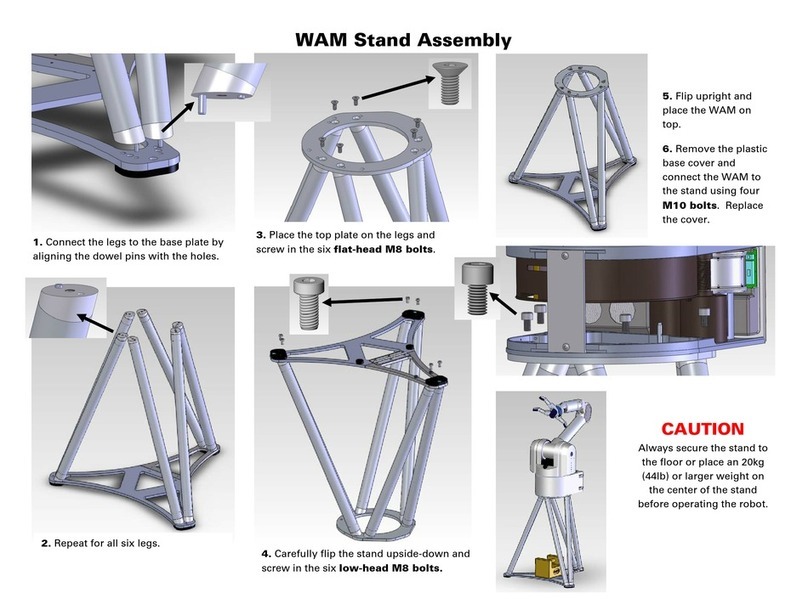

FIGURE 18 –SCREW-HOLE LOCATIONS ........................................................................................... 19

FIGURE 19 –MOUNTING-HOLE MEASUREMENTS............................................................................ 19

FIGURE 20 –WRIST CONNECTOR .................................................................................................... 21

FIGURE 21 –SEPARATING THE OUTER LINK.................................................................................... 21

FIGURE 22: CLOSE-UP OF OUTER LINK CONNECTION ...................................................................... 21

FIGURE 23 –SAFETY BOARD SWITCHES.......................................................................................... 22

FIGURE 26 –DC POWER CABLE (BLUE) .......................................................................................... 23

FIGURE 27 –PENDANT CABLES....................................................................................................... 23

FIGURE 28 –WIRELESS ACCESS POINT ON WAM BACKPLATE ....................................................... 24

FIGURE 29 –CAN CABLE (PURPLE)................................................................................................. 24

FIGURE 30 –SAFETY BOARD COVER............................................................................................... 29

FIGURE 31 –SERIAL CABLE ............................................................................................................ 29

FIGURE 32 –SERIAL CONNECTION WITH SWITCH IN “ON”POSITION .............................................. 29

FIGURE 33 –WAM SYSTEM COMPONENTS ..................................................................................... 56

FIGURE 34 –WAM SYSTEM SCHEMATIC ........................................................................................ 57

FIGURE 35 –WAM 4-DOF DIMENSIONS AND D-H FRAMES ............................................................ 58

FIGURE 36 –WAM 7-DOF DIMENSIONS AND D-H FRAMES ............................................................ 59

FIGURE 37 –WAM ARM JOINT 1FRAMES AND LIMITS................................................................... 60

FIGURE 38 –WAM ARM JOINT 2FRAMES AND LIMITS................................................................... 60

FIGURE 39 –WAM ARM JOINT 3FRAMES AND LIMITS................................................................... 61

FIGURE 40 –WAM ARM JOINT 4FRAMES AND LIMITS................................................................... 61

FIGURE 41 –WAM ARM JOINT 5FRAMES AND LIMITS................................................................... 62

FIGURE 42 –WAM ARM JOINT 6FRAMES AND LIMITS................................................................... 62

FIGURE 43 –WAM ARM JOINT 7FRAMES AND LIMITS................................................................... 63

FIGURE 44 –DENAVIT-HARTENBERG FRAMES –4-DOF +GIMBALS .............................................. 66

FIGURE 45 –WAM DIMENSIONS .................................................................................................... 72

FIGURE 46 –TOOL PLATE DIMENSIONS........................................................................................... 73

FIGURE 47 –CABLE DIFFERENTIAL ................................................................................................. 74

FIGURE 48 –PUCKS™–MINIATURE BRUSHLESS MOTOR CONTROLLERS....................................... 74

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 5 of 80

List of Tables

TABLE 1–WAM COMMUNICATION SETTINGS ............................................................................... 22

TABLE 2–HAND COMMUNICATION AND POWER SETTINGS ........................................................... 22

TABLE 3–DC POWER REQUIREMENTS........................................................................................... 23

TABLE 4–4-DOF WAM FRAME PARAMETERS (WITH BLANK OUTER LINK INSTALLED) ................. 64

TABLE 5–7-DOF WAM FRAME PARAMETERS............................................................................... 64

TABLE 6–JOINT LIMITS ................................................................................................................. 65

TABLE 7–4-DOF WAM +GIMBALS DH PARAMETERS................................................................. 67

TABLE 8–ARM TRANSMISSION RATIOS ......................................................................................... 68

TABLE 9–MAXIMUM TORQUE (MT) MATO NM CONVERSION TABLE............................................ 75

List of Equations

EQUATION 1–D-H GENERALIZED TRANSFORM MATRIX ................................................................. 64

EQUATION 2–D-H MATRIX EXAMPLE ........................................................................................... 64

EQUATION 3–TOOL FRAME MATRIX .............................................................................................. 65

EQUATION 4–TOOL END TIP POSITION AND ORIENTATION EQUATION FOR THE 4-DOF WAM ....... 65

EQUATION 5–TOOL END TIP POSITION AND ORIENTATION EQUATION FOR THE 7-DOF WAM ....... 65

EQUATION 6–WAM MOTOR-TO-JOINT POSITION TRANSFORMATIONS .......................................... 68

EQUATION 7–WRIST MOTOR-TO-JOINT POSITION TRANSFORMATIONS.......................................... 68

EQUATION 8–ARM JOINT-TO-MOTOR POSITION TRANSFORMATIONS ............................................ 68

EQUATION 9–WRIST JOINT-TO-MOTOR POSITION TRANSFORMATION ........................................... 68

EQUATION 10 –ARM MOTOR-TO-JOINT TORQUE TRANSFORMATION.............................................. 69

EQUATION 11 –WRIST MOTOR-TO-JOINT TRANSFORMATIONS ....................................................... 69

EQUATION 12 –ARM JOINT-TO-MOTOR TORQUE TRANSFORMATIONS ............................................ 69

EQUATION 13 –WRIST JOINT-TO-MOTOR TORQUE TRANSFORMATIONS ......................................... 69

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 6 of 80

1 System Description

1.1 Standard WAM*System Components

1.1.1 System Features

Thank you for choosing the Whole Arm Manipulator (WAM). The WAM is designed to overcome

the lack of backdrivability in conventional robotic arms while maintaining durability, low power

usage, light moving weight, and ease of use. The standard WAM is a four degree-of-freedom (4-

DOF) arm. The optional WAM Wrist adds three more degrees of freedom – see Section 1.2.1. The

WAM has the dexterity and slenderness to easily navigate around obstacles placed in its path and

is endowed with smooth and precise joint motion, contributing to the WAM’s popularity in

robotics control research and emerging applications.

The compactness, low system weight, and extraordinarily low power consumption make the

WAM arm uniquely portable and so an ideal choice for use with mobile platforms. Its low mass

and the absence of a controller cabinet ensure that it is significantly easier to mount than robotic

arms of the same size. The WAM can also be powered directly from small batteries on a mobile

platform without power conditioning, accepting a wide range of voltages from batteries.

While no robotic arm should be considered “safe” and all precautions should be taken as each

application demands, the backdrivability and the multiple-layer safety system of the WAM make it

one of the safest robotic arms available. Because of its 95% backdrivable cable drives (in contrast

to poorly-backdrivable gear and harmonic-based drives), the WAM can react naturally and lightly

as it contacts walls and people. These attributes have contributed to the WAM’s success as one of

the first robotic arms in surgery and rehabilitation.

We hope that you enjoy the versatility and functionality of the WAM. Please never hesitate to give

http://www.barrett.com/.

1.1.2 Documentation

The WAM comes with six separate pieces of documentation:

1. User’s Manual (this manual)

2. Quick Start Guide

3. WAM Cable Maintenance Guide

4. Wrist Cable Maintenance Guide

5. Inertial Specifications Manual

6. Support Reference Sheet

1. The User’s Manual (this manual) covers:

•System components and options

•Safety instructions

•System setup and operation

•Troubleshooting

•Technical specifications

•Frequently asked questions

2. The Quick Start Guide is a single page guide that covers the essentials of operating the WAM

and some basic demonstrations for the WAM. This includes turning on and initializing the

WAM, home position, fault recovery, and the gravity compensation and teach-and-play

demos.

*“Whole Arm Manipulator” and “WAM” are trademarks of Barrett Technology® Inc.

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 7 of 80

3. The WAM Cable Maintenance Guide covers the cabling of joints 1 through 4 and the general

rules for handling cables, and should be used in the event that a cable in the 4-DOF WAM is

damaged or is coming loose.

4. The Wrist Cable Maintenance Guide covers the cabling of joints 5 and 6 and should be used

with the introductory sections in the WAM Cable Maintenance Guide in the event that a cable

in the Wrist is damaged

5. The Inertial Specifications Manual presents the inertial data for the WAM robotic arm (the 4-

DOF version and both 7-DOF versions) in support of computed-torque control techniques.

6. The Support Reference Sheet lists the variety of support options Barrett provides and assists

the customer in using the resource most likely to answer their question most effectively.

1.1.3 WAM Arm

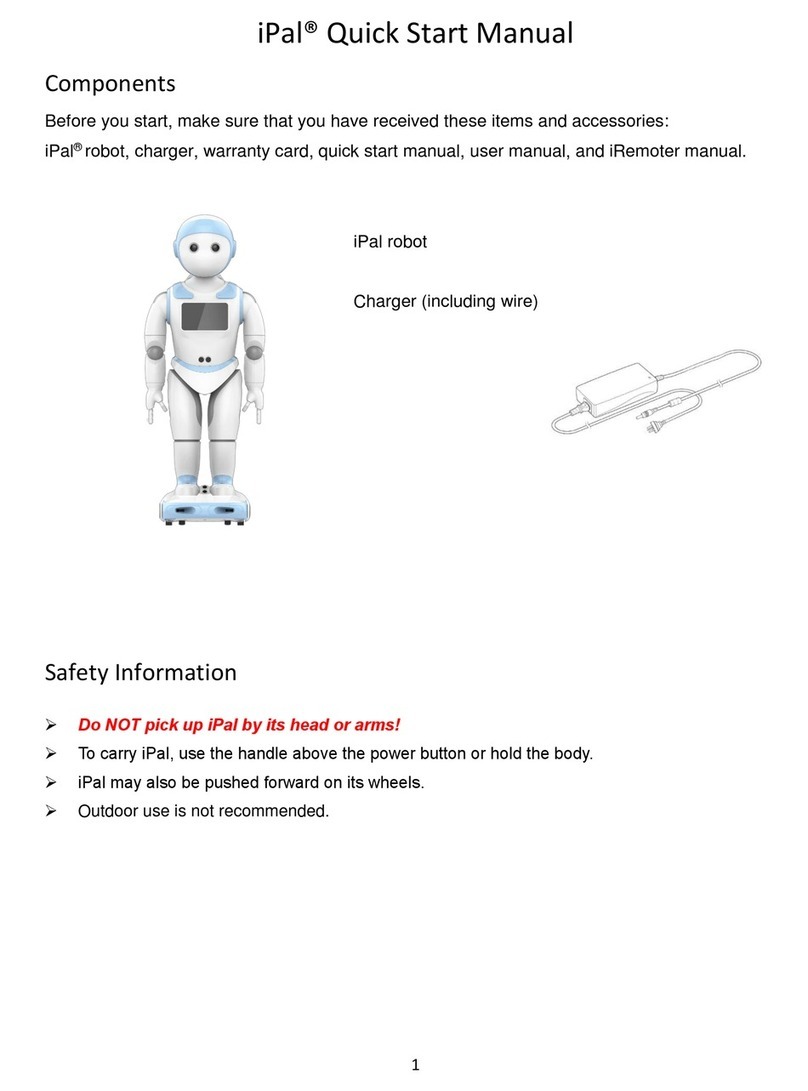

The standard four-degree-of-freedom WAM Arm, shown in Figure 1, has four cable-driven joints

labeled J1 through J4, and four brushless DC motors labeled M1 through M4. M1 controls the yaw

(J1) of the WAM and is located in the base of the WAM. Using Barrett’s patented cable

differential, M2 and M3 together control the pitch (J2) and roll (J3) of the WAM, and are

contained in the shoulder of the WAM. M4 controls the bend of the “elbow” (J4), and is located

just above M2 in the shoulder. Using Barrett’s Puck technology, all motor encoders, power

amplifiers, and controllers are located in a single compact package adjacent to each motor,

eliminating the need for a controller cabinet and heavy electrical cables.

Figure 1 - WAM Arm

The standard WAM Arm comes with an internal computer and a blank outer link (shown attached

to the end of the elbow in Figure 1 and shown in full in Figure 2). However, several options (see

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 8 of 80

Section 1.2) such as an external computer and the WAM Wrist (Figure 11) are available to replace

these (though both standard options will still be included so that you may always switch between

configurations at any time).

Figure 2 - Blank Outer Link

The WAM’s internal computer has the following specifications:

Mainboard: PFM-540I

Processor Type: AMD Geode LX800 x86 @ ~500MHz

Memory: 256MB (4MB of that is used as a video framebuffer).

Hard drive: 2GB, CompactFlash

Kernel: Linux 2.6.16.57 patched with Xenomai 2.4-rc5

Distro: Slax 5.1.8

Expansion Card: PEAK-System PC/104 CAN Card, 2 ports

Wireless: Wi-Fi 802.11 b/g

Ethernet: 10/100 Base-T

1.1.4 Tool-End Attachments

The WAM™ comes with three endpoint (tool-end) attachments that can be used to change the

setup and shape of the WAM™ Arm: the Haptic Ball, the Tool Plate, and the CAN Termination.

These items in general will be attached to either the Outer Link (Figure 2) or WAM Wrist (Figure

11). Figure 3 shows the end plates of both the Wrist and Outer Link. The wires and connector

coming out of the centers are for running the optional Barrett Hand. If using the Outer Link

without the Barrett Hand, the wiring can simply be pushed inside the large open cavity. If using

the Wrist without the Barrett Hand, the wires should be coiled neatly in the small cavity and the

Wrist Plug installed to keep the wires from getting pinched.

Figure 3 - End Plates of Wrist and Outer Link

Wrist Plug

Wrist

Outer

Link

Rotate this

direction to

attach tool

Rotate this

direction to

remove tool

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 9 of 80

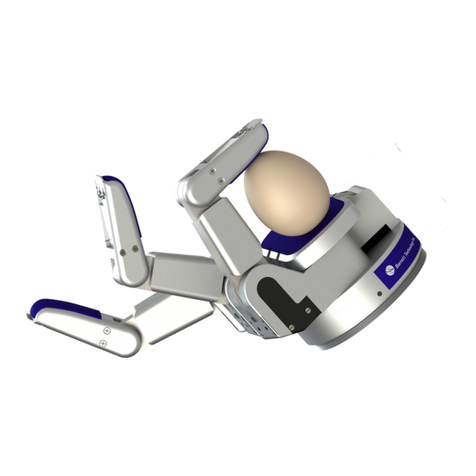

The Haptic Ball (see Figure 4) can be attached to the end of the Outer Link or the Wrist. It is used

to assist in haptic scenes by providing an easy-to-grasp, definable endpoint for the user. Systems

are generally shipped with the Haptic Ball pre-installed.

The Tool Plate (see Figure 5) can be installed on the end of the Outer Link, Wrist, or Elbow Plate

(if neither the Outer Link nor Wrist modules are installed). It provides a flat base that can be used

to attach parts other than the ones designed by Barrett. The Tool Plate has four M6 tapped holes,

evenly distributed in a circle, a 6-mm diameter dowel-pin hole, a quick-connect pin hole and slot,

and two holes to connect the CAN Termination (see Appendix B for Tool Plate hole labels and

dimensions).

The CAN Termination (see Figure 6) must be used if neither the Outer Link nor the Wrist is

attached at the end of the elbow. The CANbus must be terminated at each end with a 120 Ohm

resistor to minimize signal reflections. The termination can be attached to either the end plate of

the elbow or to the Tool Plate (if attached to the elbow) by the two small holes, which are the

same distance apart as the holes on the Termination.

Figure 4 – Haptic Ball

Figure 5 – Tool Plate

Figure 6 – CAN Termination

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 10 of 80

1.1.5 Power Supply

The WAM system generally requires an input voltage of 48 VDC. However, if you require an

alternate input voltage, contact Barrett Technology. The power requirements for both 4-DOF and

7-DOF WAMs are summarized in Section 3.6.1. Any DC power sources may be connected

directly to the WAM. Improper grounding can cause severe damage to the WAM electronics. If

you are concerned that your voltage source may damage the WAM electronics, do not hesitate to

contact Barrett for technical guidance.

The Power Supply that ships with the WAM, shown in Figure 7, can be plugged into any regular

AC power source. It provides up to 10A of direct current at 48V. This Power Supply switches

automatically to local voltage standards (100-120 & 200-240 VAC at 50-60Hz) around the globe

and contains built-in surge protection.

Figure 7 – Power Supply

1.1.6 Safety Pendants

The WAM Arm system comes with two safety pendants: a control pendant and a display pendant

(shown in Figure 8). Both pendants show the present safety status of the WAM Arm, with status

lights for the velocity, torque, voltage, and heartbeats of the robot. There is also a 7-segment LED

single-character display which shows additional information related to any existing errors. Each

pendant has a large mushroom-type emergency stop button, which can be reset (popped up) by

rotating the button clockwise for one quarter of a full turn. The control pendant has three

additional buttons: Shift, Reset/Idle, and Activate.

Figure 8 – Safety Pendants

Display Pendant

Control Pendant

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 11 of 80

1.1.7 Electrical Cables

All necessary electrical cables are included with the basic WAM System, shown in Figure 9. An

AC Line Cord connects the Power Supply to a wall source. A blue DC Power Cable connects the

Power Supply or another DC power source to the WAM. If you purchased an external WAM PC,

a purple CANbus cable is provided for CAN communication with the WAM. The pendant cables

(shown attached to the pendants in Figure 8) connect directly to the WAM. An Ethernet cable is

also provided for the option of Ethernet communication with the WAM.

Figure 9 – Electrical Cables

1.1.8 Control Software and Firmware

The WAM’s internal computer has firmware and software that are preloaded before it is shipped.

Included with a copy of the source code in electronic form are:

1. User’s Manual (this manual)

2. Quick Start Guide

3. Cable Maintenance Guide

4. Inertial Specifications Manual

5. Support Resources Reference Sheet

For more information about software and firmware, please see Section 4.

1.1.9 Maintenance Kit

Included in each WAM package is a maintenance kit (shown in Figure 10). Use the maintenance

kit in accordance with the instructions in Section 3 and the Cable Maintenance Guide. The

maintenance kit includes the following:

•1 Tool Plate (normally shipped attached to the Outer Link (or Wrist if purchased))

•4 M10 Screws, Washers, and Nuts to secure the base

•1 Set of Metric Hex Wrenches

•1 Packet of Loctite 222

•1 10-mm Combination Wrench

AC Line Cord DC Power Cable

CANbus Cable Ethernet Cable

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 12 of 80

•1 Pair of Tweezers

•2 Clamps (for clamping the WAM to a table top)

•1 Roll of 13-mm (1/2”) Masking Tape

•1 Roll of Kapton Tape

•1 Slotted Screwdriver

•1 Phillips-Head Screwdriver

•1 Push-Pull Hook

•1 Set Spare Mechanical Cables (Packaged separately from the rest of the Maintenance Kit)

Figure 10 – Maintenance Kit

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 13 of 80

1.2 System Options

1.2.1 WAM Wrist

The WAM Wrist module, shown in Figure 11, replaces the outer link of a four-degree-of-freedom

WAM, adding joints 5, 6, and 7, for another three degrees of freedom. Mechanical and electrical

quick-connect features make it easy to swap between the WAM’s outer link and the Wrist module

to convert between 4-DOF and 7-DOF configurations.

In order to minimize the inertial effects of the motors on the host robot arm, the servomotors for

joints 5 & 6 are located at the base of the wrist. The final roll joint in the WAM Wrist, motor joint

7, is the only geared axis. At very small scales, such as at joint 7, gears have slightly better

performance than cables in terms of compactness.

Figure 11 – WAM Wrist

The WAM Wrist comes with its own separate maintenance kit (shown in Figure 12), which

contains:

•1 Roll 6-mm (¼") wide Masking Tape

•1 Wrist Tension Tool

•1 Joint-7 Spanner Tool

•1 Pull Hook

•1 Wrist Safety Termination (Packaged separately from the rest of the Maintenance Kit)

Thread for quick-

connect to WAM Arm

Removable transmission cover

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 14 of 80

Figure 12 – Wrist Maintenance Kit

1.2.2 Passive Gimbals

The passive gimbals option, shown in Figure 13, replaces the Outer Link on the WAM and adds

three additional unpowered degrees of freedom. The links of the gimbals are designed to provide a

large mounting area at the intersection point between all three joint axes. A vertical bar grip comes

standard and is designed primarily for life-size haptics, exercise, and rehabilitation; but other grip

and mounting options are available. The gimbals use Barrett Technology’s quick-connect system

so that it may easily be interchanged with other end effectors.

A 6-axis force/torque (FT) sensor can be mounted at the base of the gimbals grip for gathering

additional data. This sensor is redundant with the built-in Cartesian Force/Torque control

capabilities of the WAM, but enables a separate confirmation of values at slightly higher

precision.

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 15 of 80

Figure 13 – Gimbals Option

1.2.3 External WAM PC

Barrett Technology offers an external PC (see Figure 14) for advanced control applications that

require more processing power or more memory than the WAM’s internal PC can provide. A

standard keyboard and mouse, CANbus cable, and 2-m AC line cord are provided for use with the

external PC. A monitor (not provided) is needed only during the initial setup of the computer. The

external PC has the following specifications:

Mainboard: Intel 945G Micro ATX

Processor Type: Intel Core 2 Duo E6600 Conroe @ ~2.4GHz

Memory: 2GB (4MB of that is used as a video framebuffer).

Hard drive: 80GB

Optical: DVD Drive

Kernel: Linux 2.6.24.2 patched with Xenomai

Distro: Ubuntu 7.10

Expansion Card: PEAK-System PCI ISO dual-port CAN card

Ethernet: 10/100/1000 Base-T

Figure 14 – External WAM PC

Figure 15 – Back of External WAM PC

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 16 of 80

1.2.4 Control Software/Firmware Upgrades

Barrett Technology releases software and firmware upgrades periodically (see Section 4.5 for

details on firmware upgrades). Upgrades are available free of charge for customers of Barrett’s

support subscription service. Customers with an expired support contracts can choose to renew

their contract, or purchase the upgrades separately. See the enclosed Support Reference Sheet for

more information about your support subscription service.

2 Safety and Cautions

2.1 Safety Instructions

PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE USING YOUR WAM.

Following these safety instructions will help prevent user injury and equipment damage.

•Proper precautions should be taken when selecting the location and setup of your WAM

system. DO NOT set up the system such that any part of the robot’s workspace (resembling a

sphere with an approximately one meter radius, as shown in Figure 16) reaches into a

pedestrian pathway in the lab space. The WAM is an unusually quiet mechanism – it

generates little servo or transmission noise – thereby providing very little intrinsic warning of

its enabled state.

Figure 16 – WAM Workspace

•In addition, as with any piece of robotic equipment, it is ultimately up to you to be aware of

your surroundings during robot operation. Although the WAM is intrinsically safer than other

robotic systems, you may wish to integrate standard safety measures such as mats, gates, light

curtains, etc. into the lab space surrounding the WAM.

•NEVER connect or disconnect any electrical cables while the Power Supply is turned on.

Failure to follow this instruction could impart irreparable damage to the onboard electronics

or put you at risk of electrical shock.

•Always plug the Power Supply into a properly grounded wall source. Failure to do so could

damage the WAM electronics and put you at risk of electrical shock.

•Do not allow the WAM to be exposed to liquids that may cause electrical short-circuit and put

you at risk of electrical shock.

•Keep dirt and debris away from the exposed cable drives located at the joints.

•Do not exceed the load limit of the arm: 4 kg for a 4-DOF WAM and 3 kg for a 7-DOF

WAM. Consider all loading situations including accelerated loads, cantilever loads from long

objects, robot collisions, active loads, etc.

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 17 of 80

•Remove/replace the WAM Wrist only as instructed in Section 3.4.

•Monitor the operating temperature of the WAM so that it remains between 0 °C and 70 °C.

Under normal conditions, the Pucks operate between 40 and 60 ˚C. Idling the motors, when

possible, will help keep the temperature lower.

2.2 Safety System: Pendants

2.2.1 Safety States

The WAM Arm has three safety states: E-STOP, IDLE, and ACTIVATED:

E-STOP means there is no motor bus voltage, in fact the motor bus power and ground lines are

tied together, resulting in a “resistive braking” effect on the joints of the WAM Arm. The motor

controllers are off line and do not keep track of their motor positions in this state. E-STOP is

achieved by pressing the E-STOP button on either pendant. In this state, neither the IDLE nor

ACTIVATE button lights are lit on the control pendant.

IDLE means there is voltage applied to the motor bus and the motor controllers are on line and

keeping track of their motor positions, but they are commanded to tie their motor phase leads

together (also resulting in a braking effect), and they will ignore any command torque sent to

them. To put the WAM Arm into the IDLE state (which will also reset any existing faults), press

and hold the Shift button on the control pendant, then press the Reset/Idle button (yellow) and

release both buttons. The yellow Idle button will light up, indicating that the WAM Arm is now in

the IDLE state. Make sure both E-STOP buttons are reset (popped up) before attempting to change

modes.

ACTIVATED means the motor controllers are actively applying any commanded torque they

receive from the control PC. To put the WAM into the ACTIVATED state, press and hold the

Shift button on the control pendant, then press the Activate button (green) and release both

buttons. This state may only be reached when all of the status lights are showing OK (green). All

warnings or faults must be cleared before activating the WAM. The green Activate button will

light up, indicating that the WAM Arm is now in the ACTIVATED state.

2.2.2 Status Lights

The WAM Arm has five sets of status lights: Velocity, Torque, Voltage, Heartbeat, and Other.

Velocity: Before the WAM Arm’s joint positions are initialized by the PC control software, the

velocity status lights indicate the state of the WAM’s angular joint speed. By default, there is a

yellow LED warning when any joint exceeds 0.5 radians/sec and a red LED fault when any joint

exceeds 2 radians/sec. The joint number responsible for the warning/fault is indicated by the

single-character display on each pendant. After the WAM Arm’s joint positions are initialized, the

safety system begins calculating and monitoring the WAM’s elbow and arm endpoint velocities in

Cartesian space instead of monitoring individual joint velocities. By default, there is a warning

when either the elbow (single-character “E”) or arm endpoint (single-character “A”) exceeds 0.5

m/s and a fault when either one exceeds 2 m/s. These defaults are modifiable in software (see 6.3).

Torque: The torque status lights indicate the state of the torque commands being received by the

WAM Arm from the PC control software. If the PC sends non-zero torques while the WAM is in

the IDLE state (the yellow Reset/Idle button is lit), the safety system will display a torque

warning- prohibiting the WAM Arm from being activated. If the WAM Arm is in the

ACTIVATED state (the green Activate button is lit) and the PC sends torques which exceed the

default torque warning or fault levels, the torque warning or fault light will be lit- and the

offending motor number will be shown in the single-character display. If a torque limit is

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 18 of 80

exceeded, the safety system automatically idles all motors (puts the WAM in the IDLE safety

state). See Section 6.3 for more information about how to set the torque limits.

Sometimes, when you exit a WAM control program, the torque warning light will stay on. That

just means that the last torque that the safety system saw go by was beyond the warning level for

the present state ( > 0 for E-STOP or IDLE, or > TL1 for ACTIVATED). As long as you send one

or more zero-torque commands to the pucks, the warning light should extinguish.

Voltage: The voltage status lights indicate the state of the WAM Arm’s motor bus voltage. When

the system is first powered up, the bus is off (there is no motor power), and the safety system

registers a voltage fault. This fault is cleared by pressing Shift-Idle on the control pendant. Placing

the WAM Arm into the IDLE state applies a DC voltage on the motor bus and clears the fault. If

the voltage approaches the limits, the voltage warning light is lit. If the voltage exceeds the limits,

the voltage fault light is lit.

Heartbeat: The heartbeat status lights indicate the state of the communication between the PC and

each motor controller in the WAM Arm. If the WAM is in the IDLE state and no control loop is

active between the PC and the motor controllers, the pendants will display a heartbeat warning. If

the WAM is in the ACTIVATED state, the computer must request encoder values in a constant

loop until you press Shift-Idle again. If PC or any motor controller fails to issue any

communication for longer than 16ms, the safety system will register a heartbeat fault and shut

down the WAM.

Other: The “Other” status lights presently only indicate whether an E-STOP has occurred. If this

is the case, the fault light will be lit and the single-character display will show “E”.

2.3 Handling Safety Faults

If the safety system registers a fault during WAM operation, the fault must be cleared before

continuing to use the WAM. The most common safety faults (over velocity, over torque) leave the

WAM safety system in the IDLE state (yellow button is lit). To reset the fault from this state

(when using the btdiag example application):

1) Stop any running Teach & Play playback (press ‘/’)

2) Set the position controller to IDLE mode (press ‘p’ to toggle mode)

3) Turn off gravity compensation (press ‘g’ and enter 0)

4) Reset the safety fault (press <Shift+Reset/Idle> on the control pendant)

5) Re-activate the WAM (press <Shift+Activate> on the control pendant)

6) Turn on gravity compensation (press ‘g’)

If the safety system encountered a critical fault that resulted in an E-STOP of the WAM (no

pendant buttons are lit), follow these steps to recover from the fault:

1) Exit the application (press ‘x’)

2) Reset the safety fault (press <Shift+Reset/Idle> on the control pendant)

3) Grab the WAM and move it back to the home position (the joint positions are lost after

an E-STOP)

4) Re-launch the control program and follow the on-screen instructions

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 19 of 80

Error occurs in state

E-STOP IDLE ACTIVE

Velocity exceeds VL1 No action Warn Warn

Velocityexceeds VL2 No action Fault, E-STOP Fault, IDLE, Wait 1/4s

Torque exceeds TL1 Warn for non-zero Warn for non-zero Warn

Torque exceeds TL2 Fault Fault Fault, IDLE

Heartbeat missing Warn Warn Fault, E-STOP

Voltage lower than VOLTL1 No action Warn Warn

Voltage lower than VOLTL2 Fault Fault Fault, IDLE

Voltage higher than VOLTH1 No action Warn, Bleed voltage Warn, Bleed voltage

Voltage higher than VOLTH2 No action Fault, E-STOP Fault, E-STOP

E-Stop pressed Fault, E-STOP Fault, E-STOP Fault, E-STOP

NOTE: Warnings are cleared automatically, critical faults are cleared through a RESET

Request occurs in state

E-STOP IDLE ACTIVE

E-STOP E-STOP E-STOP E-STOP

RESET / IDLE Clear faults, power up

bus, enumerate, IDLE Clear faults IDLE

ACTIVATE No Action If no warnings or faults,

ACTIVE No Action

REQUEST ERROR

Figure 17 – WAM Responses to Errors and Requests

3 System Setup

3.1 Mounting

The mounting-surface for the WAM should be designed to handle the large reaction forces

generated at the base of the arm during high-acceleration operation. The WAM can be fastened to

a prepared mounting-surface in several ways. If you use four M10 or 3/8” screws, remove the

base cover to access the four bolt holes in the base plate. The holes are located on the base of the

WAM according to Figure 18 and Figure 19. The plate thickness is 8mm. If you use M12 screws,

you can screw upwards from the opposite direction, eliminating the need to removing the base

cover. Alternatively, the WAM can be mounted using the clamps provided in the maintenance kit.

It is important that the mounting surface NOT be grounded to earth ground (see “Grounding”

section below).

Figure 18 – Screw-hole Locations

Figure 19 – Mounting-Hole Measurements

© 2008 Barrett Technology®, Inc. Document: D1001, Version: AH.00 20 of 80

3.2 Grounding

Grounding of all hardware must be considered when locating the WAM and its peripherals.

Multiple grounding paths between the external power supply, the WAM chassis, the Barrett Hand

power supply, an external computer and earth ground can cause internal communications

problems. It is important to mount the WAM itself on a non-grounded surface. However, if you

need to physically mount it to a grounded structure (upside-down to a grounded I-Beam, or

mounted to a grounded metal table, for example) contact Barrett Technology for instructions on

making a slight modification to the external wiring to avoid multiple ground paths. Additionally, it

is preferable that the metal chassis of the External Power Supply, the metal chassis of the Barrett

Hand Supply (if applicable) and the WAM chassis are not in electrical contact with each other. If

this is not possible, contact Barrett Technology for instructions. Finally, if using an external

computer connected to either the WAM through the CANBus or the external Barrett Hand Supply,

the computer should be grounded. Again, contact Barrett if this poses a problem. A computer

connected to the Ethernet port can either be grounded or not grounded.

3.3 Installing the External PC (Optional)

3.3.1 Physical Installation

Install the PC shipped with the WAM as you would any other PC. The CANbus cable connects to

the lower port of the PCI CAN card, not the built-in serial port. You will need to add a monitor

while performing initial setup of the PC. Afterwards, you may use the PC for development or

remove the monitor and use remote terminal software (such as ssh) to operate the PC remotely.

3.3.2 Software installation

The PC comes with the WAM software loaded. You will need to edit /etc/network/interfaces to set

an IP address that is compatible with your network. We do not recommend using DHCP, as we

have found that periodic address renegotiation interferes with the real-time operation of the WAM.

The Barrett Technology software library uses syslogd to log all error messages to a file. It is

highly recommended to make sure that syslogd is running. Error messages may be found in the

/var/log/syslog text file.

3.4 WAM Wrist (Optional)

To avoid damaging the WAM electronics, please make sure the WAM is powered off before

detaching or attaching any outer link. In addition, if the Wrist was shipped separately from the

WAM, a Safety Termination will be attached to the base connector of the Wrist, and must be

removed before mounting the Wrist. If the Wrist is ever removed from the WAM, ensure that the

Safety Termination is attached as soon as the Wrist is disconnected to prevent damage to the Wrist

Pucks.

Figure 21 shows that the outer link can be unscrewed and removed from the WAM to

accommodate the WAM Wrist (if the 7-DOF WAM is purchased). After removing the outer link,

connect the WAM Wrist:

1.Align the D-sub connector of the Wrist with the mating connector on the end of the “elbow” of

the WAM such that both have the same orientation.

2.Connect the alignment pins on the end of the elbow with the mating connections on the Wrist.

3.Thread the quick-connect ring onto the wrist base.

No special wrenches, fasteners, or tools are required, however, it may be necessary to shake the

outer link (or Wrist) gently back and forth while tightening or loosening the ring. This ring should

only be hand-tightened. It is normal for there to be a small number of threads left when fully

tightened. This single operation also makes all electrical connections to the WAM Wrist. Figure

20 shows the electrical connector at the end of the WAM.

Table of contents

Other Barrett Robotics manuals

Popular Robotics manuals by other brands

Ocular

Ocular RobotEye RE01 Imaging user manual

Opitec

Opitec 101.887 instruction manual

Circuitmess

Circuitmess MARV Build guide

Learning Resources

Learning Resources Botley The Coding Robot Activity Set Activity guide

WowWee

WowWee MiP Arcade user manual

Metrohm

Metrohm OMNIS Sample Robot Pick&Place product manual