Barrett Wraptor BH8-610 Series User manual

Wraptor™

BH8-610 Series User Manual

Document: D2000

Version: AB.00

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 1 of 15

Table of Contents

1 System Description ............................................................................................................................. 2

1.1 What’s new in the 610-Series Wraptor™ ................................................................................... 2

1.2 Introduction................................................................................................................................. 2

1.3 About the Wraptor™ .................................................................................................................. 2

1.4 Technical Specifications ............................................................................................................. 3

1.4.1 Overview............................................................................................................................. 3

1.4.2 Conversion ratios ................................................................................................................ 4

1.4.3 Brushless Motors ................................................................................................................ 4

1.5 Theory of Operation.................................................................................................................... 5

1.6 Control Software......................................................................................................................... 5

1.7 C-Function Library ..................................................................................................................... 5

1.8 Control Software/Firmware Upgrades........................................................................................ 5

2 Safety and Cautions ............................................................................................................................ 6

2.1 Human Safety.............................................................................................................................. 6

2.2 Wraptor Safety ............................................................................................................................ 6

3 Initial Setup and Walk-through........................................................................................................... 7

4 Supervisory Control ............................................................................................................................ 8

4.1 Commands .................................................................................................................................. 8

4.1.1 Movement Commands ........................................................................................................ 9

4.1.2 Motor Parameter Commands ............................................................................................ 10

4.1.3 Administrative Commands ............................................................................................... 11

4.2 Parameters................................................................................................................................. 11

4.2.1 Movement Parameters ...................................................................................................... 12

4.2.2 Status Parameters .............................................................................................................. 12

4.2.3 Advanced Parameters........................................................................................................ 13

4.2.4 Configuration Parameters ................................................................................................. 15

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 2 of 15

1 System Description

1.1 What’s new in the 610-Series Wraptor™

We upgraded the motor feedback sensor from an optical sensor to a more robust magnetic one.

1.2 Introduction

Thank you for choosing the Wraptor™. The Wraptor™ is designed to overcome the inflexibility of conventional industrial

grippers with DSP-enabled dexterity while maintaining durability, compactness, and ease of use. The Wraptor™ is a multi-

fingered grasper with the dexterity to secure target objects of different sizes, shapes, and orientations. Rather than rely on

gripper friction from pinching or permanent gripper-jaw-shape customization, the Wraptor™ gently envelops targets,

securely locking its joints until commanded to release the target.

System integration with any robotic arm is fast and simple. Even with its low, 7-kg, weight and compact form, it is totally

self-contained. The Wraptor™ uses industry-standard Ethernet communications, which is the common denominator of

network communications, for guaranteed universal compatibility. Eight (8) on-board DSPs combined with Barrett’s open

Grasper Control Language (GCL) endow the Wraptor™ with millisecond responsiveness.

The compactness and low weight of the Wraptor™ assures that the enhanced dexterity does not compromise arm payload.

Its low mass and short base-to-grasp-center distance minimize joint loading on the host robot and reduce extraneous arm

movements during object reorientation. The custom control-electronics package is contained entirely within the Wraptor™,

reducing electrical wiring to a single cable carrying only Ethernet communications and DC power.

We hope that you enjoy the versatility and functionality of the Wraptor™. Please never hesitate to give feedback to Barrett’s

engineers and to ask Barrett’s engineers for advice. You may contact Barrett’s engineers at <service@barrett.com>, or

US+617-252-9000, or at <http://www.barrett.com/robot/>.

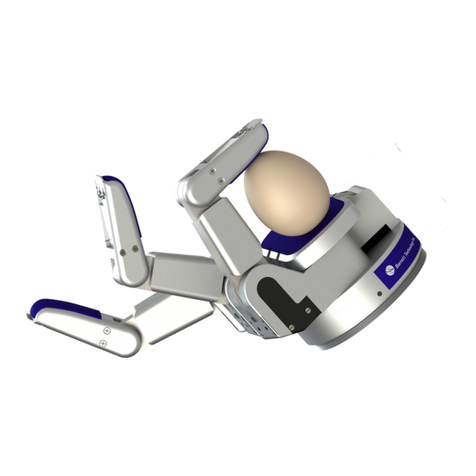

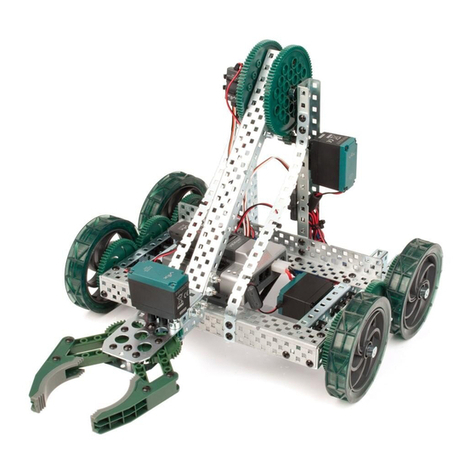

1.3 About the Wraptor™

The Wraptor™ has three fingers identified as F1, F2 and F3. Two of the fingers, F1 & F2, rotate synchronously and

symmetrically about the base joint in a spreading action. The “spread” motion around the palm allows “on-the-fly” grasp

reconfiguration to adapt to varying target object sizes, shapes, and orientations. Aside from the spread motion, each of the

three fingers on the Wraptor™ feature two joints driven by separate DC brushless servo motors. When the inner joint

contacts an object, the outer joint continues to close around it, making a secure grasp. Using the fingers together allows the

Wraptor™ to "grasp" a wide variety of objects securely. The multi-jointed fingers, combined with the spread function, make

object grasping nearly target-independent.

Figure 1: Isometric view of Wraptor showing Finger and Motor numbers

M1

M2

M3

M4

M5

M6

M7

F1

F2

F3

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 3 of 15

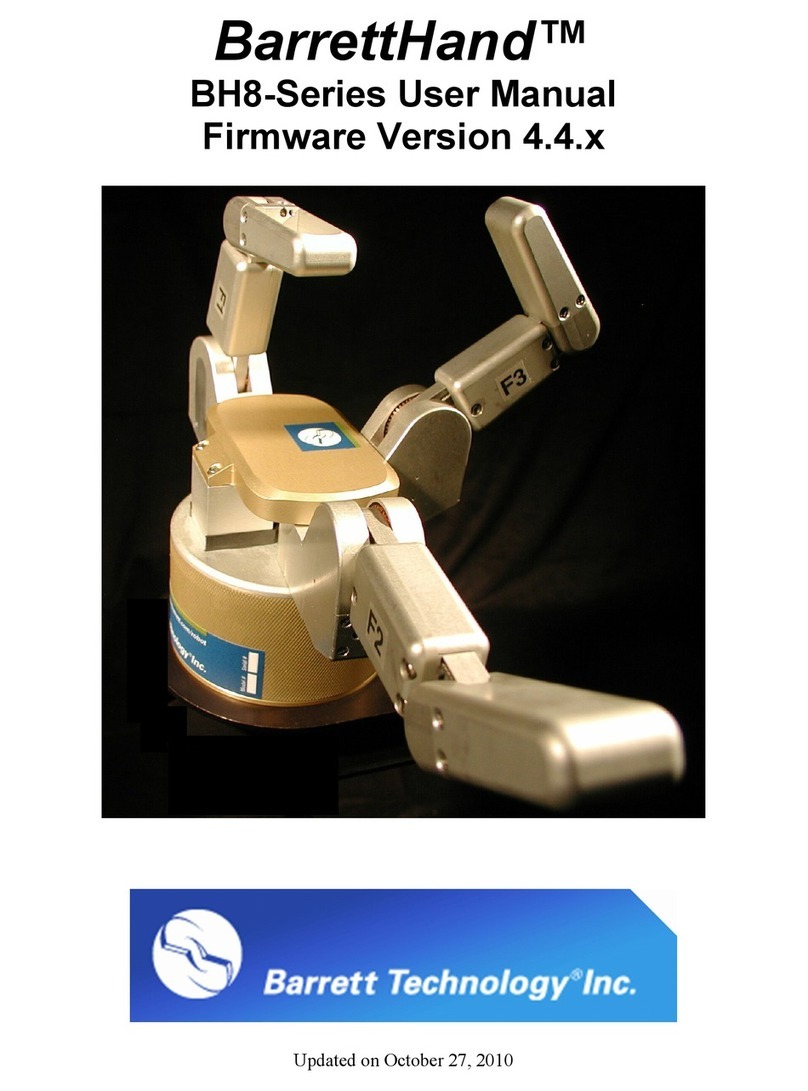

1.4 Technical Specifications

1.4.1 Overview

Dimensions: 132h x 658w x 192d (mm)

Mass: 6.9kg

Voltage requirements: 48V±2%

Current requirements: 5A Min, 15A Typ, 50A Max

Load limits: 50kg / finger

Operating temperature limits: 0 to 70 degrees C (internal)

Storage temperature limits: -25 to 95 degrees C (non-condensing)

Environmentally sealed: IP-65

Figure 2: Mechanical schematic of Wraptor

Table 1 - Joint Ranges

Inner Link Outer Link Spread

Min -5,500 -35,000 0

GCL Counts Max 72,000 79,000 37,000

Min -10 -80 0

Degrees Max 130 180 180

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 4 of 15

1.4.2 Conversion ratios

Joint rotation is measured in encoder counts at the motor shaft. To convert between the motor angle and the joint angle, use

the following table:

Table 2 – Conversion Ratios

Ratio Value

GCL Encoder Count : Motor Revolution 4096:1

Motor Revolution : Inner Link Revolution 49:1

Motor Revolution : Outer Link Revolution 39:1

Motor Revolution : Spread Revolution 18.28:1

Example Calculation- Determine the GCL encoder count value needed to move an inner link by 90º:

CountsGCL

vmotor

ntsEncoderCou

vlink

vmotorvlink 50176

Re1

4096

Re1

Re49

º360

Re1

º90 =

1.4.3 Brushless Motors

The Wraptor™ utilizes advanced DC brushless servo motors. Because the motors have no brushes, and thus less inherent

friction, they achieve a better torque/mass ratio than typical brushed servos. There is also no need to replace worn brushes

after the motors have been in service over a period of time. The following table shows Wraptor™ motor properties.

Table 3 - Wraptor™ Motor Properties

Parameter Value

Number of Phases 3

Number of Magnetic Poles 6

Rotor Magnet Material Highest-Grade Neodymium Rare-Earth

Commutation Sinusoidal Space-Vector Brushless PWM

Peak Torque 0.65 N-m

Steady State Torque 0.10 N-m

Torque Constant 0.065 N-m/amp

Motor Constant 0.042 N-m-W

1/2

Position Feedback for Spread motor 3 Digital Hall Sensors X 6 Motor Magnet Poles:

18 states per motor revolution that are interpolated

into 4,096 positions/motor rev. so true spread joint

resolution = 360/(18*18.28) = 1.1 degrees.

Position Feedback for inner and outer link motors Absolute Magnetic Encoder Sensor on Motor Shaft:

Absolute 4,096 positions/motor rev. via magnetic

encoder, so inner and outer link resolutions are

0.0018 & 0.0023 degrees respectively.

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 5 of 15

1.5 Theory of Operation

The host PC connects and communicates to the Wraptor™ using Ethernet. A device server inside the Wraptor™ converts

command packets between Ethernet and RS-232 serial (at 9600 bps) to communicate with the primary controller in the

Wraptor™ . This controller compiles the serial packet into a valid CAN packet and places it on the internal CAN (Controller

Area Network) bus to be delivered to the motor controllers (Pucks).

When the primary controller receives a CAN packet from a Puck which is addressed to the host PC, it sends the data to the

device server via RS-232 serial. The device server then routes the data back to the host PC via Ethernet.

1.6 Control Software

The BH8-610 Series System control software consists of:

1. Firmware (*.tek software), and

2. Example programs.

Included with the software in electronic form are:

1. BH8-610 Series User Manual (this manual)

The Wraptor™ has firmware that resides on the control electronics inside the palm. Depending on the configuration

purchased, you can control the Wraptor™ in one of three ways:

1. RS-232 Serial Communication: Simple, ASCII-based commands are sent over the serial port and interpreted by the

Wraptor™.

2. Ethernet Communication: Simple, ASCII-based commands are sent over an Ethernet network and interpreted by the

Wraptor™.

3. CAN Communication: High-speed, pre-compiled commands are sent directly to the motors of the Wraptor™,

eliminating the need for an interpreter and allowing absolute control of each motor.

1.7 C-Function Library

The Wraptor™ C-Function Library is a helpful tool for programming the Wraptor™ using the C language on IBM-

compatible PC’s without having to manage the issues of communication and timing of multi-axis motion control. The library

contains easy-to-use functions that streamline the development of custom motion control routines by the end user. All of the

functions are available when the library is linked to the program.

The C-Function Library is written in C and compiled for Windows 95 or higher. The library uses a multithreaded mechanism

for communications, allowing commands to be issued and responses received simultaneously. The library also manages all

input and output buffers and makes it easy to manipulate the Wraptor™ from a custom control application.

1.8 Control Software/Firmware Upgrades

Barrett Technology makes software and firmware upgrades periodically. Upgrades are available for purchase or free of

charge for customers of Barrett’s subscription service. Refer to Barrett’s enclosed Warranty and Subscription Service Policy

for more information.

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 6 of 15

2 Safety and Cautions

PLEASE READ THIS SECTION IN ITS ENTIRETY BEFORE USING YOUR WRAPTOR™.

Following these safety instructions will help prevent user injury and equipment damage.

2.1 Human Safety

•The Wraptor™ has been designed to apply human-scale maximum active forces of several kilograms even though the

Wraptor™ is designed to lift 50 kg once the fingers have secured their grasp. HOWEVER, the safety of the Wraptor™

is limited by the system safety, including the arm, which may be capable of tons of force. If the arm that transports the

Wraptor™ is able to move, then the end user must be aware that the Wraptor™ is capable of (and will) transmit the

arm’s end forces directly to people and delicate equipment. If an articulated robotic arm is rated for 50 kg, for example,

it is likely to be able to produce many tons of force in many leveraged configurations or when it is moving fast upon an

impact.

•Beware of situations when the Wraptor™ is stationary and secured on the end of a high-payload robot, but there is other

active moving equipment nearby. The Wraptor™ generally will not accommodate and reduce the force of any collision,

if it occurs.

•Do not place any part of your body or delicate objects within the grasp of the Wraptor™ without first verifying control

of the unit and confirming appropriate force levels.

•Beware that the sharp finger-nail like claws attached nominally to the outer links can cause pain and possibly cut bare

human skin depending on details of the grasp.

2.2 Wraptor Safety

•Do not connect or disconnect any electrical cables while the Power Supply is turned on. Failure to follow this instruction

could impart irreparable damage to the onboard electronics.

•Ensure that input power to the Positive- and Negative-voltage terminals are never reversed.

•Never allow power to be connected to the communication pins at the input connector of the Wraptor

•Do not exceed the load limit of the fingers, 50kg per finger. Consider all loading situations including accelerated loads,

cantilever loads from long objects, robot collisions, active loads, etc. (See also, next paragraph.)

•Similar to the concerns about Human safety when the Wraptor™ is mounted on a robotic arm, one must recognize that,

for example, a 50-kg lift robotic arm is easily capable of producing several tons (!!!) of force even when moving slowly

(in many configurations with high mechanical leverage) or when moving quickly just before a collision (regardless of

configuration). Since forces cannot be seen by eye, any contact with rigid surfaces or even with the base or other links of

the robotic arm can easily exceed tons of force without operator awareness. It is advisable to be very cautious when

running the full system to minimize these collisions or to ensure that a force/torque sensor or collision-break-away

mechanism is installed between the tool-plate of the robot and the base of the Wraptor™.

•Do not allow the Wraptor™ to be exposed to corrosive liquids that may cause damage to the body or cable of the unit.

•The operating temperature of the Wraptor™ is monitored continuously and automatically so that no Puck can approach

OTEMP, which is set nominally to 82 C. If the temperature reaches within 16C of OTEMP, then the max command

torque (motor current) will be temporarily limited to prevent damage. Under normal conditions, the Wraptor™ operates

between 35 and 60C. The Wraptor™ was designed with non-backdrivable finger joints to take advantage of the motors’

peak operating performance in short bursts. The spread, however, is backdrivable to aid in target-independent grasping

and requires constant motor current to actively hold position. Idling the spread motor (thus activating the spread brake),

when possible, will help keep the temperature lower.

•Do not immerse the Wraptor™ in liquid.

•Do not expose the Wraptor™ to corrosive liquids.

•Do not expose the Wraptor™ to mud or slurries.

•Ensure that the electrical Wraptor™ cable and connector cannot be damaged by collision, cutting, pulling, or twisting.

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 7 of 15

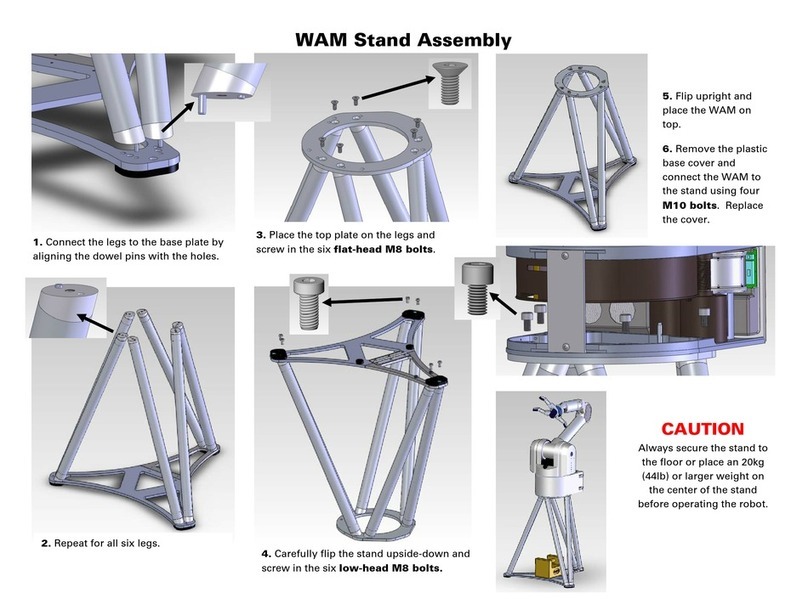

3 Initial Setup and Walk-through

1) Mount the Wraptor™ securely to a robot arm or test stand.

2) Supply the Wraptor™ with 48V using the included power supply.

3) Plug the Wraptor™ into an Ethernet network.

4) Launch the “DS Manager” utility, select “DS Settings”.

5) Enter a free IP address on your Ethernet subnet. Save your changes and exit the DS Manager.

6) Launch the TeraTerm application.

7) Type “HI” to perform a “Hand Initialize” on the Wraptor™.

a. Note: All commands must be followed by pressing <Enter>.

b. Note: All commands are case-insensitive and all white space is optional.

8) Get the initial temperature of the inner joint motors: Type “123 GET TEMP”

a. Note: “123 GET TEMP” is read as “Motors 1, 2, and 3, Get your TEMPerature”

b. Note: The Wraptor™ should return with its inner joint temperatures, in degrees C.

9) Move the fingers to position 20000: “123 M 20000”

a. Note: “123 M 20000” is read as “Motors 1, 2, and 3, Move to position 20000”

10) Move the spread (motor 4) to its mid-position: Type “4 M 18500”

11) Close finger 1: Type “1 C”

12) Open the whole hand: Type “O” (that is the letter ‘O’)

13) Get the final temperature of the inner joint motors: Type “123 GET TEMP”

14) Save the present positions for shutting down: Type “SAVE”

15) Remove power from the Wraptor™.

Figure 3: Screenshots of computer windows

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 8 of 15

4 Supervisory Control

Supervisory mode leverages the primary controller onboard the Wraptor™. This processor interprets incoming Supervisory

Commands and then applies control signals across the set of seven (7) motion-control microprocessors. Supervisory mode

allows you to command individual or multiple motors to close, open, and move to specific positions; it also provides for

setting the various configuration parameters and reporting positions and torques.

At the simplest level, Supervisory mode allows you to type and receive ASCII text characters on a terminal (using any type

of computer hardware or operating system, such as UNIX, Macintosh, PalmPilot, and proprietary robot controllers, etc.). To

automate grasping applications, you can write programs, scripts, or macros that send and receive these text characters through

an Ethernet connection (e.g. the optional Wraptor™ C-Function Library).

4.1 Commands

When the Wraptor™ firmware is ready to process a command, it prints a prompt of “=> “ to your host computer. A

command can then be entered as a single line, terminated by a carriage return character (0x0d). Once the firmware receives

the carriage return, it processes the line, executes the command, and then prints a new prompt. Once a command has been

started, no configuration changes can be made until the command has completed.

Many of the commands take one or more parameters; space characters should separate these from the command and each

other. The command syntax is:

<motorPrefixes><command> [<Arguments>]

Motor commands refer to one or more of the seven motors. By default, all seven motors are affected and the Wraptor™ will

simulate the BarrettHand’s functionality. To select fewer than seven motors, a motor prefix must be placed before the

command (with no space between the prefix and the command).

The motor prefixes and the resulting motors selected are:

Table 4 – Motor Prefixes

Value

Motor

1 Finger 1 (motors 1 and 5)

2 Finger 2 (motors 2 and 6)

3 Finger 3 (motors 3 and 7)

4 Spread (motor 4)

5 Finger 1 outer link (motor 5)

6 Finger 2 outer link (motor 6)

7 Finger 3 outer link (motor 7)

G Grasp (fingers 1, 2, and 3)

S Spread (motor 4)

IL Inner Links (motors 1, 2, and 3)

OL Outer Links (motors, 5, 6, and 7)

<No Motor Specified> All motors

Example:

"12SET DP 8000" sets the default position for fingers 1 and 2 to 8000 GCL counts

Supervisory mode commands are organized into the following categories:

1) Movement Commands

2) Motor Parameter Commands

3) Administrative Commands

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 9 of 15

4.1.1 Movement Commands

Movement commands are motor commands: they immediately affect one or more of the motors. Each can take motor

prefixes.

Command: C

Name: Close

Purpose: Commands the selected motor(s) to move fingers in close direction with a velocity ramp-down at target

limit. If selected, each finger moves towards the palm, and the spread motor moves so that fingers F1 and

F2 are adjacent to finger F3.

Arguments: (none)

Example: SC

Notes: The C command is similar to a MOVE command, with the value of the Close Target (CT) motor parameter

as the destination. Move is trapezoidal: Uses ACCEL to ramp up the velocity to MV, then uses –ACCEL

when approaching the target position. If an object is encountered before the trapezoidal velocity profile

completes, the torque will ramp up to MT. See HOLD for more info.

Command: HI

Name: Hand Initialize

Purpose: Initializes the selected motor controller(s), preparing them for use by other movement commands.

Arguments: (none)

Example: HI

Notes: HI must be run before any other movement command. Generally it is run without a motor prefix,

initializing all four motors; although, if desired, a subset of the motors can be specified. After an HI, all

motors are in their home position; at 0 encoder counts.

Command: HOME

Name: Home

Purpose: Moves the selected motor(s) to position 0.

Arguments: (none)

Example: SGHOME

Notes:

Command: IO

Name: Incremental Open

Purpose: Opens the selected motor(s) DS counts.

Arguments: (none)

Example: 12IO

Notes:

Command: IC

Name: Incremental Close

Purpose: Closes the selected motor(s) DS counts.

Arguments: (none)

Example: GIC

Notes:

Command: M

Name: Move

Purpose: Moves the selected motor(s) to the given position. If no argument specified, then the motor(s) move(s) to

the position given by parameter DP.

Arguments: Target position in GCL counts (optional)

Example: 13M 1000

Notes: Move is trapezoidal: Uses ACCEL to ramp up the velocity to MV, then uses –ACCEL when approaching

the target position. If an object is encountered before the trapezoidal velocity profile completes, the torque

will ramp up to MT. See HOLD for more info.

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 10 of 15

Command: O

Name: Open

Purpose: Commands the selected motor(s) to move fingers in open direction with a velocity ramp-down at target

limits. If selected, F1, F2, and F3 open away from the palm, and the spread motor moves so that fingers F1

and F2 are opposite finger F3.

Arguments: (none)

Example: GO

Notes: The O command is similar to a MOVE command, with the value of the OT motor parameter as the

destination. Move is trapezoidal: Uses ACCEL to ramp up the velocity to MV, then uses –ACCEL when

approaching the target position. If an object is encountered before the trapezoidal velocity profile

completes, the torque will ramp up to MT. See HOLD for more info.

Command: T

Name: Terminate power

Purpose: Turns of power to the selected motor(s).

Arguments: (none)

Example: ST

Notes:

Command: TC

Name: Torque-Controlled Close

Purpose: Sets the torque of selected motor(s) to MT.

Arguments: (none)

Example: STC

Notes: Does not check for hitting joint limits. Torque is applied until a new torque is applied or a different

movement command is issued. Use caution when issued with a high MT- there is no velocity limit imposed

during a torque move.

Command: TO

Name: Torque-Controlled Open

Purpose: Sets the torque of selected motor(s) to –MT.

Arguments: (none)

Example: STO

Notes: Does not check for hitting joint limits. Torque is applied until a new torque is applied or a different

movement command is issued. Use caution when issued with a high MT- there is no velocity limit imposed

during a torque move.

4.1.2 Motor Parameter Commands

Motor parameter commands act on the configuration parameters for one or more of the motors. See Section 4.2 for a

complete list of motor parameters.

Command: FSET

Name: Finger Set

Purpose: Sets the given parameter to the given value for the selected motor(s)

Arguments: <parameterName> <parameterValue>

Example: SFSET DS 100

Notes: SET is a synonym for FSET.

Command: FGET

Name: Finger Get

Purpose: Gets and prints the given parameter's value for the selected motor(s). Each parameter prints one value for

each selected motor separated by spaces.

Arguments: <parameterName>

Example: SFGET DS

Notes: GET is a synonym for FGET

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 11 of 15

Command: FLOAD

Name: Finger Load

Purpose: Loads the parameters of the selected motor(s) from non-volatile storage. This is done whenever the

firmware starts up.

Arguments: (none)

Example: 3FLOAD

Notes: The non-volatile storage used does not depend on the super capacitor, so it retains its value even if the

firmware is lost. LOAD is a synonym for FLOAD.

Command: FSAVE

Name: Finger Save

Purpose: Sets the parameters of the selected motor(s) to non-volatile storage.

Arguments: (none)

Example: 123FSAVE

Notes: SAVE is a synonym for FSAVE.

Command: FDEF

Name: Finger Default

Purpose: Sets the parameters of the selected motor(s) back to their factory default values.

Arguments: (none)

Example: SFDEF

Notes: Does not save the changed values to non-volatile storage. DEF is a synonym for FDEF.

4.1.3 Administrative Commands

Administrative commands implement various housekeeping functions.

Command: RESET

Name: Reset

Purpose: Resets the controller software. This is equivalent to doing a power cycle.

Arguments: (none)

Example: RESET

Notes: An HI is necessary after a RESET command.

Command: VERS

Name: Version

Purpose: Prints the firmware version.

Arguments: (none)

Example: VERS

Notes:

4.2 Parameters

Motor parameters change how a motor functions. Parameters are organized into the following categories:

1) Movement Parameters

2) Status Parameters

3) Advanced Parameters

4) Configuration Parameters

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 12 of 15

4.2.1 Movement Parameters

Movement parameters affect how a given motor moves.

Parameter: DP

Name: Default Position

Purpose: Destination of M command if no argument specified

Values: -2E9 to +2E9 (GCL counts)

Default: Inner Link: 25000

Outer Link: 25000

Spread: 18500

Notes: This parameter’s true range of useful values is bounded by the joint limits of the axes (see Table 1- Joint

limits).

Parameter: DS

Name: Default Step

Purpose: Size of IC or IO command movement if no argument specified

Values: -32768 to +32,767 (GCL counts)

Default: Inner Link: 4096

Outer Link: 4096

Spread: 4096

Notes: This parameter’s true range of useful values is bounded by the joint limits of the axes (see Table 1- Joint

limits). Setting DS to a negative number is allowed, but it is not recommended. Doing so would make the

finger move in the open direction during an IC (Incremental Close) command, for example.

Parameter: MT

Name: Max Torque

Purpose: Maximum torque to apply during any joint movement.

Values: -32768 to +32,767 (mA, roughly)

Default: 6000

Notes: It is useful to set this parameter before issuing a TC, TO, or M command.

Parameter: MV

Name: Max Velocity

Purpose: Maximum velocity to spin the motor during a trapezoidal move (M) command.

Values: -32768 to +32,767 (GCL counts / ms)

Default: Inner Link: 100

Outer Link: 100

Spread: 20

Notes: During a trapezoidal move, the joint will accelerate with ACCEL up to MV.

4.2.2 Status Parameters

Motor status parameters are read-only and give information about the state of a motor.

Parameter: P

Name: Position

Purpose: The present position of the motor in GCL Counts.

Values: See Table 1- Joint limits

Default: N/A

Notes:

Parameter: TEMP

Name: Temperature

Purpose: The present temperature on the controller in degrees C.

Values: 0 to 125

Default: N/A

Notes:

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 13 of 15

Parameter: PTEMP

Name: Peak Temperature

Purpose: The maximum temperature ever experienced by this controller

Values: 0 to 125

Default: N/A

Notes: This value is never reset; it is maintained through power failures and firmware downloads.

Parameter: SN

Name: Serial Number

Purpose: The serial number of the controller.

Values: N/A

Default: N/A

Notes: This value is never reset; it is maintained through power failures and firmware downloads.

4.2.3 Advanced Parameters

Users do not generally need these commands, but they might be useful.

Parameter: ACCEL

Name: Acceleration

Purpose: Maximum acceleration and deceleration when moving from one position to another.

Values: 0 to 65,535

Default: Inner Link: 100

Outer Link: 100

Spread: 10

Notes: While the ACCEL parameter has a rather large range of values that it can accept, the motor can only follow

a small subset of those values. In general, the useful range is from 0 to approx. 60. Above 60, the motors

cannot provide enough torque to accelerate that quickly. The units for acceleration is defined as 256 * GCL

Counts / ms / ms. So ACCEL = 10 yields 10/256 cts/ms/ms acceleration.

Parameter: CT

Name: Close Target

Purpose: This is the position gone to by a C (“Close”) command.

Values: -2E9 to +2E9

Default: Inner Link: 72000

Outer Link: 72000

Spread: 37000

Notes: This parameter’s true range of useful values is bounded by the joint limits of the axes (see Table 1- Joint

limits).

Parameter: HOLD

Name: Hold

Purpose: If non-zero, then the motor is left energized after each motion command in order to hold the position

constant.

Values: 0, 1

Default: Inner Link: 0

Outer Link: 0

Spread: 1

Notes: Since the fingers are not back-drivable, this is generally set to 1 only for the spread motor.

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 14 of 15

Parameter: IOFF

Name: Initialization Offset

Purpose: Number of GCL counts to move from the joint limit encountered during initialization (HI). After this move

is complete, the joint’s zero position is defined as the present position.

Values: -2E9 to +2E9

Default: Inner Link: 5575

Outer Link: -79872

Spread: 0

Notes: During an HI, the joint is driven into its joint limit at velocity IVEL, then moved away from the limit by

IOFF GCL counts. The final position is defined as the joint’s zero position. This parameter’s true range of

useful values is bounded by the joint limits of the axes (see Table 1- Joint limits).

Parameter: IVEL

Name: Initialization Velocity

Purpose: Velocity at which to drive the joint into its limit during initialization (HI).

Values: -32768 to +32,767 (GCL counts / ms)

Default: Inner Link: -20

Outer Link: 50

Spread: -10

Notes: During an HI, the joint is driven into its joint limit at velocity IVEL, then moved away from the limit by

IOFF GCL counts. The final position is defined as the joint’s zero position. This parameter’s true range of

useful values is bounded by the joint limits of the axes (see Table 1- Joint limits).

Parameter: KD

Name: Derivative Gain

Purpose: The difference between the previous position error and the present position error is multiplied by this gain

to obtain the derivative component of the generated command torque.

Values: -32768 to +32,767

Default: Inner Link:8000

Outer Link: 8000

Spread: 0

Notes: Increasing this value reduces the instability caused by a high KP with a risk of instability due to

overcompensation.

Parameter: KI

Name: Integral Gain

Purpose: The historical sum of the position errors are multiplied by this gain to obtain the integral component of the

generated command torque.

Values: -32768 to +32,767

Default: Inner Link: 12

Outer Link: 12

Spread: 0

Notes: Increasing this value makes the actual position and command position align more closely with a risk of

instability.

Parameter: KP

Name: Proportional Gain

Purpose: The error between the command position and the actual position is multiplied by this gain to obtain the

proportional component of the generated command torque.

Values: -32768 to +32,767

Default: Inner Link: 2500

Outer Link: 2500

Spread: 1500

Notes: Increasing this value makes the joint control stiffer with a risk of instability.

Wraptor™ User Manual service@barrett.com www.barrett.com

© 2007 Barrett Technology®, Inc. Document: D2000, Version: AB.00 Page 15 of 15

Parameter: OT

Name: Open Target

Purpose: This is the position gone to by an O (“Open”) command.

Values: -2E9 to +2E9

Default: 0

Notes: This parameter’s true range of useful values is bounded by the joint limits of the axes (see Table 1- Joint

limits).

Parameter: TSTOP

Name: Time to Stop

Purpose: Time in milliseconds before motor is considered stopped.

Values: 0 to 65,535

Default: Inner Link: 1000

Outer Link: 1000

Spread: 1000

Notes: WARNING: Please use caution when adjusting this parameter. Setting TSTOP higher than its default can

result in the motors heating up very quickly under moderate to heavy usage.

4.2.4 Configuration Parameters

Global configuration parameters affect the hand as a whole.

Parameter: BAUD

Name: Baud rate

Purpose: Controls the serial port baud rate.

Values: 300, 1200, 2400, 9600, 19200, 28800

Default: 9600

Notes: If you change BAUD, you will need to change the baud rate at which the Tibbo Ethernet device server

communicates with the primary Wraptor™ controller. Changes to BAUD are not saved between power

cycles.

Parameter: OTEMP

Name: OverTemperature

Purpose: When the controller temperature comes within 16 C of OTEMP, MT is automatically reduced for every

degree rise in temperature. When the temperature >= OTEMP, MT is set to zero. As the controller cools,

MT is automatically increased up to its preset value.

Values: 0 to 125

Default: 82

Notes: Value is temperature in degrees C.

Parameter: TIE

Name: Tie the commands of one motor to another

Purpose: Echo commands from one motor to another. Primarily to simplify control of the inner and outer links.

Values: -32768 to +32,767 (GCL counts / ms)

Default: Motor 1: 5, Motor 2: 6, Motor 3: 7, Motor 4: 0, Motor 5: 0, Motor 6: 0, Motor 7: 0

Notes: “1 SET TIE 5” will make motor 1 echo to motor 5 any commands it receives. “1 SET TIE 0” will turn off

the TIE.

Table of contents

Other Barrett Robotics manuals