Barrus SHIRE 14 85 WB User manual

SHIRE WORK BOAT MANUAL

SHIRE 14 85 WB

SHIRE 14 130 WB

ISSUE 10

Please read in conjunction with

John Deere Operational Manual

&

PRM Gearbox Manual

optional:

VDO Travel Power Manual

Note there may be several optional extras, or alternative components, that might be

fitted to an engine that are not shown in this book.

Enter your engine identification details in the spaces provided above.

E. P. BARRUS LIMITED, Launton Road, Bicester, Oxfordshire. OX26 4UR

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 2 of 52

Tel: 01869-363636 Fax: 01869-363610 www.barrus.co.uk

PLEASE NOTE:

This manual has been compiled to help you to operate your engine and its associated

parts with safety and pleasure. Please read it carefully and familiarise yourself with the

engine and its parts before operation.

E.P.Barrus reserve the right to change the specification of its products and manuals

without prior notice.

Depending upon the equipment specification of the engine and accessories fitted, there

may be discrepancies with the information presented in this handbook. No claims may

be pursued in this respect.

WARNING:

THIS MANUAL FORMS AN INTEGRAL PART OF THE ENGINE IT ACCOMPANIES,

IF A TRANSFER OF TITLE OCCURS, IT MUST ALWAYS BE HANDED OVER TO THE

NEW OWNER.

WARRANTY

This Limited Warranty provides coverage for three (3) years (or 2000 hours which ever

occurs first) for commercial users from the date of warranty registration. The repair or

replacement of parts, or the performance of service under this warranty, does not

extend the life of this warranty beyond its original expiry date.

PRM gearboxes are covered by a two (2) year warranty.

To ensure that you have been registered for your warranty, please ask your Boat-

Builder or Engine supplier to provide your portion of the registration form.

The Warranty will only apply if the following have been carried out:

1/ The Installation Check List in the Installation Section has been fully completed.

2/ The boat builder or engine installer has completed the Boat Builder Section on the

Service Record Card (located at the back of this manual) regarding hand over and

commissioning of boat.

3/ The registration form has been completed and returned to E.P Barrus.

Engine alternator, starter motor and electrical components are only covered by a one

(1) year warranty.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 3 of 52

CONDITIONS THAT MUST BE MET IN ORDER TO OBTAIN WARRANTY COVERAGE

Warranty coverage is only available from an authorised dealer in the country in which

the sale occurred. Routine maintenance outlined in the Owners Manual must be

performed using genuine parts in order to maintain warranty coverage. If the customer

performs maintenance, Barrus reserves the right to make future warranty coverage

possible only with proof of proper maintenance.

WARRANTY CLAIMS

Warranty claims shall be made by an authorised dealer or boat builder.

The dealer or boat builder will then arrange for the inspection and any necessary

repairs. If the repairs carried out are not covered by the warranty, purchaser shall pay

for all related labour and material, and any other expenses associated with that service.

WHAT IS NOT COVERED

This limited warranty does not cover routine maintenance items, adjustments, normal

wear and tear, damage caused by abnormal use, operation of the product in a manner

inconsistent with the recommended operation/duty cycle section of the Owners Manual,

accident, submersion, improper installation (proper installation specification and

techniques are set forth in the Operations and First time running sections in this

manual), use of an accessory or part not manufactured or sold by us, or alteration or

removal of parts. Expenses related to crane-out, launch, towing, storage, telephone,

rental, inconvenience, slip fees, insurance coverage, loan payments, loss of time, loss

of income, or any other types of accidental or consequential damages are not covered

by this warranty.

Failure to use John Deere approved oils and coolants will invalidate any warranty.

Engine electrical systems fitted with alternator boost charge systems or any other

electrical management systems other than those approved by Barrus are not covered

by warranty.

Engine and fuel equipment is not covered by warranty if bio-diesel is used in the fuel

system. Also if no type of water trap is incorporated into fuel system.

Damage due to rust or corrosion, submersion, or unreasonable exposure to the

environment, such as exposure to high humidity, rain fall, or seawater, or conditions

resulting in the freezing of cooling water are also not covered.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 4 of 52

Dirty Fuel:

Engines that do not operate correctly as a consequence of using fuel that is not of the

correct grade, or is contaminated with either dirt, water or biological growth, is not

covered by warranty. Also, any replacement parts that are required as a consequence

of using incorrect or contaminated fuel are also not covered by warranty. Engine Fuel

Injection equipment is only covered by warranty for the period of three years.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 5 of 52

Contents

SECTION 1 - SAFETY PRECAUTIONS .................................................................................... 7

1. General ...................................................................................................................... 7

2. Lifting ......................................................................................................................... 7

3. Rotating Shafts and Belts ........................................................................................... 7

4. Exhaust System ......................................................................................................... 8

5. Launching and Lifting Boats ....................................................................................... 8

6. Batteries..................................................................................................................... 9

SECTION 2 - ENGINE IDENTIFICATION ................................................................................ 10

SECTION 3 - INSTALLATION ................................................................................................. 11

1. Ventilation ................................................................................................................ 11

2. Engine Beds............................................................................................................. 11

3. Pressurised Water Header Tank .............................................................................. 11

4. Shaft Connection and Propeller selection................................................................. 13

5. Engine Anti-Vibration Mounts ................................................................................... 13

6. Engine Mount Installation ......................................................................................... 14

7. Engine Alignment ..................................................................................................... 15

8. Engine Inclination..................................................................................................... 16

9. Electrics ................................................................................................................... 16

10. Electrical Options ..................................................................................................... 17

11. Belt Replacement..................................................................................................... 18

12. Engine Oil ................................................................................................................ 19

13. Fuel.......................................................................................................................... 20

14. Coolant..................................................................................................................... 21

15. Calorifier (optional) ................................................................................................... 22

16. Control Cables ......................................................................................................... 22

17. Domestic Battery Bank (with optional Twin Alternator Engines)................................ 23

18. Control Panel ........................................................................................................... 24

19. Seawater Strainer..................................................................................................... 25

20. Exhaust System (Dry Exhaust)................................................................................. 25

21. Hydraulic Drive Transmissions ................................................................................. 28

22. Engine Start Battery ................................................................................................. 28

23. Installation Check list................................................................................................ 29

SECTION 4 –OPERATION ..................................................................................................... 30

1. Starting The Engine For The First Time.................................................................... 30

2. Starting Procedure ................................................................................................... 30

3. Stopping Procedure.................................................................................................. 31

4. Refuelling ................................................................................................................. 31

5. Diesel Fuel Additive.................................................................................................. 32

6. Exhaust Back Pressure ............................................................................................ 32

7. Shifting in and out of gear......................................................................................... 32

SECTION 5 - SERVICE PROCEDURE .................................................................................... 33

1. Engine Oil and Filter Change ................................................................................... 33

2. Air Filter Check & Change ........................................................................................ 34

3. Gearbox Oil Change................................................................................................. 34

4. Disposal of Oil and Related Items ............................................................................ 35

5. Primary Fuel Filter Water Drain ................................................................................ 36

6. Primary Fuel Filter Change....................................................................................... 37

7. Secondary Fuel Filter Change.................................................................................. 37

8. Fuel System Bleeding .............................................................................................. 37

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 6 of 52

9. Cooling System ........................................................................................................ 38

10. Belt Adjustment (Twin Alternators) ........................................................................... 38

11. Belt Maintenance...................................................................................................... 39

12. Belt Replacement..................................................................................................... 40

13. Deluxe Panel Maintenance....................................................................................... 41

14. Sacrificial Anode Change ......................................................................................... 41

15. Raw Water Pump Impeller Change .......................................................................... 42

16. Engine Heat Exchanger Tube Stack Flushing. ......................................................... 42

17. Winterization of Seawater Cooling System. .............................................................. 42

SECTION 6 - SERVICE PARTS............................................................................................... 43

SECTION 7 - SERVICE SCHEDULE ....................................................................................... 44

SECTION 8 - WIRING DIAGRAMS.......................................................................................... 45

1. Engine Wiring Diagram, Shire 14 85/130 WB........................................................... 46

2. Deluxe Control Panel Wiring Diagram ...................................................................... 47

3. RDG20710111 - Deluxe Control Panel..................................................................... 48

4. 5kW VDO Travel Power System............................................................................... 48

SECTION 9 –AFTERLIFE RECYCLING ................................................................................. 49

SECTION 10 - DEALER LIST .................................................................................................. 50

SERVICE RECORD CARD...................................................................................................... 52

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 7 of 52

SECTION 1 - Safety Precautions

1. General

It is the responsibility of the installer/operator to ensure that the finished installation

complies with the relevant health & safety requirements and or any other legislative

requirements before commissioning.

Ensure that the engine battery isolator switch is in the off position and the key removed

from the control panel before carrying out any maintenance or repairs.

Ensure that all installations and boat alterations comply with any appropriate local,

regional, national or international regulations. When installing new propulsion systems

(that are not identical to the original ones) into existing craft, a new vessel Post

Construction Assessment will be required, and carried out by an independent notified

body.

2. Lifting

DANGER: CRUSH HAZARD!

NEVER STAND UNDER A HOISTED ENGINE. IF THE HOIST MECHANISM FAILS,

THE ENGINE WILL FALL ON YOU, CAUSING SERIOUS INJURY OR DEATH.

The lifting points supplied with the engine are for lifting the engine/gearbox only. A

suitable spreader bar must be employed to prevent over-stressing either bracket during

any lift.

3. Rotating Shafts and Belts

WARNING:

SEVERE HAZARD! KEEP HANDS AND OTHER BODY PARTS AWAY FROM

MOVING/ROTATING PARTS. WEAR TIGHT FITTING CLOTHING AND KEEP YOUR

HAIR SHORT OR TIE BACK. REMOVE ALL JEWELLERY BEFORE COMMENCING

WORK. CHECK BEFORE STARTING THE ENGINE THAT ANY TOOLS OR RAGS

USED DURING MAINTENANCE HAVE BEEN REMOVED FROM THE AREA.

The engine and its accessories are not intended to be put into operation until it is

integrated into the boat as a whole. No person should be in the engine compartment

whilst the engine is running.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 8 of 52

4. Exhaust System

WARNING:

EXHAUST HAZARD! NEVER OPERATE ENGINE IN A BOATS ENGINE BAY

WITHOUT PROPER VENTILATION. NEVER BLOCK VENTS OR OTHER MEANS OF

VENTILATION. ALL COMBUSTION ENGINES CREATE CARBON MONOXIDE GAS

DURING OPERATION. ACCUMULATION OF THIS GAS COULD CAUSE ILLNESS OR

EVEN DEATH.

WARNING:

BURN HAZARD! WAIT UNTIL THE EXHAUST COOLS BEFORE YOU TOUCH IT.

Exhaust gases may have temperatures as high as 650oc and contain elements which

are harmful if ingested. It is therefore essential that exhaust systems are gas tight and

lagged to prevent accidental burning.

5. Launching and Lifting Boats

Care must be taken when launching or craning new boats into or out of the waterway,

so that water does not enter the engine via the exhaust system or air vents. It is

recommended that these are blocked temporarily whilst undertaking this procedure.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 9 of 52

6. Batteries

DANGER:

EXPLOSIVE GASES

EXPLOSION HAZARD! NEVER SHORT OUT THE BATTERY TERMINALS,

INCLUDING WHEN CHECKING THE REMAINING BATTERY CHARGE THIS WILL

RESULT IN A SPARK AND MAY CAUSE AN EXPLOSION OR FIRE.

WARNING:

BURN HAZARD! BATTERIES CONTAIN SULPHURIC ACID. NEVER ALLOW

BATTERY FLUID TO COME IN CONTACT WITH SKIN, EYES OR CLOTHING.

SEVERE BURNS COULD RESULT. MAKE SURE THE CORRECT PERSONAL

PROTECTION EQUIPMENT IS WORN.

•Batteries can produce explosive gases, keep sparks and flames away from the

battery.

NO SMOKING

•Batteries contain sulphuric acid; if splashed on skin or eyes, flush well with water

and seek medical advice.

•Keep the battery tops and battery compartment ventilated at all times.

•If disconnecting the battery; remove the earth lead FIRST; and re-connect it last.

•If charging the battery; ensure that the charger is switched off before connecting and

disconnecting.

•Do not tip the battery on its side.

•Please see label on battery or manufacturer’s instructions for specific information.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 10 of 52

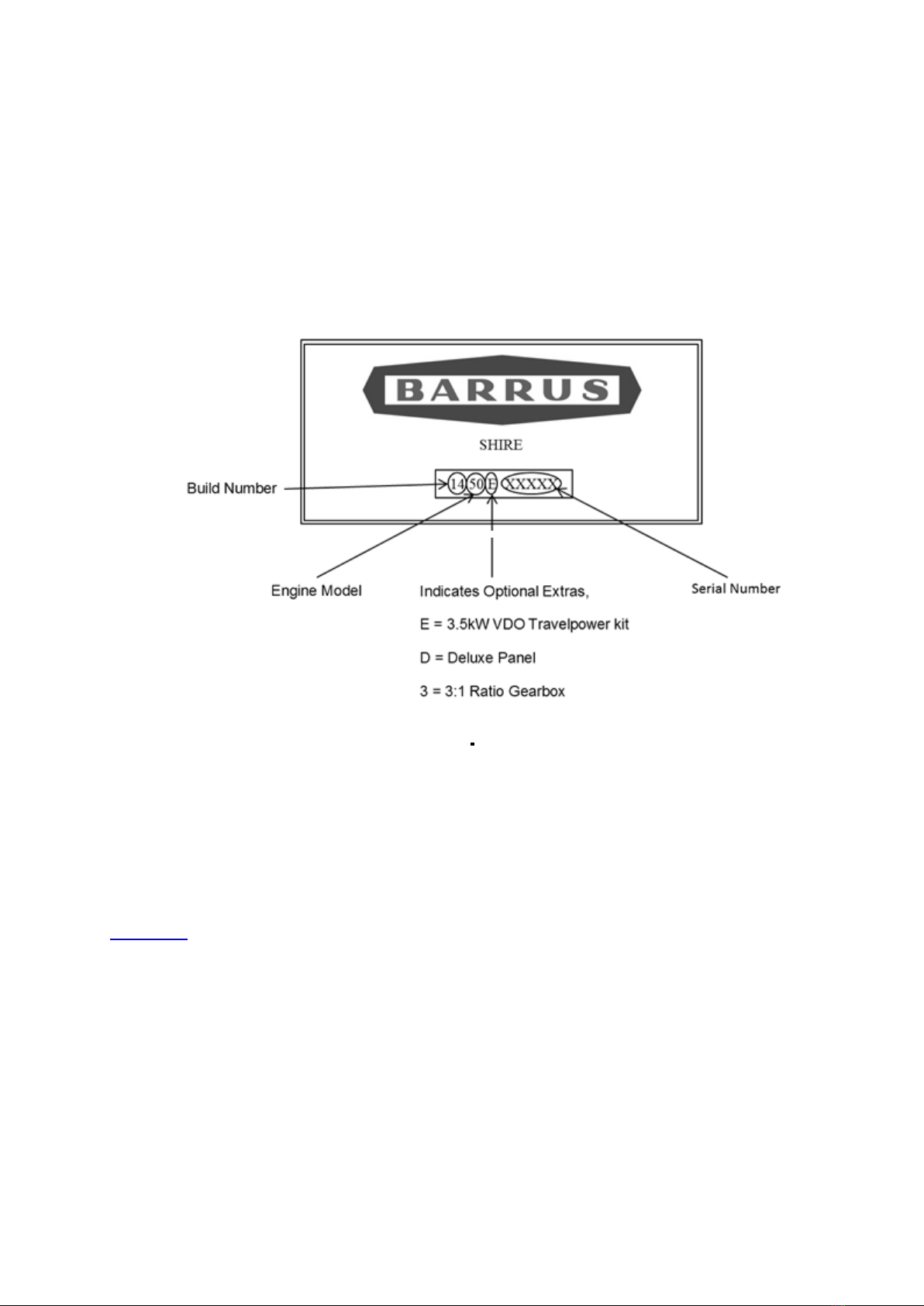

SECTION 2 - Engine Identification

Please quote the engine identification number during any enquiry or when ordering

spare parts.

This is found engraved into the brass plate, on top of the engine rocker cover and

stamped to the crankcase above the starter motor.

An example of the engine identification plate is as follows:

Figure 2-1: Engine Identification Badge

Note: There are a number of optional extras that may be fitted to an engine for

particular customer’s engine that are not listed here.

A list of common item service part numbers can be found in Shire service parts, in

Section 6 Service Parts.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 11 of 52

SECTION 3 - Installation

1. Ventilation

•All internal combustion engines radiate heat and require cool, clean air for complete

combustion purposes.

•Please ensure that adequate engine room ventilation is provided, by fitting at least

two vents of an aperture of not less than 15,000 mm2each (24 in2).

An allowance must be made for any grills or louvres placed in the

airflows and generally, an increase of 25% in area is sufficient to overcome any

restriction problems.

2. Engine Beds

•These should be a minimum of 10mm thick and extended rearward and be welded

to the hull and forward to the bulkhead. There must be webs or gussets welded in

place midway to prevent flexing. They may be steel or stainless steel glassed into a

GRP hull.

3. Pressurised Water Header Tank

•The pressurised header tank should be mounted higher than the level of the engine

and no more than 1 metre and not less than 300mm from the engine, to prevent

cooling system air locks.

•Shire 14 85 WB - The smaller internal diameter hose tail (left side of tank) should be

connected to the top of the engine. This is the air-bleed. The larger internal diameter

hose-tail (right side of tank) should be connected to the lower pipe on the engine

(circled left). This is the water-fill. The hoses MUST be connected correctly. A

constant rise on pipework is required to prevent air locks

See Figures 3-1 and 3-2

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 12 of 52

Figure 3-1: Shire 14 85 WB Header Tank Connections (Crank mounted pump)

Figure 3-2: Shire 14 85/130 WB Header Tank Connections (Belt Driven Pump)

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 13 of 52

4. Shaft Connection and Propeller selection

•Some type of flexible coupling must be used to connect the gearbox output flange to

the propeller shaft flange. Various coupling flanges are widely available to assist with

this.

•Please note, underperforming engines will not be covered under warranty if the

cause of the poor performance is found to be the use of an inappropriate propeller.

5. Engine Anti-Vibration Mounts

•Ensure that the engine feet do not end up at the top of the thread on the engine

mounts, this puts undue pressure on them and can result in excessive engine

movement and premature mount failure. Mount the engine using the steel packing

plates supplied under the engine mounts RDG3906, see general arrangement

drawings.

•Ensure that the engine has been installed for at least 24 hours before shaft

alignment is checked, this allows the mounts time to settle under the engine weight.

•Ensure that the anti-vibration mount centre screw is sufficiently raised so as not to

touch the engine bed. If this occurs excessive engine vibration will be experienced

through the hull.

•For best results, fit the front anti vibration mounts into the front holes in the engine

rails. If engine room space is a problem the mounts can be fitted slightly further back

in alternative holes, and the front of the rail cut off –leaving 50mm of material to

retain strength (measuring from the centre of the mount hole to the front end of the

rail). Note: this procedure is only possible on non E Kit/VDO TravelPower engines,

and may result in a very slight increase in vibration. The hole positions are show in

Figure 3-6.

•The Anti Vibration mounts have a small number stamped into them, a Shire 14 85

has “55”(Shore Hardness), and a Shire 14 130 has “65”(Shore Hardness). For Part

Numbers, see the Service Parts section.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 14 of 52

6. Engine Mount Installation

Figure 3-3: Correct Anti-Vibration Mount Installation

•Care should taken to install mounts parallel to the engine rails with the washer and

locknut firmly tightened on the cover of the mount. The maximum distance from the

top of the locknut to the base of the adjusting nut must not exceed 5mm; any greater

adjustment should be made using shims.

Figure 3-4: Correct Anti-Vibration Mount Installation

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 15 of 52

Figure 3-5: Anti-Vibration Mount Installation Points

7. Engine Alignment

•The gearbox output shaft flange and propeller shaft input flange must be almost

perfectly aligned. A maximum of 0.05mm (0.002") misalignment in any plane is

acceptable. Ensure alignment is rechecked after the first 4 hours of running, at the

end of the first month and annually thereafter.

•If the engine is out of alignment it will result in excessive vibration and possible

damage to the stern tube and propeller shaft.

•Boats that are fitted with fully flexible drive couplings should still have the engine and

shaft alignment as close as possible. A dummy shaft may be required for this

purpose.

Some types of flexible shaft couplings require the input and output to be

misaligned, check with the coupling manufacturer’s installation instructions.

Normal mounting position.

Alternative mounting position if

engine compartment space is

restricted.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 16 of 52

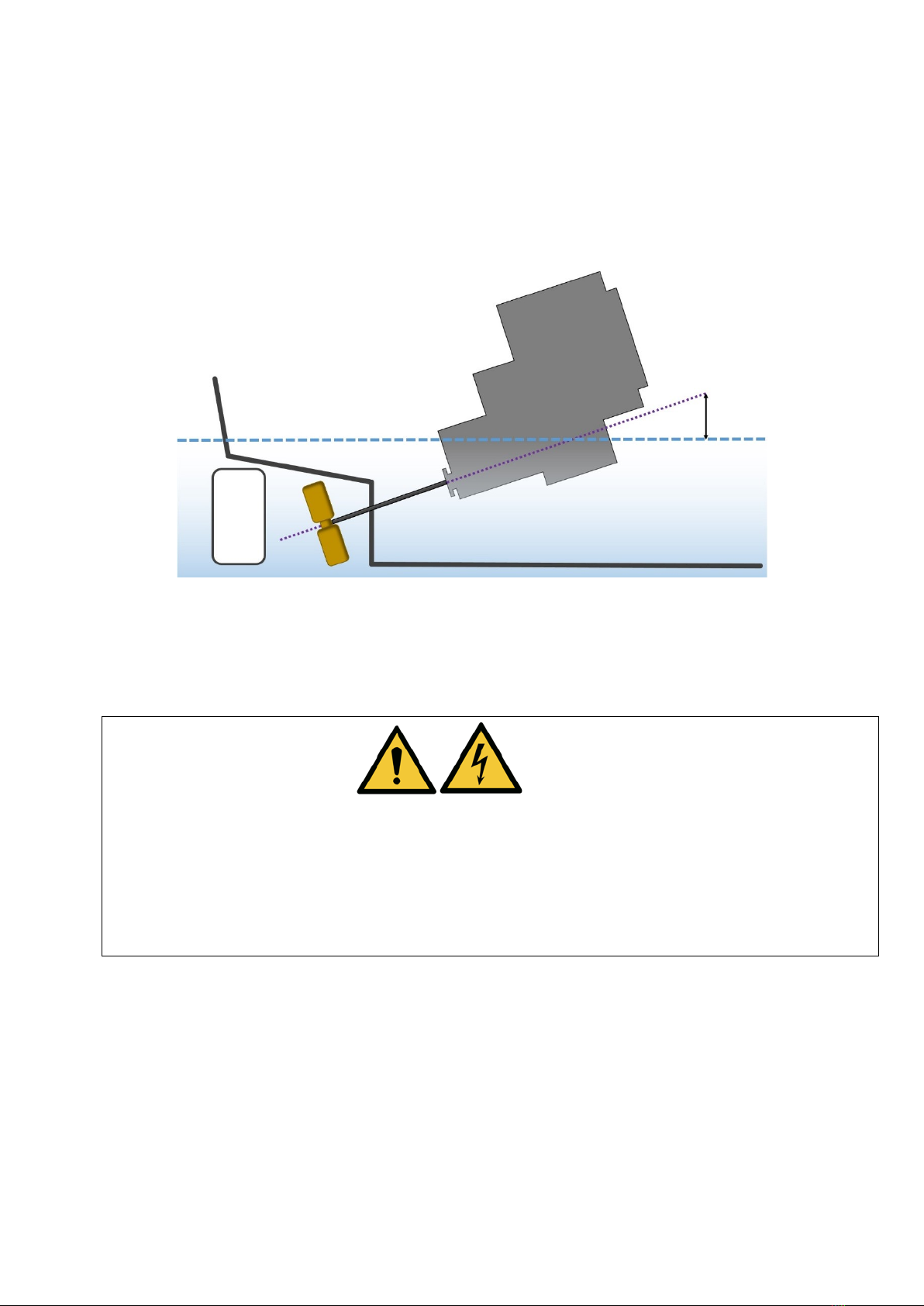

8. Engine Inclination

•The engine installation angle is the angle of the crankshaft centre to the water line

(Figure below).

•The Propulsion Efficiency decreases as the engine installation angle increases

•The maximum engine installation angle is 15°.

Figure 3-6: Maximum Engine Installation Angle

9. Electrics

WARNING:

The blue link wire must be removed when the domestic battery positive terminal lead has

been connected to the terminal post.

Do not run the engine without this wire in place or without the domestic battery positive lead

connected otherwise alternator damage will occur.

If the engine is going to run for more than 1 hour with the blue link wire in place, remove

domestic alternator drive belt to prevent alternator damage.

•If an optional larger output alternator, or 24V equipment, is fitted to either a new

engine, or fitted to an old engine as an upgrade, ensure that all cables, master switches,

terminals, split charge relays etc are of sufficient capacity for the increased

current/voltage.

•Do not attach any part, hose or cable to the engine wiring harness. There is a

warning label attached to the harness to remind you of this.

Water Line

Engine Installation Angle

MAX 15°

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 17 of 52

Single Alternators

•On engines fitted with single alternators, connect the main positive battery cable to

the starter motor solenoid terminal.

•Do not attach any part, hose, or cable to the engine wiring harness. There is a

warning label attached to the harness to remind you of this.

•Connect the wiring extension harness multi plug to the panel plug, and the other end

to the engine.

•Connect the start battery positive cable to the engine starter motor solenoid terminal.

•Starter motor battery cable size to be a minimum of 50mm2.

Twin Alternators

•Shire 14 85/130WB - Connect the domestic battery positive cable to the 120A

alternator B+ terminal (see wiring diagram). This ensures that the 140A charges the

start battery.

•Use 50mm2cable for 240A alternator and 40mm2cable for 140A

•Both negative battery terminals can be connected to a common earth point.

10. Electrical Options

•If the engine is fitted with the optional 230V VDO travel power system, refer to the

manual supplied with it for correct wiring, control box installation and operation.

•The Shire range can be supplied with other optional additional 12v or 24v

alternators. A 24 V Alternator will be supplied fitted but not wired. It is the

responsibility of the boat builder to ensure that this is correctly wired to the boats

electrical system.

•If an optional 24V equipment is fitted to either a new engine, or fitted to an old

engine as an upgrade, ensure that all cables, master switches, terminals, split

charge relays etc are of sufficient capacity for the increased current/voltage.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 18 of 52

11. Belt Replacement

•Ensure that you have the correct new belt prior to starting this procedure. Loosen

the top adjuster bolts, and the lower mounting pivot nut and bolt.

•Push the alternator towards the engine to loosen the belt.

•Remove the seawater pump (may not be required, depending on seawater pump

option fitted).

•Remove the belt.

•Hold the belt in position over the top alternator pulley; rotate the engine, if

required, by hand, to guide the new belt into the pulley “V”s check it is correctly

seated in the pulley.

•Replace seawater pump (if required).

•Re-tension the belt as above.

Note: Some engines maybe fitted with a side mounted belt driven seawater pump.

A similar belt tightening procedure will apply for this.

CAUTION:

REMOVE THE IGNITION KEY BEFORE WORKING IN ENGINE COMPARTMENT.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 19 of 52

12. Engine Oil

WARNING:

BURN HAZARD! WAIT UNTIL THE ENGINE COOLS BEFORE YOU DRAIN THE

ENGINE OIL. HOT ENGINE OIL MAY SPLASH AND BURN YOU.

WARNING:

ENGINE OIL WITH A HIGHER API CLASS THAN SPECIFIED IS UNSUITABLE FOR

BOAT ENGINE OPERATION AND WILL CAUSE ENGINE DAMAGE IF USED.

•All Shire engines are supplied fully run in.

•Check oil levels in engine and gearbox before starting. (The gearbox uses the same

grade of oil as the engine).

•Shire 14 85/130 WB - use John Deere engine oil, part number VC50002X020 “Plus

50 II Oil (20 Litres)”, or alternatively VC83070-020 “Torq-Gard Supreme (20 Litres)”,

available from Barrus.

•Avoid mixing different types of oil as the additives may interfere with each other.

RDG603A11 - Issue 10 - Shire 14 85, 130 WB Owners Manual Page 20 of 52

13. Fuel

WARNING:

DIESEL FUEL IS FLAMMABLE AND EXPLOSIVE UNDER CERTAIN CONDITIONS.

WARNING:

DIESEL FUEL IS HARMFUL TO SKIN. MAKE SURE THE RELEVANT PERSONAL

PROTECTION EQUIPMENT IS WORN.

•Ensure the main fuel tank is clear of dirt & water.

•A separate water trap must be fitted to all engine installations. (The engine is

supplied with a small water trap as standard).

•Connect fuel feed and return hoses from engine to main fuel tank via supply and

return lines. Ensure that they are connected the correct way around.

•Shire 14 85/130 WB –connect to the inlet to the primary fuel filter inlet hose.

•The fuel supply and return hoses are fitted with 10mm (3/8”) hose tails.

•The engine hoses should have sufficient slack to absorb engine movement without

placing strain on the hoses, and be securely clipped to prevent accidental damage

and chafing.

•Initially fill the fuel system loosening the bleed bolt on the top of the primary fuel

filter/water trap. For Shire 14 85/130 WB, pump the primer on the primary filter.

Close when fuel begins to flow clearly (no bubbles). It is rarely necessary to bleed

the injection pump or injectors upon installation as the engine will already have fuel

in it from the engine run-in and test procedure.

This manual suits for next models

1

Table of contents

Other Barrus Boat manuals

Popular Boat manuals by other brands

Ship Harbor Yacht Charters

Ship Harbor Yacht Charters Mary K Operation manual

Fountaine Pajot

Fountaine Pajot ELBA 45 owner's manual

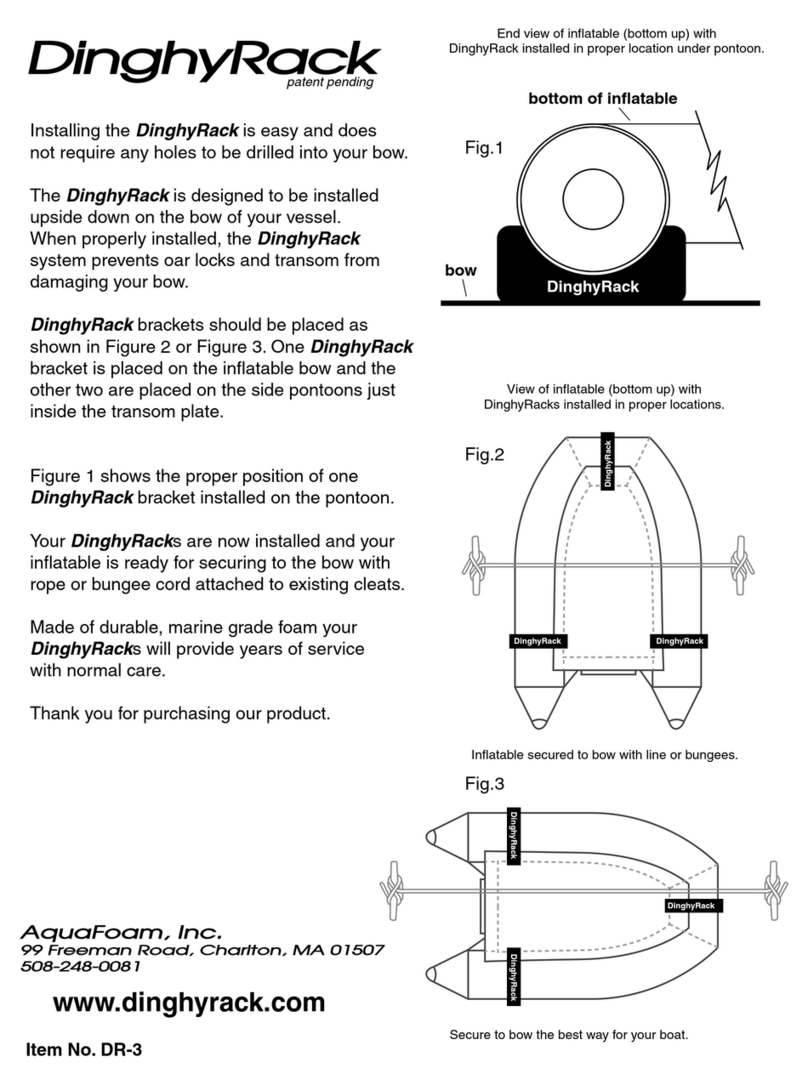

AquaFoam

AquaFoam DinghyRack instructions

Old Town Canoe Co.

Old Town Canoe Co. 01.1315.2380 owner's manual

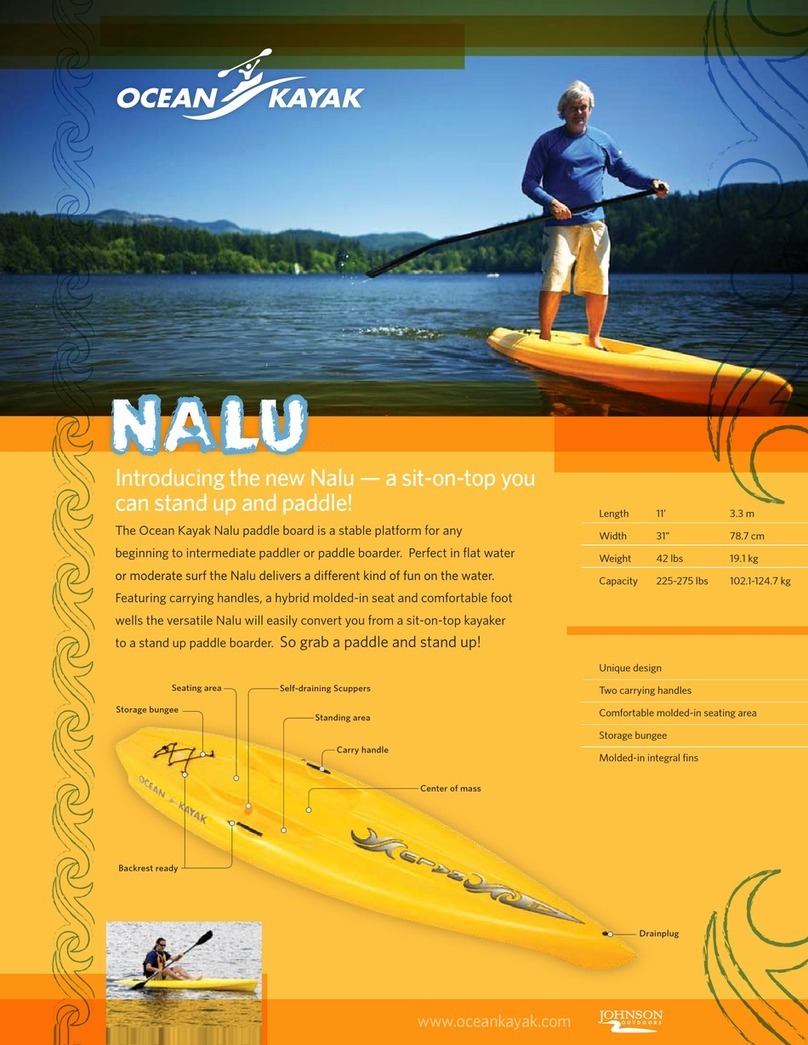

Ocean Kayak

Ocean Kayak Nalu brochure

PURSUIT

PURSUIT 2870 Walkaround owner's manual