15. Seawater Strainer......................................................................................................29

16. Control Panel.............................................................................................................29

17. Calorifiers (Optional)..................................................................................................30

18. Installation Check List................................................................................................32

SECTION 5 –Operation.....................................................................................................33

1. Starting the engine for the first time...........................................................................33

2. Starting Procedure.....................................................................................................33

3. Stopping Procedure...................................................................................................34

4. Full Load Running......................................................................................................34

5. Refuelling...................................................................................................................34

6. Diesel Fuel Additive...................................................................................................34

7. Exhaust Back Pressure (Work Boat with dry exhaust)...............................................35

SECTION 6 –Service Procedure ......................................................................................36

1. Engine Oil and Filter Change.....................................................................................36

2. Air Filter Check and Change......................................................................................37

3. Gearbox Oil Change..................................................................................................37

4. Disposal of Oil and Related Items..............................................................................38

5. Primary Fuel Filter Drain............................................................................................38

6. Primary Fuel Filter Change........................................................................................39

7. Secondary Fuel Filter Change...................................................................................40

8. Fuel System Bleeding................................................................................................41

9. Cooling System..........................................................................................................41

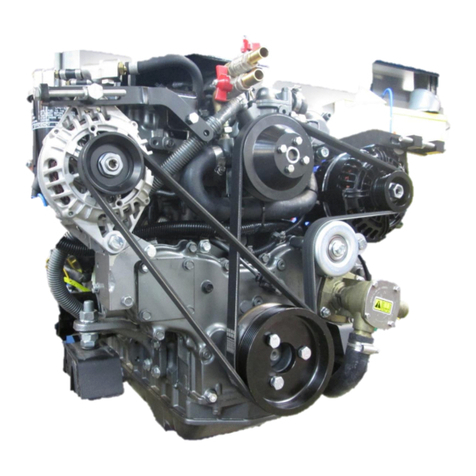

10. Belt Adjustment..........................................................................................................42

11. Belt Maintenance.......................................................................................................43

12. Belt Replacement ......................................................................................................43

13. Control Panel Maintenance........................................................................................45

SECTION 7 –Service Schedule........................................................................................46

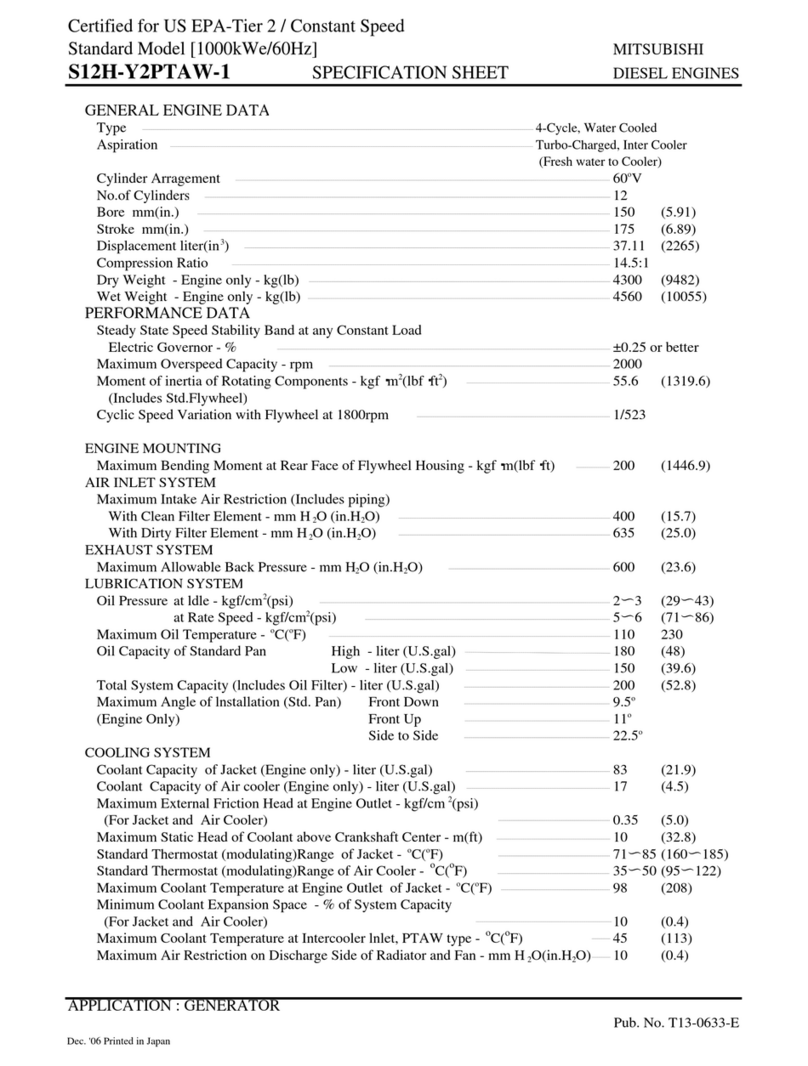

1. Specifications and Capacities....................................................................................46

2. Service Intervals........................................................................................................47

SECTION 8 –Wiring Diagrams .........................................................................................48