Barrus SHIRE 15 YM DB BARNES Operation instructions

Table of contents

Other Barrus Engine manuals

Barrus

Barrus Shire 90 Operation instructions

Barrus

Barrus Shire 15 Work Boat YM Operation instructions

Barrus

Barrus Shire 15 15 CB User manual

Barrus

Barrus Shire 30 WB User manual

Barrus

Barrus Shire 39 User manual

Barrus

Barrus Shire 15 15 CB User manual

Barrus

Barrus Shire 43 WB Operation instructions

Barrus

Barrus 4JH57 User manual

Barrus

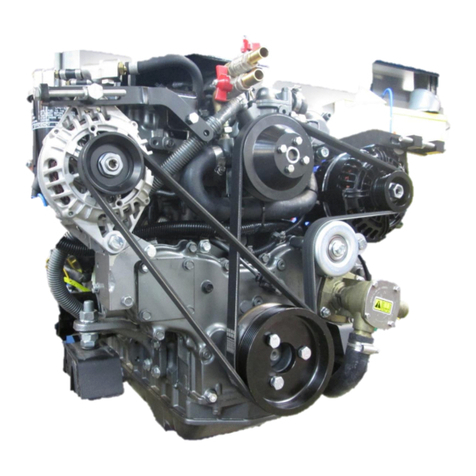

Barrus SHIRE 70 WB User manual

Barrus

Barrus Shire 70 User manual

Popular Engine manuals by other brands

Perkins

Perkins 854F-E34T Troubleshooting

Mercury

Mercury Diesel 3.0L TDI Tier III Service bulletin

Ametek

Ametek dunkermotoren BG 75 instruction manual

Hyundai

Hyundai L500 SERIES Installation and operation manual

Nissei

Nissei F2 Series installation manual

O.S. engine

O.S. engine GF40 Owner's instruction manual

Tecumseh

Tecumseh GEO-TEC quick start guide

Mitsubishi

Mitsubishi 4G9 series Workshop manual

Elliott

Elliott 99400 Series Operating and maintenance instructions

Petter

Petter PH Range Series Workshop manual

Ametek

Ametek Dunkermotoren BG 45 15 Series instruction manual

DETROIT

DETROIT GHG17 DD Operator's manual