Contents

SECTION 1 - Safety Precautions...................................................................7

1. General................................................................................................................................................. 7

2. Lifting.................................................................................................................................................... 7

3. Rotating Shafts and Belts..................................................................................................................... 7

4. Exhaust System ................................................................................................................................... 7

5. Launching and Lifting Boats................................................................................................................. 7

6. Batteries............................................................................................................................................... 8

SECTION 2 - Engine Identification................................................................9

SECTION 3 - Installation..............................................................................10

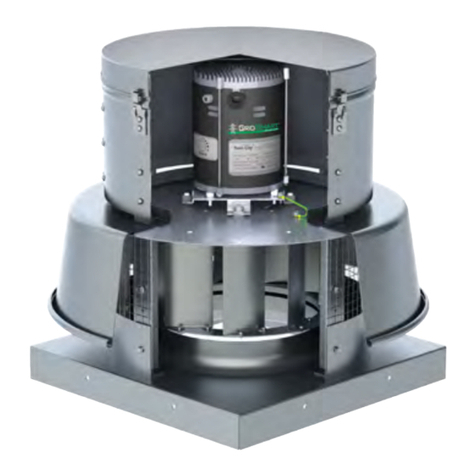

1. Ventilation........................................................................................................................................... 10

2. Engine Beds....................................................................................................................................... 10

3. Cooling System.................................................................................................................................. 10

4. Skin Tanks.......................................................................................................................................... 10

5. Engine Cooling Water Inlet and Outlet Hose Connections................................................................ 11

6. Pressurised Water Header Tank........................................................................................................ 11

7. Shaft Connection and Propeller Selection ......................................................................................... 17

8. Engine Anti-Vibration Mounts............................................................................................................. 17

9. Engine Alignment............................................................................................................................... 19

10. Electrics.......................................................................................................................................... 20

11. Electrical Options............................................................................................................................ 20

12. Engine Oil....................................................................................................................................... 21

13. Fuel................................................................................................................................................. 21

14. Coolant ........................................................................................................................................... 22

15. Calorifier ......................................................................................................................................... 22

16. Control Cables................................................................................................................................ 22

17. Domestic Battery Bank................................................................................................................... 23

18. Control Panel.................................................................................................................................. 23

19. Exhaust System.............................................................................................................................. 24

20. Hydraulic Drive Transmissions....................................................................................................... 24

21. Hydraulic Pump Drive Option (Shire 38 / 40 / 45 / 50)................................................................... 25

22. Installation Check list...................................................................................................................... 26

SECTION 4 - Operation................................................................................27

1. Starting the Engine for the First Time ................................................................................................ 27

2. Starting Procedure ............................................................................................................................. 27

3. Stopping Procedure ........................................................................................................................... 28