3

1. Introduction .....................................................................................................................................................5

1.1. General.................................................................................................................................................5

1.2. Intended application.........................................................................................................................6

1.3. Warranty ..............................................................................................................................................6

1.4. Information on electromagnetic compatibility...........................................................................6

1.5. Required qualifications for personnel who handle the motor .................................................6

1.6. Safety................................................................................................................................................... 7

1.7. Contraindications.............................................................................................................................. 7

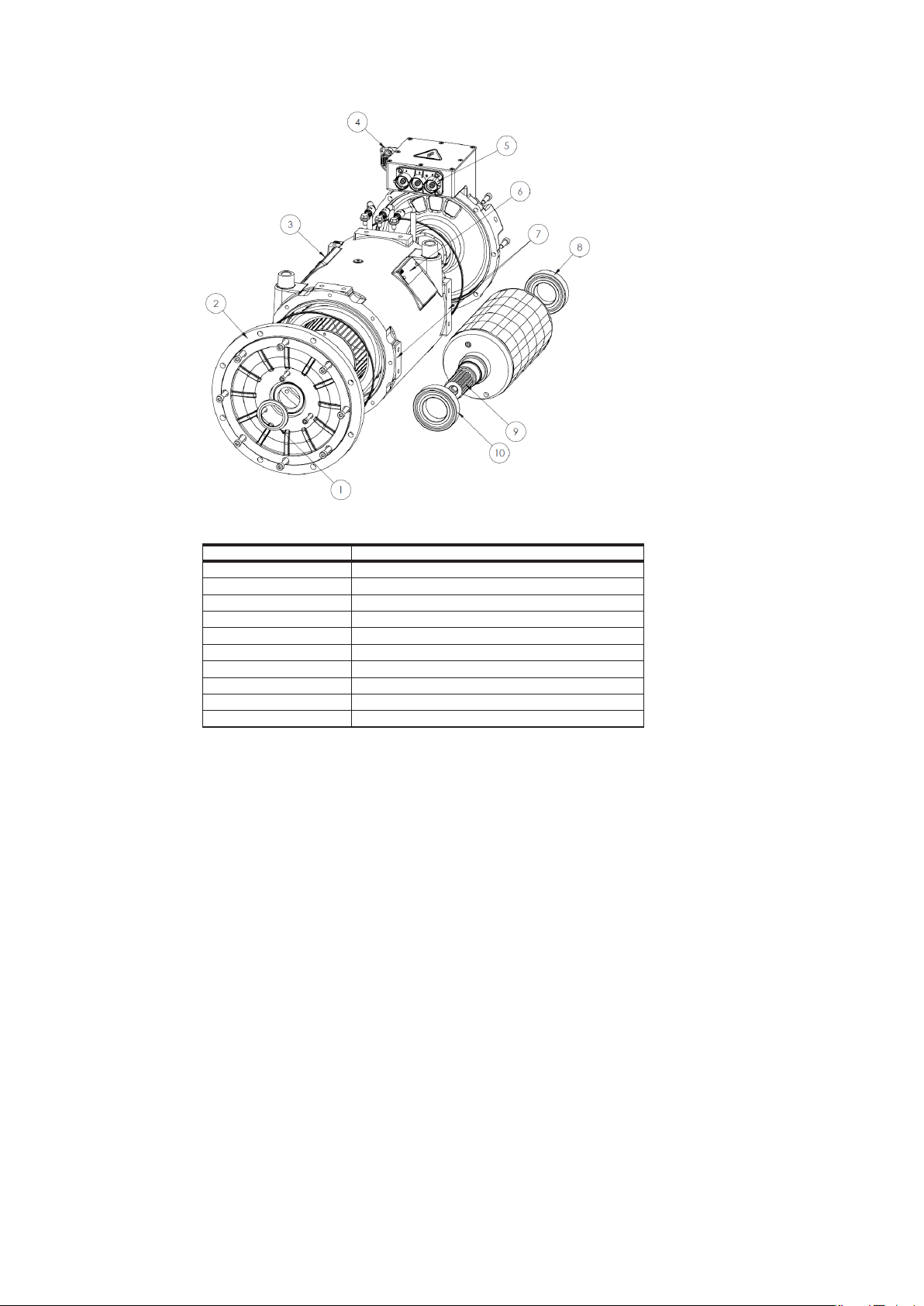

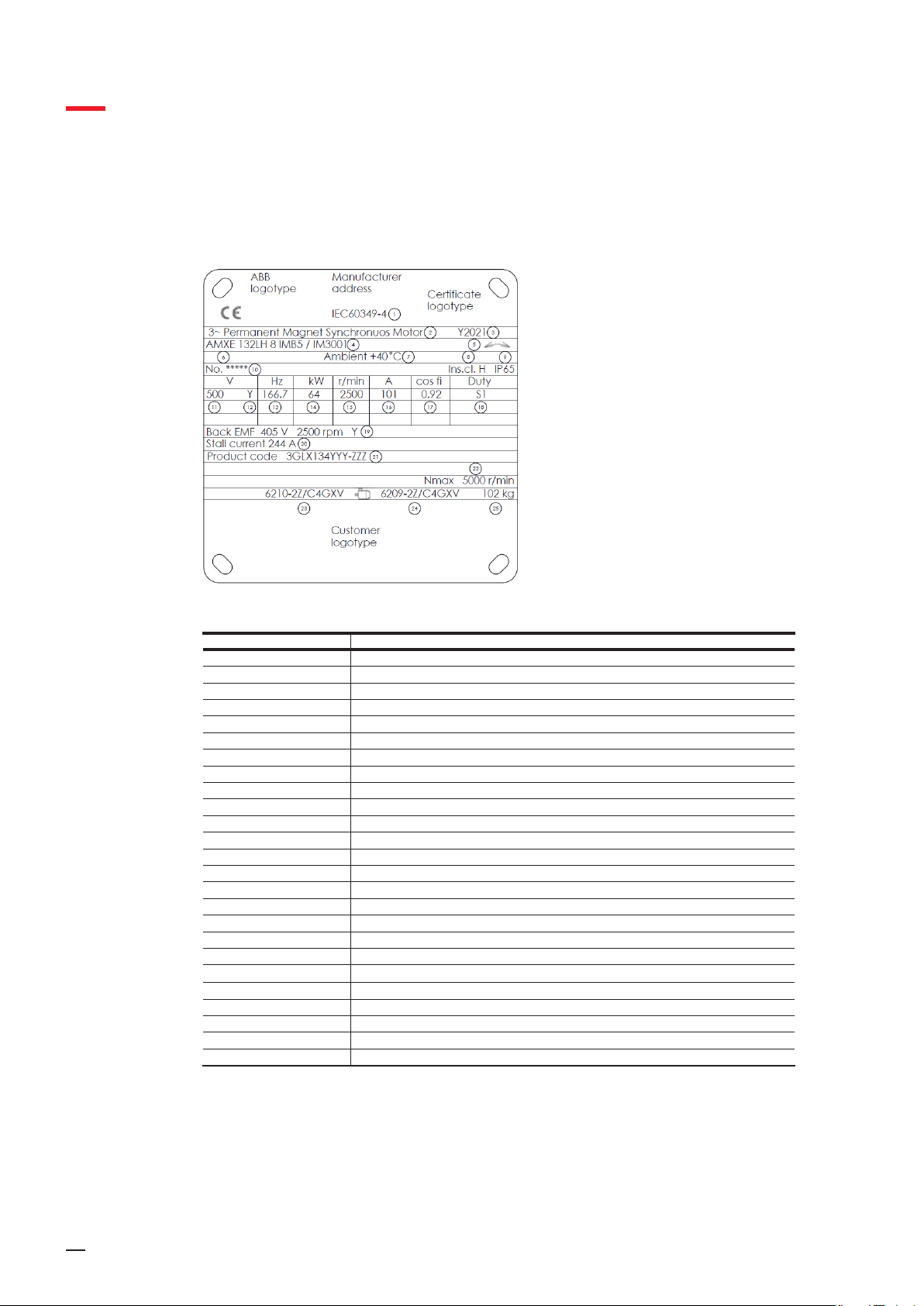

2. Product description .......................................................................................................................................8

2.1. Technical data .................................................................................................................................. 10

2.2. Expected lifetime..............................................................................................................................11

3. Transportation and Storage....................................................................................................................... 12

3.1. Transportation................................................................................................................................. 12

3.1.1. Delivery to customer ..................................................................................................... 12

3.1.2. Inspection of delivery..................................................................................................... 12

3.1.3. Lifting of motor .............................................................................................................. 13

3.2. Storage ............................................................................................................................................. 15

3.3. Removal of Tectyl before commissioning................................................................................... 15

3.4. Insulation resistance check ........................................................................................................... 15

4. Motor installation in vehicle........................................................................................................................ 16

4.1. Mechanical installation................................................................................................................... 16

4.1.1. Preparation and lifting................................................................................................... 16

4.1.2. Installation of coupling.................................................................................................. 16

4.1.3. Installation of motor in vehicle .....................................................................................17

4.2. Liquid cooling system installation............................................................................................... 18

4.3. Electrical installation ...................................................................................................................... 19

4.3.1. High voltage connection ............................................................................................... 19

4.3.2. Low voltage connection ................................................................................................ 21

5. Operation........................................................................................................................................................22

5.1. Failure mode operation.................................................................................................................. 22

6. Inspection and maintenance ......................................................................................................................23

6.1. Safety Instructions.......................................................................................................................... 23

6.2. Inspection and Maintenance intervals ........................................................................................24

6.3. Inspections and maintenance.......................................................................................................24

6.3.1. Visual inspections...........................................................................................................24

6.3.2. Detailed visual inspections...........................................................................................24

6.3.3. Bearings............................................................................................................................25

6.3.4. External shaft seal ..........................................................................................................25

6.3.5. Shaft spline ......................................................................................................................25

6.3.6. External cleaning.............................................................................................................25

6.3.7. Re-painting.......................................................................................................................26

7. Spare parts and consumables.................................................................................................................... 27

8. Trouble shooting...........................................................................................................................................28

9. Waste disposal and Recycling ....................................................................................................................30

Appendix 1 Installation check list ...................................................................................................................... 31

—

Table of contents