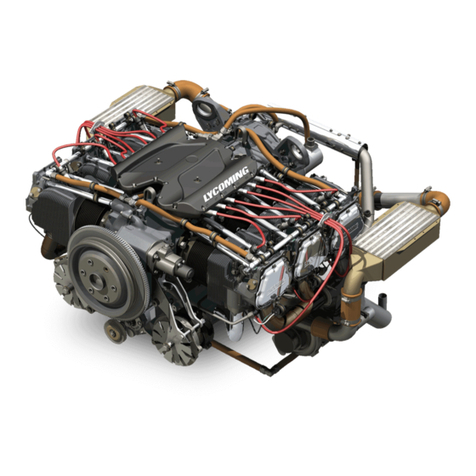

SECTION 1 LYCOMING OPERATORS MANUAL

DESCRIPTION VO, IVO & TIVO-540 SERIES

Accessory Housing The accessory housing and accessory housing cover are made from magnesium alloy

castings and are fastened to the bottom of the crankcase. This assembly forms a housing for the oil pump

and the various accessory drives. A scavenge oil sump is fastened to the bottom of the accessory housing.

Cooling System The engine is designed to be cooled by air pressure built up on one side of the cylinder

and discharged, with an accompanying drop in pressure, through cylinder finning. This cooling air on rotor-

driven aircraft is supplied by an external fan installed by the airframe manufacturer. Close fitting baffles

direct the flow of air around the cylinder fins and the discharge air is exhausted to the atmosphere.

Induction System (Carbureted Engines) These engines are equipped with either single or dual MA-6-AA

carburetors (see Table of Models for model application). This carburetor incorporates an automatic mixture

control and idle-cut-off. The fuel air mixture, after passing from the carburetor to the center distributing

zone is distributed to the cylinders through individual intake pipes.

Induction System (Fuel Injected Engines) (See Table of Models for model application.) Either a Bendix

RS system or RSA system is used on subject engines.

The RS system operates by measuring the air flow through the throttle body of the servo valve regulator

controls, and uses this measurement to operate a servo valve within the control. The regulated pressure

established by the servo valve is used to control the fuel distributor valve assembly, which then establishes

fuel flow in proportion to air flow and fuel vaporization takes place at the individual intake port.

The RSA system is based on the principle of measuring air flow and using the air flow signal in a stem

type regulator to convert the air force into a fuel force. This fuel force (fuel pressure differential) when

applied across the fuel metering section makes fuel flow proportional to air flow. Vaporization takes place

at individual intake ports.

Turbocharger System (TIVO-540) A turbocharger is supplied as an integral part of the TIVO-540 model.

The function of the turbocharger is to provide constant air density to the fuel injector inlet from sea level to

critical altitude. Regulating the amount of exhaust gas fed to the turbine wheel controls the output which

determines engine power. This factor is regulated by the control system which has two components, namely

the density controller and the exhaust bypass valve (waste gate). The position of the waste gate is

determined by oil pressure acting on a piston which is connected to the butterfly valve by linkage.

Increasing oil pressure on the piston closes the waste gate valve and increases power; decreasing oil

pressure opens the valve and decreases power. The bleed oil required to activate the piston is controlled by

the density controller. The density controller action is automatic and modulating to continue and reverse the

process as engine power, speed and altitude change.

Lubricating System The dry sump, fuel pressure lubrication system is actuated by an impeller type oil

pump enclosed within the accessory housing. This pump incorporates a pressure pump and a scavenge pump

driven by a common drive shaft. The pressure pump draws oil from the externally mounted supply tank and

forces it through drilled passages to the oil filter. From the filter the oil is directed through a check valve to

the oil pressure regulating valve. The check valve prevents gravity oil from draining into the crankcase

when the engine is shut down and the oil pressure valve maintains the oil pressure within limits and

discharges excess oil back to the inlet side of the pump. After completing its passage through the engine the

oil is conducted to the scavenge pump in the accessory housing and returned to the external tank.

1-2