Contents

I - 1

Operating Instructions Radiation sensors R3XX

Table of Contents

1System description .........................................................................................................................1

1.1 Properties and fields of use....................................................................................................1

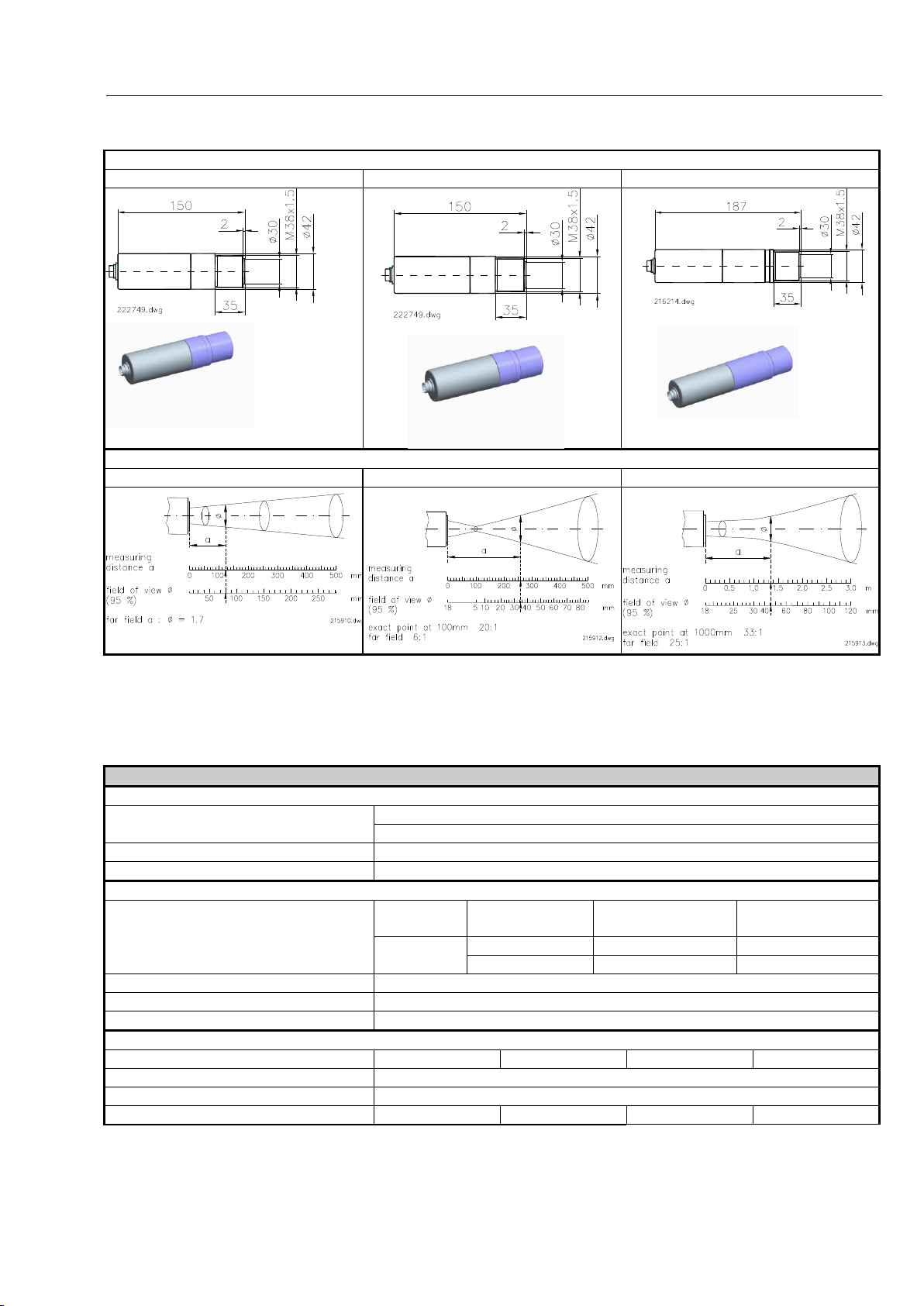

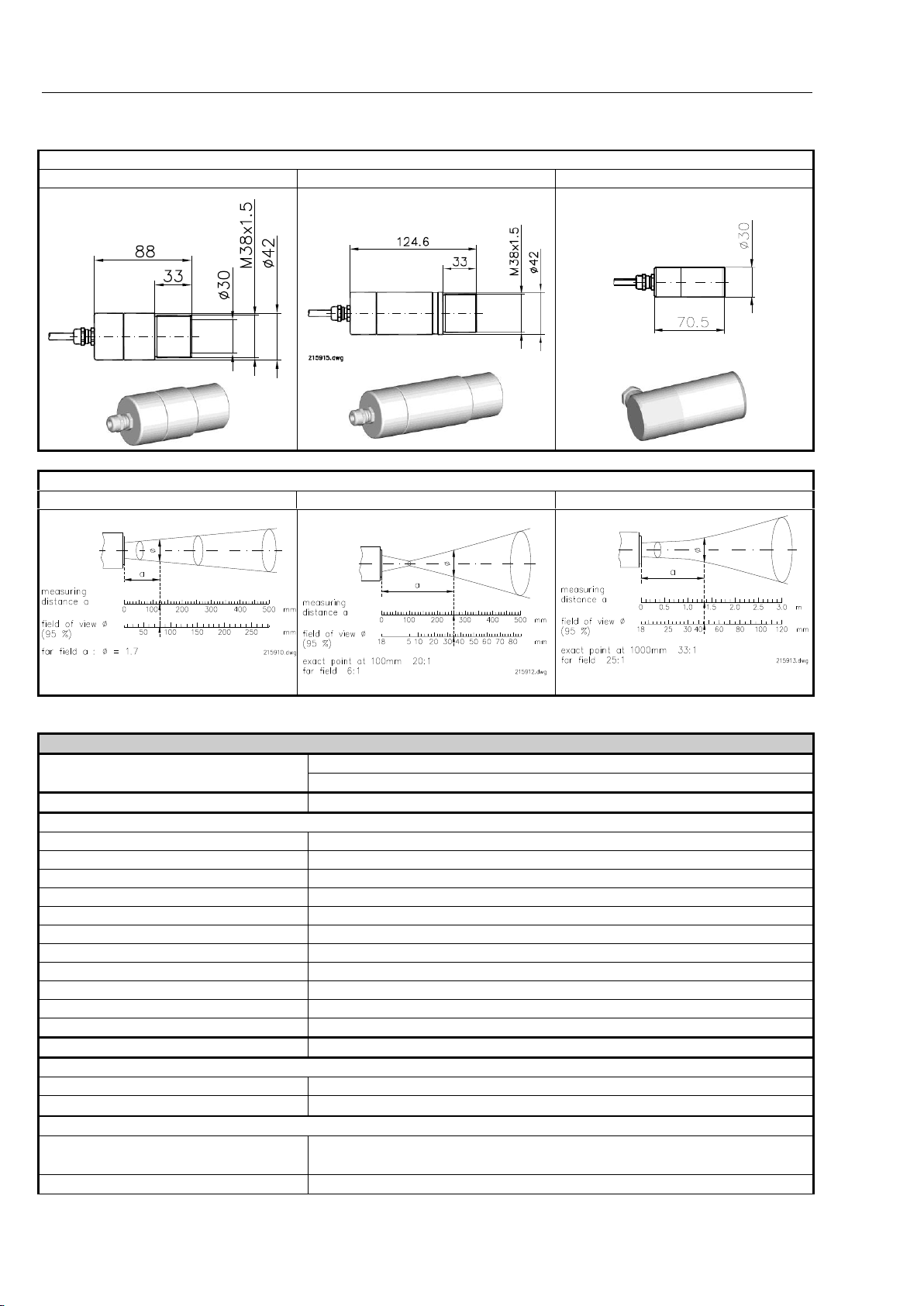

1.2 Sensor versions......................................................................................................................2

1.3 Scope of delivery....................................................................................................................3

1.4 Technical data ........................................................................................................................4

1.4.1 Thermophil®INFRAsmart ....................................................................................................4

1.4.2 Thermophil®INFRAht ..........................................................................................................5

2Safety precautions ..........................................................................................................................9

2.1 General information................................................................................................................9

2.2 Installation location.................................................................................................................9

2.3 Electrical connection.............................................................................................................10

2.4 Operating the equipment......................................................................................................10

3Installation......................................................................................................................................12

3.1 Installation location...............................................................................................................12

3.2 Measurement distance.........................................................................................................13

3.3 Aids, accessories..................................................................................................................14

3.3.1 Safety instructions for the operation of Laserpointer type R300-101................................26

3.3.2 Safety instructions for the utilisation of the IR protection window Zn-Se ..........................26

type R300-136 (order no. 301954)

3.4 Connection ...........................................................................................................................27

3.4.1 R 300, R 301, R 302 ..........................................................................................................27

3.4.1.1 Connection via plug........................................................................................................27

3.4.2 R 310, R311, R312, R320 .................................................................................................28

4Operation........................................................................................................................................31

4.1 Measurement operation........................................................................................................31

4.2 Configuration ........................................................................................................................31

4.2.1 Configuration with transmitter TR 41-10............................................................................32

4.2.1.1 Configuration process ....................................................................................................32

4.2.1.2 Parameters.....................................................................................................................33

4.2.1.3 Default values.................................................................................................................37

4.2.1.4 Configuration of the sensor data (not implemented).....................................................38

4.2.1.5 Test mode.......................................................................................................................41

4.2.2 Configuration with the HART®modem, Type R 300-107 ..................................................42

4.2.2.1 Connecting the HART®modem......................................................................................42

4.2.2.2 Software .........................................................................................................................43

5Configuration PACTware..............................................................................................................45

6Maintenance...................................................................................................................................57

7HART®protocol .............................................................................................................................61

8Additional instructions for use in dust-explosive areas...........................................................65