11-85M6-7D0001/B-11/2017-EHT-414087

Reservation Technical data subject to change without notice. Changes, errors and misprints may not be used as a basis for any claim for damages.

www.bartec.de DE 2/4

BARTEC

Operating Instructions Optical point sensor PSO+ and PSO Type 17-85M6-1102.A00 M

Intended use

The PSO+ point sensor and the PSO point sen-

sor are components of the BARTEC water detec-

tion system. They can be combined with the SCR

sensor cable and/or the PS point sensor. The RLW,

RLAnet, RDW03 and RDA01 electronic monitoring

systems as well as corresponding accessories (see

catalogue) are also part of the BARTEC water de-

tection system.

Product description

General information

The point sensor is used to detect electrically

non-conductive liquids such as oil, enabling the

location of the leak to be detected quickly.

Thanks to the special optics, it can operate reliably

also when facing metallic surfaces (e.g. oil catch

pan made of sheet steel).

The PSO point sensor consists of a PVC sensor

enclosure with three spacer feet. In conjunction

with the BARTEC electronic monitoring system

(e.g. RDW, RDA, RLW or RLA), an alarm is sig-

nalled as from a leak height of 2 mm (height can

be adjusted using the screw feet).

The removable enclosure lid permits free access to

the terminals. Up to 50 sensors can be connected

in series. An integrated final resistance makes it

possible to monitor cable breaks.

The integrated load relay can operate actuators,

such as a check valve, directly on site. A second

changeover contact reports the circuit state to the

electronic monitoring system

Dierence between PSO+ and PSO

The PSO+ point sensor and PSO can be supplied

centrally with DC 24 V via the signal cable. It is

similarly possible to provide a decentralised power

supply by means of a commercially available plug-

in power supply unit.

With its additional terminal block, the PSO+ point

sensor can be combined with the SCR and PS sen-

sors as required. In addition, this terminal block

and the integrated series resistors with R = 62 Ω

corresponding to 10 m sensor cable permits the

positioning function (with RLAnet or RLW).

Safety instructions

• Before commissioning, please make certain

that the PSO+ and the PSO are suitable for the

designated use.

• For electrical installations, the pertinent

installation and operating regulations must

be followed (e.g. DIN VDE 0100 series or

other relevant national regulations).

• All general statutory regulations and other

binding guidelines on occupational health and

safety, accident prevention and environmental

protection must be complied with.

Assembly and commissioning

Assembly

The device must be positioned in a suitable place

where leaked liquid can collect. This is aided by a

catch pan with a ridge.

Installation

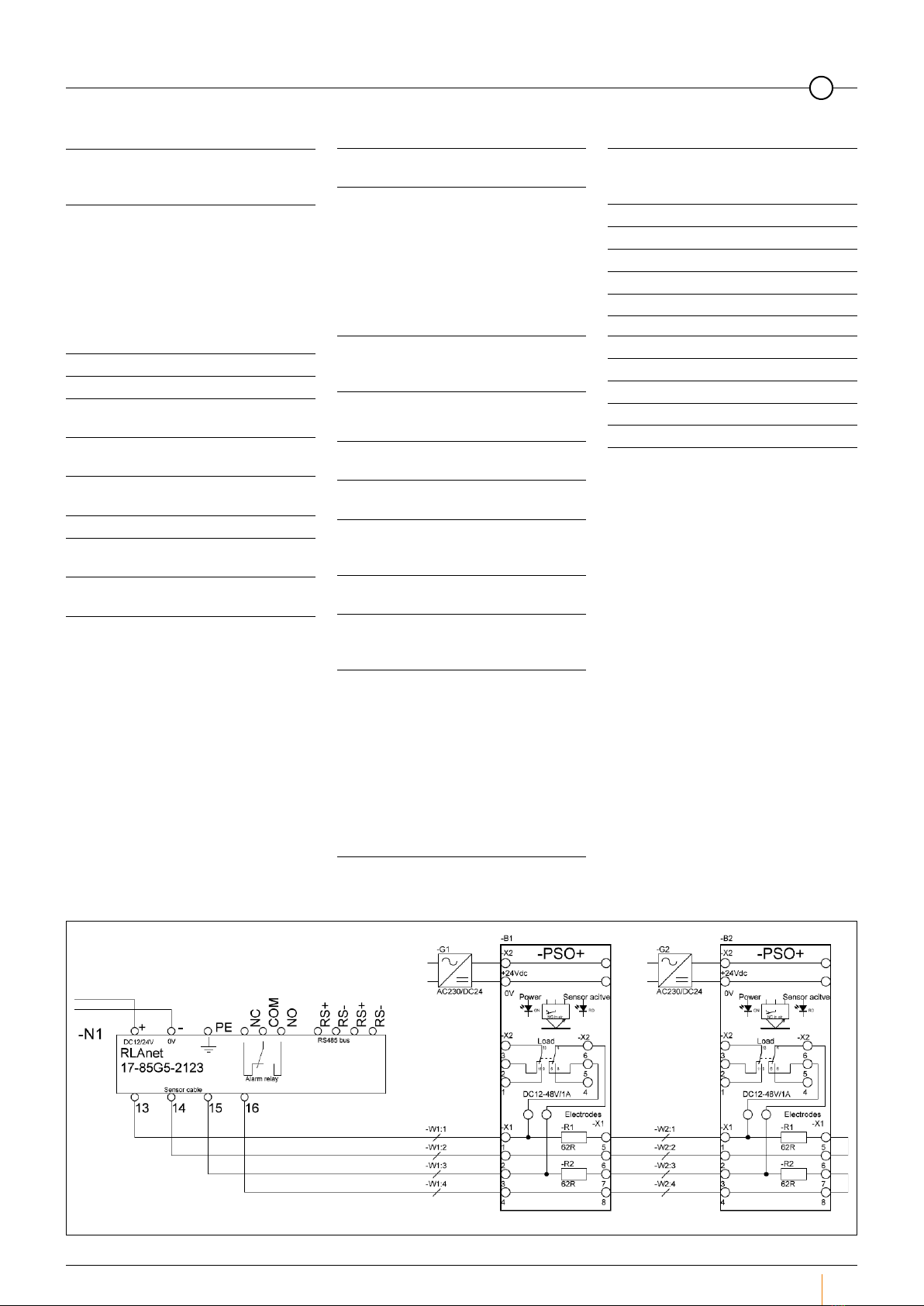

The device must be connected according to the cir-

cuit diagram, complying with the specified current/

voltage data. The ends of the conductors should be

appropriately prepared when connecting stranded

or finely stranded conductors.

Plug-in connections on the installation path must be

laid so they remain dry. For this purpose, the cus-

tomer must insert spacers between the conductor

and the ground when monitoring areas.

Commissioning

The device may only be operated in a clean and un-

damaged condition. If damage is visible, the device

must be taken out of service and corresponding

repair measures must be initiated.

Commissioning must be performed in the following

steps:

• Connect the device to the power supply

• The green LED indicates that voltage is ON

• The red LED signals that the relay is active

(fail-safe circuit), when the optics are in the

open

• If the optics are immersed in the leaked liquid,

the relay sinks and the red LED is extinguished

Operation, maintenance

The company operating an electrical installation

must keep the operating equipment in good con-

dition, must operate and monitor it as intended,

and must carry out maintenance and repair work.

All electrical equipment must be selected according

to its suitability. Applicable laws and guidelines must

be followed before putting it back into operation.

The specified safety instructions must be observed

before maintenance and/or troubleshooting.

It is necessary to ensure that the optics of the PSO+

and of the PSO are kept clean and free of grease at

intervals that are suitable considering the degree of

soiling or dust to be expected.

Alarm management

Alarm output

The isolated relay output is primarily used as group

alarm output in the closed current/NC = normally

closed” operating mode. This means the contact

remains closed (relay is activated) as long as there

are no faults. This operating principle enables wire

breaks and power failures to be detected (1).

Function table

Leaking fluid not available available

PSO+/PSO

Operating condition

ready alarm

LED rot

„ready“

ON OFF

Relay coil current currentless

Relay contact

NO - C

closed (1) open

Relay contact

NC - C

open closed (2)

Measuring circuit monitoring

The connected point sensor is transmitted to elec-

tronic monitoring system (e.g. RDW, RDA, RLW or

RLA) via the relay contact NC - C. This also allows

the parallel connection of several point sensors (2).

In addition, the measuring circuit is monitored for

the following errors:

• Interruption of the measuring circuit

If this error occurs, the load circuit is opened and a

corresponding fault message generated.