EXaminer®CUI 310 E NB

Reservation Technical data subject to change without notice. No claims for damages arising from alterations, errors or misprints shall be allowed.

3

ATEX/IECEx certification

Reference Standard

EXaminer®CUI 310 E NB sensor is designed in accordance with

the following standards.

Standards Document

Number Title

EN IEC 60079-0:2018

IEC 60079-0:2017

Explosive atmospheres, Part 0:

Equipment General requirements

EN 60079-11:2012

IEC 60079-11:2011

Explosive atmospheres, Part 11:

Equipment protection by intrinsic safety “i”

ATEX/IECEx Approval

IECEx DNV 21.0037X Ex ia IIC T4 Ga

-40 °C ≤ Ta ≤ +80 °C

DNV 21 ATEX 73941X II 1G Ex ia T4 IIC Ga

Tamb -40 °C to +80 °C

DNV GL Presafe AS

2460 Veritasveien 3

N-1363 Høvik

Norway

Label

Installation and Startup

Installation of the EXaminer®CUI 310 E NB

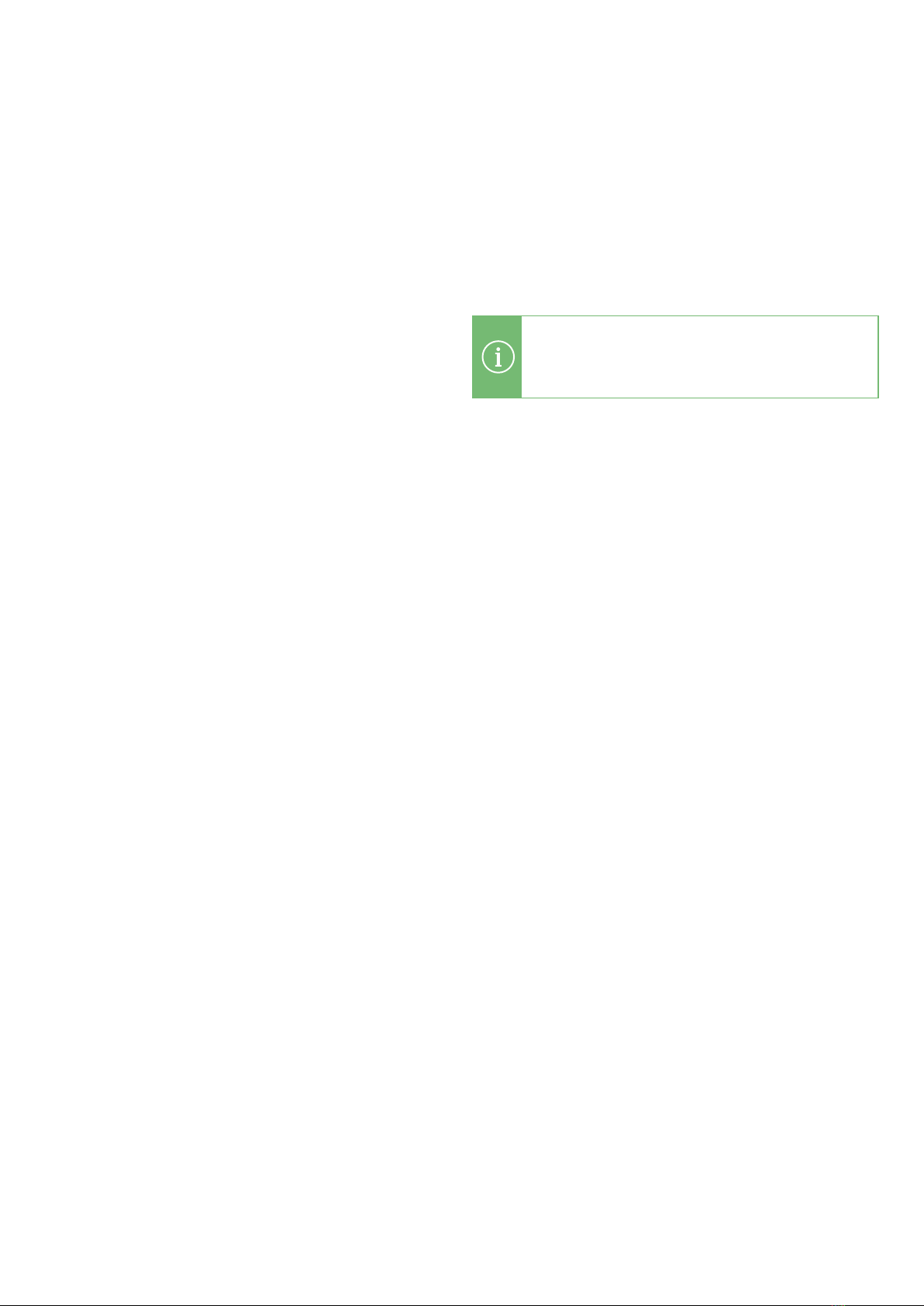

The EXaminer®CUI 310 E NB sensor is designed for mounting on

the cladding on pipes for measurement of temperature, relative

humidity and if water is present. The included drill bit has a Torx

T30 head.

Mounting the sensor on components with normal operating

surface temperature of 80 °C or higher or below -40 °C must be

avoided.

Operating in temperatures outside normal operating

temperatures (5 °C to 40 °C) may have significant impact on

battery lifetime.

Specific conditions for EXaminer®CUI 310 E NB

“X”- Equipment must be mounted on the metallic enclosure and/

or contact with earth must be assured.

The sensor is marked:

WARNING

POTENTIAL ELECTROSTATIC CHARGING HAZARD –

SEE INSTRUCTION

Mounting principle

NOTE

Before mounting the sensor ensure that the place selected is

not near a cladding joint or other obstructions/irregularities

preventing the sensor to rest securely on the cladding.

Preferably, the centre of the hole in the cladding should be no

closer than 40 mm from such irregularity.

Installation by using a designated jig

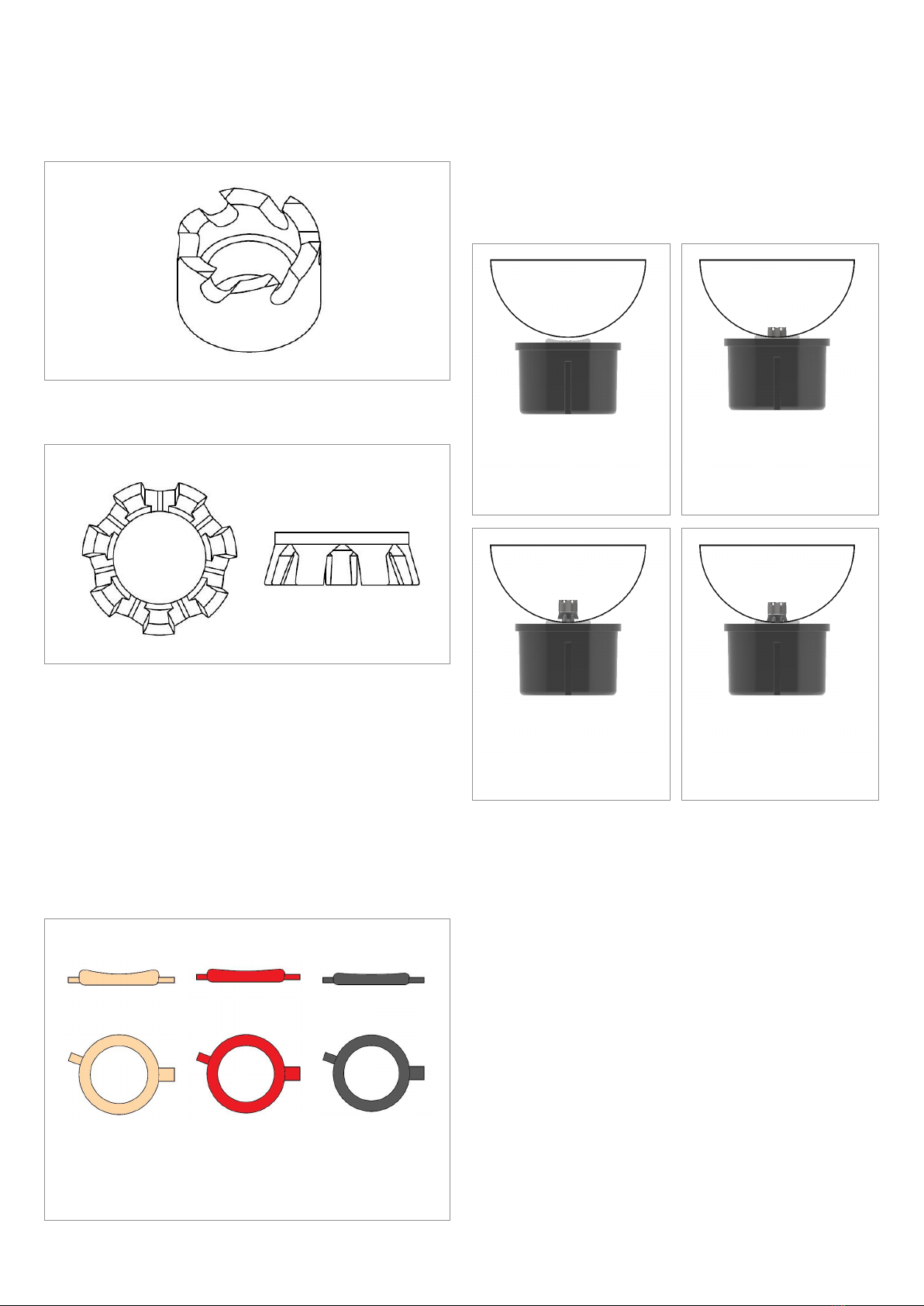

The sensor is fitted with an integrated drill bit allowing installa-

tion by a special designed installation jig. Once installed correctly

in the jig and positioned on the cladding, the jig will apply correct

pressure and rotational speed to the sensor drill bit.

Manual installation

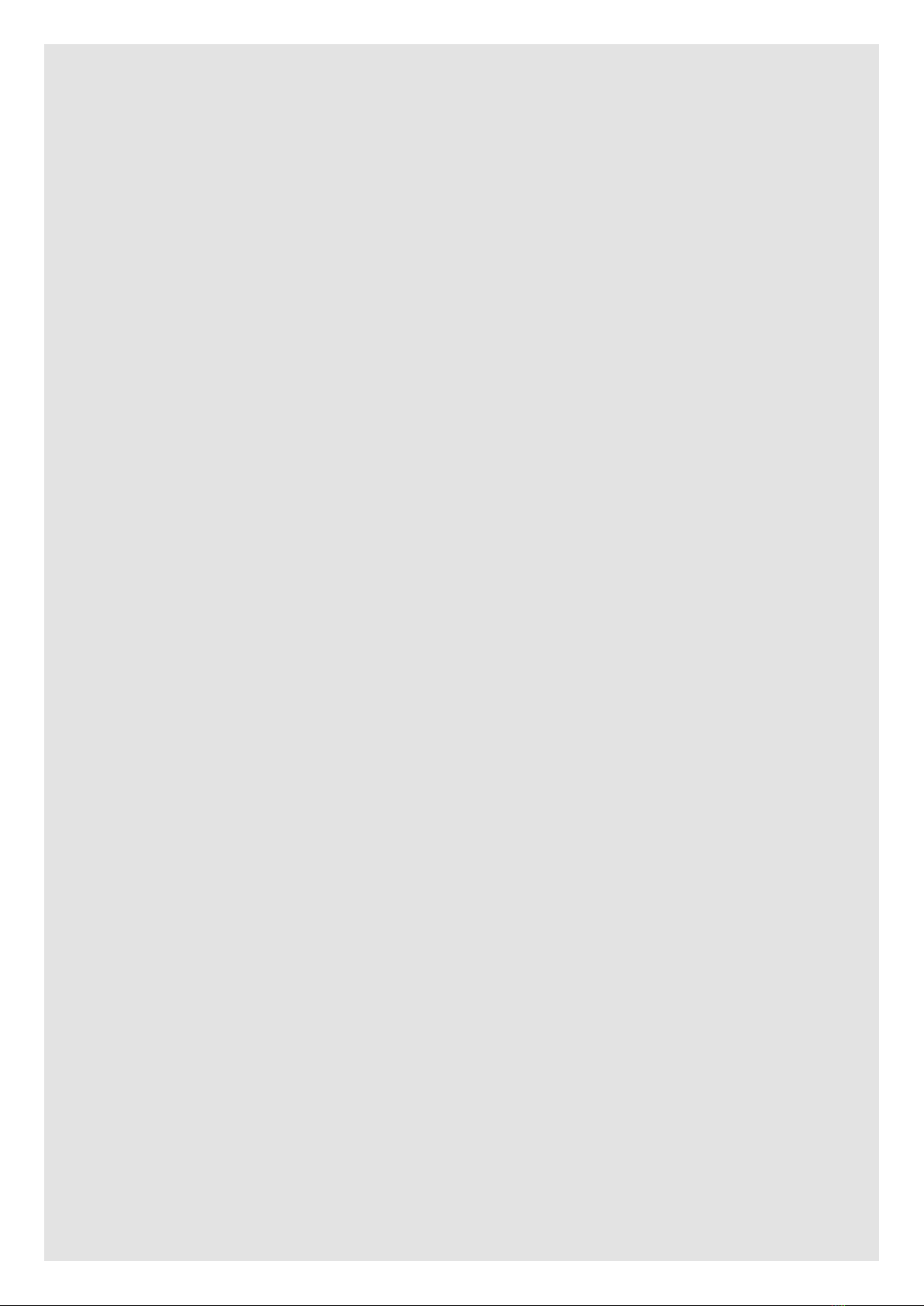

Alternatively 12 or 14mm holes can be pre-drilled in the cladding

and then by positioning the sensor drill bit center/center in the

hole, use a screwdriver or similar to press the drill bit assembly

though the hole all the way in until the Umbrella Sensor Lock is

engaged on the inside of the cladding.

NOTE

• Please ensure that the sensor is properly attached and seals

off the hole.

• The Flat sides on the sensor housing must be positioned as

shown on figure 3.

Robotic installation

The mountable sensor is also configured to allow installation by a

robot as it only requires a single driving force to mount the sensor

at a desired location.The robot is being developed separately.

EXaminer CUI®310 E NB

17-2131-****/****

EX II 1G Ex ia IIC T4 Ga -40 °C ≤ Ta ≤ +80 °C

IECEx DNV 21.0037X

ATEX DNV 21 ATEX 73941X

WARNING - POTENTIAL ELECTROSTATIC

CHARGING HAZARD - SEE INSTRUCTION

0044

IP 67

Batch No. YYWW

XX:XX:XX:XX:XX:XX

Data

Matrix

Code

97980

Bad Mergentheim

Germany