5

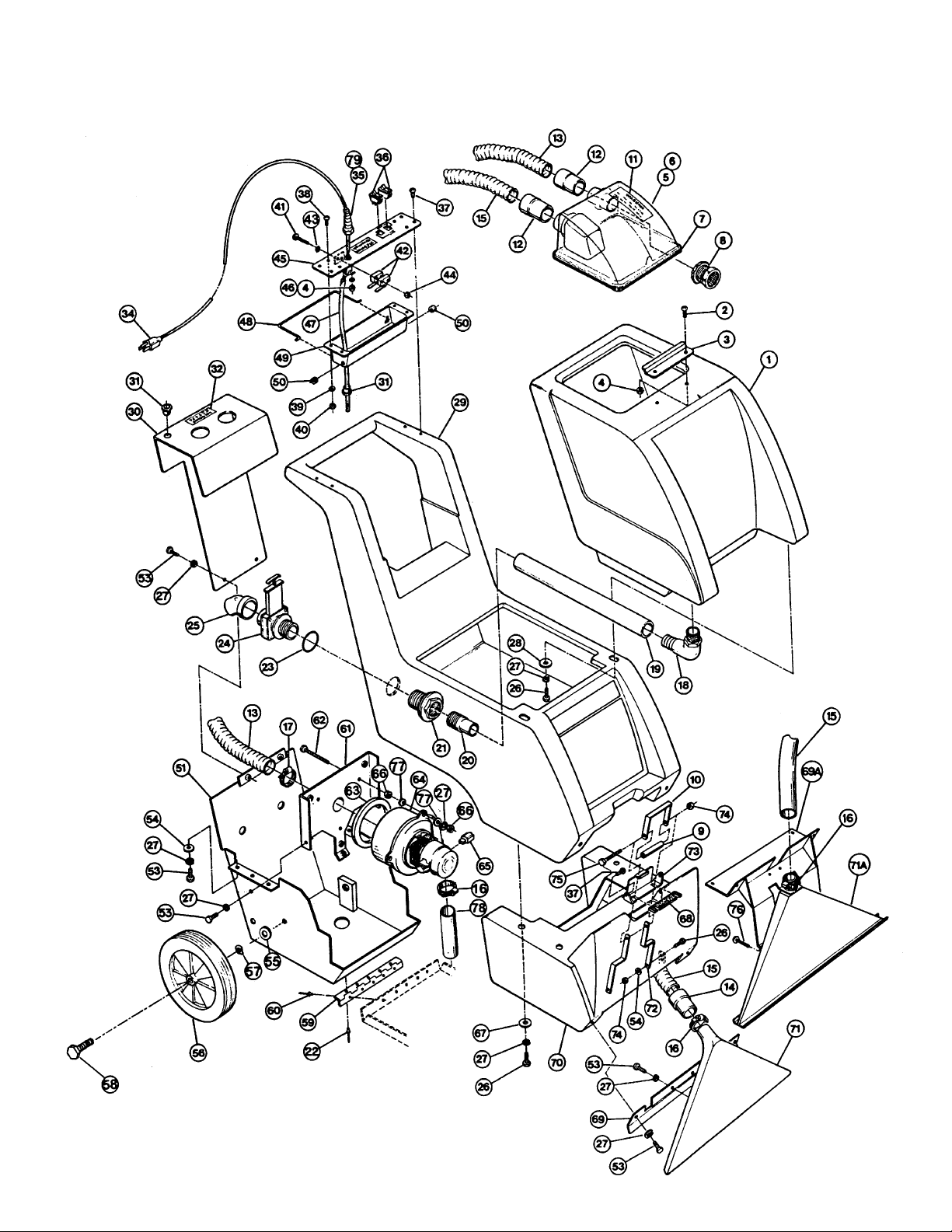

OPERATING PROCEDURES

The ACHIEVER 80/110 machines are the most “user

friendly” self-contained extractors available. The following

procedures are intended to describe and detail proper opera-

tion of your machine. Failure to follow these recommended

procedures can reduce the machine’s performance and may

result in damage to the machine.

1. Vacuum the area to be cleaned. Your machine will

do a more thorough job if the loose dirt and debris are

removed before the extraction process begins.

2. Fill the fresh water tank (lower tank) with water and

Heavy Duty Carpet Extraction chemical. Hot water is

recommended, but not required. Do not use water hotter

than 60°C (140°F). Mix in chemicals according to the

chemical manufacturer’s recommendations. For best

results use Steamex Heavy Duty Carpet Cleaner.

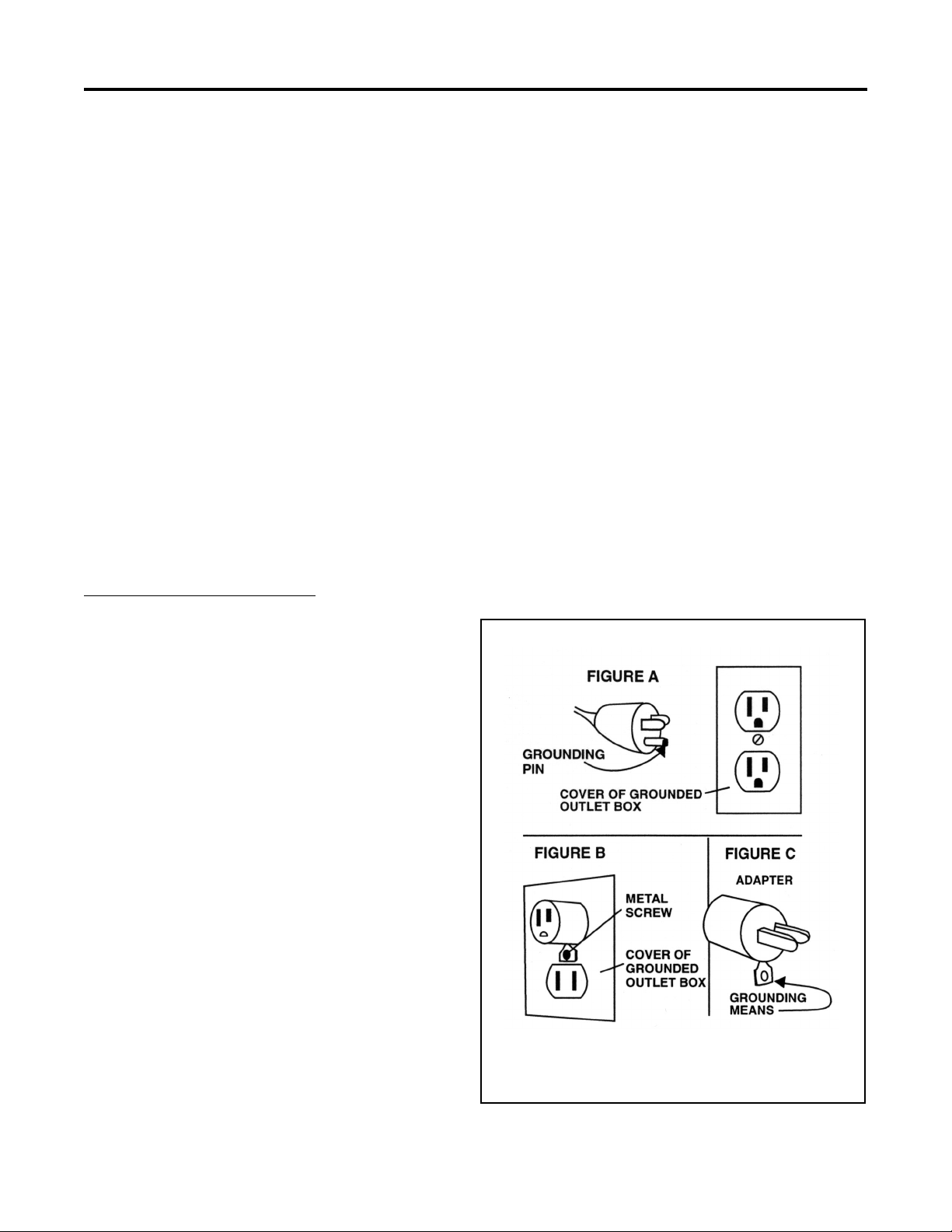

3. Use of an extension cord is not recommended. How-

ever, if one is necessary, use only a 14 gauge or larger

cord. Smaller or inferior cords are dangerous and may

cause damage to your machine.

4. After the machine is filled with solution, connect the

power cord plug to a 115 volt grounded wall socket.

See Grounding Instructions.

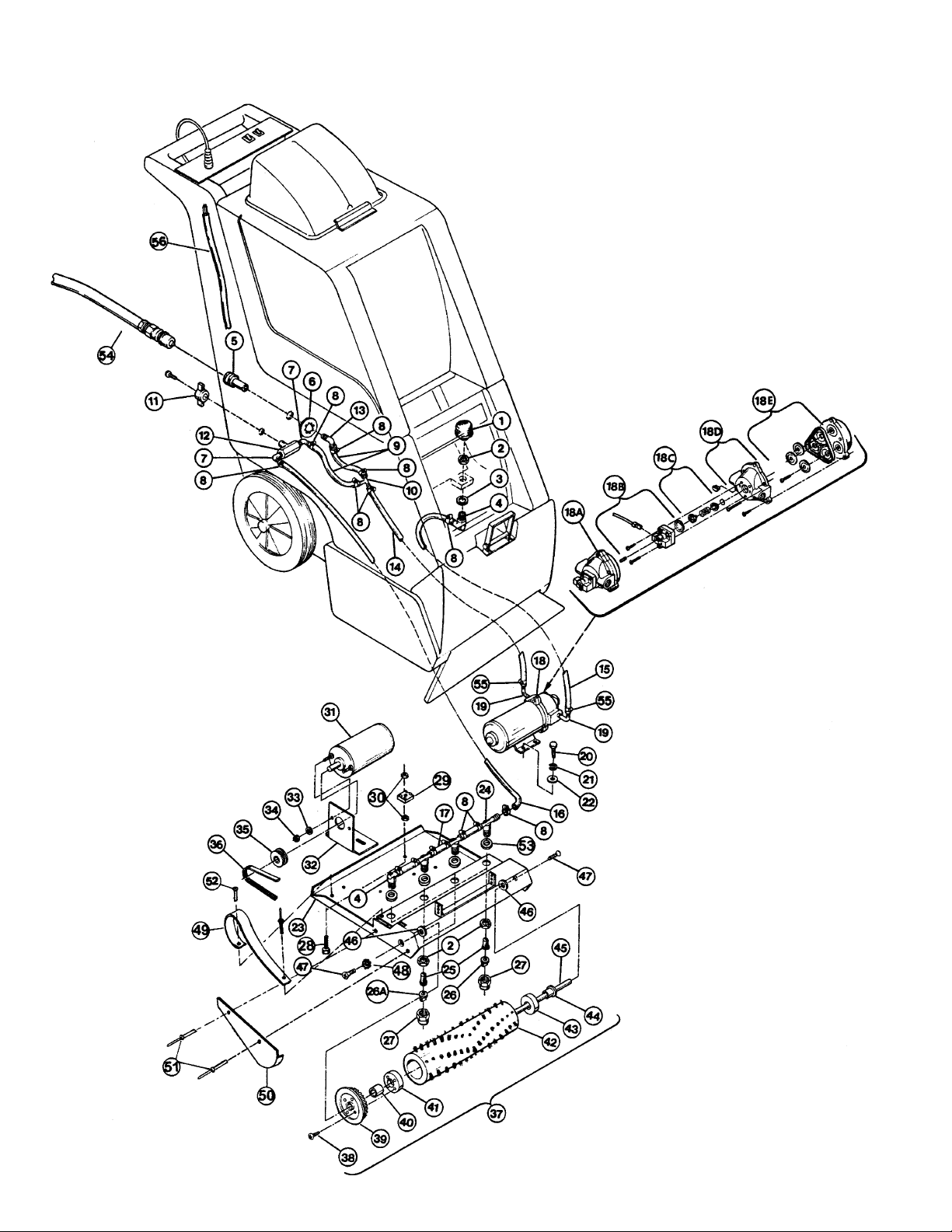

5. Lower the floating brush chassis using the lift handle

located in the front of the machine. Lift the handle off

the lift stop bracket and lower until the brush contacts

the floor. Remember to always raise and lock the brush

chassis for storage and transport.

6. Turn the spool valve knob (located on the back of the

machine) to the:

a) “Machine” (horizontal) position for routine

carpet extraction as a self-contained unit, or

b) Turn it in the “Tool” (vertical) position when using

a wand or tool.

7. The switch panel is located on top of the handle and

contains the following:

a) Turn the vacuum switch on to start the vacuum

motor.

b) Accessory only pump switch: Do not turn on the

accessory pump switch unless the spool valve knob

is turned to the tool position.

8. Pull backward during operation. DO NOT AT-

TEMPT TO OPERATE IN A FORWARD DIREC-

TION. Position yourself behind the machine, grasp

the handle and gently lift up on the actuator bar.

Lifting the actuator bar activates the brush drive motor

and the pump. Walk slowly backward to perform the

cleaning process.

9. Release the actuator bar approximately 6 inches

before completing each pass. The spray jets are

located behind the vacuum head making it necessary

to pull the machine a few inches further to pick up the

last amount of solution dispensed onto the carpet.

10. Tilt the machine back on the rear wheels and walk

forward to position the machine along side the previ-

ous pass (slightly overlapping).

11. As dirty solution is recovered, some foaming may be

noted. Excessive foaming can be counteracted with

liquid defoamer applied according to the chemical

manufacturing directions. Do not allow foam to rise

into or near the dome. Use defoamer or empty and

flush the recovery tank.

12. To drain the recovery tank, place an empty bucket

under the drain valve located on back of the machine.

To open the drain valve pull the T-Handle up. Close

the drain when the bucket is full or the recovery tank

is empty. Dispose of the recovered water properly.

13. If streaking occurs after a period of operating time,

this means the solution (fresh water) tank is near

empty. Streaking is eliminated by adding more water

and chemical solution to the tank.

14. To drain the solution tank, attach the small drain or

“pump out” hose to the accessory quick connect on

the back of the machine. Turn the spool valve knob

to the “tool” position. Place the open end of the hose

into a bucket and turn on the accessory pump switch.

When empty, turn off the pump switch and remove

the hose from the quick connect. Also return the spool

valve knob to the “machine” position.

15. After each use clean the dome, intake filter and

gasket. Do not reinstall the dome until the next use,

this will allow the recovery tank to dry out.

16. Raise the brush chassis for storage.