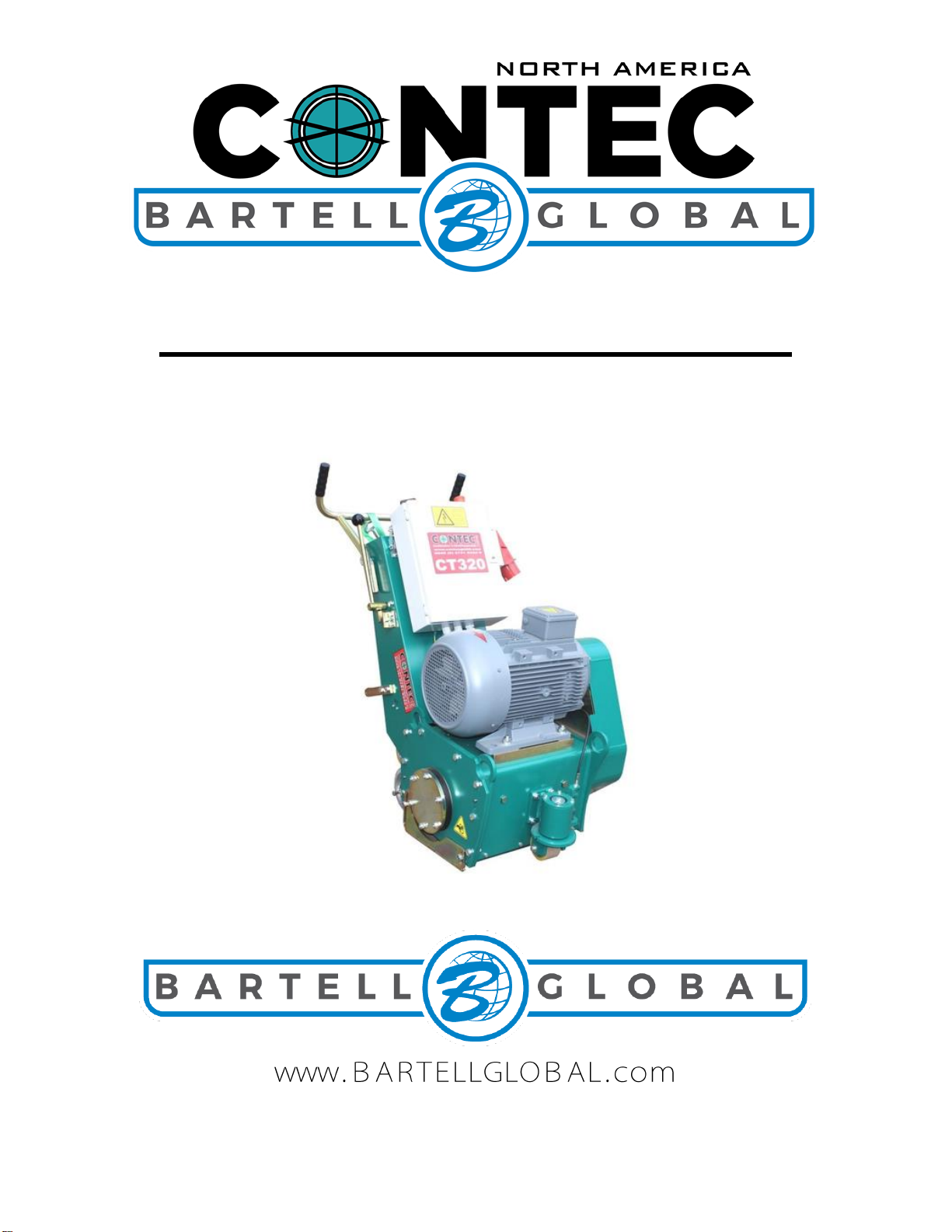

Bartell Global CONTEC CT320 User manual

Doc. # OIPB-C15005

Orig. Rel. –05/2020

Curr. Rev. - 00

FLOOR PLANER/SCARIFIER

CT320

OWNER’S MANUAL AND PARTS BOOK

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

1

OIPB –C15005

Bartell Morrison Inc.

170 Traders Blvd E

Mississauga, Ontario, Canada

L4Z 1W7

Tel: (647) 953-4100

Fax: (647) 953-4101

Bartell Morrison USA LLC

200 Commerce Drive, Unit A

Freehold, NJ, USA

07728

Tel: (848) 225-8100

Fax: (848) 225-8101

SPE International Ltd

Honeyholes Lane

Dunholme, Lincoln, England

LN2 3SU

Tel: 01673 860709

Fax: 01673 861119

Innovatech

4701 Allmond Ave

Louisville, Kentucky, USA

40209

Tel: (425) 405-9100

Fax: (425) 405-9101

ORIGINAL LANGUAGE OPERATING MANUAL FOR

CONTEC FLOOR PLANAR

© 2020 Bartell Morrison Inc.

No part of this work may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying and recording, or by any information storage or retrieval

system without the prior written permission of Bartell Morrison Inc. unless such copying is

permitted by federal copyright laws.

Address inquiries or reference permissions care of:

Bartell Morrison Inc., 170 Traders Blvd E., Mississauga, Ontario, Canada, L4Z 1W7

REV.

DATE

DESCRIPTION

APPROVED BY:

00

05/2020

Initial Release

AN

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

2

OIPB –C15005

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an explosive

atmosphere, near combustible materials, or

where ventilation does not clear exhaust fumes.

WARNING

BURN HAZARD

Never come into contact with the engine or

muffler when engine is operating or shortly after it

is turned off. Serious burns may occur.

CAUTION

ROTATING HAZARD

Never place hands or feet inside safety guard

rings. Serious injury will result from contact with

rotating blades.

CAUTION

MOVING PARTS

Before starting the machine, ensure that all

guards and safety devices are in place and

functioning properly.

ATTENTION

READ OWNER’S MANUAL

Read and understand owner’s manual before

using this machine. Failure to follow operating

instructions could result in serious injury or death.

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

3

OIPB –C15005

TABLE OF CONTENTS

QUALITY ASSURANCE/ MACHINE BREAK IN 4

WARRANTY INFORMATION 4

SPECIFICATIONS 5

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN 6

oROUTINE SERVICE SCHEDULE 7

oROUTINE SERVICE INTERVALS 7

OPERATING SAFETY PRECAUTIONS 8

OPERATION INSTRUCTIONS 9

oSETTING UP YOUR CT320 PLANER 9

oPRIOR TO OPERATION 9

oCHANGING OR INSTALLING TOOLING 9

oADJUSTING THE DRUM ALIGNMENT 9

oOPERATION 10

PARTS BREAKDOWN 12

PARTS LIST 1 –CT320 MAIN ASSEMBLY 13

oCT320 MAIN ASSEMBLY –PARTS LIST 1 14

PARTS LIST 2 –CT320 BELT DRIVE AND SHAFT 17

oCT320 BELT DRIVE AND SHAFT –PARTS LIST 2 18

PARTS LIST 3 –CT320 CONTROL PANEL 19

oCT320 CONTROL PANEL –PARTS LIST 3 20

PARTS LIST 4 –CT320 DRUM 21

oCT320 DRUM –PARTS LIST 4 21

PARTS LIST 5 –CT320 DRUM WITH TOOLS 22

oCT320 DRUM WITH TOOLS –PARTS LIST 5 22

PARTS LIST 6 –CT320 DRUM WITH BLADES 23

oCT320 DRUM WITH BLADES –PARTS LIST 6 23

ELECTRICAL SCHEMATIC 1 –MAIN MOTOR 25

ELECTRICAL SCHEMATIC 2 –DRIVE MOTOR 26

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

4

OIPB –C15005

QUALITY ASSURANCE/ MACHINE BREAK IN

The Contec Floor Planer is the product of extensive engineering development designed

to give long life and unmatched performance. The Floor Planer are shipped completely

assembled.

You can help ensure that your Floor Planer will perform at top levels by observing a

simple routine on first use. Consider that your new Planer is like a new car. Just as you would

break in a new car to the road or any new machine to the job, you should start gradually and

build up to full use. Learn what your machine can do and how it will respond. Full throttle and

control may be used after this time period, as allowed by material. This will serve to further

break in the machine on your specific application, as well as provide you with additional

practice using the machine.

We thank you for the confidence you have placed in us by purchasing a Contec Floor

Planer and wish you many years of satisfied use.

WARRANTY INFORMATION

Bartell agrees to furnish without charge, F.O.B. our plant, a replacement for any part or

portion thereof, comprising the main unit of the Contec Floor Planer, consisting of the handle,

housing assembly, save and except tooling, and power units, prove upon our examination, to

be defective in either material or workmanship within a period of twelve (12) months from date

of purchase, provided that notice of such defective part or portion thereof is given to Bartell Ltd.

within the twelve month warranty period. No further or other guarantee or warranty expressed

or implied in connection with the sale of the Planer is given and our sole liability consists in

replacing defective parts or portions thereof. We shall not be responsible for any special,

indirect or consequential damages arising in any manner whatsoever.

This guarantee is for the sole benefit of the original purchaser as end user. Our

responsibility under this guarantee ends in the case the original purchaser transfers ownership

of the Floor Planer, makes any changes or adds any parts or devices not of our manufacture to

the Floor Planer machine.

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

5

OIPB –C15005

SPECIFICATIONS

CT320

Dimensions

Width of Cut, mm (in)

320 (12.5)

Overall Width, mm (in)

610 (24)

Overall Length, mm (in)

1100 (43)

Overall Height, mm (in)

1100 (43)

Weight

Weight with Drum, kg (lb)

230 (507)

Power Source

Power kw (HP)

17.3 (23.5)

Volts (V)

460

Frequency (Hz)

60

Amperage (A)

30

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

6

OIPB –C15005

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN

This Contec Floor Planer has been assembled with care and will provide years of

service. Preventative maintenance and routine service are essential to the long life of your

Floor Planer. Your dealer is interested in your new machine and has the desire to help you get

the most value from it. After reading through this manual thoroughly, you will find that you can

do some of the regular maintenance yourself. However, when in need of parts or major service

be sure to see your Bartell dealer. For your convenience, we have provided this space to record

relevant data about your Floor Planer. When in need of parts or service be prepared to provide

your Floor Planer serial number. Locate the serial number now and record in the space below.

Date Purchased:

Type of Machine:

Dealer Name:

Model:

Dealer Phone:

Serial Number:

Replacement Parts Used

Maintenance Log:

Part No.

Quantity

Cost

Date

Date

Operation

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

7

OIPB –C15005

ROUTINE SERVICE SCHEDULE

Routine Service Intervals

Each

Use

After 1.5

months

or 50 hrs

Each 3

months

or 100

hrs

Each 6

months

or 200

hrs

Each 9

months

or 300

hrs

Each 12

months

or 400

hrs

General Inspection

Guards

Check

O

O

O

O

O

Warning Stickers

Check

O

O

O

O

O

Test Run

Check Operation

O

O

O

O

O

Fasteners

Check Tightness

O

Electrical

Cord

Check for

Damage

O

Plug

Check for

Damage

O

Switches/Buttons

Check

O

Planer Components

Tooling

Check Life

O

Tooling Drum

Check

O

O

O

O

Joints

Grease

O

O

Belt Drive

Check Tension

O

O

O

O

O

Motor

Fan

Check - Clean

O

O

O

O

O

ROUTINE SERVICE INTERVALS

Due to the nature and environment of use, Floor Planers could be exposed to severe operating

conditions. Some general maintenance guidelines will extend the useful life of your machine.

• The initial service for your Planer should be performed after 25 hours of use, at which time

your mechanic (or authorized repair shop) should complete all the recommended checks in the

schedule above. The maintenance log is handy for keeping a record of the maintenance

performed and the parts used for servicing your Planer.

• Regular service according to the schedule above will prolong the life of the floor Planer and

prevent expensive repairs.

• Keeping your floor Planer clean and free from debris is the single most important regular

maintenance operation, over and above the checks in the service schedule above, that can be

performed. After each use your Planer should be cleaned to remove any dust and debris from

the undercarriage and surrounding components.

• In the Service Schedule above, items that should be checked, replaced or adjusted are

indicated by “o” in the appropriate column. For ease of recording place, a checkmark through

the “o” when the item is complete. If an item is not required or not completed place an “x”

through the “o” in the box.

• Failure to have your Floor Planer regularly serviced and properly maintained in accordance

with the manufacturer’s instructions will lead to premature failure and void the warranty.

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

8

OIPB –C15005

OPERATING SAFETY PRECAUTIONS

The CT320 Floor Planers are constructed according to existing safety rules and

regulations. These technical precautions should not be removed or changed under any

circumstances. While operating the machines the following points should also be kept in mind:

The instructions provided in this manual are done so to ensure the operator’s safety as well

as that of others, the equipment, and the job site. Failure to follow these guidelines can lead to

serious personal injury and even death. The operator and any service personnel should read

and understand the entire manual before working with or servicing any Contec Floor Planer.

•The Planers should always be operated with all safety covers and technical precautions.

•During transport, cleaning, repair or maintenance the Planer must be disconnected from

the power supply. That also applies to the changing of tools.

•The operator should never leave the machine unattended during operation.

•Before leaving the machine, all rotary parts should be brought to a standstill. Electric

models must be disconnected from the power supply. Make sure that the machine

cannot roll or move by itself.

•After any maintenance and adjustment all safety covers must be reattached.

•Ear protectors must be worn.

•Eye protectors must be worn.

•Safety shoes with steel caps must be worn.

•In the event of a large amount of dust during operation, connect a dust collector to the

Planer.

•Depending on the floor (floor coating) planeing can produce gases. The operator must

be held responsible if these generated gases are dangerous and if protection is

necessary. planeing floors containing asbestos is especially dangerous and can cause

health problems. Special masks must be worn which keep the breathing air clean. A dust

collector must be used and should be equipped with filters suitable for asbestos dust.

•The floor must be brushed before grinding because loose material could get into the

tools and fly away. Anchor screws and bolts coming out of the floor can also be seen

better if the floor is clean. If the grinding head hits an anchor screw or bolt, then serious

damage can be caused to the machine or planeing drum.

IMPORTANT: NEVER attempt to disable or circumvent these safety devices. They are

present for the operator’s protection and any tampering will result in substantial risk to

the operator and all present at the job site. If your planer’s safety devices have been

tampered with, do not use the equipment. Immediately contact your sales representative

to obtain replacement parts or return the planer to your dealer for repairs.

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

9

OIPB –C15005

OPERATION INSTRUCTIONS

SETTING UP YOUR CT320 PLANER

Your CT320 Floor Planer comes fully assembled with handle and motor fully installed.

The tooling drum may also be installed from factory, if drum is not installed please see the

installation instructions below.

PRIOR TO OPERATION

•Make sure that all dust, debris etc., are thoroughly removed from the unit prior to

operation. Special effort should be given to the bottom of the machine where the tooling

drum is located.

•Check all bolts and screws for tightness and make sure all bolts and screws are securely

tightened. Loose bolts and screws may cause damage to the unit. Make sure tooling is

properly installed.

•The height adjustment lever must be in the upper position before machine can be

switched on

•Before switching the machine on turn the height adjustment hand wheel counter-

clockwise as far as possible

CHANGING OR INSTALLING TOOLING

•Lift the machine with the lever so that the tools are well clear of the floor.

•Remove the M10 screws on the right side of the plate. Carefully remove the side plate

•Take out the drum. Remove worn out tools. Check the drum for wear and tear. If

necessary, replace new tools on the drum.

•Before reinstalling drum, grease the shaft, then reinstall drum.

•Put the side plate back on and use the screws to mount it.

ADJUSTING THE DRUM ALIGNMENT

During operation the drum shaft and rear wheel axis may fall out of alignment. This results in an

uneven track on the floor. One side touches the floor before the other side and therefore

resulting in an uneven surface. Follow instructions below to align the drum

•Place the planer on an even floor. Lift the tools off the floor using the hand wheel.

•Loosen the clamping screw of the eccentric shaft of the rear wheels.

•On the other side of the rear wheel is a screw which keeps the wheel on the shaft.

Turning the screw will also turn the eccentric shaft. The floor planer moves up and down

on one side.

•Keep turning the screw, clockwise, until all the tools on the drum are an equal distance

from the floor. Caution: Turning the screw counter- clockwise will loosen the screw.

ATTENTION: Before working on the Planer bring the motor to a total stand still and

disconnect from the power supply.

CAUTION: Tools can be hot after use.

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

10

OIPB –C15005

OPERATION

Operating

After mounting the appropriate tools, the operation of the Planer can begin.

Switch the motor on and lower the planar with the lever to the operating position. Turn the hand

wheel height adjustment until the tools are lowered to the floor. Keep turning the handwheel

until you reach your desired finish

Dust emission should be prevented by connecting a dust collector.

Stopping Procedure

Turn the machine off and raise the cutters off the floor using the lever and/or hand wheel.

Disconnect the cord if you are done with the machine.

ATTENTION: Lowering the tools too much decreases the performance of the

machine. You will destroy the shafts in the drum and the bearings of the machine.

ATTENTION: Never switch on machine while the grinding head is on the floor.

ATTENTION: Lowering cutter adjuster too far will cause cage shafts to pinch cutters

between the shaft and the surface. This will cause cutters shafts and cage to break. The

cutters should always be able to move freely.

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

11

OIPB –C15005

This Page Left Intentionally Blank

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

12

OIPB –C15005

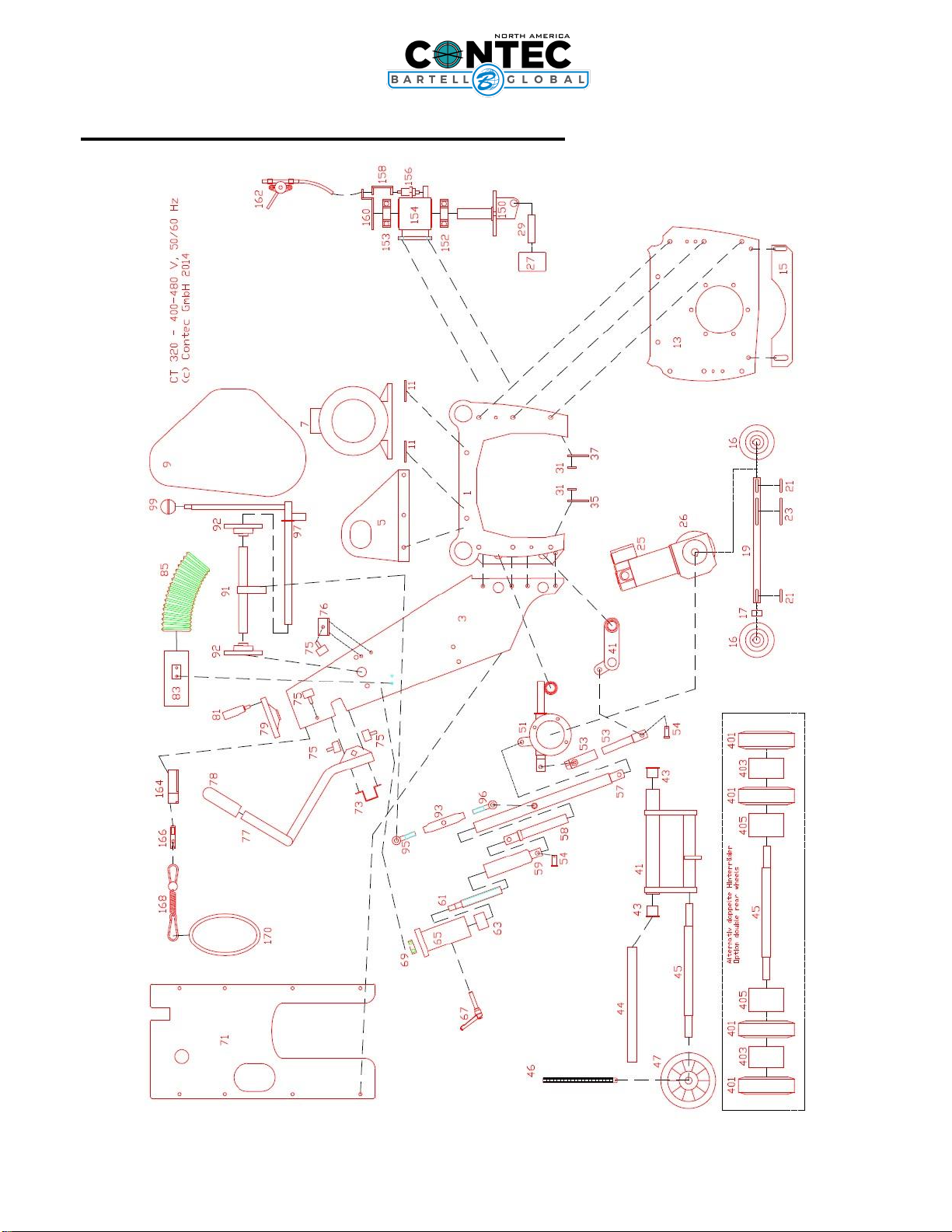

PARTS BREAKDOWN

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

13

OIPB –C15005

PARTS LIST 1 –CT320 MAIN ASSEMBLY

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

14

OIPB –C15005

CT320 MAIN ASSEMBLY –PARTS LIST 1

Item #

Part #

Description

QTY

Remarks

1

8719104000

Drum Housing Complete

1

3

8719104300

Handle Frame

1

5

8719104901

Belt Cover rear Plate

1

7

8755044675

Motor

1

9

8719104801

Belt Cover

1

11

8719104202

Motor Bracket

2

13

8719104100

Side Plate right

1

15

8719104600

Sealing Slide

2

16

8780203100

Drive Wheel

2

17

8790219552

Clamping Ring Drive Shaft

1

19

8719102001S

Drive Shaft

1

21

8768854067

40x6x6 mm DIN 6885 Key

2

23

8768858067

80x6x6 mm Key

1

25

8750202019

Drive Unit Motor

1

26

8750202020

Gearbox

1

27

8780208060

Front Wheel

1

29

8719100107

Front Wheel Axis

1

31

8719104701

Bracket Rubber Sealing front/back

2

35

8770104701H

Rubber Sealing rear

1

37

8770104701V

Rubber Sealing front

1

41

8719100409

Rear Wheel Swing

1

43

8761245030

Bronze Bearing

4

44

8719100405L

Axis

2

45

8719100406S

Rear Wheel Axis Inside Cut Pattern

1

46

8790200053

Ruler

1

47

8780203160

Wheel

2

51

8719100802

Motor Mounting

1

53

8719105410

Level Adjustment

1

54

8760331225

Pin for lifting Rod

2

57

8719105420

Lifting Rod lower Part

1

58

8719100506

Lifting Rod upper Part

1

59

8719100503

Height Control Piston

1

61

8719100502C

Height Adjustment Screw

1

63

8761244046

Bronze Bearing

1

65

8719100501

Housing Height Adjustment

1

67

87GN6049510

Clamp Lever

1

69

8761206302

Bearing

1

71

8719104401

Handle Frame Cover

1

73

8770261800

Bracket for Rubber Block

2

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

15

OIPB –C15005

75

8770263000

Rubber Block

7

76

8719105422

Lever Catch

1

77

8719104502

Handle with flexible Rubber Block

1

78

8770212610

Rubber Grip

2

79

8790219550

Level Adjustment Wheel

1

81

8790219551

Knob for Handwheel

1

83

8719104501

Hose Connector

1

85

8770250250

Dust Hose

2

91

8719105433

Pipe Lifting Lever

1

92

87612063063

Flange Bearing

2

92

87612063063

Flange Bearing

2

93

8719100507

Spanner Nut

1

95

8761310055

Eye Screw

1

96

8761501260L

Eye Screw Left Hand Thread

1

99

8790214512

Ball Head

1

150

8719106410

Shaft Front Wheel

1

152

87612062062

Bearing

1

153

87612063062

Bearing

1

154

8719106400

Bearing Housing

1

156

87GN61310GK

Locking Pin

1

158

8719106406

Clamping Yoke

1

160

8719106405

Lid

1

162

87MS005313

Bowden Cable

1

164

87XCSPA591

Safety Switch

1

166

87XCSZ11

Pin Safety Switch

1

168

8770212410

Safety Strip

1

401

8780202052

Binding Wheel

4

403

8719111102

Wheel Hub outside

2

405

8719111101

Wheel Hub Inside

2

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

16

OIPB –C15005

This Page Left Intentionally Blank

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

17

OIPB –C15005

PARTS LIST 2 –CT320 BELT DRIVE AND SHAFT

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

18

OIPB –C15005

CT320 BELT DRIVE AND SHAFT –PARTS LIST 2

Item #

Part #

Description

QTY

Remarks

111

8719105002

Bearing Housing Lid

1

113

876163102RS

Bearing

1

114

87612050110

Sealing

1

115

8719105001

Bearing Housing

1

117

8719211707

Hexagon Ring

1

119

8719211706

Drum Shaft

1

121

87688550108

Key

1

123

8719100701

Spacer

1

125

8761300180

Circlip

1

127

87612063072

Bearing

2

129

8719101703

Spacer

1

131

8719101701

Bearing Housing

1

132

87191017037

Spacer

1

133

8790242003TB

Drum Pulley

1

135

879024251735

Taper lock

1

137

8770262790

Belt Tensioner

1

139

8790241123TB

Pulley

1

141

879024201242

Taper lock

1

143

8770241207RP

Belt

3

CT320 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

19

OIPB –C15005

PARTS LIST 3 –CT320 CONTROL PANEL

This manual suits for next models

1

Table of contents