www.micro-components.com, microComponents@bartels-mikrotechnik. e

Tel: +49-231-9742-500, Fax: +49-231-9742-501

1. General

This operating manual contains all necessary instructions or the installation, commissioning, operation and

maintenance o the mp6 and mp6-pp micropump and o the controller mp-x, mp6-OEM and mp6-EVA with

the mp6 and mp6-pp.

The unit has been designed with state-o -the-art technology and in accordance with all relevant sa ety

regulations. However, a risk o damage to the units, other property, the operator and/or other persons

cannot be ully excluded.

Always comply with the ollowing general instructions:

•Be ore working with a pump, you must be ully amiliar with its operation and unctions.

•Prior to operating the pump, read this operating manual and adhere to all instructions.

•Re rain rom any operations that might endanger the sa ety o the unit.

Bartels Mikrotechnik GmbH rejects any responsibility or damages to persons or property resulting rom

non-compliance with the instructions in this manual. In this case all warranties shall be void.

1.1 Declaration of conformity

Bartels Mikrotechnik GmbH is certi ied according to DIN EN ISO 9001:2000 and declares that the products

are compliant to the RoHS directive and the controller comply with the requirements o EMC 89/336/EEC

and CE markings have been a ixed to the devices.

1.2 Description of functions

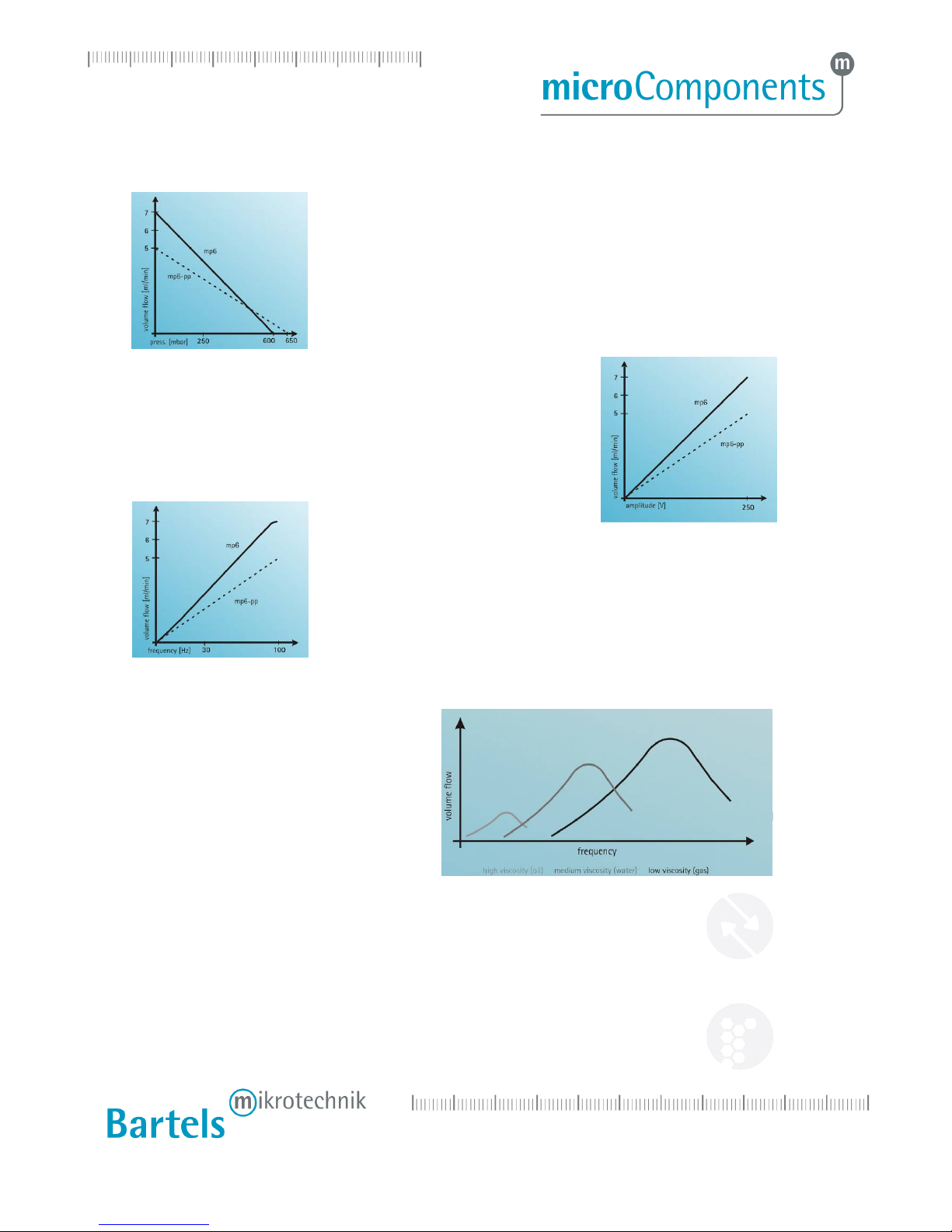

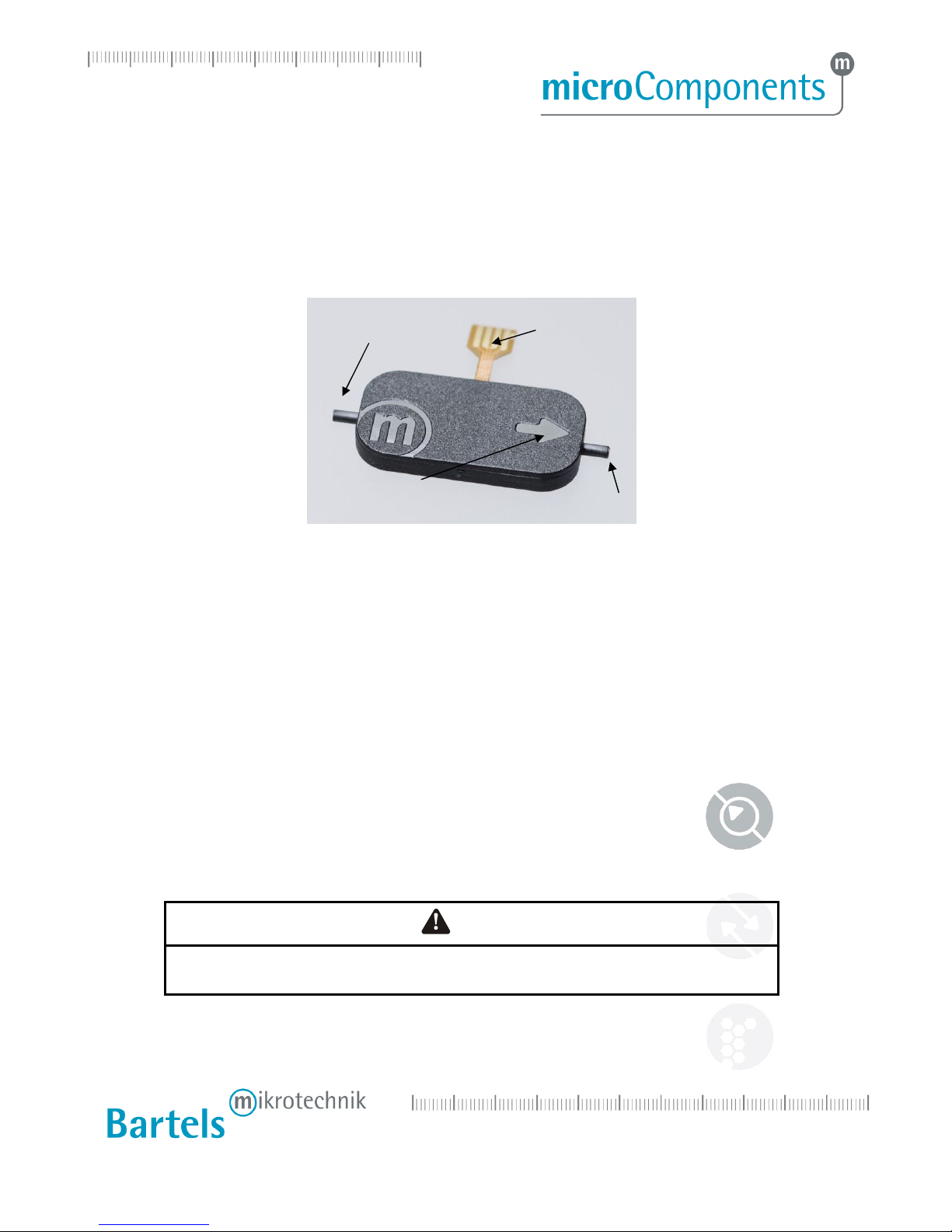

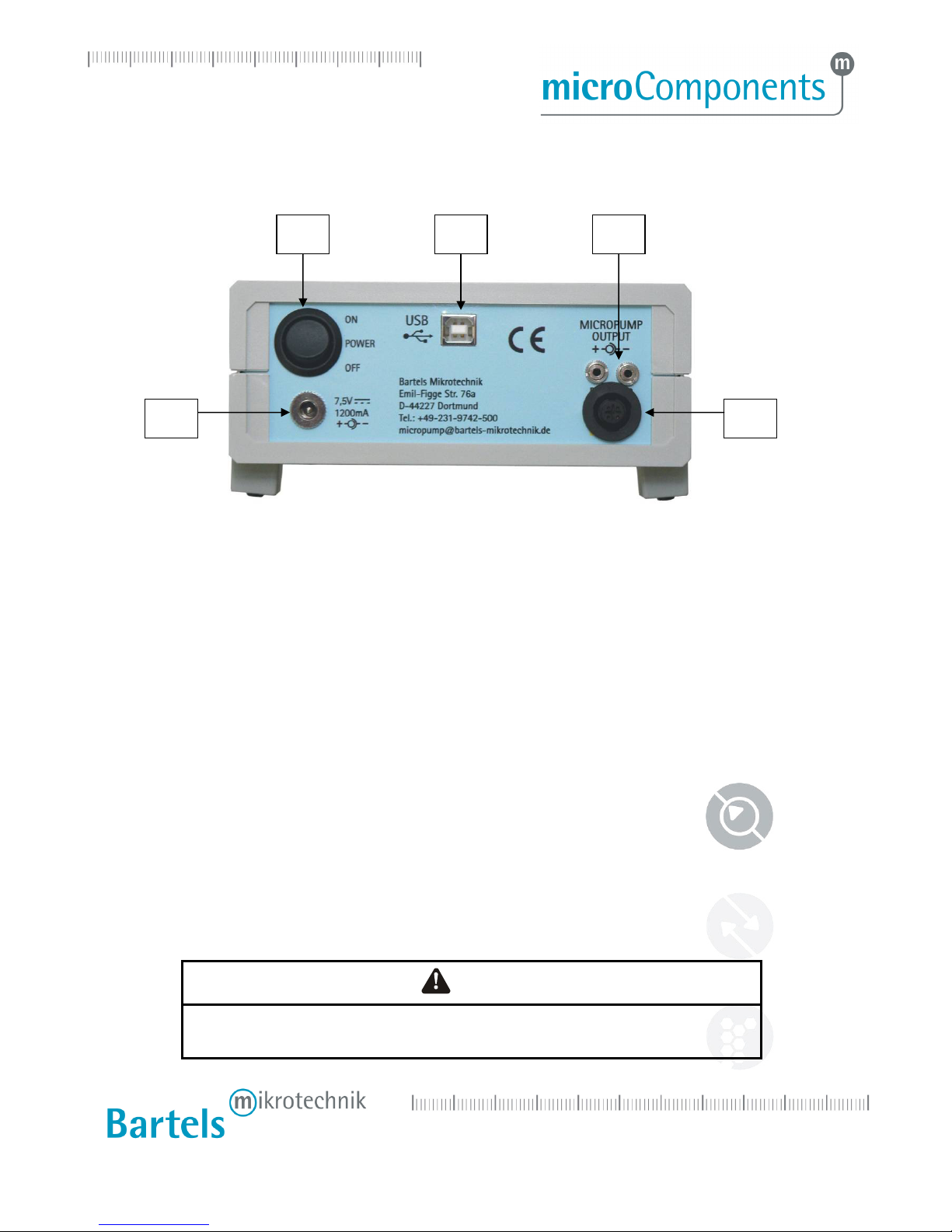

The micropumps have been developed or the transport o gases or liquids. The mp-x controller, the mp6-a

controller, mp6-OEM and mp6-EVA controller have been developed or operating one mp6 or one mp6-pp.

Bartels Mikrotechnik can assume no liability or damages resulting rom the pump media. This applies

especially or hazardous luids.

The pumps must be operated with Bartels Mikrotechnik electronics. Bartels Mikrotechnik GmbH cannot

guarantee the proper work o the units with customer speci ic electronics. I other controllers than the ones

rom Bartels Mikrotechnik are used, Bartels Mikrotechnik disclaims any warranty.

Please make sure that only skilled personnel works with the pump control and micropump. The micropump

shall be under constant supervision at running conditions. And please note that components o the

controller and pump are operating with high-voltage. There ore persons wearing pacemakers are

recommended to avoid the operating system.

Bartels Mikrotechnik assumes no liability or abnormal handling, improper or negligent use o the

micropump and the controller that is not con orm to the speci ied purpose o the system. This applies

especially or micropump controllers, components and systems o other manu acturers, which have not

been certi ied by Bartels Mikrotechnik.

We guarantee that the micropumps comply with the actual state o scienti ic and technical knowledge and

due to this the operational risks are limited to a minimum.

Do not open the housing o the micropump and the controllers. In those cases Bartels Mikrotechnik can not

issue a guaranty anymore. Please keep this manual sa e and give a copy to all users.