Barth Mini-PLC STG-115 User manual

BAR

H

Elektronik GmbH

®

1/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

TABLE OF CONTENT

Mini-PLC STG-115

Art. No. 0850-0115

MANUAL

1 SAFETY INSTRUCTIONS ......................................2

2 DESTINATED USE ..................................................2

3 DISCLAIMER ..........................................................2

4 PRODUCT DESCRIPTION .....................................2

4.1 Features ..................................................................2

4.2 Applications ...........................................................2

4.3 General description ..............................................2

4.4 Programming with miCon-L .................................3

4.5 Delivery content ....................................................3

5 INSTALLATION .......................................................3

5.1 Mounting ................................................................3

5.2 Wiring ......................................................................4

5.3 Overview .................................................................4

5.3.1 Connecting the power supply .................................4

5.3.2 Connecting the inputs .............................................4

5.3.3 Connecting the outputs ...........................................5

6 OPERATION AND PROGRAMMING .....................5

7 APPENDIX ..............................................................6

7.1 Specications ........................................................6

7.1.1 General ....................................................................6

7.1.2 Power supply ...........................................................6

7.1.3 Inputs .......................................................................6

7.1.4 Outputs ....................................................................7

7.1.5 Display .....................................................................7

7.1.6 Electrical connection ...............................................7

7.1.7 Electromagnetic compatibility (EMC) ......................7

7.1.8 Security features ......................................................7

7.1.9 Program and data memory .....................................7

7.1.10 Environmental conditions ........................................7

7.1.11 Weight and dimensions ...........................................7

7.1.12 Ordering information ...............................................7

7.2 Disposal ..................................................................8

7.3 Conformity declaration ........................................8

7.4 Documents, videos and software .......................8

BAR

H

Elektronik GmbH

®

2/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

1 SAFETY INSTRUCTIONS

This manual contains notices which you should observe

to ensure your own personal safety, as well as to protect

the product and the connected equipment. These notices

are highlighted in the manual by a warning symbol and are

marked as follows according to the level of danger:

Only qualied personnel should be

allowed to install and work on this

equipment. Qualied persons are dened

as persons who are authorized

to commission, to ground and to tag

circuits, equipment and systems in

accordance with established safety

practices and standards.

Turn off the power supply before

performing any wiring operations!

Short circuits can be harmful, critical and

can cause explosions and serious burns!

Please read this manual carefully and

observe all safety instructions!

2 DESTINATED USE

The Mini-PLC is designed for universal measuring, con-

trolling and regulating applications.

It must not be used for life critical, medical or fail safe

applications.

3 DISCLAIMER

BARTH Elektronik GmbH assumes no liability for usage

and functionality of the Mini-PLC in case of disregar-

ding this manual. The strict accordance of this manual

is important since the installation methods, peripheral

connections, usage and maintenance can not be con-

trolled by BARTH Elektronik GmbH. Therefore BARTH

Elektronik GmbH assumes no liability for any claim.

4 PRODUCT DESCRIPTION

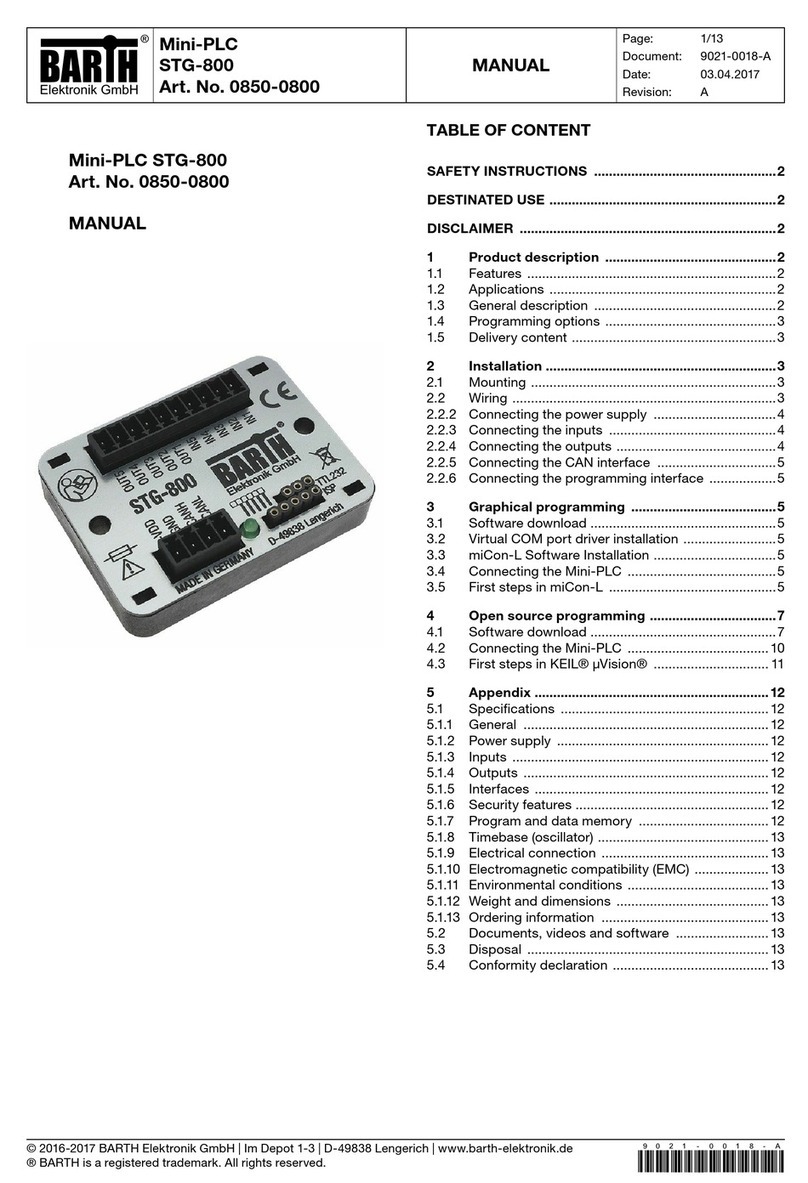

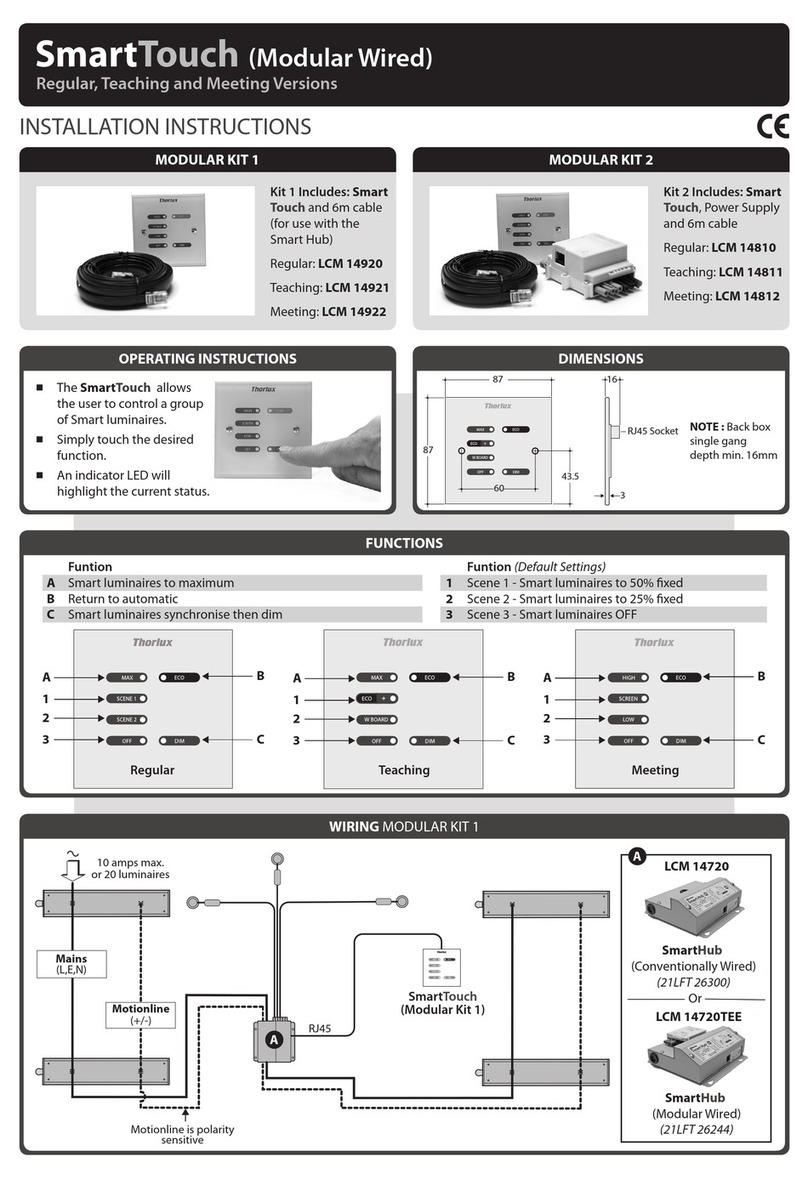

The picture below shows the BARTH®Mini-PLC STG-115

with it´s panel mount housing (front and backside).

4.1 Features

• Compact Panel Mount Mini-PLC

• Splashproof Front Panel

• 8 analog Inputs 0 to 30 VDC

• 2 analog Inputs 0 to 10 VDC / 4 to 20 mA

• 8 Power Outputs up to 1.5 A

• 1 Relay Output 1A/30V

• Backlid LCD 2x16 Characters

• Intuitive graphical Programming Capability

• Freely programmable LCD

• Programmable Keypad (4 Keys)

• USB Interface

• Plugable Spring Terminal Connectors

• Wide Operating Temp. Range -20..+55°C

• Engineered and manufactured in Germany

4.2 Applications

• Industrial Automation

• Building Automation

• Metering and Dispensing Technology

• Environmental Technology

• Light and Show Technology

4.3 General description

The BARTH® STG-115 extends the established Mini-PLC

series with graphical programming capability featuring a

rugged panel mount housing with backlid LCD and four pro-

grammable enter keys.

The splashproof front panel housing in combination with the

freely programmable LCD open up a variety of application

elds in industrial applications.

The STG-115 does not need any peripheral components to

operate. Both inputs and outputs features highly integrated

and rugged protection circuits to operate the Mini-PLC in

really harsh environment.

The BARTH® Mini-PLC STG-115 is also available as custo-

mer-tailored OEM version.

BAR

H

Elektronik GmbH

®

3/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

4.4 Programming with miCon-L

Without learning a difcult programming language the

BARTH®Mini-PLC can be easily programmed using sim-

ple and vivid graphical function blocks. This block design

meets graphical standards of the latest graphical program-

ming languages.

The miCon-L software suite features programming, simula-

tion and test in one unique software design tool. The exible

programming option offers a variety of possibilities in indus-

trial, automotive and maritime applications.

Programming the STG-115 follows using the USB port of

your PC with installed miCon-L software suite.

miCon-L also supports full simulation and visualisation ope-

ration modes.

The software provides a variety of visualisation blocks and

interactive elements to control and debug the Mini-PLC.

For detailed information please read the BARTH®miCon-L

manual and the BARTH® Application Notes on:

www.barth-elektronik.de

4.5 Delivery content

• BARTH®Mini-PLC STG-115

• Spring terminal connectors (for supply, input, output)

5 INSTALLATION

5.1 Mounting

The STG-115 must be installed and wired

by a trained technician who knows and

complies with both the universally appli-

cable engineering rules and the regulati-

ons and standards that apply in specic

cases.

The STG-115 is intended for panel mount using four M4

screws to x the PLC.

Before mounting create a cut-out for the Mini-PLC with the

dimensions 68 x 92 mm.

To x the PLC place four holes diameter 4.5 mm with the

distances 100 x 80 mm.

To ensure the IP65 protection grade of the

front panel an additional sealing is man-

datory. The sealing has to be applied bet-

ween the front panel and the housing.

The 3M type 5915 is suitable for most

applications.

Please verify the sealing for your applica-

tion! Otherwise the degree of protection

may be insufcient!

Take care to meet the environmental con-

ditions of the STG-115.

After creating the cut-out, place the Mini-PLC properly and

x it using four M4 screws.

Only use M4 cylinder head type screws

fastening the Mini-PLC, applying a maxi-

mum torque of 0.5 Nm !

Otherwise damage of the front panel may

occur !

BAR

H

Elektronik GmbH

®

4/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

5.3.2 Connecting the inputs

You can connect sensors, switches or buttons to the inputs.

The sensors may be temperature, ow, pressure, photo-

electric sensors or proximity switches, for example.

The STG-115 is well suitable for any sensor featuring a vol-

tage or current loop output, 0 to 10 VDC or 4 to 20 mA, for

example.

Common features of the inputs IN1-IN10 (X6, X7)

• IN1 to IN8 are selectable analog/digital inputs

• IN9 and IN10 are switchable inputs 0-10VDC or 4-20mA

• Wide input voltage range 0 to 32VDC

• Comprehensive integrated protection circuits

• Outstanding electromagnetic compatibility (EMC)

• Electrostatic discharge protection (ESD)

Due to the pull-down resistors integrated in the STG-115,

any switch (NO/NC) can simply be connected between the

positive supply (+VDD) of the STG-115 and the desired input.

The voltage at any input must not exceed

32VDC referred to ground (GND).

Higher voltages or reverse voltage lower

than -32VDC may cause irreversible

damage of the Mini-PLC!

At both IN9 and IN10 the applied signal

must not exceed 12VDC or 25mA!

The 8-pole X6 connector named ‚IN1‘ to ‚IN8‘ contains all

common 0-30VDC inputs of the Mini-PLC.

The 2-pole X7 connector contains two special inputs named

‚IN9‘ and ‚IN10‘ which are DIP-switchable from 0-10VDC to

4-20mA. The default value of both inputs is 4-20mA.

To change the input IN9 from 4-20mA to 0-10V please set

the switch 1 of the S1 DIP switch from ON to OFF.

To change the input IN10 from 4-20mA to 0-10V please set

the switch 2 of the S1 DIP switch from ON to OFF.

Switches 3 and 4 of S1 are not related to any function.

Using the inputs IN9 and IN10 as current loop 4-20mA type

a pull-down resistor of 470 Ohm is used within the STG-115

to receive a voltage from a current signal.

Using the miCon-L software suite you have to know wether

or not the inputs IN9 and IN10 are congured as current

loop type to recalculate the current from the received vol-

tage value within miCon-L.

5.2 Wiring

5.3 Overview

Connectors

X1: Power supply (fused)

X2: USB connection (PC interface for miCon-L)

X4: Common output ports OUT1-OUT8

X5: Relay output OUT9

X6: Common input ports IN1-IN8

X7: Special input ports IN9-IN10 (0-10V/4-20mA)

X8: Common ground (bridged parallel)

S1: DIP switch to congure X7 ports IN9 and IN10

5.3.1 Connecting the power supply

The STG-115 features an outstanding wide supply voltage

range from 16 to 32 VDC at lowest current consumption.

So the Mini-PLC can be integrated within battery sup-

plied 24V DC systems (cars, trucks, battery powered cars,

forklifts and digger, for example).

Turn off the power supply before perfor-

ming any wiring operations!

False electrical connection, voltage

reversal or disregarding the electrical

specications may cause irreversible

damage of the Mini-PLC!

Connect the supply voltage of 16 to 32 VDC to the X1 termi-

nal named ‚+VDD‘ and ‚GND‘ of the STG-115.

Wire the positive supply to the ‚+VDD‘ marked terminal. The

negative (ground) will be wired to the ‚GND‘ terminal.

All connectors are carried out as plugable spring terminal

connectors for a wire gauge of 0.25 to 1.5mm².

Ensure correct power supply voltage

range and polarisation! External fusing of

8A max. is mandatory!

Disregard may cause irreversible damage

of the Mini-PLC!

BAR

H

Elektronik GmbH

®

5/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

5.3.3 Connecting the outputs

Depending on load type and current the STG-115 is able

to directly drive electric loads without any additional driver

or protection circuit. The Mini-PLC provides 8 digital solid-

state highside outputs and one isolated relay output.

Common features of outputs OUT1 to OUT8 (X6)

• Rugged solid-state higside switch up to 1.5A

• Paralleling permissible up to 6A

• Short circuit protection and current limitation

• Fast demagnetization of inductive loads

• Stable behaviour at undervoltage

• Comprehensive integrated protection circuits

• Outstanding electromagnetic compatibility (EMC)

• Electrostatic discharge protection (ESD)

Features of output OUT9 (X5)

• Relay NO/NC changeover output type 1A/30VDC

• Electrically isolated

• Outstanding electromagnetic compatibility (EMC)

• Electrostatic discharge protection (ESD)

The 9-pole connector X4 named ‚OUT1‘ to ‚OUT8‘ contains

all digital outputs of the Mini-PLC. While OUT1 to OUT8 are

overload-protected highside switches, OUT9 (X5) is carried

out as electrically isolated relay changeover NO/NC switch.

A logical HIGH within miConL will switch the Mini-PLS´s

supply voltage at OUT1 to OUT8, while the isolated contact

of OUT9 changes over (NC/NO-NO/NC).

Aviod a current exceeding 1A/30VDC at OUT9 because this

outputs is not protected against short-circuiting or overload

current !

The total current sourced by OUT1 to

OUT8 must not exceed 6A!

Avoid reverse voltage at any output higher

than the Mini-PLC´s supply voltage!

OUT9 provides NO short circuit protection.

Take care the contact current not exceeds

1A! Negligence may cause irreversible

damage of the Mini-PLC!

6 OPERATION AND PROGRAMMING

To operate the STG-115 rst establish proper power supply

connection at both +VDD and GND terminals.

For programming and PC connection the connection cable

VK-12 (Art. No. 0091-0012) and a PC with installed Windows

operating system are mandatory.

Before you connect the Mini-PLC to the PC you have to ins-

tall the USB-/COM-port driver (folder ‚USBdriver‘) from the

software download package:

www.barth-elektronik.de/download/9045-0008-A.zip

Now install the miConL software suite from the ‚miCon-L‘

folder. Follow the setup instructions of miConL. Afterwards

establish the PC connection using the VK-12 connection

cable and run miConL.

For choosing the correct COM-Port please click the right

button (congure serial interface) located on the main menu

page and conrm the added COM-Port used by the STG-

115.

Now start miConL with creating a new project (Project->

New) or open a miCon-L sample application (Project-

>Open).

BAR

H

Elektronik GmbH

®

6/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

Creating a new project the desired Mini-PLC model and the

project name have to be dened.

After opening or creating a project the workspace of miConL

with it´s libraries (right) is shown.

Additional help and a detailed user manual is provided

within the miCon-L help and the miConL context menu

(right mouse button).

7 APPENDIX

7.1 Specications

7.1.1 General

Hardware design BARTH®Mini-PLC, splashproof

panel mount version, super-at

and rugged housing with plugable

spring terminal connectors

Programming miCon-L Software,

graphical (function block style),

simulation, programming and

visualisation, free license model

Interfaces USB

reserved for miCon-L software

communication only

7.1. 2 Power supply

Operating voltage 16 to 32 VDC

Current consumption < 7 mA at 32 VDC

LCD backlight switched off

in miCon-L application

Fusing 8 A max. (external)

mandatory for voltage reversal

protection

Voltage reversal protection yes

(combined with external fuse)

ESD/TVS protection yes

Heat dissipation

(at full load)

normally < 4 W

7.1.3 Inputs

Number analog 8+2

Analog input IN1 - IN8 UIN = 0..30 VDC

RIN > 11 kOhm

fIN <= 100Hz

tIN >= 10 ms

Analog input IN9 - IN10 UIN = 0 to 10 VDC

RI= 470 Ohm

IIN = 4 to 20 mA (DIP switchable)

Accuracy ADC

IN1 - IN8

± 3% (0.5 VDC)

ADC resolution

(internal)

10 Bit

Potential isolation no (common GND)

ESD/TVS protection yes

Permissible cable lenght

(per input)

normally 40 m

BAR

H

Elektronik GmbH

®

7/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

7.1.4 Outputs

Number digital 8+1

Output OUT1 - OUT8 Output type: solid state

IOUT <= 1,5 A (resistive load)

@ fOUT = 0..100 Hz

UOUT >= UIN-0,45 V

ITOT<= 6 A (paralleling permissible)

Maximal allowable load

inductance for a single switch off

(one output):

VDD=12VDC, IL=1.5A, ZL<=70mH

VDD=12VDC, IL=1A, ZL<=200mH

On-state resistance VDD to OUT:

RON<=180mOhm

Turn-on time: tON<=250µs

Turn-off time: tOFF<=270µs

Relay output OUT9 Output type: NO/NC changeover

INO/NC <= 1 A (resistive load)

@ fOUT = 0..5 Hz

UNC/NO <= 30 VDC

Potential isolation yes

7.1.5 Display

Display Type STN blue

transmissive negative mode

Backlight LED, lightguide, white

Display contents 16 x 2 characters

Character pitch 3.55 x 5.95 mm

Character size 2.95 x 5.55 mm

Character font 5 x 8 dots

Dot size 0.55 x 0.65 mm

Operating Temperature -20 to +70°C

7.1.6 Electrical connection

Electrical Connection plugable spring terminal

connectors 0.25 to 1.5 mm²

7.1.7 Electromagnetic compatibility (EMC)

Electrostatic discharge

(ESD) on IN1 to IN10

20 kV air discharge

30 kV contact discharge

(IEC/EN 61 000-4-2, level 3)

Electrostatic discharge

(ESD) on OUT1 to OUT9

8 kV (human body model)

(MIL-STD883D)

Electromagnetic elds Field strength 10 V/m

(IEC/EN 61000-4-3)

7.1.8 Security features

Security Features Watchdog (WD)

Brown out detection (BOD)

Power up timer (PUT)

7.1.9 Program and data memory

Flash program memory 64 k

cell endurance: 10.000 min

characteristic retention: 40 yrs

EEPROM data memory 1024 byte

byte endurance 100.000 min.

characteristic retention: 40 yrs

7.1.10 Environmental conditions

Operation temperature -20..+60 °C

(IEC 60068-2-1/2)

Storage temperature -40..+70 °C

(IEC 60068-2-1/2)

Relative humidity 5 to 95% non-condensing

(IEC 60068-2-30)

Air pressure (in operation) 500 to 1500 hPa

Shock resistance min. 50 m/s²

(IEC 60068-2-27)

Vibration resistance min. 25 m/s² @ 10..100 Hz

(IEC 60068-2-6)

Degree of protection IP 65 (EN 50178, IEC 60529)

(front panel with applied sealing)

Drop Drop height: 50mm

(IEC 60068-2-31)

Free fall (packaged) 500 mm

(IEC 60068-2-32)

7.1.11 Weight and dimensions

Weight 165 g

(without connectors)

Dimensions PLC: 110 x 90 x 36 mm (LxWxH)

Cut-out: 68 x 92 mm (LxW)

Hole distance: 100 x 80 mm

Hole diameter: 4.2 mm

Mounting via four M4 screws

(only cylinder head type)

7.1.12 Ordering information

Ordering information

Mini-PLC

Mini-PLC STG-115

Art. No. 0850-0115

Ordering information

accessory

USB connection cable VK-12

Art. No. 0091-0012

BAR

H

Elektronik GmbH

®

8/8

9021-0003-A

23.10. 2015

A

Page:

Document:

Date:

Revision:

Mini-PLC

STG-115

Art. No. 0850-0115

MANUAL

© 2014-2015 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved. 9021-0003-A

7.2 Disposal

If you wish to nally dispose of the

product, ask your local recycling centre

or dealer for details about how to do

this in accordance with the applicable

disposal regulations.

7.3 Conformity declaration

For the following designated product it is hereby conrmed,

that the construction in that technical design brought by us

in trafc corresponds to the standards specied below. In

the event of any alternation which has not been approved

by us being made to any device as designated below, this

statement shall thereby be made invalid.

Description Mini-PLC

Type STG-115

Art. No. 0850-0115

Directive

2004/108/EG relating to-

electromagnetic

compatibility (EMC)

Applied norms:

EN55022:2006+A1:2007

EN55024:1998+A1:2001

+A2:2003

EN61000-3-2:2006

+A1:2009+A2:2009

EN61000-3-3:2008

EN61000-6-2:2005

RoHS Directive

2011/65EU

We herby declare that our

product is compilant to the RoHS

Directive on restriction of the use

of certain hazardous substances

in electrical and electronic appli-

ances.

BARTH®Elektronik GmbH

Lengerich, 10.10.2013

Dipl.-Ing. (FH) D. Barth

Managing Director

7.4 Documents, videos and software

Detailed information, additional documents, application

notes and videos relating to this product are downloadable

from www.barth-elektronik.de and www.micon-l.de

This manual suits for next models

1

Table of contents

Other Barth Controllers manuals

Popular Controllers manuals by other brands

Sinovo

Sinovo SD300-2S-0.7G user manual

Peaktronics

Peaktronics DHC-301 instruction manual

Sinfonia Technology

Sinfonia Technology C10 Series instruction manual

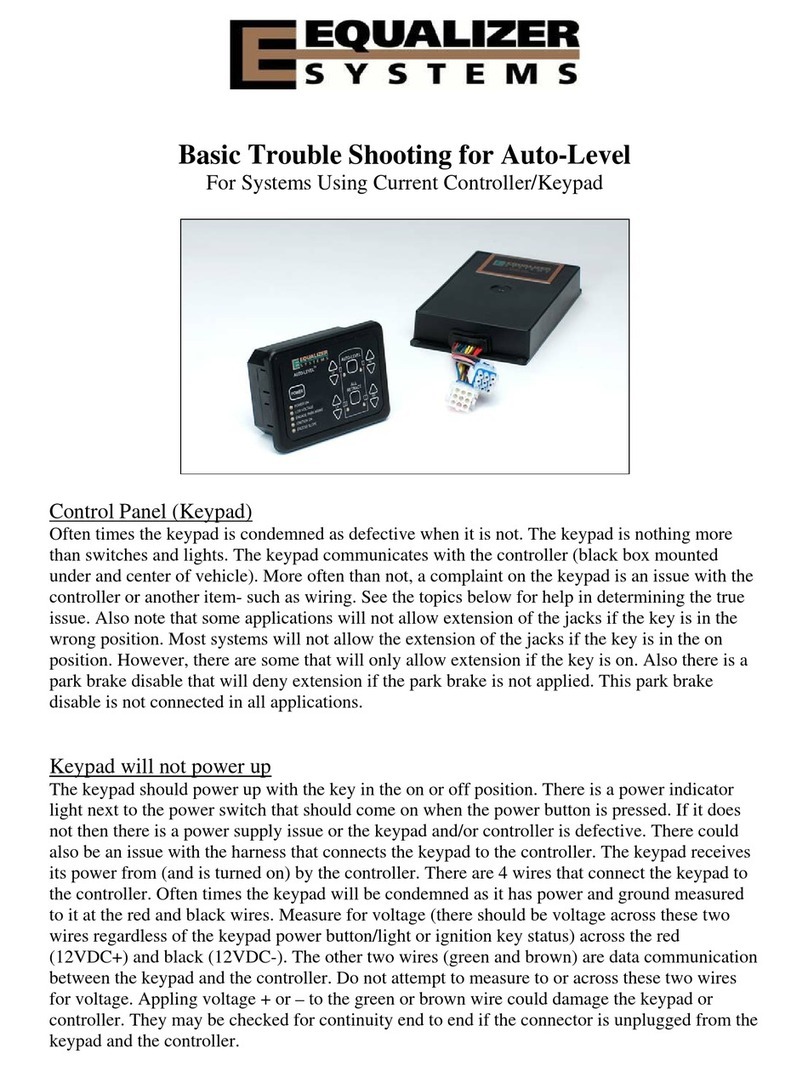

Equalizer Systems

Equalizer Systems Auto Level Basic Troubleshooting

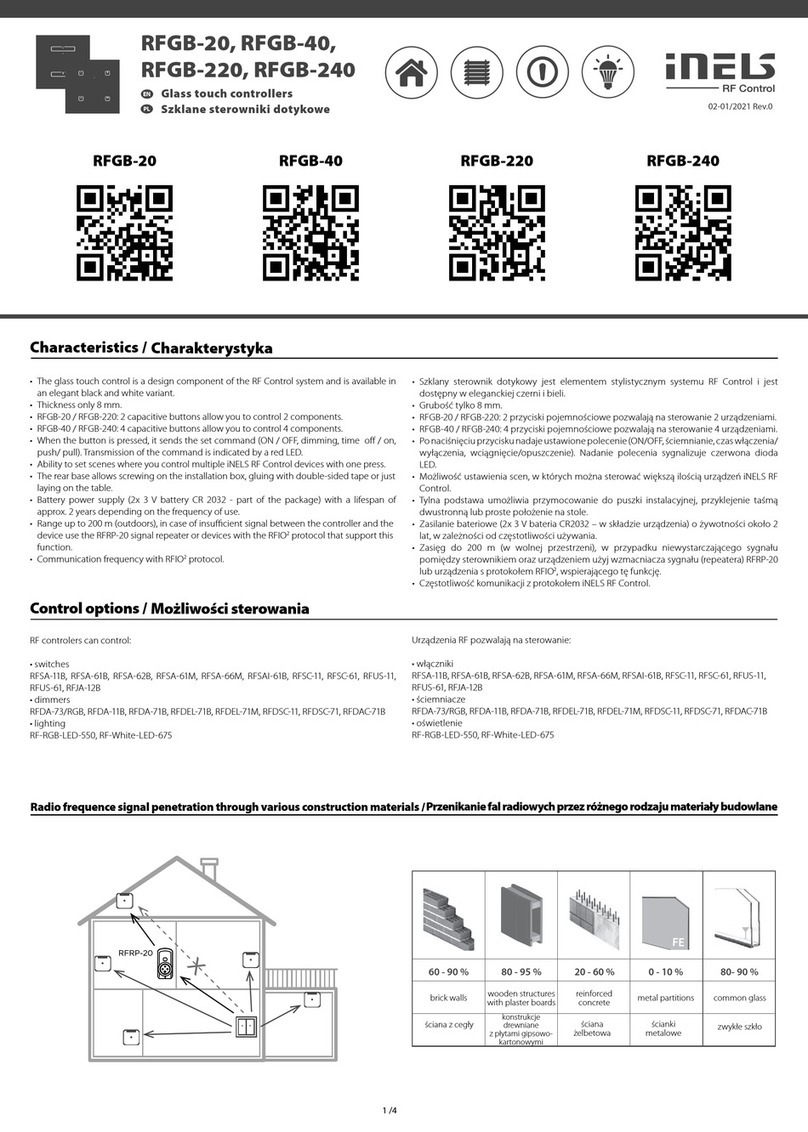

Elko

Elko iNELS RFGB-20 manual

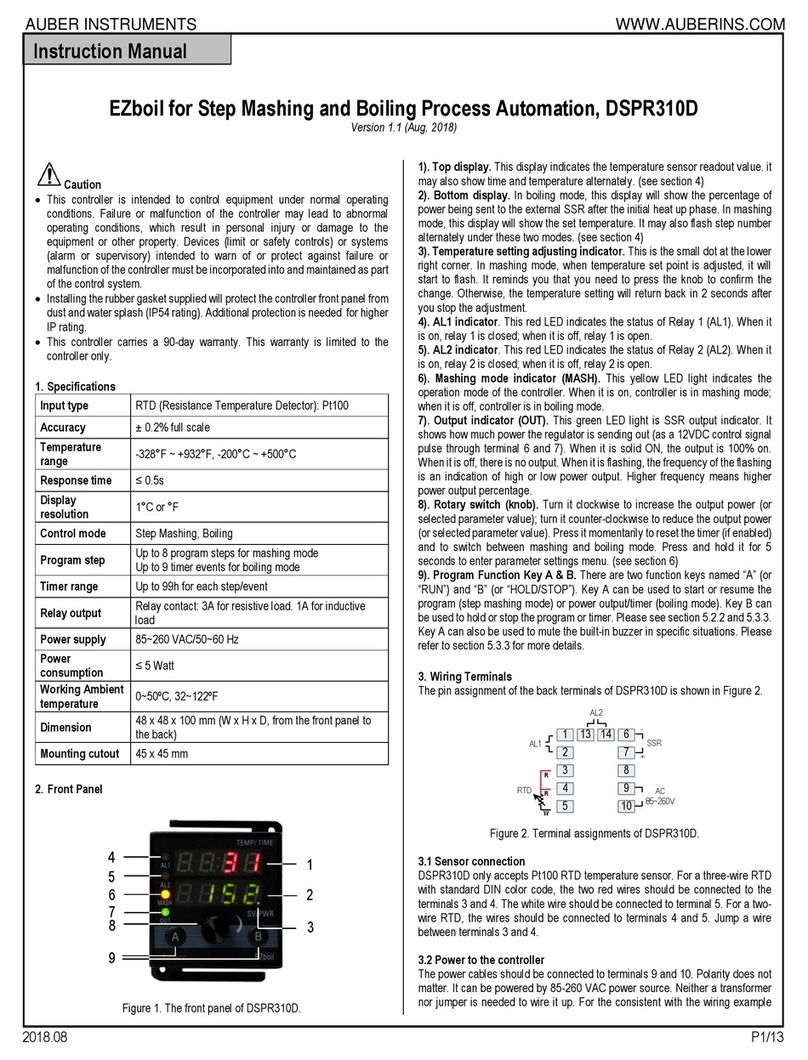

Auber Instruments

Auber Instruments EZboil DSPR310D instruction manual

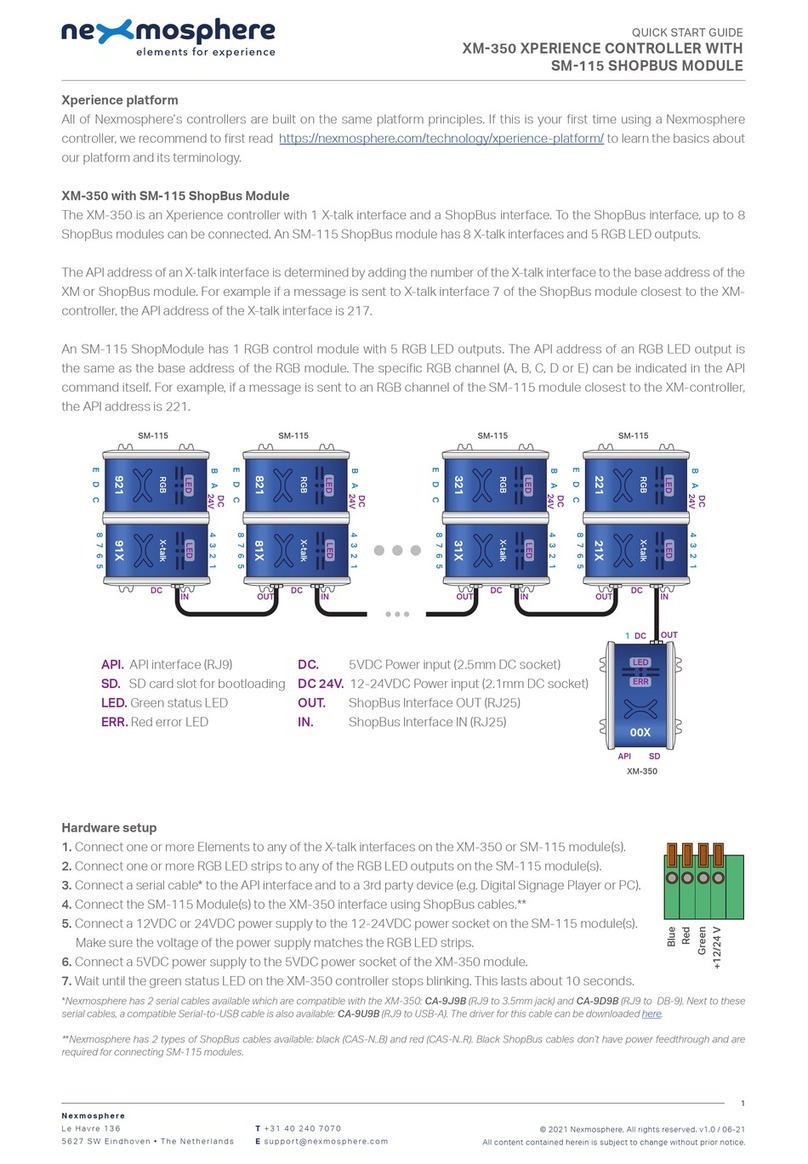

Nexmosphere

Nexmosphere XM-350 quick start guide

MSA

MSA GasGard XL operating manual

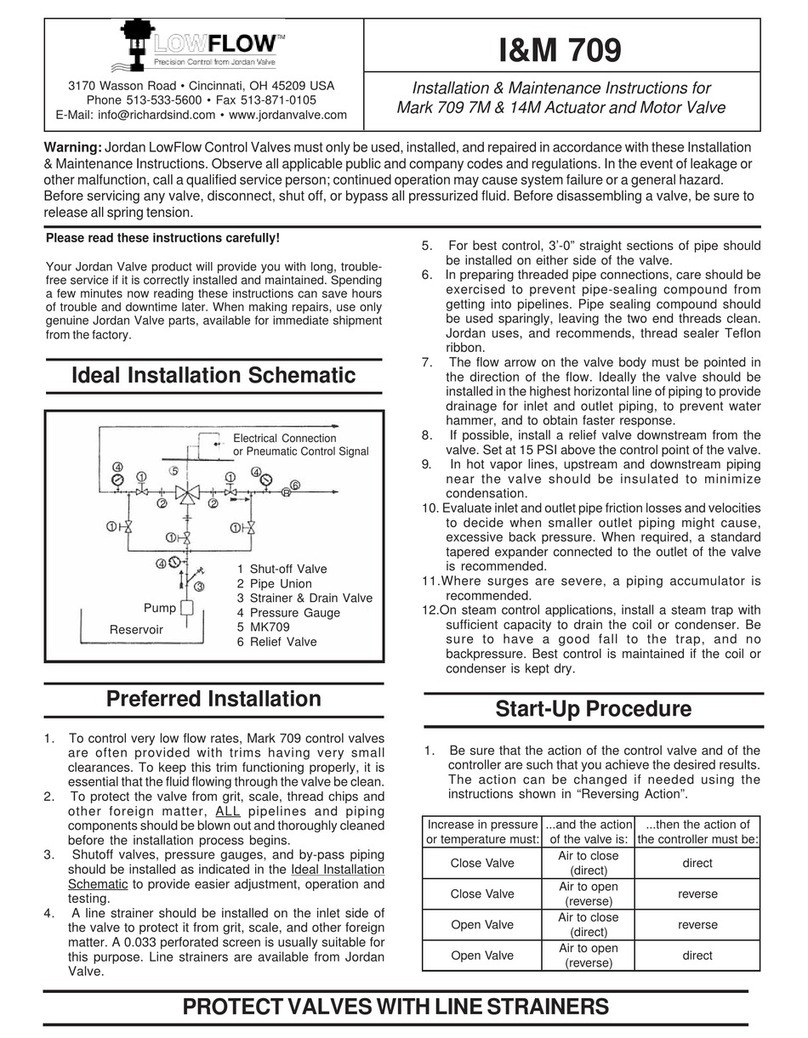

Jordan Valve

Jordan Valve LowFlow Mark 709 7M Installation & maintenance instructions

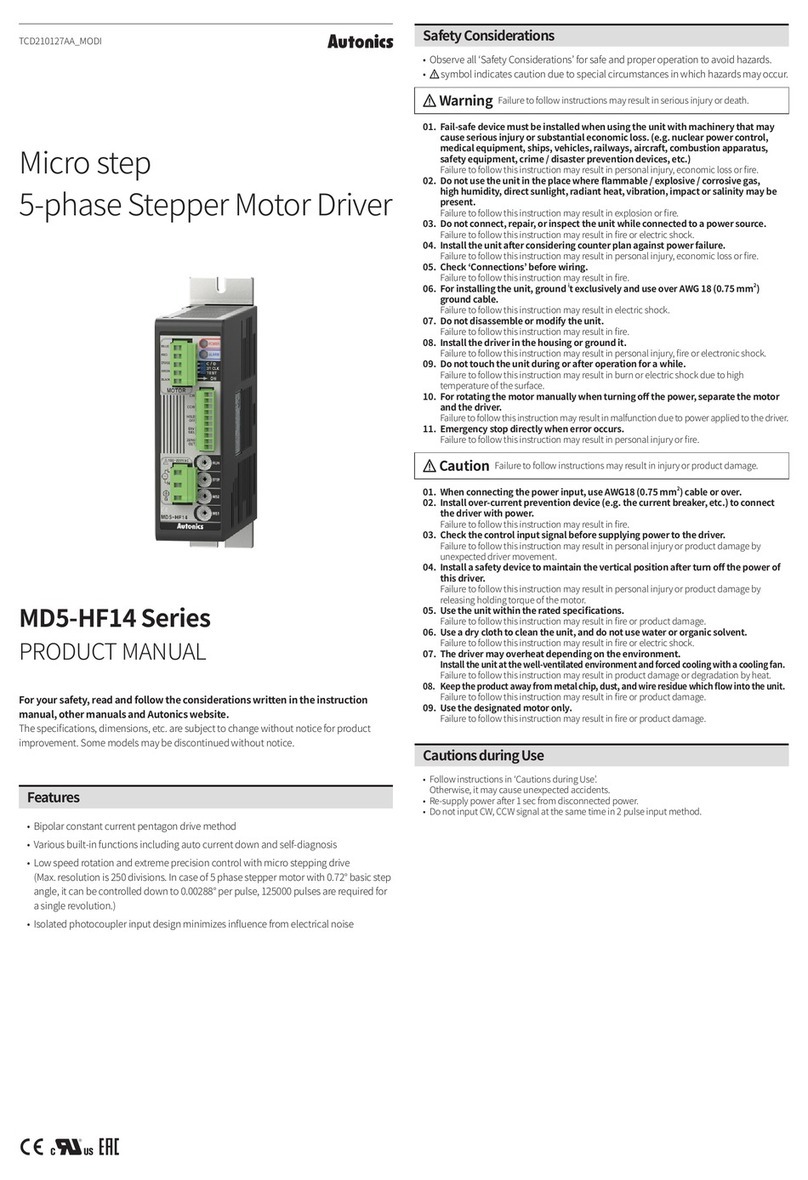

Autonics

Autonics MD5-HF14 Series product manual

Controlli

Controlli MVE2-65 Series Installation, Application, And Technical Instructions

Fri-Jado

Fri-Jado 9128135 Technical manual