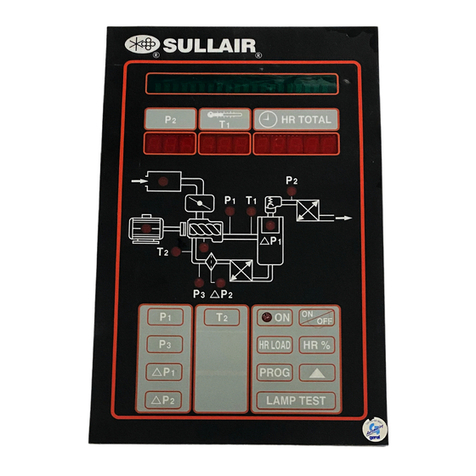

Sullair EC2000 User manual

Table of contents

Other Sullair Controllers manuals

Sullair

Sullair Supervisor II User manual

Sullair

Sullair Supervisor IE User manual

Sullair

Sullair 900 User manual

Sullair

Sullair SUPERVISOR I User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair 02250160-842 User manual

Sullair

Sullair WSPC User manual

Sullair

Sullair 02250165-411 R01 User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair ShopTek User manual

Popular Controllers manuals by other brands

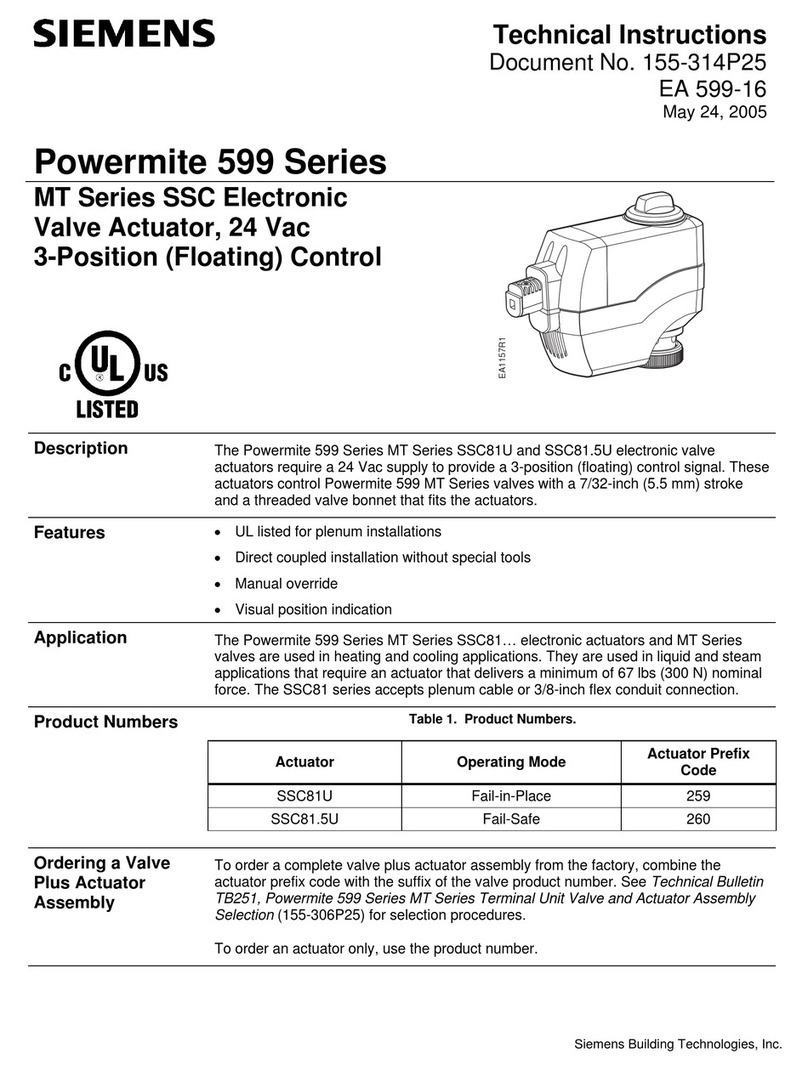

Siemens

Siemens SIRIUS 3RA142 8XC21 Sries operating instructions

Titan Controls

Titan Controls Helios 17 instruction manual

Snap One

Snap One B-960-MOIP-4K-TR-A Regulatory compliance and safety information

TAC

TAC GUITAR MANIA Usage instructions

RESEARCH CONCEPTS

RESEARCH CONCEPTS RC3050 user manual

Rockwell Automation

Rockwell Automation Allen-Bradley Logix5000 Programming manual