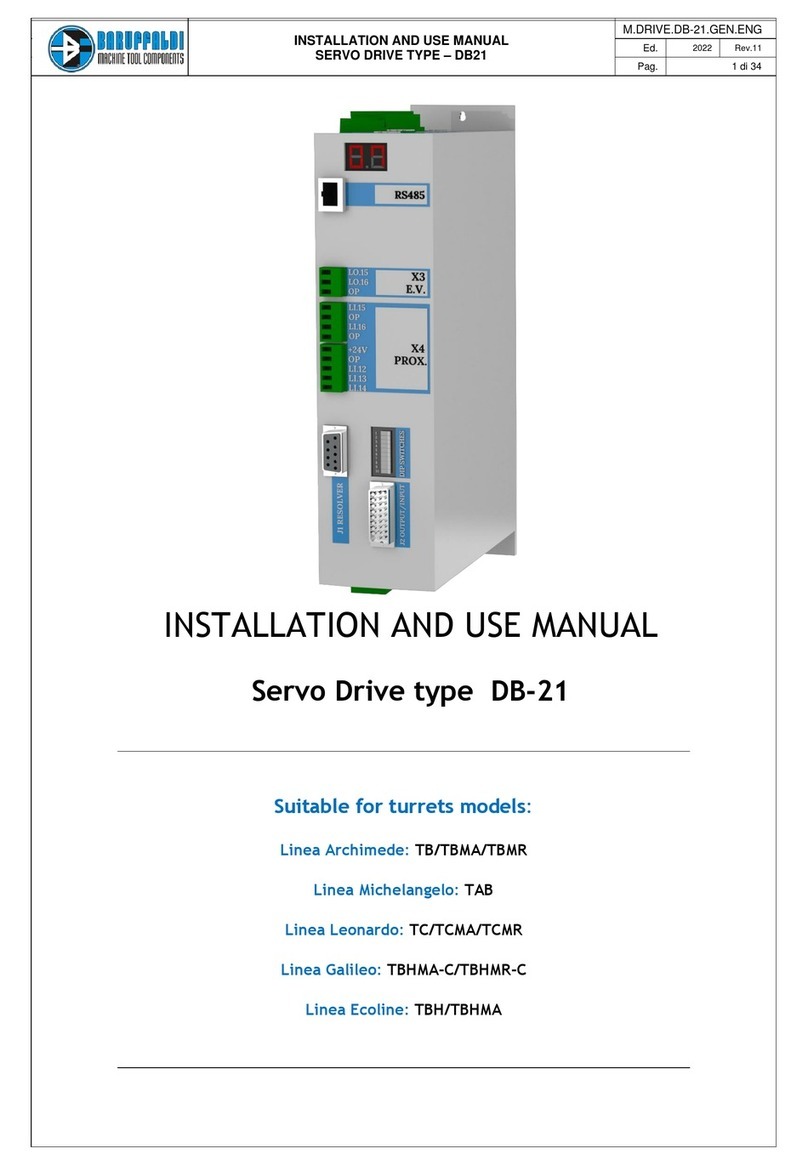

Baruffaldi DB-21 Guide

INSTALLATION AND USE MANUAL

SERVO DRIVE TYPE –DB21

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 1 di 31

INSTALLATION AND USE MANUAL

Servo Drive type DB-21

Suitable for turrets models:

Linea Archimede: TB/TBMA/TBMR

Linea Michelangelo: TAB

Linea Leonardo: TC/TCMA/TCMR

Linea Galileo: TBHMA-C/TBHMR-C

Linea Ecoline: TBH/TBHMA

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 2 di 31

1SAFETY AND INSTALLATION_____________________________________ 4

1.1 SAFETY CONSIDERATION AND INSTALLATION CONSTRAINS _________________________________ 4

1.2 EMC ADVICES ______________________________________________________________________ 4

1.2 SPECIFICATIONS ____________________________________________________________________ 5

2. ELECTRICAL CONNECTIONS ____________________________________ 6

3. DRIVE AND TURRET LAYOUT____________________________________ 7

4. TURRET CONNECTIONS _______________________________________ 8

4.1 TB/TBH SERIES (STANDARD ELECTRICAL BOARD ON THE TURRET) __________________________ 8

4.2 TB/TBH SERIES (HARTING CONNECTOR) ________________________________________________ 9

4.3 TAB SERIES (STANDARD ELECTRICAL BOARD ON THE TURRET)_____________________________ 10

5. J1 INPUT/OUTPUT __________________________________________ 11

5.1 CONSENT TO WORK ________________________________________ 11

5.2 POSITION FEEDBACK _______________________________________________________________ 11

5.3 ALARMS _________________________________________________ 11

5.4 START COMMAND __________________________________________ 11

5.5 OPERATIVE MODE__________________________________________________________________ 12

5.6 POSITION REQUIRED _______________________________________________________________ 12

6. DIPSWITCH SETTING (FOR TURRET TYPE SELECTION) ________________ 13

7. WORKING LOGIC AND POSITIONING INQUIRY_______________________ 15

8. OPERATIVE MODE___________________________________________ 16

9. DRIVE SET-UP (NEW TURRET INSTALLATION) ______________________ 17

10. DUTY CYCLE (BARUFFALDI LIVE TOOL TOOLING SYSTEM)____________ 19

11. DUTY CYCLE (BMT/DIN5480/DIN1809 LIVE TOOL TOOLING SYSTEM)____ 20

12. DRIVE ALARM _____________________________________________ 21

13. SERVICE _________________________________________________ 22

13.1 TROUBLESHOOTING_______________________________________________________________ 22

13.2 COMPATIBILITY WITH PREVUIOUS VERSIONS___________________________________________ 25

13.2.1 drive and motor timeline _________________________________________________________________ 25

13.2.2 turret serial number identification _________________________________________________________ 25

13.3 DRIVE REPLACEMENT (SET-UP AND SETTING) __________________________________________ 26

13.3 MOTOR REPLACEMENT_____________________________________________________________ 29

13.4 RESOLVER ACQUISITION ___________________________________________________________ 29

13.5 ZERO SENSOR SETTING ____________________________________________________________ 30

13.6 CABLE ADAPTER FOR OLD DRIVE INTERFACING ________________________________________ 31

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 3 di 31

DIPSWITCH N° MOTOR TYPE

6400V 50/60Hz

6 230V 50/60Hz

GENERAL WARNINGS

Before setting at work, carefully read instructions for use and follow them!

Only qualified personnel, that has carefully read instructions, is allowed to operate on tool holder

turrets.

Responsibility and warranty are excluded if:

-Instructions for use are not followed.

-The turret is not operated in a correct way.

-Maintenance is not performed correctly and regularly.

-Functional changes of any type are brought without manufacturer’s consent.

-Original spare parts are not used.

This symbol highlights critical operations:

- a wrong procedure can cause damages to the turret

- nonobservance can determine wrong settings at work

- nonobservance can impair operator’s safety

INSTALLATION WARNING

The Drive is pre-set for an input voltage of 400V.

If might be necessary to switch the input voltage to 220V before to turn ON the

drive/machine follow the instructions at the chapter 9.

ON

OFF

ON

OFF

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 4 di 31

1SAFETY AND INSTALLATION

1.1 SAFETY CONSIDERATION AND INSTALLATION CONSTRAINS

It is important to ensure that cable and connection are carried out by a qualified technician. Wrong

connections can cause damage to the device or generate dangerous situations for the user.

Dangerous voltages can be found inside the drive and on the external clamps, therefore

maximum attention should be paid during all phases of installation and/or maintenance so

that people are not placed in dangerous situations.

►After switching off the drive, the internal components and the output connectors can still be powered for

several seconds. Before doing anything, check with a Voltmeter that there are no dangerous voltages

on the external clamps.

►Between the control signals and the main power supply the insulation is guaranteed only for functional

purposes and not for user safety.

►All the logic signals, besides the power lines, must be protected against the user direct contact.

►During installation or normal operation, do not use damaged cables or spoiled ones.

►Connect to the ground all the shields and the ground cables. Avoid untidy or twisted cables.

►The converter must be installed in vertical position into the cabinet. Ventilation conditions and surrounding

atmosphere must be settled in a way that the converter cannot work without nominal temperature

range (0÷40°C).

►A 100mm clearance area must be considered under the drives and 10mm on the sides in order to

guarantee a high cooling efficiency to the fan.

►The converter heat sink can reach high temperature during normal operations. Avoid direct contacts and

remove inflammable components into the closeness of the converter.

►Before proceeding with the setup of the device it is necessary to check the ground connections, network

voltage and the correct connection (according to this manual) of the control signal connections

1.2 EMC ADVICES

It is advisable to install the power parts of the motor control unit (drive, transformer, filters and resistances) in

metallic divisions separate from those assigned to command and control devices. If the power supplies of

the power groups are the same as the control apparatus, they should be connected in the same position

(entrance point of the electronic device) in a star configuration.

External line filters are recommended (ie: Arctoronics F.LL.D3.016A.BN.R1 for 10A)

It is advisable to maintain maximum separation between the lay out of power and signal cables, using as an

example, separate canalisations (with a distance of at least 30cm one from the other) when laying cables.

Where it is necessary to intersect the lay out between signal cables and power cables, it is better that the

intersections are made with cross angles of 90.

An insulation transformer on the power line decoupling the drives from the grid is always a high efficiency

EMC barrier.

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 5 di 31

1.2 SPECIFICATIONS

PARAMETERS

Power supply

3x230V

3x400V

+10/-15% 50÷60Hz 2KW

Logic power supply 24VDC ±10%

Current 4/16Arms

Method of current

control

SPWM, chopper frequency

3÷10 KHz

Motor control method

Torque control, speed

control,

angular position control

Clamp resistance 47Ω/50W

Protection grade IP 20

LIMITS OF USE

Atmospheric temp. 0/+40°C

Storage 0°C/+60°C

Relative humidity 5-95% *

Altitude <1000m slm

VOLUME AND WEIGHT

Width 72 mm

Height 278 mm

Depth 164 mm

Weight 2 Kg

FRONT SIDE REAR SIDE

278mm

fixed screw M4

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 6 di 31

2. ELECTRICAL CONNECTIONS

X1 (INPUT)

POWER SUPPLY

Power net (L1-L2-L3)

Voltage option 1: 220Vac 3 phase +10/15%

Voltage option 2: 400Vac 3 phase +10/15%

Pmin power transformer 2KVA

4Arms / 16Arms peak Class S3

Size cable Ømin=1,5mm2

Protection devices and breakers are needed on the power line.

Delayed fuses or a thermal switch and a differential breaker are

recommended size 16A

Differential protection (Id) 300mA

RS485

J1 (OUTPUT/INPUT)

DIGITALS INPUT/OUTPUT

Out 24Vdc x 100mA

In sink 24Vdc ≤5mA

Level H (min): 20VDC (typ.7mA@24VDC,

Vin(max)=30VDC Level L (max): 12VDC

D26sub connector pin used for dialogue

between plc and drives (details page 6)

X5 (OUTPUT)

MOTOR (U-V-W-T)

3 phase shielded cable Ømin=1,5mm2

with ground

J2 (INPUT)

ANGULAR POSITION TRANSDUCER

Use cable with shielded twisted pairs and

external shield Ømin=0,22mm2 up to 25m,

more than 25m: 0,50mm2.

We recommend to use only high quality

cable in order to prevent electromagnetic

noise issues

X4 (OUTPUT)

EXTRA PORTS

Li.15 –not is use

OP –not is use

Li.15 –not is use

OP –not is use

INDUCTIVE SENSORS

+24 Proximities supply (out)

OP Common (out)

Li.12 Unlocked turret prox.switch

Li.13 Locked turret prox.switch

Li.14 Zero proximity switch

X3 (OUTPUT)

ELECTROVALVES OUTPUT

Lo15 Unlocking command

Lo16 Locking command

OP Com 0V

24Vdc I

max 3A.

We recommend the use of auxiliary

relais for supply the solenoid valves

X2 (INPUT)

LOGIC SUPPLY

Pin (+24 OP)

24Vdc ±5% I

max 3A

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 7 di 31

3. DRIVE AND TURRET LAYOUT

U

V

W

ground

shield

X5

X4

J2

X3

RS485

J1

X3

Software supervisior only for Service support

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 8 di 31

4. TURRET CONNECTIONS

4.1 TB/TBH SERIES (STANDARD ELECTRICAL BOARD ON THE TURRET)

X1

X4

X3

2

X2

Power supply

220Vac +10/15%

400Vac +10/15%

Pmin =2KVA

Auxiliary supply

24Vdc ±10%

Circuit consumption is 500mA.

Total consumption depend of

relais/electrovalve

Electrovalve

Use auxiliary relays to

pilotate the electrovalve.

Imax Output=2,5A

I/O

Digital I/O connect to PLC.

Details at page N°6.

All signals are optoisolated.

After a short circuit is

necessary to switch

off the auxiliary supply

J2

X5

U

V

W

Black U Motor phase

Blue V Motor phase

Pink W Motor phase

Green-Yellow PE Motor phase

White C Shield

Yellow 1Thermal switch

Yellow 2Thermal switch

White-Red 3 ref

White-Yellow 4 0 ref

Black 5 0 cos

Red 6 cos

Yellow 7 sin

Blue 8 0 sin

Pink 9 Shield

1

2

3

4

5

6

7

8

9

LI

.1

5

O

P

LI

.1

6

O

P

+2

4v

O

P

LI

.1

2

LI

.1

3

LI

.1

4

Brown 10 +24V

Blue 11 0V

Black 12 Turret Unlock

Black 13 Turret Lock

Black 14 Zero Sensor

Brown 10 +24V

Blue 11 0V

Black 12 Turret Unlock

Black 13 Turret Lock

Black 14 Zero Sensor

Black A Live Tool Lock

Black B Live Tool Unlock

Turret Unlock

*The use of the Live Tool Locking signal is optional and up to

the user

L1

L2

L3

+

-

T2

LIVE TOOL TURRET VERSION

TURRET (sensors 24Vdc no pnp LMax=200mA)

RESOLVER (Shielded Cable 4x(2x0.25mm²))

T1

MOTOR (Shielded Cable (4x1.5mm²))

T2

T2

Serial Port

+24v

OP

LO.15

LO.16

OP

ELECTRICAL TERMINAL BLOCK - T1

ELECTRICAL TERMINAL BLOCK –T2

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 9 di 31

4.2 TB/TBH SERIES (HARTING CONNECTOR)

X1

X4

X3

2

X2

Power supply

220Vac +10/15%

400Vac +10/15%

Pmin =2KVA

Auxiliary supply

24Vdc ±10%

Circuit consumption is 500mA.

Total consumption depend of

relais/electrovalve

Electrovalve

Use auxiliary relays to

pilotate the electrovalve.

Imax Output=2,5A

I/O

Digital I/O connect to PLC.

Details at page N°6.

All signals are optoisolated.

After a short circuit is

necessary to switch

off the auxiliary supply

J2

X5

U

V

W

Black U Motor phase

Blue V Motor phase

Pink W Motor phase

Green-Yellow PE Motor phase

White C Shield

Yellow 1 Thermal switch

Yellow 2 Thermal switch

White-Red 3 ref

White-Yellow 4 0 ref

Black 5 0 cos

Red 6 cos

Yellow 7 sin

Blue 8 0 sin

Pink 9 Shield

1

2

3

4

5

6

7

8

9

LI.15

OP

LI.16

OP

+24v

OP

LI.12

LI.13

LI.14

Brown 10 +24V

Blue 11 0V

Black 12 Turret Unlock

Black 13 Turret Lock

Black 14 Zero Sensor

L1

L2

L3

+

-

MOTOR (Shielded Cable (4x1.5mm²))

Serial Port

+24v

OP

LO.15

LO.16

OP

THERMAL SWITCH

TURRET (sensors 24Vdc no pnp LMax=200mA)

Yellow 1Thermal switch

Yellow 2Thermal switch

RESOLVER (Shielded Cable 4x(2x0.25mm²))

T1 THERMAL SWITCH

Brown 10 +24V

Blue 11 0V

10

11

1

2

3

4

5

6

7

8

9

21

22

23

18

19

12

13

14

HARTING CONNECTOR (FEMALE) - T1

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 10 di 31

4.3 TAB SERIES (STANDARD ELECTRICAL BOARD ON THE TURRET)

X1

X4

X3

2

X2

Power supply

220Vac +10/15%

400Vac +10/15%

Pmin =2KVA

Auxiliary supply

24Vdc ±10%

Circuit consumption is 500mA.

Total consumption depend of

relais/electrovalve

Electrovalve

Use auxiliary relays to

pilotate the electrovalve.

Imax Output=2,5A

I/O

Digital I/O connect to PLC.

Details at page N°6.

All signals are optoisolated.

After a short circuit is

necessary to switch

off the auxiliary supply

J2

X5

U

V

W

Black U Motor phase

Blue V Motor phase

Pink W Motor phase

Green-Yellow PE Motor phase

White C Shield

Yellow 1 Thermal switch

Yellow 2 Thermal switch

White-Red 3 ref

White-Yellow 4 0 ref

Black 5 0 cos

Red 6 cos

Yellow 7 sin

Blue 8 0 sin

Pink 9 Shield

1

2

3

4

5

6

7

8

9

LI.15

OP

LI.16

OP

+24v

OP

LI.12

LI.13

LI.14

Brown 10 +24V

Blue 11 0V

Black 12 Turret Unlock

Black 13 Turret Lock

Black 14 Zero Sensor

L1

L2

L3

+

-

T2

T1

MOTOR (Shielded Cable (4x1.5mm²))

T2

Serial Port

+24v

OP

LO.15

LO.16

OP

ELECTRICAL TERMINAL BLOCK - T1

ELECTRICAL TERMINAL BLOCK –T2

T1 THERMAL SWITCH

TURRET (sensors 24Vdc no pnp LMax=200mA)

Yellow 1Thermal switch

Yellow 2Thermal switch

RESOLVER (Shielded Cable 4x(2x0.25mm²))

T1 THERMAL SWITCH

Brown 10 +24V

Blue 11 0V

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 11 di 31

5. J1 INPUT/OUTPUT

5.1 CONSENT TO WORK

It is possible to start to work only when both signals are active:

- ST INDEX (J1pin.8) = turret in position

- ST LOCK (J1pin.17) = turret closed

In addition to these two signals is possible using the binary outputs of the POSITION FEEDBACK to make sure

that the turret is in the position required.

Outputs are reset:

- in case of alarm

- during rotation of the turret

- drive reset (mode = 0)

5.2 POSITION FEEDBACK

n° 5 binary outputs communicate the position of the turret. The position can be seen on display in the front of

the drive.

The outputs are only active with turret indexed ie has already been done a positioning or zero search (even

hidden).

The outputs are active when:

- the turret is closed in the position

- no alarms are present

- the drive is not in reset mode (mode bit off)

The position feedback is in binary code (see table at left) without the parity bit

5.3 ALARMS

N°5 binary outputs communicate the presence of an active alarm. In order to facilitate the

diagnosis, the active alarm is displayed on the front display.

The activation determines:

- rotation stop

- deactivation of outputs St index, St lock and position feedback.

To perform a new positioning is necessary to reset the alarm by setting the operating mode zero.

5.4 START COMMAND

Should be minimum 100ms.

It 'important that the command is given with a delay of at least 50ms after the setting of the required position.

INPUT

+24VDC –MAX 100Ma

PIN DESCRIPTION

3 Mode bit 1

12 Mode bit 2

20 Mode bit 3

13 Position bit 1

21 Position bit 2

5 Position bit 3

14 Position bit 4

22 Position bit 5

23 Parity bit

25 Start

OUTPUT

+24VDC –MAX 100Ma

PIN DESCRIPTION

1 Feedback bit 1

10 Feedback bit 2

2 Feedback bit 3

11 Feedback bit 4

19 Feedback bit 5

6 Alarm bit 1

15 Alarm bit 2

7 Alarm bit 3

16 Alarm bit 4

24 Alarm bit 5

8 Turret in position

17 Turret Locked

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 12 di 31

It is recommended to manage the parity bit

using the Boolean function EXOR (available

in all PLCs) applied to the position bit.

5.5 OPERATIVE MODE

5.6 POSITION REQUIRED

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 13 di 31

6. DIPSWITCH SETTING (FOR TURRET TYPE SELECTION)

TURRET SELECTION

The setting of the turret type, the number of positions and dynamic profile must be performed before

starting the drive (24Vdc).

CUSTOM PROFILE

For nonstandard applications can be set via software a specific profile setting manually the

transmission

ratio (T.R.), number of stations and dynamic profile, in this case a red label will be applies on the

drive.

In order to replace the drive will be necessary reset the profile via p.c. on the new one.

The custom profile is added to the standard profiles.

DYNAMIC PROFILE

It is possible to optimize the dynamic response of the drive according to the real load condition and

unbalance applied to the turret.

The dynamic profile acts on the values of rounding ramp, target speed, acceleration, deceleration and

compensation of inertia.

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 14 di 31

RESOLVER ACQUISITION

With this operation will be stored in the drive the value of the resolver when the turret is in position 1,

this value will be used to verify that the required station is reached by the turret at the end zero

research (also hidden zero research).

This procedure is performed in the factory during the test drive turret and need to be repeated only in

the case that the drive or the motor are substituted or when the motor is removed from the turret.

SEQUENCE

-Make sure the turret is closed in position 1

-Switch on the drive

-Set to ON DIP No. 10. The display will start a count from 0 to 5 "

-At the end of the count back to OFF the DIP No.10

-The SA message on the display means that the data has been saved

-Switch off the drive or make a reset then call a station.

FAST PROFILE

Preferable when the inertia

is low. It allows to obtain

positioning times lower.

MEDIUM PROFILE

Similar to the universal but

with lower ramp rounding.

LOW PROFILE

Limited speed

Can be used during machine the setup.

UNIVERSAL PROFILE

Very soft acceleration

and deceleration

ramps. Ideal for any

type of inertia.

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 15 di 31

7. WORKING LOGIC AND POSITIONING INQUIRY

During the start it is important that the operative mode 1 (see chapter 5) is selected

so any possible alarm will be displayed.

TURN ON THE CNC

Supply the Drive

Display Shows

SET UP DRIVE

(4”)

EV Locking Comand

DRIVE READY

Setup ZERO REASERACH

Positioning Frame

Setup Positioning Inquiry

Positioning Frame

Start to work

Work Complete

The display will alternate the turret set up and the voltage set up

5 -CODE FOR K5 TURRETS + 0 -CODE FOR LAFERT 10KHz MOTOR

3 -CODE FOR K3 TURRETS 0 -CODE FOR BD21 10KHz MOTOR

2 -CODE FOR K2 TURRETS 1 -CODE FOR LAFERT 5KHz MOTOR

2 -CODE FOR MAGNETIC MOTOR

40 -CODE FOR 400V INPUT VOLTAGE SETUP

23 - CODE FOR 230V INPUT VOLTAGE SETUP

In the case of WRONG SET UP could be activate one of the following alarms:

- Voltage not set-up or incorrect (EE)

- Resolver failure 8.0 at startup

- Locking Error (5.x) after position inquiry

- Position Error (6.x) after position inquiry

ZERO SEARCH*

Zero search (also hidden) has to be performed

after switch on the drive or a reset.

ZERO SEARCH

-Operative mode 1

-Position required = 0

-Wait ≥50ms

- START (≥100ms)

The turret will rotate in the CW direction at

low speed and will stop in the mechanical

station 1.

HIDDEN ZERO SEARCH

-Operative mode 1

-Position required ≥ 2

-Wait ≥50ms

-START (≥100ms)

The turret will rotate in the CW direction at

low speed, pass over through the mechanical

station 1 without stops and goes straight to the

position required.

Operative mode 1

Position required 0

Delay start ≥50ms

START (duration)

≥100ms

ST INDEX ON

ST LOCK ON

Output FEEDBACK 1

EV unlocking ON

Px switch turr.unlock ON

Motor rotation Clockwise

Arrival in the position OK

EV locking ON

Px switch turr.lock ON

Operative mode 1

Position required >0(i.e.7)

Delay start ≥50ms

START (duration)

≥100ms

TOOL CHANGE COMPLETED

DISPLAY Turret in Position

Motor status disabled

ST INDEX ON

ST LOCK

ON

FEEDBACK POSITION 1

TOOL CHANGE NOT COMPLETED

DISPLAY Alarm

Motor status disabled

ST INDEX OFF

ST LOCK

OFF

FEEDBACK POSITION 0

DISPLAY

DISPLAY

VOLTAGE SET UP

TURRET SET UP

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 16 di 31

8. OPERATIVE MODE

By setting the bit on the J2 connector you can select one of the following operatives mode:

MODE 0 - RESET/ EMERGENCY [Li.1, Li.2, Li.3 = Off]

RESET duration ≥ 300ms

Setting Off all bits the drive is disabled, in this condition

the engine and outputs st. index, st. lock and position feedback are reset.

This mode is necessary to reset an alarm.

After a reset to recall a position you must repeat the

zero search or hidden zero search.

MODE 1- AUTOMATIC POSITIONING IN THE SHORTEST WAY AND ZERO SEARCH [Li.1=On Li.2,Li.3 = Off]

Use this modality by default.

When the mode 1 is selected the turret will reach the required position by choosing the shortest way.

The mode 1 is necessary also to perform a zero search or hidden zero search.

It is recommended to set this mode already at switch on otherwise an alarm is not displayed.

MODE 2 - AUTOMATIC POSITIONING WITH FORCED CLOCKWISE ROTATION [Li.2=On Li.1,Li.3 = Off]

MODE 3 - AUTOMATIC POSITIONING WITH FORCED COUNTERCLOCKWISE ROTATION[Li.1,Li.2=On Li.3 = Off]

The turret will reach the required position respecting the direction of rotation chosen

even though this means a greater distance.

MODE4 - NEXT/PREVIOUS TOOL REQUEST (JOG MODE) [Li.3=On Li.1,Li.2 = Off]

With this modality the user is able to change the turret position without a program. This function is useful for

manual operations (pre-setting, tool replacement).

For each START command the turret will perform a jump of 1 station in the direction of rotation set:

Mod.4 + 1 position clockwise rotation

Mod.4 + 2 position counter-clockwise rotation

MODE 5 - SERVICE MODE [Li.1,Li.3=On Li.2 = Off]

Use this function for understand if the electrovalve system it's ok or evaluate the turret noise.

These operations are only possible if st index, st lock and feedback are disabled.

For each START command the turret will do one of the following:

Mod.5 + Position 1 - fast continuous rotation clockwise

Mod.5 + Position 2 - fast continuous rotation counter-clockwise

Mod.5 + Position 5 - slow continuous rotation clockwise

Mod.5 + Position 6 - slow continuous rotation counter-clockwise

Mod.5 + Position 4 - EV locking turret

Mod.5 + Position 8 - EV unlocking turret

Set RESET (mod.bit = 0) to stop continuous rotation.

The parity bit should be managed according to the required position.

MODE 6 –AUTOTEST [Li.2,Li.3=On Li.1 = Off]

Use the autotest to skip the plc program and check if the turret works correctly.

Set the mode to 6, give the START command , wait 5" after

the turret will search for zero and at intervals of 5" recall

some positions.

Set RESET (mod.bit = 0) to break the cycle.

MODE7 - RESOLVER ACQUISITION [Li.1,Li.2,Li.3=On]

This is an alternative procedure to the one made with dipswitch pin n°10, with the difference of the unlocking

turret.

Set the turret locked in the position 1.

Set mode 7

Give the 1st START - EV unlocking command will be executed

Give the 2nd START - EV locking command will be executed.

The operative mode n°2-3-

4 are enabled only after a

positioning in the operating

mode 1

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 17 di 31

9. DRIVE SET-UP (NEW TURRET INSTALLATION)

CAREFULLY CHECK THE SERVO DRIVE INPUT VOLTAGE SETTING.

A WRONG SETTING OF THE INPUT VOLTAGE WOULD DAMAGE IRREVERSIBLY THE UNIT.

THE DRIVE ARRIVE WITH THE TURRET PRE-SET, PERFORM THE OPERATION SEQUENCE 2a AND

2b ONLY IN CASE OF WRONG PRESELECTION OF THE TURRET SIZE AND TYPE AND EVENTUALLY

CONTACT BARUFFALDI.

DIPSWITCH N° VOLTAGE RANGE

6400V 50/60Hz

6 230V 50/60Hz

Sequence of operations N°1

(VOLTAGE SETTING)

1. Drive OFF (24Vdc Off)

2. Set OFF dipswitch n°6 if the input voltage

is 400V, set ON dipswitch n°6 if input voltage

is 230V.

3. Drive ON

ON

OFF

ON

OFF

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 18 di 31

TURRET

MODEL 1 2 3 TB-TBH

N° pos

4 5 6 Profile 7 8 9 10

TB-TBH 120/160 - - - 8 - -

Voltage Selection

Univ. - -

Drive Set-up

Acquisition

TB-TBH 200/250 - - 12 - Fast -

TB 320 - - 16 - Medium -

TB 400 - 24 Slow

TB 100 - -

TAB

N° pos

4 5

TAB 210/265 4

(if set K3)

- -

TAB 340/440 8

(if set K5)

- -

6

(if set K3)

-

Custom 12

(if set K5)

-

24

(if set K5)

Sequence of operations N°2b*

1. Drive OFF (24Vdc Off)

2. Turret Locked on the first position

4. Select the turret voltage (see operations sequence 1.) , type

and number of positions as the table below

5. Turn ON the drive (auxiliary supply 24V dc)

6. Set to on the dipswitch n°10 and after 5” set them off

7. Make a Zero reference

8. Turret is ready to work

ON

OFF

*The drive arrives pre-set for the turret. Perform this procedure only

in case of any error, and contacting Baruffaldi first

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 19 di 31

10.DUTY CYCLE (BARUFFALDI LIVE TOOL TOOLING SYSTEM)

(A) Only motorized turrets

(B) Keep the live tool engine at

100÷150rpm during the closing of

the turret

(2) Hidden Zero search: with turret

not indexed (for ie after start up or

a reset) you can directly call a

station, the turret will rotate in the

CW direction at low speed, pass

over through the mechanical

station 1 without stops and goes

straight to the position required.

(3) Engine stays in position control

ΔT Minimum time before the new

position request

Tb120/160 ΔT≥2"

Tb200/250 ΔT≥4"

Tab 210/265

Tb320/400 ΔT≥5

Tab 340/440

(1) Engagement of the proximity live tool switch engaged

The use of the signal of the live tool engaged is optional and at the discretion of the manufacturer of the CNC.

If you wish to handle the signal of live tool engaged, keep in mind that the live tool may not be engaged even if the

turret is closed due to the fact that the teeth of the motor and live tool are attested. This condition is provided,

the effective coupling andtherefore also the signal from the proximity switch will arrive as soon as the tool will lean

to the workpiece

M.DRIVE.DB-21.GEN.ENG

Ed. 2021 Rev.04

Pag. 20 di 31

11.DUTY CYCLE (BMT/DIN5480/DIN1809 LIVE TOOL TOOLING SYSTEM)

(A) Only motorized turrets

(B) Keep the motor in the offset

position

(1) Px switch live tool engaged:

management borne by the

manufacturer of CNC.

(2) Hidden Zero search: with turret

not indexed (for ie after start up

or a reset) you can directly call a

station, the turret will rotate in the

CW direction at low speed, pass

over through the mechanical

station 1 without stops and goes

straight to the position required.

ΔT Minimum time before the new

position request

Tb120/160 ΔT≥2"

Tb200/250 ΔT≥4"

Tab 210/265

Tb320/400 ΔT≥5

Tab 340/440

(2) Management of the proximity live tool switch engaged

The use of the signal of the live tool engaged is optional and at the discretion of the manufacturer of the CNC.

If you wish to handle the signal of live tool engaged, keep in mind that the live tool may not be engaged even if

the turret is closed due to the fact that the teeth of the motor and live tool are attested. This condition is

provided, the effective coupling andtherefore also the signal from the proximity switch will arrive as soon as the

tool will lean to the workpiece.

Other manuals for DB-21

1

Table of contents

Other Baruffaldi Servo Drive manuals

Popular Servo Drive manuals by other brands

Emerson

Emerson Control Techniques Epsilon Eb-202 installation manual

Control Techniques

Control Techniques SM-Encoder Plus user guide

Mitsubishi

Mitsubishi MR-JE-10A instruction manual

LinMot

LinMot E1250-IP-UC user manual

SYNAPTICON

SYNAPTICON SOMANET Circulo Series installation guide

Vescent Photonics

Vescent Photonics D2-125 manual

Parker

Parker PSD1-SW1200 installation instructions

Allen-Bradley

Allen-Bradley Kinetix 5700 user manual

Sumitomo

Sumitomo Cyclo BBB4 quick start guide

National Instruments

National Instruments NI 9505 Operating instructions and specifications

Moog

Moog MSD Servo Drive Device Help

Danfoss

Danfoss VLT AutomationDrive FC 360 quick guide