Emerson Control Techniques Epsilon Eb-202 User manual

Other Emerson Servo Drive manuals

Emerson

Emerson LX Series User manual

Emerson

Emerson Unidrive M702 User manual

Emerson

Emerson Epsilon Eb Series User manual

Emerson

Emerson PACMotion IC830DP00307 User manual

Emerson

Emerson Mini Maestro DCD60x3/6 User manual

Emerson

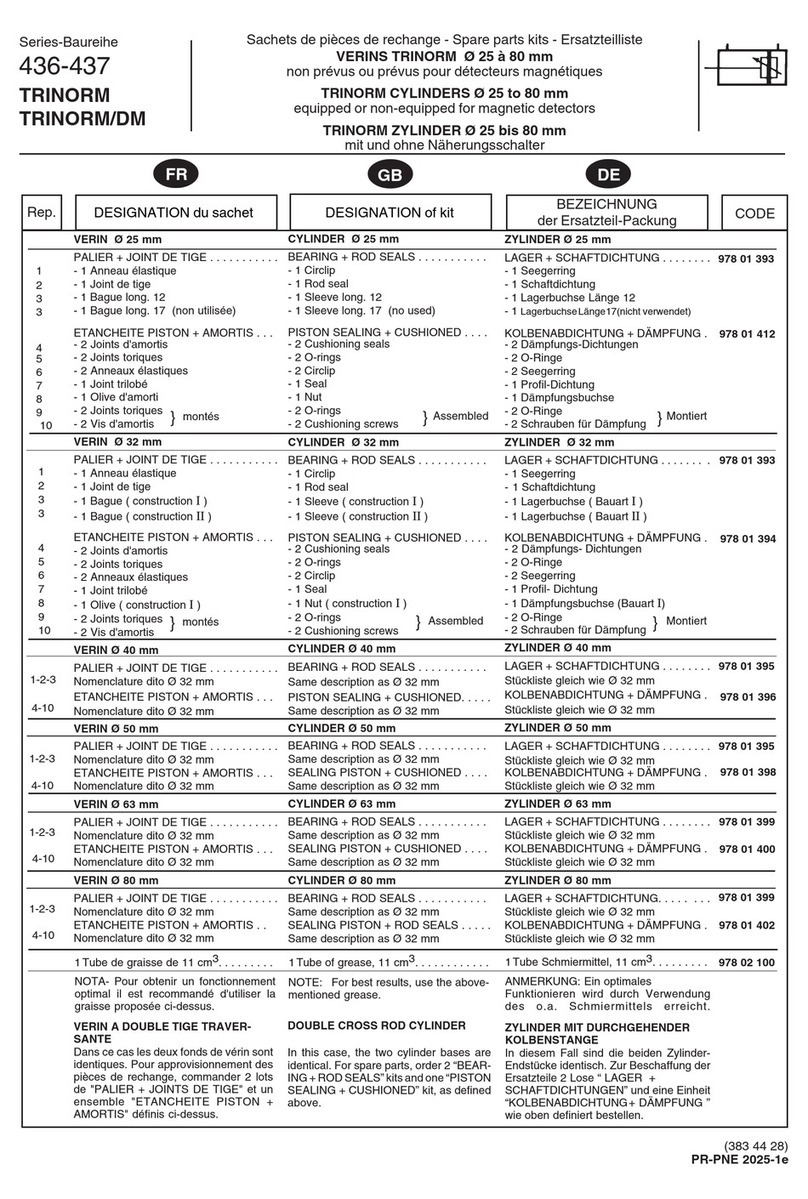

Emerson TRINORM 436 Series User manual

Emerson

Emerson PACMotion IC830DP00306 User manual

Emerson

Emerson Epsilon EP Drive 400518-01 User manual

Emerson

Emerson SP1201 User manual

Popular Servo Drive manuals by other brands

Lenze

Lenze m850 Mounting and switch-on instructions

Baumuller

Baumuller b maXX 3000 Instruction handbook

Baumuller

Baumuller b maXX 5000 Instruction handbook

Baumuller

Baumuller b maXX 5500 Instruction handbook

Danfoss

Danfoss VLT HVAC Drive FC 102 operating instructions

Omron

Omron CK5M-CPU 1 Series Startup guide