BASF EXACTUS User manual

EXACTUS

®

OPTICAL THERMOMETER

Manufactured By BASF Corp

USER’S MANUAL

Sin le or Multi-Channel System

Version 5.04

BASF Corp

Temperature Sensing Group

46820 Fremont Blvd.

Fremont, CA 94 38-6 40

Phone: ( 10) 490-21 0

Fax: ( 10) 2 2-1871

http://www.catalysts.basf.com/Main/temperature_sensing

Additional support available:

BASF Temperature Sensing, Portland, Oregon

4011 SE International Way, Suite 604

Portland, OR 97222

Phone: ( 03) 794-4073

Fax: ( 03) 794- 91

Copyright© 2001 BASF Catalysts, LLC. All rights reserved.

Exactus is a registered trademark for which BASF Catalysts LLC has rights. The data contained in this publication are based on our

current knowledge and experience. In view of the many factors that may affect processing and application of our product, these data

do not relieve processors from carrying out their own investigations and tests; neither do these data imply any guarantee of certain

properties, nor the suitability of the product for a specific purpose. Any descriptions, drawings, photographs, data, proportions,

weights, etc. given herein may change without prior information and do not constitute the agreed contractual quality of the product. It

is the responsibility of the recipient of our products to ensure that any proprietary rights and existing laws and legislation are observed

(08/2007). BF-8807

Although all statements and information in this publication are believed to be accurate and reliable, they are presented gratis and for

guidance only, and risks and liability for results obtained by use of the products or application of the suggestions described are

assumed by the user. NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING PRODUCTS DESCRIBED

OR DESIGNS, DATA OR INFORMATION SET FORTH. Statements or suggestions concerning possible use of the products are

made without representation or warranty that any such use is free of patent infringement and are not recommendations to infringe any

patent. The user should not assume that toxicity data and safety measures are indicated or that other measures may not be required.

©2007 BASF Catalysts LLC.

This page blank.

Table of Contents

1.

Introduction

......................................................................................................... 1-3

Company Profile ..............................................................................................................1

Theory of Operation.........................................................................................................1

Overview of the BASF EXACTUS

®

Optical Thermometer ............................................2

Advantages of the BASF EXACTUS

®

Optical Thermometer ........................................3

2

.

System Description

........................................................................................... 4-6

Collection Optics..............................................................................................................

Probe Head.......................................................................................................................6

Interface Module, Analog and Digital Output .................................................................6

Power Supply:..................................................................................................................6

3

.

System Startup

.......................................................................................................7

Getting Started .................................................................................................................7

Mounting the probe..........................................................................................................7

4.

Soft are Interface

.......................................................................................... 8-18

Software Installation ........................................................................................................8

Starting up TemperaSure

®

................................................................................................8

Installation Troubleshooting ............................................................................................8

Using TemperaSure

®

Software Functions.................................................................. 9-12

Probe and TemperaSure

®

Software Setup............................................................... 12-16

Advanced Probe Features......................................................................................... 16-18

All Probes.......................................................................................................................18

Analog Output................................................................................................................18

Graph Setup....................................................................................................................20

Tips and Shortcuts.................................................................................................... 20-21

5.

Warnings

...............................................................................................................22

6.

Troubleshooting

..................................................................................................23

7.

Glossary of Terms

........................................................................................ 24-31

8.

Specifications

.................................................................................................. 31-32

9.

Appendices

...................................................................................................... 32-42

Appendix 1: Multi-Channel Interface Box Installation Guide................................. 36-4

Appendix 2: Probe Transmit Data Protocol ............................................................. 46- 7

Appendix 3: Analog Output Guide .......................................................................... 8-63

Table of Fi ures

Figure 1 Probe Head Conceptual Diagram .................................................................2

Figure 2A Single Channel System ................................................................................4

Figure 2B Multi Channel System ................................................................................5

Figure 3 TemperaSure

®

Graphical User Interface (Main Display Screen)..............9

Figure 6 Graph Setup Windo s .................................................................................12

Figure 7 Probe Setup Windo ....................................................................................13

Figure 10 Auto Calibration Feature............................................................................16

Figure 11 Advanced Probe Functions Tab .................................................................17

Figure 12 Menu for All Probes ...................................................................................19

Figure 13 Analog Output Setup..................................................................................19

Figure 14 Dra ing of Probe ith Lens Collection Optics (Pyrometer)..................33

Figure 15 Dra ing of Probe ith Lightpipe..............................................................34

Figure 16 Lightpipe Detail ..........................................................................................35

Appendices Figures

Figure A-15 Analog Output/ Digital Interface Module Connections ......................37

Figure A-16 External Po er Jumper .........................................................................38

Figure A-17 External Po er Wiring .........................................................................39

Figure A-18 Analog Output Scaling ..........................................................................40

Figure A-19 Analog Output Calibration...................................................................42

-1-

1 Introduction

BASF Temperature Sensing offers the EXACTUS

®

line of optical thermometers. EXACTUS

®

instruments provide the most advanced temperature measurement system available today. This

system is designed to provide you with very precise and stable temperature readings. With

numerous features and options, it can be customized for many different applications. Please

contact BASF Temperature Sensing if you have any questions regarding your temperature

measurement needs or the use of this instrument.

BASF Temperature Sensing has technical support staff with extensive experience in all aspects

of temperature measurement and temperature control, and will be happy to provide assistance in

solving your temperature measurement challenges.

1.1 Company Profile

BASF is the worlds leading chemical company with over 100 production sites worldwide. Some

facts about BASF:

•

Over 90,000 employees

•

Business contacts in 170 countries

•

8000 product manufactured

•

Sales of over 6 Billion Euro in 2007

EXACTUS

®

optical thermometers are developed, manufactured and supported at BASF facilities

in Portland Oregon, Fremont California, and Rome Italy.

1.2 Theory of Operation

The following is a quick introduction to the field of Optical Thermometry, also known as

Pyrometry or Radiation Thermometry. An optical thermometer is a device that measures light

and is calibrated to indicate temperature. An optical thermometer detects the radiant flux from a

hot object and utilizes an algorithm to calculate the surface temperature of the object. The

algorithm used is based on the Planck Blackbody Radiation Equation. In 1860, Gustav

Kirchhoff conceived of the ideal emitter known as a Blackbody, and then in 1900 Maxwell

Planck mathematically described how a blackbody emits light as a function of its own

temperature and wavelength.

Please see the recommended references at the end of the Glossary for further reading on

pyrometry and wafer temperature measurement.

-2-

1.3 Overview of the EXACTUS

®

Optical Thermometer

The main components of the EXACTUS

®

optical thermometers are:

1. Collection Optics: The collection optics acquire light emitted from a hot object and directs it

to the filter and photo detector. Many standard and custom options for collection optics,

including lens systems (small spot size), lightpipes, and flexible fiber optic cables.

2. Wavelength Selective Filters: These select which wavelengths of light are measured. Care

must be taken that these filters are kept clean and dry.

3. Photo Detector: Photo detectors convert light (photons) into an electrical signal. BASF uses

only high efficiency (D*) solid-state photo detectors of either silicon, InGaAs, or a new

patented 900nm narrow band detector.

4. Amplifier: The amplifier takes the small electrical signal from the photo detector and

amplifies it before sending it to the signal processor. The amplifier circuit is extremely

sensitive and allows signals as small as 10

-1

amps to be detected and measured.

. Signal Processor: The signal processor converts the amplified signal into a temperature

reading. This processing is a combination of electrical conditioning, including Analog-to-

Digital conversion, and software algorithms, including the Planck equation.

6. Output: Several types of data output are available from the instrument:

• Direct digital data to a host computer or process controller.

• Viewed using BASF’s TemperaSure

®

data acquisition and graphing software.

• Analog output via 4-20mA or 0 – 10 VDC analog output.

• Specialized processed measurement modes such as peak, valley, or process standard

deviation.

Figure 1: Probe Head Conceptual Diagram

-3-

1.4 Advanta es of the BASF Optical Thermometer

The EXACTUS

®

line of optical thermometers provides many advantages for optically based

temperature measurement. These include:

1.

The ability to measure small signals and lo er temperatures at short avelengths

Careful design and use of an advanced amplifier circuit enables measurement of signals as

small as 10

-1

amps from the photo detector. The ability to measure smaller signals enables

the measurement of lower temperatures while using short wavelengths. Short wavelengths

significantly reduce emissivity errors and are ideal for many applications such as the

measurement of silicon wafers in the semiconductor industry. (See Resolution in Section 7.)

2. High resolution, ith measurements to 0.01°C

Precise amplification also means less electrical noise, and therefore lowers noise in the

temperature measurements. This enables measurement and control of smaller changes in the

process temperatures, leading to more stable process control and higher yields.

3. High speed, digital readings at up to 1,000 readings per second

EXACTUS

®

instruments can provide temperature readings ranging from one reading per

minute all the way up to 1,000 readings per second. In addition, the instrument performs all

the A/D conversions internally, so each instrument provides a digital signal output. BASF

also offers an analog output module for applications where a proportional to temperature

current or voltage output is desired.

4. The ability to read a ide range of temperatures - from 25°

°°

°C to 4,000°

°°

°C

The electronics design also allows a wider range of temperatures to be measured. Typically,

hot objects from about room temperature (2 °C) to 4,000°C can be measured. Contact your

sales technician for more specific details.

5. Lo -drift electronics

Special care has been taken in the selection and design of components to minimize drift in

the electronics. This has resulted in electronics drift of only 0.10ºC or less per year.

6. A highly compact design hich provides flexibility in placement and eliminates the

need for fiber-optic cables

The small (1” diameter x 4. ” length / 2 .4mm x 11 mm) package with world-class

performance allows the EXACTUS

®

instrument to be placed close enough to hot objects to

eliminate the need for long flexible fiber-optic elements required by other systems. This is

critical since about 80% of the light (and therefore about 80% of the signal) can be lost when

fiber-optic cables are used to transmit light to the photo detector. In applications where fiber

optic cables are required, BASF’s sensitive electronics still provide a significant advantage

and we offer a full line of flexible quartz fiber-optic cables for those situations where they are

needed.

-4-

2 System Description

A single channel EXACTUS

®

system is composed of four parts:

• Collection optics: either a lightpipe or lens assembly

• Probe head: a stainless steel tube (0.998" diameter × 4. " long / 2 .4mm × 114.3mm)

• Interface module: for conditioning power and communicating with a PC.

Single Channel: (4.6" × 2.8" × 1" / 118mm × 72mm × 2 mm)

Multi-Channel (10 Channel): (17.62 ” x 12. ” × 2” / 447.7mm × 317. mm × 0.8mm)

Optional analog output, 0 to 10 volts or 0 to 20ma (4 to 20ma) analog output (same size as

Single Channel)

• Po er supply: 12 volt (4" × 2" × 1.4" / 101.6mm × 0.8mm × 3 .6mm)

Figure 2A: Single Channel System

-5-

A multi-channel EXACTUS

®

system:

Figure 2B: Multi Channel System provides Ethernet communication to a PC along

with up to eight analog outputs and two latching relays.

2.1 Collection Optics

There are two basic types of collection optics: lightpipes and lenses. The advantage of the

lightpipe is its small diameter, which only requires a small access hole into the process being

measured, and its ability to collect light from a wide range of angles, which can help decrease

emissivity or roughness errors. Lens systems allow the user to view a small collection spot

on a hot object from greater distances and they can be used to look through a window or view

port when direct access to the hot object is not available. Lightpipes are more efficient at

collecting light than lens systems, therefore they are better suited for low temperature

measurements. BASF manufactures custom collection optics for specific user needs and

measurement applications. Lightpipes and lenses can be coupled directly to the measurement

electronics or coupled via fiber optic transmission cables.

-6-

2.2 Probe Head

The probe head comes with either a lightpipe or a lens assembly. The wavelength of the detector

is chosen based on the temperature and nature of the application, and is defined by the

combination of a bandpass filter and photo detector. BASF offers three photo detector options:

Si, InGaAs and a proprietary, patented detector specifically designed for looking at silicon

wafers. The output is a high-speed digital temperature measurement with up to 1,000 readings

per second. The probe head can be placed up to 1 meters from the interface module.

See Figures 14 - 16 for detailed probe and lightpipe drawings.

2.3 Di ital and Analo Interface Modules

Sin le Channel System

The Digital Interface Module allows the probe head to be connected to any PC. This box also

isolates the probe head from any electrical noise, and supplies a “clean” 6 VDC to the probe.

There are three connections on the single channel box: on one side of the box is an RJ4

connector for the probe cable and a female DB9 connector for the host computer. On the other

side of the box is the connection for power from the power supply. The interface box has a green

LED that indicates when power is being supplied.

The probe can communicate with a host computer using either RS-232 or RS-422 serial

communication. If it is configured for RS-232 than the interface box should be placed within 2

meters of the PC or digital data logger.

BASF also offers an Analog Output Option, which can be configured to either a voltage or

current output. The value of the analog output can be scaled as needed using the TemperaSure

software from 0 to 10 volts or 0 to 20 mA to any temperature range.

See Figure 9 and Appendix 3 for analog output details.

Multi-Channel System

The multi-channel interface box (Mux) allows one or many probes to be connected to a PC. This

box, like the single channel system, isolates the probes from electrical noise and supplies power

to the probes. The probes plug into the interface box with RJ4 connectors. The interface box

connects to the PC with an Ethernet cable.

2.4 Power Supply

A single channel system is powered with a 12VDC Power Supply Module through the Digital

Interface Module as shown in Figure 2A; the Digital Interface Module may be powered by any

DC voltage between 10 and 12 volts. The multi-channel system is powered via 24VDC.

-7-

3 System Startup

EXACTUS

®

optical thermometers have been designed with ease-of-use in mind, and are very

simple to operate. The recommended start up procedure is to assemble the system and run it

using the BASF TemperaSure

®

user interface software. Please start by reviewing the warnings

in Section .0, and then carefully follow the steps listed below to begin using your new

instrument. This will allow you to begin measuring temperatures and logging data.

3.1 Gettin Started

Please read the Warnings in Section 5.0 before you begin.

1. Carefully unpack the parts of the system.

2. Check that you received all the parts of your measurement system. Please contact BASF

immediately if you have any questions or if parts have been damaged in shipping.

3. We recommend that you assemble the system in a lab or office before installing it on a

process in order to familiarize yourself with the operation of the instrument.

4. Connect the system as shown in Figure 2A, or Figure 2B if you are configuring a multi-

channel system. Connect the probe head to the interface module with the provided cable.

The cable end that connects to the probe head has a round connector with a small red dot.

Line up this red dot with the red dot in the plug on the back of the probe head and push the

two together until you hear a click. This connector has a locking mechanism, so be sure to

insert it all the way until you hear a click. (To unplug the cable, grasp the grooved part of the

plug and slide it back before pulling to unplug the cable). The other end of this cable has a

RJ4 connector, which plugs into the interface box.

. Connect the interface module to the po er supply.

6. Connect the interface module to your PC or host computer.

7. The probe head and interface box each have a green LED to indicate power is being supplied.

8. Multi-Channel Systems: Please refer to Appendix 1 for software installation information for

the multiple channel interface box.

9. When using analog output -- check the operation carefully before connecting to or

controlling with analog output signal. See Appendix 3 for analog output module details.

3.2 Mountin the Probe

When choosing a location to mount the probe, select a place that is:

• In a fixed position and able to provide the desired spot size.

• Unlikely to have the view blocked during operation. (Even a small obstruction can make a

difference in the measurement.)

• Unlikely to be bumped or jostled in such a way that the lightpipe might be broken during

installation or while it is in use.

• Least likely to get dirty.

• As close to the hot object as is convenient. Lens based systems should be mounted at the lens

focal distance to minimize the measurement spot size.

• Does not expose the measurement electronics to temperatures greater than 60°C (unless

cooling is provided).

BASF’s Temperature Sensing support staff has years of experience in mounting optical probes.

Please contact us if you need assistance or to review your mounting ideas with our technical

staff.

Once the probe is mounted and the cables are connected, you may start taking measurements.

-8-

4 Software Interface

BASF TemperaSure

®

graphical user software gives the user the ability to log and/

or display temperature readings and set-up values obtained from the probes. This section

describes how to install and set up the software. The data logged while taking measurements can

be saved in binary files for re-viewing with this program or in text files that can be opened by

programs such as Microsoft

®

Excel

or Notepad.

4.1 Software Installation

To install the TemperaSure user software, copy the TemperaSure.exe program and all the other

files from the supplied disk onto your hard drive. We recommend making a new directory for the

program and supporting files. After the program and files have been copied onto the hard drive

it can be run by either double clicking on program icon or on the file TemperaSure.exe in

Microsoft

®

Explorer. The user software can save data to files anywhere you select.

4.2 Startin up TemperaSure

Launch the TemperaSure program by double-clicking on the program’s icon. The program’s

graphical interface consists of a menu bar, communication ports, and a graph area where the data

will be displayed. The left vertical area displays either temperature or current. The bottom

horizontal area displays time in seconds, minutes or hours.

4.3 Installation Troubleshootin

Connect the probe per Figure 2A or 2B, and then launch the TemperaSure software by double

clicking on TemperaSure.exe. The user-interface screen (Figure 3) will appear. The COM ports

may need to be selected first. To configure COM ports go to the “Options” menu and choose

“Connection” and select the COM ports. The probe readings ill appear in the boxes along

the top of the user-interface screen if the probe is connected correctly and COM ports are

selected.

If temperature values do not appear in the box(es) along the top of the screen then there is a

problem. If the box says Searching or No Probe then the probe is not being “seen” by the

software and is most likely not connected correctly. If Error appears in the box, most likely the

COM port is not selected correctly.

Check the cabling. Be certain that the probe, po er supply and interface box are all connected

and fully plugged in, per Figure 2A or 2B.

• Check to see if the green LED on the back of the probe and interface box are lit. These

indicate the probe head and interface box have power.

• Check that the correct COM port(s) on the computer is being used.

•

Consult Section 6 “Troubleshooting” in this manual if cabling and LED are all OK.

• Call BASF Temperature Sensing in Portland, OR ( 03) 794-4073 or Fremont, CA ( 10) 490-

21 0 for additional help.

-9-

Figure 3: TemperaSure Graphical User Interface Main Window

4.4 Usin TemperaSure Software Functions

The TemperaSure program has menu options:

• File

• Run

• Vie

• Options

• Help

4.4.1 File

Use the File menu for common tasks. The File menu has the following options:

Open: Use to open an existing “.bin” (binary) data file to view data graphically. The data can

also be saved to a .txt file from any open .bin file.

Temperature

Readings

Status

Graph and

Measurement

Rate

Y-Axis

Zoom

Control

Annotation

Box

Mouse

Coordinates

Start and Stop Logging

Time Scale

Zoom

Data Zoom and

Track Control

Y-Axis Quick

Buttons

-10-

Save: Use to save data collected to a “.bin” data file. The .bin file is used for viewing data at a

later time with this program.

Export (ASCII): Use to export a data file for use in another program, such as Microsoft

®

Excel

©

or Notepad

©

. The fields that can be exported are:

• Temperature

• Current

• Peak, Valley, and Plateau

Temperature

• Ambient Temperature

• Emissivity

• Calibration factor

• Transmission Factor

• Current Offset

• Annotation

• Start Time

The exported file format is selected under this menu option as fixed

width, tab separated, or comma separated. The user can transfer all

the data in the file or just the data along the currently displayed X-

Axis. The Export (ASCII) setup screen is shown at right.

Annotation: Allows a user to create a set of notes regarding the

measurement files being saved. The annotation entry will be

added to each file saved until it is removed, edited, or

TemperaSure program is exited.

Exit: Exits the software program. The exit function will give you the option to save your data.

4.4.2 Run

Use the Run menu to control the data logging.

Start: Starts the data acquisition. If you have more than one probe the software will force all

probes to run and log at the same rate.

Stop: Stops the data acquisition.

Macro: Macro mode allows data acquisition to occur automatically for a prescribed period of

time and then restart after a prescribed pause. The acquisition will continue until the Macro

Mode is halted. Resulting data files are stored in a user selected directory with a format as

described under the Export (ASCII) portion of Section 4.4.1 See Figure for Macro Mode setup

screen.

Reset: Erases the data from the graph and re-boots the probe(s). Warning Data Will Be Lost!

Figure 4: Text file

export configuration

menu.

-11-

Figure 5: Macro Mode setup screen

4.4.3 View

Find Data: This feature finds the most up-to-date readings and centers the data in the graph.

Find Data is like a beam finder, it auto-scales the graph and places the measurements in view.

The Quick-Button at the top of the screen and Right-clicking the mouse also provides access to

Find Data.

Undo Zoom: After you have “zoomed” the display in or out by any method, this feature will

become enabled, and selecting it will return the display to its previous horizontal and vertical

scale. Undo Zoom keeps track of multiple zoom operations, so that you can undo them in

sequence if desired. The Quick-Button at the top of the screen and Right-clicking the mouse also

provides access to Undo Zoom.

4.4.4 Options

Use the Option menu to control the probe’s settings. The Option menu has the following choices:

Connection: Allows the communication port(s) to be selected. The PC often already uses COM

1, 2, and 3. TemperaSure can utilize any unused COM port. TemperaSure can also talk to

probes through a USB port and serial converter box like those from Inside Out Networks.

Graph: Allows the graph to be customized, see section 4.7 and Figure 6: Graph Setup Screens,

for more details.

Probes: Allows you to change the probe’s parameters. See section 4.4 and Figure 7: Probe Setup

Window, for more details.

All Probes: Allows you to see the settings of all the probe’s parameters (See Figure 8).

Analog Calibration: Allows the analog voltage or current to be calibrated (See Figure 10).

Probe Statistics: Opens a window which provides statistical information on the current

measurements, including the mean, standard deviation, minimum, and maximum of the current

readings. Calculations are based on a user input value of N readings.

-12-

Figure 6: Graph Setup Windows

4.5 Probe and TemperaSure Setup

After connecting the probe, start the TemperaSure program. Probe settings can only be changed

if probe(s) are connected. There are a number of probe setting options, and these settings ill

affect the measurement accuracy. Therefore, it is very important that the probes be set up

correctly. Graph settings will not affect the measurements, only the display of the data. If you

are not certain about the correct settings please call BASF for application support.

4.5.1 Lo in Rate:

The graph rate is the number of readings per second (Rd/Sec) transmitted by the probe. The

value is important as it will affect the response and resolution of the measurements, the detail of

the temperature changes, the time over which measurements are averaged, and the size of data

files created. Graph rate is displayed and adjusted via the pull down selection menu at the top

left of the screen (see Figure 3); the current value is also displayed at the bottom left of the

screen. The instrument will measure and log temperature and photo diode current (light level)

from one reading per minute (1/60) to 1,000 readings per second. The probes can make very fast

measurements, however care must be exercised when many probes are used because very large

files can be created quickly with fast graph rates and multiple probes. Even a fast PC can

quickly become overwhelmed and lock up with multiple probes running at high speeds. Slower

graph rates will also produce less noisy temperature readings.

-13-

4.5.2 Probe Setup Options:

(The key to good measurements!)

Figure 7: Probe Setup Window

All instrument settings, with the exception of “graph rate”, can be edited using the Probe

Parameters menu for the individual instrument. To access the Probe Parameters for a particular

instrument, click on the number box above the instruments measurement display box, or choose

Options, Probe. There are six tabs in the Probe Parameter Window; General, Modes, Analog

Output, Calibration, Modbus, and Advanced. Each tab has a common area at the bottom which

allows a user to select which probe they are viewing or editing via the Change Probes buttons, or

either Save or Apply the probe settings.

Important Note: The difference between Save and Apply is important. Apply should be used

for short-term changes or testing a change; Save should be done when the change is to be

maintained for future measurements. Applied changes are lost whenever the probes are reset,

TemperaSure is restarted, or power to the probe is lost.

Save: Saving parameters stores values in the probes EEPROM (Electrically Erasable

Programmable Read Only Memory), saved parameters will be the default parameters the

next time the probes are power cycled or reset.

-14-

Apply: Applying parameters stores values in the probes RAM, these changes will be lost

when the probe is power cycled or reset.

1) General: The General tab has four main sections.

• Probe: In the Probe section a user can rename a probe from its default serial

number to something more meaningful for the process. The probe serial number,

channel number, and COM port (if applicable) are also displayed in the Probe

section.

• Settings and Options: Displays the current log rate, what data sets are being

transmitted from the probe to the TemperaSure software, and whether the probe is

configured to send updates to the analog output.

• Temperature Corrections: Displays the probe’s calibration factor (relationship

between light energy and temperature relative to its original calibration or to a

factory standard; depending on the type of optics used) and provides a box for

making a quick emissivity (or slope for a dual-wavelength instrument) adjustment.

The emissivity or slope can be set to vary with measured temperature through the

Advanced tab.

• Display Settings: The graph color for the probe can be changed and whether the

probe is to be displayed on the graph or just stored can be selected.

2) Modes: The Exactus instrument can be configure for several different operating modes;

please see Sections X.XX for details. Not all probes ship from the factory with these

modes activated; please contact the factory for assistance if you are interested in

activating these modes. Below is a brief description of the available modes:

• Peak Temperature: Outputs a calculated peak temperature. Once a lower threshold

temperature is reached the probe will begin to seek a Peak measurement. When the

lower threshold is reached, the peak measurement will be transmitted to

TemperaSure and the analog output module. The peak will either be the highest

value obtained or an average of the values measured between the leading edge and

trailing edge threshold values. A number of points immediately following the

leading threshold, or leading the threshold values may be ignored.

• Valley Temperature: Outputs a calculated valley temperature. The configuration

parameters are similar to those of the Peak Temperature but the direction of the

temperature change at the threshold value is reversed.

• Rising and Falling Plateau Temperatures: These values can be used to pick out

events that occur during generally increasing or decreasing temperatures.

• Variance Mode: When Variance Mode is selected, the probe will calculate both the

average and standard deviation of the temperature measurements within a user

defined sample size. If a two channel analog output module is available, both of

these values can be output to the module.

-15-

Figure 8: Modes menu

3) Analog Output: The Analog Output for each probe is also configured from the probe

parameters. Users can activate the analog output, select whether the output is to be 0 –

10 VDC or 4 – 20mA, and set the minimum and maximum temperatures. The minimum

and maximum temperatures can be any value within the calibrated range of the

instrument.

Figure 9: Analog output configuration menu

-16-

4) Calibration: The Calibration Tab is used to input the calibration factor or to calculate a

new value. Great care is taken in generating the initial calibration of the Exactus

instrument. We recommend discussing recalibration with the factory before proceeding.

Place the lightpipe or lens so that it is looking at a very stable and well-known

temperature target, preferably a blackbody. Then type the known temperature into the

Desired Temperature box and click the Auto-Cal button followed by the OK button. (See

Figure 10).

Figure 10: Auto Calibrate menu.

) Modbus: Use the modbus menu to assign a polling address. Please see Appendix X for

information on communicating with the Exactus probe via Modbus.

6) Advanced: The Advanced tab has several unique features which are available

exclusively in the Exactus instrument; please see Section 4. .3 for details about this

important configuration tab.

4.5.3 Advanced Features:

The advanced features in the Exactus instrument are designed to allow the user to correct and

manage a variety of pyrometric measurement issues, including adjustment of emissivity or slope

correction, signal averaging (Averaging Buffer) and heat transfer (Transfer Function). These

features can also be entered in table form, with corresponding temperatures for each table entry,

so the parameter will automatically adjust the target temperature changes. These features are set

up for each instrument using the Advanced tab in the Probe Parameters menu.

Emissivity: This feature allows the user to type in a single emissivity value that will cover the

entire measurement range, or enter a table of emissivity values and corresponding temperatures.

Based on the entered table, the instrument will automatically adjust the emissivity as the

temperature changes.

The table may include one row or as many as eight (8) rows to map emissivity verses

temperature. The table can be edited, or rows can be added or deleted using the buttons below

the table. Smaller values of emissivity will increase the temperature readings. An emissivity of

1.0 is used when the box above the table is not checked. By checking the Hold or Extrapolate

buttons below the table, the user can select whether the emissivity will be held at the last entries

or linearly extrapolated beyond the last entries; the user should verify the extrapolation makes

physical sense (emissivity never greater than 1.0 or less than 0.0 within the temperature range of

the instrument.

Table of contents

Popular Thermometer manuals by other brands

Bistos

Bistos BT-36 Operation manual

Extech Instruments

Extech Instruments 421504 instruction manual

ChoiceMMed

ChoiceMMed CFT-308 user manual

Lutron Electronics

Lutron Electronics TM-906A Operation manual

VisioFocus

VisioFocus PRO 06480 operating instructions

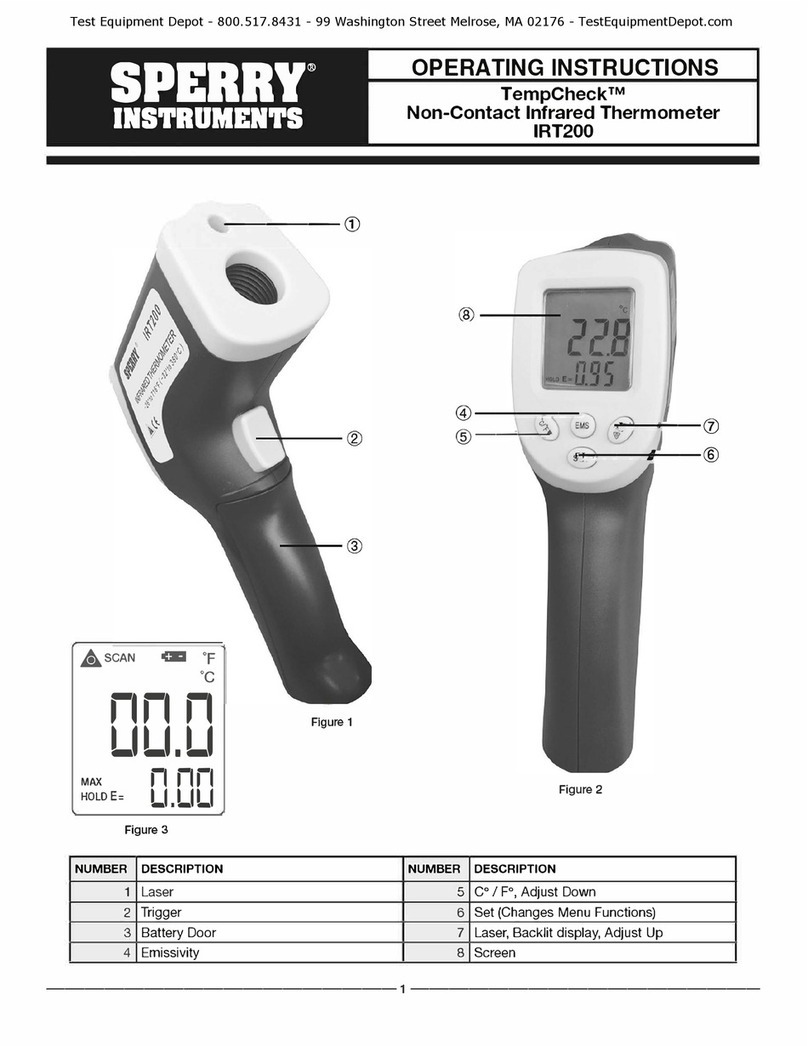

Sperry instrument

Sperry instrument TempCheck IRT200 operating instructions