Basil 3600 User manual

OPERATOR MANUAL

Basil®3600 Bedding Dispenser

(2008-02-04) P122996-163

i

Introduction Operator Manual 122996-163

This manual contains important information on the proper use of the

Basil®3600 Bedding Dispenser. Refer to SECTION 5, ROUTINE MAIN-

TENANCE,for instructions in routine care of this bedding dispenser.

All personnel and department heads are urged to carefully

review and become familiar with the Safety Precautions and

instructions contained herein. These instructions are important to

protect the health and safety of personnel operating this bedding

dispenser and should be retained in a conveniently accessible area

for quick reference. This equipment is specifically designed only for

the uses outlined in this manual.

Complete instructions for uncrating and connecting utilities, as well

as the equipment drawing, have been provided. If they are missing,

contact STERIS for replacement copies, providing the serial and

model numbers of the bedding dispenser.

Advisory IMPORTANT: A listing of the Safety Precautions to be observed

when operating and servicing this bedding dispenser can be found in

SECTION 1 of this manual. Do not operate the equipment until you

have become familiar with this information.

Any alteration of this equipment not authorized or performed by

STERIS will void the warranty. Alteration of this equipment which

could adversely affect its operation and efficacy may violate national,

state and local laws or regulations.

Indications For Use The Basil 3600 Bedding Dispenser is an automatic, conveyorized

unit designed to dispense bedding into animal cages as they pass

through the unit. The dispensers are capable of handling most solid

bedding used in the care of laboratory animals.

A WORD FROM STERIS CORPORATION

©2008, STERIS Corporation. All rights reserved. Printed in Canada.

ii

122996-163 Operator Manual Introduction

Service Information A thorough preventive maintenance program is essential to help

ensure safe and proper equipment operation. Customers are

encouraged to contact STERIS concerning our comprehensive

annual maintenance program. Under the terms of the program, pre-

ventive maintenance, adjustments and replacement of worn parts

are performed on a scheduled basis to help ensure equipment per-

formance at peak capability and to help avoid untimely or costly

interruptions.

STERIS maintains a global staff of well-equipped, qualified service

technicians to provide this service, as well as expert repair services.

Please contact STERIS for details.

Corporation STERIS

Canada

Québec, Qc, CANADA

ISO 13485

ISO 9001

Certified

Facility

The base language of this document is

ENGLISH. Any translations must be

made from the base language document.

STERIS Limited

STERIS House

Jays Close

Viables

Basingstoke

Hampshire

RG22 4AX

United Kingdom

Sales and Service:

STERIS Corporation

5960 Heisley Road

Mentor, Ohio 44060

440-354-2600 • 800-444-9009

www.steris.com

iii

Table of Contents Operator Manual 122996-163

A WORD FROM STERIS CORPORATION..................................................................i

Advisory............................................................................................................................................................ i

Indications For Use........................................................................................................................................... i

Service Information...........................................................................................................................................ii

1 SAFETY PRECAUTIONS ......................................................................................1-1

2 INSTALLATION VERIFICATION...........................................................................2-1

2.1 General ................................................................................................................................................... 2-1

2.2 Installation Checklist............................................................................................................................... 2-1

2.3 Technical Specifications......................................................................................................................... 2-2

2.3.1 Voltage, Amperage and Power Consumption................................................................................. 2-2

2.3.2 Permissible Environmental Conditions............................................................................................ 2-2

2.3.3 Seismic Anchorage System ............................................................................................................ 2-2

3 COMPONENT IDENTIFICATION...........................................................................3-1

3.1 General ................................................................................................................................................... 3-1

3.2 Component Identification ....................................................................................................................... 3-1

3.2.1 Cage Conveyor System .................................................................................................................. 3-1

3.2.2 Bedding Dispenser System ............................................................................................................ 3-1

3.2.3 Service Access Panels and Cleanout Door .................................................................................... 3-1

3.2.4 Drain Connection and Removable Debris Tray .............................................................................. 3-1

3.2.5 Adjustable Legs .............................................................................................................................. 3-1

3.2.6 Cage Flip-Over System ................................................................................................................... 3-1

3.2.7 Photoelectric Conveyor Stop........................................................................................................... 3-1

3.2.8 Control Panel................................................................................................................................... 3-3

3.2.9 Dust Collection System ................................................................................................................... 3-4

4 OPERATING INSTRUCTIONS ..............................................................................4-1

4.1 Before Operating Bedding Dispenser.................................................................................................... 4-1

4.2 Operating Bedding Dispenser ............................................................................................................... 4-1

4.3 Shutdown................................................................................................................................................ 4-2

5 ROUTINE MAINTENANCE....................................................................................5-1

5.1 General Information ................................................................................................................................ 5-1

5.2 Preventive Maintenance ......................................................................................................................... 5-2

Continued...

TABLE OF CONTENTS

Section

Number Description Page

iv

122996-163 Operator Manual Table of Contents

5 ROUTINE MAINTENANCE (Cont’d)

5.3 Weekly Cleaning..................................................................................................................................... 5-3

5.3.1 Clean Cage Conveyor Rollers......................................................................................................... 5-3

5.3.2 Empty Dust Collection System Bag ................................................................................................ 5-6

5.3.3 Clean Bedding Dispenser Exterior.................................................................................................. 5-7

5.4 Weekly Maintenance .............................................................................................................................. 5-8

5.4.1 Verify Gearbox Oil Level ................................................................................................................. 5-8

5.4.2 Grease Cage Conveyor Bearings ................................................................................................... 5-9

5.4.3 Adjust Dispenser Take-Up Bearings............................................................................................. 5-10

5.4.4 Adjust Dispenser Driving Chain Tensioner ...................................................................................5-11

5.4.5 Replace Shear Pin on Torque Limiter ........................................................................................... 5-12

6 TROUBLESHOOTING ...........................................................................................6-1

7 REPLACEMENT PARTS AND PRODUCTS............................................................7-1

TABLE OF CONTENTS (Cont’d)

Section

Number Description Page

v

List of Illustrations Operator Manual 122996-163

Section 3: Component Identification

3-1 Basil 3600 Bedding Dispenser ......................................................................................................... 3-2

3-2 Basil 3600 Bedding Dispenser Control Panel...................................................................................3-3

3-3 Dust Collection System ..................................................................................................................... 3-4

Section 5: Routine Maintenance

5-1 Cleaning and Maintenance ............................................................................................................... 5-4

5-2 Removing Roller (Fixed End) ............................................................................................................ 5-5

5-3 Removing Roller (Removable End) ................................................................................................... 5-5

5-4 Empty Dust Collection Bag ............................................................................................................... 5-6

5-5 Verify Gearbox Oil Level ................................................................................................................... 5-8

5-6 Grease Conveyor Bearings............................................................................................................... 5-9

5-7 Adjust Dispenser Take-Up Bearings............................................................................................... 5-10

5-8 Adjust Dispenser Driving Chain Tensioner .....................................................................................5-11

5-9 Replace Shear Pin on Torque Limiter ............................................................................................. 5-12

LIST OF ILLUSTRATIONS

Figure Description Page

1-1

Safety Precautions Operator Manual 122996-163

1

SAFETY PRECAUTIONS

The following Safety Precautions must be observed when operating or servicing this Basil®3600 Bedding Dispenser.

WARNING indicates the potential for personal injury and CAUTION indicates the potential for damage to equipment.

For emphasis, certain Safety Precautions are repeated throughout the manual. It is important to review ALL Safety

Precautions before operating or servicing the bedding dispenser.

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

WARNING – PERSONAL INJURY HAZARD:

WARNING – ELECTRIC SHOCK AND/OR BURN HAZARD:

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Repairs and adjustments to this equipment must be made only by STERIS or STERIS-trained service

personnel. Non-routine maintenance performed by unqualified personnel or installation of unauthorized

parts could cause personal injury, result in improper equipment performance, void the warranty or result

in costly damage. Contact STERIS regarding service options.

Regularly scheduled preventive maintenance is required for safe and reliable operation of this equip-

ment. Contact STERIS to schedule preventive maintenance.

Keep fingers and hands away from chains, gears or any other moving parts. Also avoid wearing loose

clothing that could get caught in mechanical parts.

Disconnect all utilities to dispenser before servicing. Do not service dispenser unless all utilities have

been properly locked out. Always follow local lockout-tagout and electrical safety-related work practice

standards.

Fasteners and star washers are used to ensure protective bonding continuity. Always reinstall any star

washer which may have been removed during installation or servicing.

Do not wash conveyor rollers in water exceeding 140°F (60°C).

Use non-abrasive cleaners when cleaning dispenser. Follow directions on container and rub in a back-

and forth motion (in same direction as surface grain). Abrasive cleaners are harmful to stainless steel.

1-2

122996-163 Operator Manual Safety Precautions

The table below contains symbols which may be on your bedding dispenser components:

The table below contains symbols which may be on the identification nameplate of your bedding dispenser:

Table 1-1. Definition of Symbols

Symbol Definition

Protective Earth (Ground).

Warning! Risk of Electrical Shock.

Warning. Refer to Manual For Further Information.

Rotation Direction.

Table 1-2. Definition of Symbols

Symbol Definition

MOD. Model Number of Bedding Dispenser.

SER. Serial Number of Bedding Dispenser.

kW Power Rating of Bedding Dispenser.

VVoltage Rating of Bedding Dispenser.

AAmperage Rating of Bedding Dispenser.

PH/Hz Phase of Bedding Dispenser / Frequency Rating of Bedding Dispenser.

WIRE X + PE Number of Wires [X] in the Electrical Cable and Protective Ground Wire.

2

2-1

Installation Verification Operator Manual 122996-163

INSTALLATION VERIFICATION

2.1 General An equipment drawing (122-998-267 or 122-998-283), showing all

utility and space requirements, was supplied with the Basil®3600

Bedding Dispenser. The clearance space specified on the equip-

ment drawing is necessary for ease of installation and to help ensure

proper operation and maintenance of equipment. If document is

missing or misplaced, contact STERIS, giving the serial and model

numbers of the bedding dispenser. A replacement copy will be sent

promptly.

2.2 Installation

Checklist

After bedding dispenser has been installed by a qualified service

technician, complete the following checklist to help ensure complete

and correct installation. If desired, contact STERIS to schedule a

demonstration of proper equipment operation.

❑Disconnect switch (not by STERIS), capable of being locked in

OFF position only, is installed in the electrical supply line in the

same room as the bedding dispenser, and within 10 feet (3 m) of

the electrical control box.

❑Bedding dispenser is positioned, as shown on the equipment

drawing, with the required service clearance space and in rela-

tion to building supply lines.

❑Electrical supply for bedding dispenser is as specified on the

equipment drawing.

❑Both conveyor motors (loading/unloading drive motor and bed-

ding conveyor motor) rotate in the direction shown by the arrow.

❑Verify exhaust guard, elbow and dust bag are in proper position.

❑Verify cage flip-over system is firmly installed and in proper posi-

tion.

❑Verify photoelectric switch is properly installed at the end of the

unload conveyor.

2-2

122996-163 Operator Manual Installation Verification

2.3 Technical

Specifications

These specifications are intended to describe the technical informa-

tion given on the bedding dispenser identification nameplate and to

state other relevant information. Verify equipment drawing (122-998-

267 or 122-998-283) or identification nameplate, located in chemical

storage compartment, for proper voltage and amperage.

2.3.1 Voltage, Amperage and

Power Consumption

The Basil 3600 Bedding Dispenser operates on:

• 208 V, 60 Hz, three-phase, neutral, four-wire

• 480 V, 60 Hz, three-phase, three-wire

Maximum current and power consumptions are:

Refer to Uncrating/Installation Instructions (P122997-217) for proper

connection.

2.3.2 Permissible

Environmental Conditions

This equipment is designed to give optimal results in an environment

where maximum relative humidity is 80% for temperatures up to 88ºF

(31ºC) decreasing linearly to 50% relative humidity at 104ºF (40ºC).

2.3.3 Seismic Anchorage

System

A seismic anchorage system is available for high-risk seismic zones.

Amp kW

• 208 V 13.9 2.6

• 480 V 5.6 2.7

3

3-1

Component Identification Operator Manual 122996-163

COMPONENT IDENTIFICATION

3.1 General Before operating the Basil®3600 Bedding Dispenser, it is important

to become familiar with the location and function of all components

and controls (see Figures 3-1, 3-2 and 3-3).

3.2 Component

Identification

See Figure 3-1.

3.2.1 Cage Conveyor System The cage conveyor system includes twenty-six 1-1/2" (38 mm)

diameter PVC rollers to move the cages. The rollers are designed for

free movement on hub and easy removal for cleaning purposes. The

cage conveyor system motor is 1/6-hp speed reducer, ac, 1 ph.

3.2.2 Bedding Dispenser

System

The bedding dispenser system includes a heavy chain belt that

allows bedding to pass through the chain without jamming in the

drive sprockets. Low-friction UHMW guides and wear pads provide

smooth, quiet travel throughout the dispensing cycle.

The dispenser belt motor is 1-hp, variable speed motor.

3.2.3 Service Access Panels

and Cleanout Door

The four service access panels allow sprocket and chain repair of

the cage conveyor system rollers. Unload end of the dispenser has

two access panels. Loading hopper has a hinged cover. The bedding

dispenser belt has a removable cover.

The cleanout door, on unload end, allows access to lower hopper.

3.2.4 Drain Connection and

Removable Debris Tray

The drain connection with plug in lower hopper helps with cleaning

and draining of the bedding dispenser.

3.2.5 Adjustable Legs The adjustable legs allow leveling of the bedding dispenser and

adjusting of the conveyor height.

3.2.6 Cage Flip-Over System The system is provided at load end of the Basil 3600 Bedding Dis-

penser to grab the cages coming out of the Basil®6700 Tunnel Cage

Washer, and flip them right side up onto the cage conveyor before

filling them with bedding.

3.2.7 Photoelectric Conveyor

Stop

A photoelectric switch can be provided at the unload end of the

cage conveyor to stop rollers when an item reaches the end of the

cage conveyor.

3-2

122996-163 Operator Manual Component Identification

SIDE VIEW

FRONT VIEW

(Load Side)

Cage Flip-Over

System

Cage Conveyor

(Load) Cage Conveyor

(Unload)

Photoelectric

Conveyor Stop

Service Access Panel

(One on Each Side of

Roller Conveyor)

Ventilation

System Service Access Panel

(One on Each Side of

Roller Conveyor)

Drain Connection

Bedding Dispenser Belt

Bedding Hopper

Access Panel

Control Panel

Cleanout Door

Service Access

Panel

Adjustable Leg

Service Access Panel

(One on Each Side of

Roller Conveyor)

Drain Connection

Figure 3-1. Basil 3600 Bedding Dispenser

Drive

3-3

Component Identification Operator Manual 122996-163

3.2.8 Control Panel See Figure 3-2.

•Power ON/OFF selector switch: turning Power ON/OFF selector

switch to ON position activates control and unit operations.

Turning Power ON/OFF selector switch to OFF position cuts

electrical supply to the unit.

•Unit STOP pushbutton (red): Stops cage conveyor rollers,

bedding dispenser belt and dust collection system operations.

When rollers, belt and dust collection system are stopped, the

corresponding red indicator light is ON.

•Dispenser ON/OFF pushbutton: Press Dispenser ON/OFF

pushbutton to ON position to activate the bedding dispenser belt

drive motor. Press Dispenser ON/OFF pushbutton to OFF

position to cut electrical supply to bedding dispenser belt drive

motor.

•Dispenser Adjustment knob: Turn Dispenser Adjustment

knob to the left to decrease bedding flow. Turn Dispenser

Adjustment knob to the right to increase bedding flow.

•Dust Collector ON/OFF pushbutton: Press Dust Collector ON/

OFF pushbutton to ON position to activate dust collection system.

Press Dust Collector ON/OFF pushbutton to OFF position to cut

electrical supply to dust collection system.

•Indicator lights: An indicator light is linked to the unit electrical

supply power, dispenser, unit and dust collection system. When

an indicator light is ON, corresponding system is activated.

Figure 3-2. Basil 3600 Bedding Dispenser Control Panel

OFF

ON

Power Dispenser

ON/OFF

Dust Collector

ON/OFF

Unit

STOP Low High

Dispenser Speed

Adjustment

3-4

122996-163 Operator Manual Component Identification

3.2.9 Dust Collection System See Figure 3-3.

The system removes dust generated by the filling operation and

eliminates the need for connection to building exhaust. The system

includes a 2-hp blower and a 55-gallon drum connected to the

bedding dispenser ventilation system. The dust collection system

has a Dust Collector ON/OFF pushbutton on the control panel.

.

Figure 3-3. Dust Collection System

Blower

Dust Collection

Drum

TOP VIEW

4

4-1

Operating Instructions Operator Manual 122996-163

OPERATING INSTRUCTIONS

4.1 Before Operating

Bedding Dispenser

Verify hopper is filled with bedding. Fill as necessary as follows:

1. Open hinged cover (refer to Figure 3-1).

2. Fill bedding up to wire netting.

Maximum capacity 11-1/2 ft3(0.3 m3) of bedding.

3. Close hinged cover.

4.2 Operating Bedding

Dispenser

Refer to Figure 3-2 for control location.

1. Position Power ON/OFF selector switch to ON.

2. Pull Unit STOP pushbutton (red) to start conveyor.

3. After pulling Unit STOP pushbutton, wait two seconds and push

Dispenser ON/OFF pushbutton to activate bedding dispenser

system.

4. With Dispenser ON/OFF pushbutton in OFF position, you may

run bedding dispenser conveyor without dispensing material.

5. Press Dust Collector ON/OFF pushbutton to activate dust col-

lection system.

6. If necessary, adjust amount of bedding desired in cages using

Dispenser Adjustment knob to increase/decrease bedding flow.

7. Place cages top side up on conveyor rollers.

NOTE: Cages of cage flip-over system are automatically flipped

from inverted position to top side up position when exiting Basil®

6700 Tunnel Cage Washer.

8. As cages pass through unit, a controlled level of bedding mate-

rial is dispensed into cages.

NOTE: Cages can pass beneath hopper in any random pattern

and will still be filled with the same amount of bedding per square

inch.

9. When cages are filled with bedding, remove cages from unload

conveyor rollers.

With photoelectric conveyor stop system, conveyor rollers stop

automatically when a cage reaches end of unload conveyor.

IMPORTANT: Conveyor, bedding dispenser and dust collection

system operations may be halted at any time by pressing red

Unit STOP pushbutton.

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing this bedding

dispenser can be found in SECTION 1 of this manual. Do not operate the equipment until you have become

familiar with this information.

WARNING–PERSONAL INJURY

HAZARD: Keep fingers and

hands away from chains,

gears or any other moving

parts. Also avoid wearing

loose clothing that could get

caught in mechanical parts.

4-2

122996-163 Operator Manual Operating Instructions

4.3 Shutdown At the end of the day:

1. Press Dispenser ON/OFF pushbutton to OFF.

2. Press Dust Collector ON/OFF pushbutton to OFF.

3. Position Power ON/OFF selector switch to OFF.

4. Clean bedding dispenser as explained in SECTION 5, ROUTINE

MAINTENANCE.

5

5-1

Routine Maintenance Operator Manual 122996-163

ROUTINE MAINTENANCE

5.1 General

Information

Procedures described in this section should be performed at regular

intervals as indicated.

Due to local conditions (air quality, amount of usage), more frequent

maintenance than indicated may be required. Customer should

maintain a record of all maintenance procedures performed on the

Basil®3600 Bedding Dispenser.

Should a problem occur, refer to SECTION 6, TROUBLESHOOTING.

Refer to SECTION 7, REPLACEMENT PARTS AND PRODUCTS, for replace-

ment parts list.

NOTE: Never permit unqualified persons to service the bedding dis-

penser.

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing this bedding

dispenser can be found in SECTION 1 of this manual. Do not operate the equipment until you have become

familiar with this information.

WARNING–PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Regularly scheduled

preventive maintenance is

required for safe and reliable

operation of this equipment.

Contact STERIS to schedule

preventive maintenance.

WARNING–ELECTRIC SHOCK

AND/OR BURN HAZARD:

• Disconnect all utilities to

dispenser before servicing.

Do not service dispenser

unless all utilities have been

properly locked out. Always

follow local lockout-tagout

and electrical safety-related

work practice standards.

• Fasteners and star washers

are used to ensure protective

bonding continuity. Always

reinstall any star washer

which may have been

removed during installation

or servicing.

5-2

122996-163 Operator Manual Routine Maintenance

5.2 Preventive

Maintenance

Table 5-1 is to be used as a preventive maintenance record and,

along with the instructions in this section, as a guide to performing

preventive maintenance.

IMPORTANT: Preventive Maintenance is not covered under warranty.

Table 5-1. Preventive Maintenance Guide

Recommended frequency of inspection is indicated in the right column. Usage and

utility conditions may require more or less frequent inspections.

Suggested

Frequency

1.0 PREPARATION FOR PREVENTIVE MAINTENANCE

1.1 Discuss equipment with operators. As required

1.2 Follow appropriate safety procedures; prepare unit for preventive maintenance. As required

2.0 MISCELLANEOUS CHECKS

2.1 Inspect mechanical parts for obvious wear. Replace parts if necessary.* 6 X/ year

2.2 Verify proper operation of pushbuttons and selector switch (refer to SECTION 3.2.8). 6 X/ year

2.3 Verify gearbox oil level as described in SECTION 5.4.6X/year

3.0 BEDDING DISPENSER BELT

3.1 Verify proper amount of bedding is being dispensed by unit into cages. Adjust

Dispenser Adjustment knob as necessary. 6 X/ year

3.2 Verify shovel-type blades are bringing bedding to top of hopper. 6 X/ year

3.3 Grease dispenser belt bearings as described in SECTION 5.4.4X/year

3.4 Verify proper adjustment and tracking on conveyor take-up bearings. 6 X/ year

3.5 Inspect dispenser belt for looseness. Tighten if necessary. 6 X/ year

4.0 CAGE FLIP-OVER SYSTEM

4.1 Inspect cage flip-over system for component looseness. Tighten if necessary. 6 X/ year

4.2 Inspect drive chain for looseness. Tighten if necessary. 6 X/ year

4.3 Inspect mechanical parts for obvious wear. Replace parts if necessary.* 6 X/ year

4.4 Grease drive chain. As required

5.0 FINAL CHECKOUT AND TEST

5.1 Clean dirt and lint from components. Verify all wiring, terminals and socket connec-

tions for damage or fraying. 6 X/ year

5.2 Verify unit has proper labels (caution, warning). 6 X/ year

5.3 Run a few cages to verify proper operation. 6 X/ year

5.4 Reinstall any panel or cover removed. Inspect area to ensure removal of all materials

used during inspection. 6 X/ year

5.5 Notify customer preventive maintenance inspection is completed. 6 X/ year

* Contact STERIS for this service. Service charges may be incurred. Consult your warranty for details.

5-3

Routine Maintenance Operator Manual 122996-163

5.3 Weekly Cleaning

5.3.1 Clean Cage Conveyor

Rollers

See Figures 5-1, 5-2 and 5-3.

Once a week, cage conveyor rollers must be thoroughly cleaned to

remove gross soil and debris (see Figure 5-1).

1. Before cleaning or servicing cage conveyor rollers, remove as

follows:

a. Remove holding collar from long axle, located on removable

end of roller (see Figure 5-3).

b. Place left hand on removable roller end cap, to hold firmly in

place on frame (see Figure 5-3).

c. Slide roller on axle towards removable end.

d. Lift fixed end up and away from short axle (see Figure 5-2).

e. Repeat Steps a to d for each roller to be removed.

2. Clean rollers in hot water using a mild detergent.

3. Rinse under running water.

4. Dry each roller using a clean, dry, lint-free cloth.

5. Repeat for each roller.

6. Apply stainless-steel cleaner for general stains or stainless-steel

stain remover for stubborn stains.

7. Using a damp cloth or sponge, rub in a back-and-forth motion, in

same direction as surface grain.

8. Polish surface with a clean, dry, lint-free cloth, using stainless-

steel polish, if desired.

9. After cleaning conveyor rollers, reassemble as follows:

a. Insert roller on long axle (pulling roller towards frame).

b. Push roller assembly firmly against roller cap (see Figure 5-3).

NOTE: Ensure O-ring is correctly placed and in good

condition. If not, replace O-ring. Refer to SECTION 7,

REPLACEMENT PARTS AND PRODUCTS, for ordering information.

c. Turn holding collar until it locks in position over shaft.

d. Align roller on fixed end cap. Slide and push firmly into place

(see Figure 5-2).

e. Snap holding collar over axle (see Figure 5-3).

f. Repeat Steps a to e for each roller to be reinstalled.

WARNING–ELECTRIC SHOCK

AND/OR BURN HAZARD:

Disconnect all utilities to dis-

penser before servicing. Do

not service dispenser unless

all utilities have been properly

locked out. Always follow local

lockout-tagout and electrical

safety-related work practice

standards.

CAUTION – POSSIBLE EQUIP-

MENT DAMAGE:

• Do not wash conveyor rollers

in water exceeding 140°F

(60°C).

• Use non-abrasive cleaners

when cleaning dispenser.

Follow directions on con-

tainer and rub in a back-

and forth motion (in same

direction as surface grain).

Abrasive cleaners are harm-

ful to stainless steel.

5-4

122996-163 Operator Manual Routine Maintenance

SIDE VIEW

FRONT VIEW

(Load Side)

Gearbox

Cage Flip-Over

System

Oil Level Plug

Conveyor Rollers

Ventilation System

Curtain

Conveyor Bearing

Conveyor Bearing

Service Access Panel

Conveyor Bearing

Take-Up Bearing

Cleanout Door

Figure 5-1. Cleaning and Maintenance

Drive

Table of contents

Popular Dispenser manuals by other brands

ViscoTec

ViscoTec Preeflow eco-CONTROL EC200-K Operation and maintenance instructions

Textron

Textron Greenlee 910 instruction manual

Sunlight

Sunlight ART-SL810 manual

Dispense-Rite

Dispense-Rite SLR-2F-CSD installation instructions

ophardt

ophardt SanTral CEU 1 Instructions for use

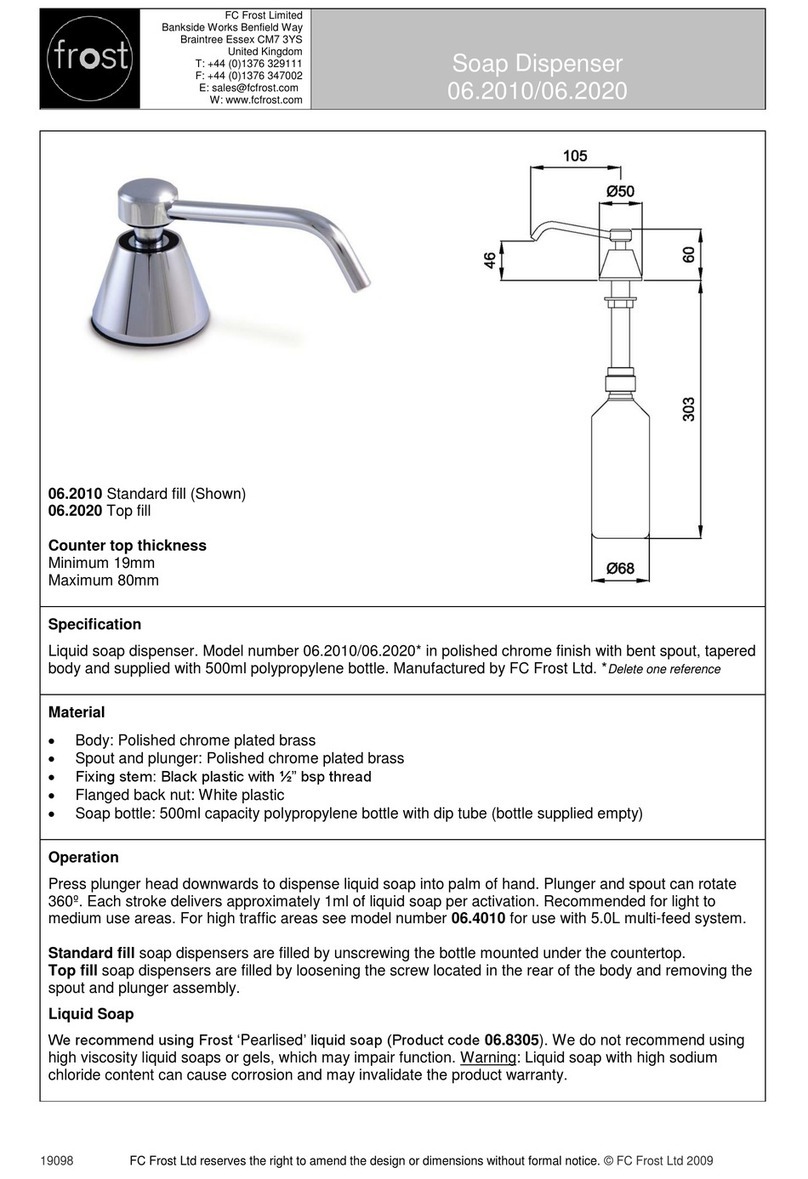

FROST

FROST 06.2010 quick start guide