Table of Contents

Page 1. Introduction

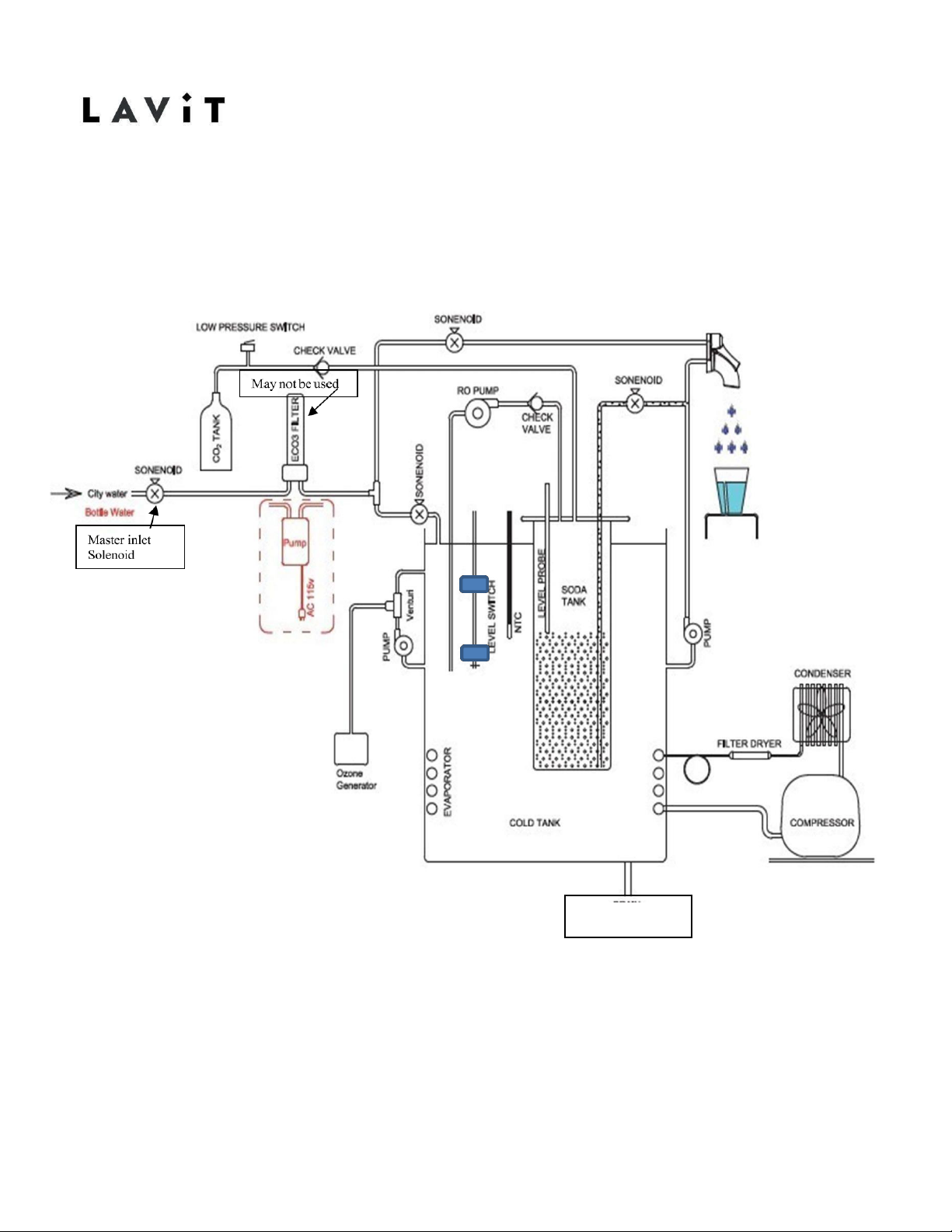

Page 2. Water Flow Diagram

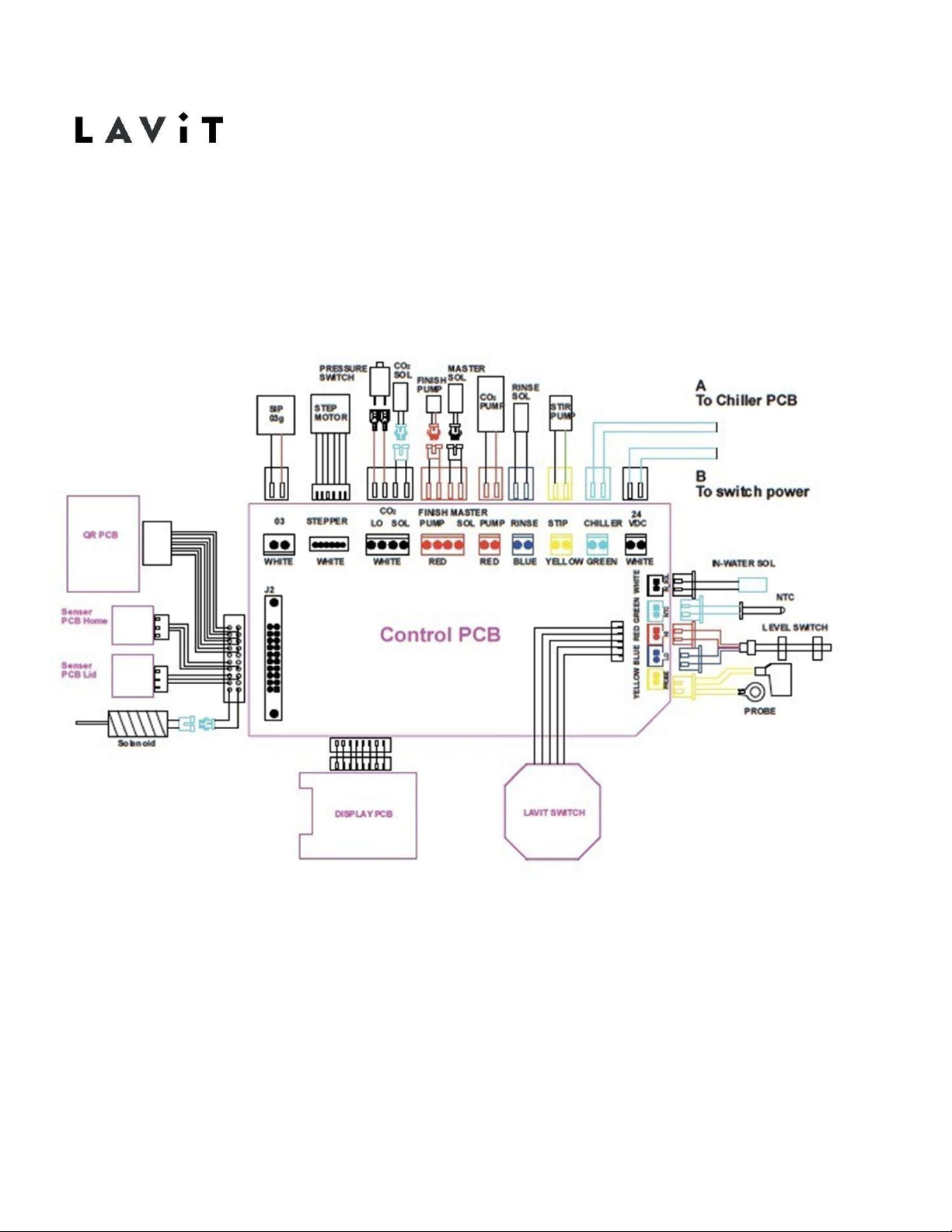

Page 3-4 Electrical Diagrams

Page 5. Beverage Dispense Splatters/Multiple

Streams Page 6-7 “Clean Brewer” Screen Appears

Page 8. “Close Brewer Lid” Error when Brewer lid is

Closed Page 9. “Possible Water Leak” Error Screen

Page 10. No Soda Water –Gas Only

Page 11-13 Troubleshooting the Soda Water Circuit

Page 14 -16 Replacing the Soda Probe

Page 17-18 Soda Solenoid Valve Replacement

Page 19. No Still Water Dispense

Page 20-23 Water Stream Calibration

Page 24 -25 Water Tanks Not Filling at Start Up

Page 26- 27 Water Run On

Page 28 Blank or Black Touchscreen

Page 29 All white touch screen

Page 30 Touch Screen Calibration

Page31WaterChillingScreen

Page 32 Unit not Cooling or Chilling

Page 33-35 Basic Troubleshooting

Page 36 Large Amount of water left inCapsule

Page 37-38 Lavit Quick installation guide

Page 39 Lavit User Guide

Page 40 Draining & Decommission