Batmatic CBH1450 User manual

FORWARD

PLATE COMPACTOR MOD.

CBH1450 – CBR1450

FOREWORD

We thank You to choose a BATMATIC plate compactor.

Your new machine is an useful and safety job’s tool.

Observing the safety regulations and the instructions in

this book there will not be physical injury and the plate will

be always in good condition.

Worn-out machine parts are to be replaced as soon as

possible. You will find the code numbers to order the

spare parts in the chapter “Spare parts” in this instruction

book.

batmatic CB1450 June 2008 R03

-3 -

INDEX

SAFETY INSTRUCTIONS FOR PLATE COMPACTORS...............................................................4

SAFETY......................................................................................................................................4

TRANSPORT AND LIFTING.......................................................................................................4

MAINTENANCE .........................................................................................................................5

PERIODIC MAINTENANCE........................................................................................................5

FIRE ...........................................................................................................................................5

RESIDUAL RISK ........................................................................................................................5

CLIMBING ABILITY .......................................................................................................................6

FUNCTION.....................................................................................................................................6

APPLICATIONS.............................................................................................................................6

CHECKS BEFORE STARTING ..................................................................................................7

ENGINE STARTING (MANUAL).................................................................................................7

ENGINE STOPPING (MANUAL).................................................................................................7

ENGINE OIL ...............................................................................................................................7

AIR FILTER (DRY)......................................................................................................................8

AIR FILTER (OIL BATH).............................................................................................................8

MAINTENANCE .............................................................................................................................9

TROUBLE, CAUSE, SOLUTION..................................................................................................10

LUBRIFICANTS ...........................................................................................................................11

ENGINE / EXCITER REVS...........................................................................................................11

TECHNICAL DATA......................................................................................................................12

SOUND MEASUREMENTS......................................................................................................12

VIBRATION MEASUREMENTS ...............................................................................................12

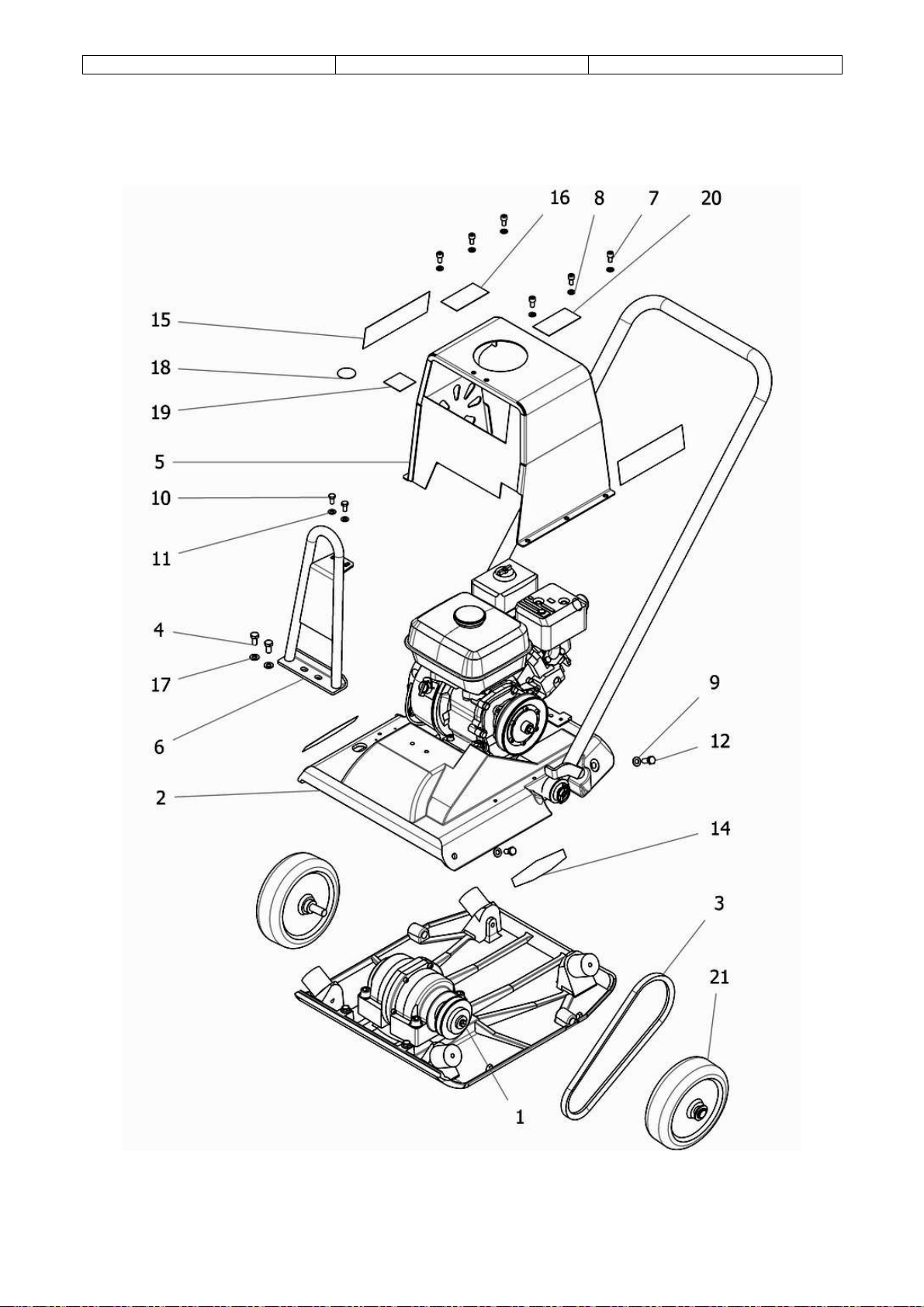

EXPLODED VIEW........................................................................................................................13

WARRANTY.................................................................................................................................23

batmatic CB1450 June 2008 R03

- 4 -

SAFETY INSTRUCTIONS FOR PLATE COMPACTORS

SAFETY

•Plate compactors must only be operated by person who:

∗is at least 18 years old;

∗is physically and mentally fit for this job;

∗may be expected to carry out the job he’s charged with carefully.

∗the employer must directly assign people who guide plate compactor.

•Plate compactors must only be used for compaction jobs observing safety and operating

instructions.

•People who work with plate compactors must know everything regarding safety

instructions.

•Do not take drugs or drink alcohol before using plate compactors.

•Always wear appropriate protective clothes (ear protections, gloves, protecting shoes and

helmet).

•Do not alterate the operation devices of the plate compactor.

•Do not leave control elements during compaction.

•Store the compactor with engine off in a safe place.

•Always refill fuel tank when the engine is off. Do not allow fuel to come into contact with the

hot parts of compactor and engine.

•Do not smoke when using compactor. Keep the compactor out of open flames.

•Always check fuel tank cap. If there is a fuel cock, shut it off when the engine is not

working.

WARNING

If fuel tank leaks, replace it immediately: A fuel tank in bad conditions could

explode

•Do not use the compactor in places where there are gaseous exhalations.

•Do not use the machine indoors or in an enclosed area unless inadequate ventilation.

•Always wear appropriate protective clothes.

•When the work area is near slopes, the compactor could turn over.

•When you use compactor in reverse and in a narrow place, the operator must be sideways

from the handle in order to avoid stumbling.

•Always operate in safe conditions in order to avoid accidents.

•Always operate in maximum stability conditions.

•Use transport wheels only for movements in yard. In all the other situations they must be

removed.

•Always make sure of the proper functioning of the safety and control devices.

•If there are any problems, stop immediately the machine and inform the person responsible

of the yard.

TRANSPORT AND LIFTING

•Do not lift the compactor when is running.

•Check that lifting points are not damaged.

•For loading and unloading the compactor, appropriate lifting-gear are necessary which

have to be used on the lifting points.

•Be sure that the ramps are fixed and check the tolerable weight in order to avoid turnovers.

batmatic CB1450 June 2008 R03

- 5 -

•Do not transport compactors when engine is running.

•Tie the machine on vehicle to prevent sliding or tipping over.

•For long transports, empty completely the fuel tank and close it.

WARNING

Do not lift or hook the plate compactor by the handle.

MAINTENANCE

•Use original spare parts only.

•Do not alterate the operation devices of plate compactor.

•Do not turn the engine on without air filter.

WARNING

Modifications in this machine are subject to the express approval of

BATMATIC which in case of non observance will refuse all liabilities and all

warranties.

•Do not make maintenance operations when machine is running or when engine is on.

•As soon as maintenance and repair jobs have been completed, all safety devices have to

be properly reinstalled.

PERIODIC MAINTENANCE

Regular maintenance is required for a good performance of the compactor.

FIRE

In the case of a fire in the machine, if possible use an AB class powder extinguisher.

RESIDUAL RISK

Plate compactors are designed for absorbing a large part of machine vibrations.

Depending on the operation, the ground conditions and exposure time, the recommended limits for

hand-arm vibrations may be exceeded.

WARNING

Do not use the machine on grounds already compacted.

Long exposure to vibrations can damage the hands and wrists. Do not use the machine if you

experience discomfort, cramp or pain and consult a doctor before restart working with the machine.

Long exposure to loud noise without ear protector can cause permanent damage to hearing.

Please also observe regulations valid in Your yard.

batmatic CB1450 June 2008 R03

- 6 -

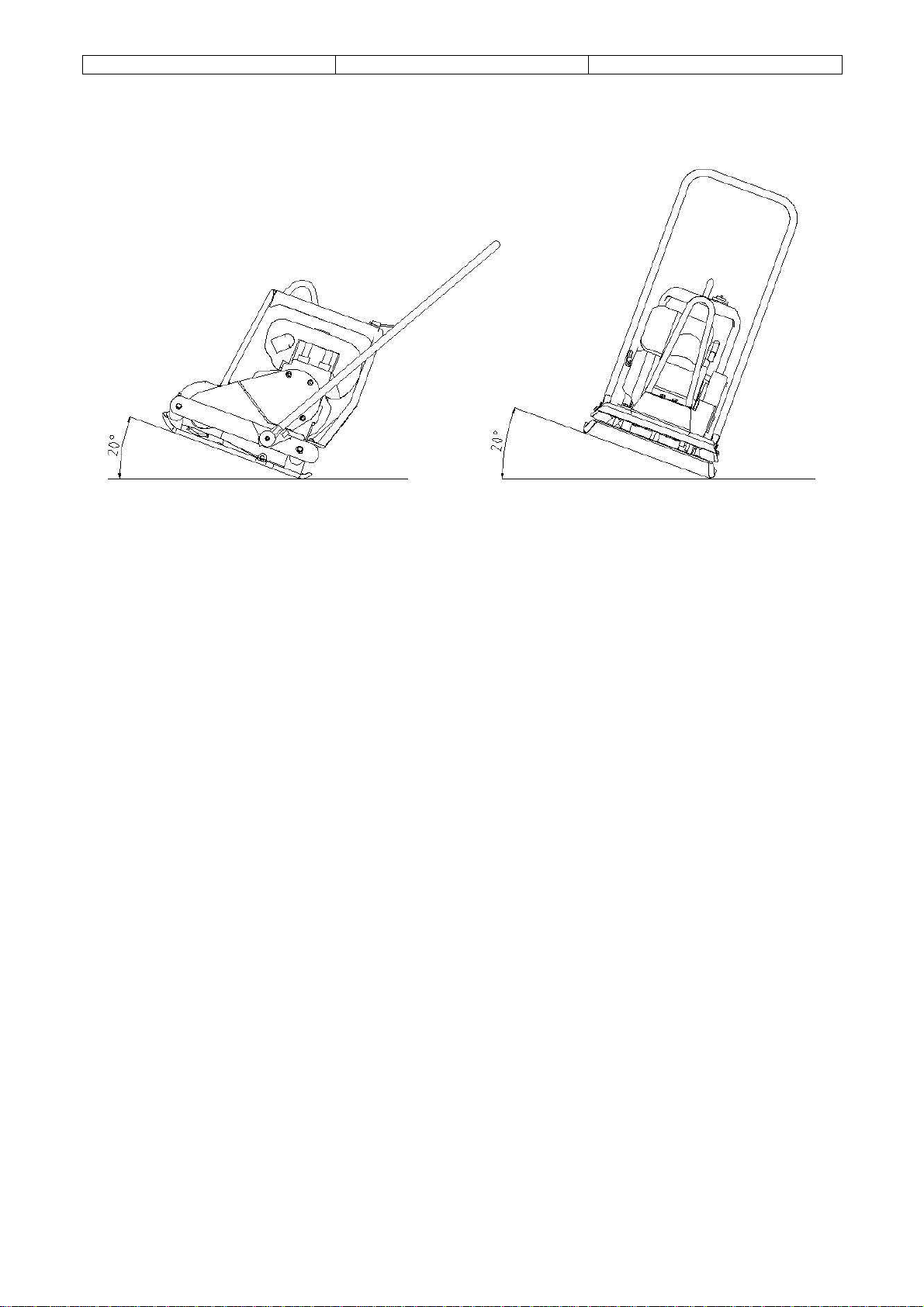

CLIMBING ABILITY

FUNCTION

The vibration required for tamping is produced by the exciter which is on the compacting plate.

The engine starts the exciter and the torque is transmitted by the centrifugal clutch and by the belt.

In order to allow the idling of the drive engine, the centrifugal clutch, at low engine speeds,

interrupts the flow of power to exciter. The compactor must always be used with the gas handle in

the “OPERATIVE” position.

The engine supporting and the compacting plates are connected by 4 shockmount, which are

mounted to avoid that vibrations reach the operator.

APPLICATIONS

The compactor CB1450 is suitable for asphalted road maintenance, pavé and interlocking tiles

laying, compaction of any kind of soils.

batmatic CB1450 June 2008 R03

- 7 -

OPERATION

CHECKS BEFORE STARTING

•Before start using compactor, carefully read instruction manual.

•Engine oil level

Check oil level using the proper dipstick. If necessary refill with SAE 15 W 40 oil.

•Air filter

Check that air filter is clean and in good condition. If necessary clean or replace it.

•Fuel

Never use oil/gasoline mixture or dirty fuel. Avoid getting dirt, dust or water into fuel tank.

Refuel avoiding leaks on engine.

ENGINE STARTING (MANUAL)

•Open the fuel valve.

•Move the throttle lever to 3/4 position.

•Turn the choke lever (if present).

•Turn the engine switch on the ON position.

•Pull the starter grip lightly until resistance is felt, then pull briskly.

Pull hand crank until it starts, in order to avoid counterblows

•As the engine warms up, gradually move the choke lever (if present).

•Warm up the engine at the minimum speed for some minutes.

•The compactor will start moving when the throttle lever is in operative position.

ENGINE STOPPING (MANUAL)

•Move the throttle lever to the minimum position. Warm up the engine at the minimum speed

for some minutes.

•Turn the engine switch on the OFF position.

WARNING

Never operate the engine switch when the engine is at the maximum speed.

•Turn the fuel valve on the OFF position.

ENGINE OIL

•Check oil level using the proper dipstick, if necessary refill with SAE 15 W 40 oil.

Oil change

•Drain oil at warm engine.

•Refill with SAE 15W40 oil.

WARNING

Only use oil with characteristics advised by the manufacturer engine (see

engine book).

batmatic CB1450 June 2008 R03

- 8 -

AIR FILTER (DRY)

WARNING

Clean air filter daily in order to avoid engine damages.

•Open air cleaner and remove element.

•Lightly and repeatedly tap the element on a hard surface to eliminate all excess dirt.

•Clean the element.

•Refit the air filter. Do not run the engine without the air filter.

AIR FILTER (OIL BATH)

WARNING

Clean air filter daily in order to avoid engine damages.

•Open air cleaner and remove upper element.

•Wash the upper filtering element with soap and water.

•Clean the upper bowl.

•Remount the upper filtering element.

•Remove the lower filtering element.

•Clean and dry filtering element.

•Drain and clean bowl.

•Fill with engine oil up to level mark.

•Reassemble air cleaner.

WARNING

Never use gasoline or low flash point solvents for cleaning the air filter to

avoid fire and explosions.

Do not disperse oil, batteries, fuel and dangerous substances in the

environment, as they have high pollution power.

batmatic CB1450 June 2008 R03

- 9 -

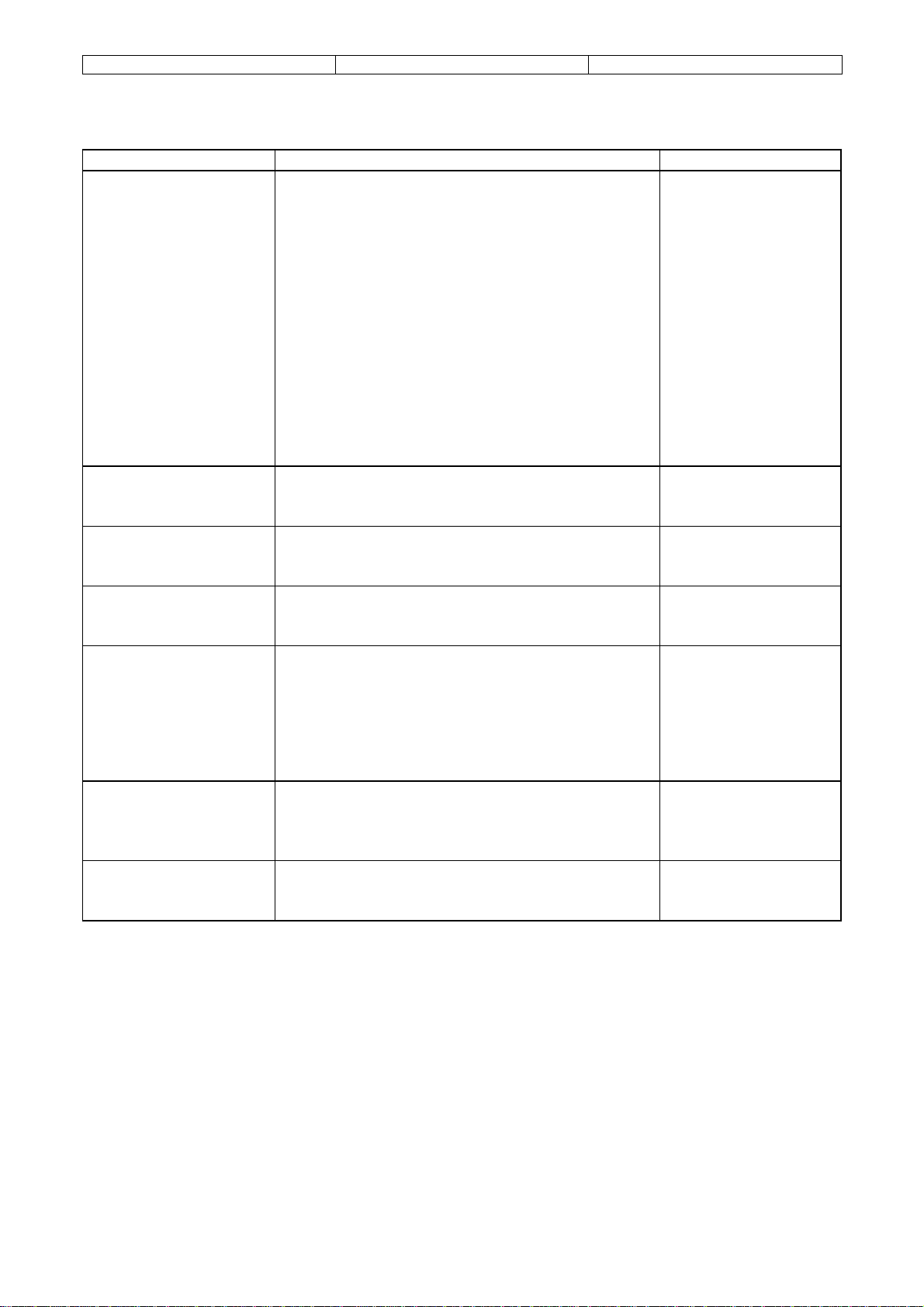

MAINTENANCE

PARTS MAINTENANCE INTERVAL

Air filter

Fuel tank

Engine

Engine

Exciter

Check filter, clean or replace if necessary

Check filter oil level (only oil bath models)

Check fuel tank and fuel cap lid. If necessary

replace.

Check oil level, refill if necessary

Check engine RPM

Check exciter lid

daily

Engine

First oil change

After 20 h

Engine

Clean spark plug

Monthly

V-Belt

Check V-belt tension

Monthly

Fuel Tank

Engine

Check fuel filter, replace if necessary

Oil change

After 100 h

Exciter

Check oil level, refill if necessary

After 150 h

Exciter

Oil change

After 250 h

batmatic CB1450 June 2008 R03

- 10 -

TROUBLE, CAUSE, SOLUTION

TROUBLE POSSIBLE CAUSE SOLUTION

The transmission belt is

broken

The wear and tear has

caused the belt to loosen up

Replace the belt

The engine works properly

but the machine does not

vibrate

The centrifugal clutch has

broken Replace the centrifugal clutch

Verify that during compaction

gas lever is in “OPERATIVE”

position

The engine rpm is not correct

Reset the number of engine rpm

Reduced or irregular speed

The transmission belt has

loosened up Tension the transmission belt

and, if necessary, replace it

The engine rpm are low but

the exciter does not stop Centrifugal clutch malfunction

Repair the centrifugal clutch

and, if necessary, replace it

The exciter heats up to over

90° There is too much of

oil in the

vibrator

Top up the oil level. Check

whether the oil seal has been

damaged; if necessary replace it

The engine works with

difficulty and the vibrator is

too noisy and it stops or slows

down

Mechanical block of the

exciter (bearings, shaft)

Remove the element causing

the failure or, if necessary,

replace the exciter

Fuel tank empty Add fuel

Oil lack Add oil

Dirty air filter Clean air filter, if necessary

replace it

The engine turns off or does

not work properly

Engine damaged Contact an engine service

center

batmatic CB1450 June 2008 R03

- 11 -

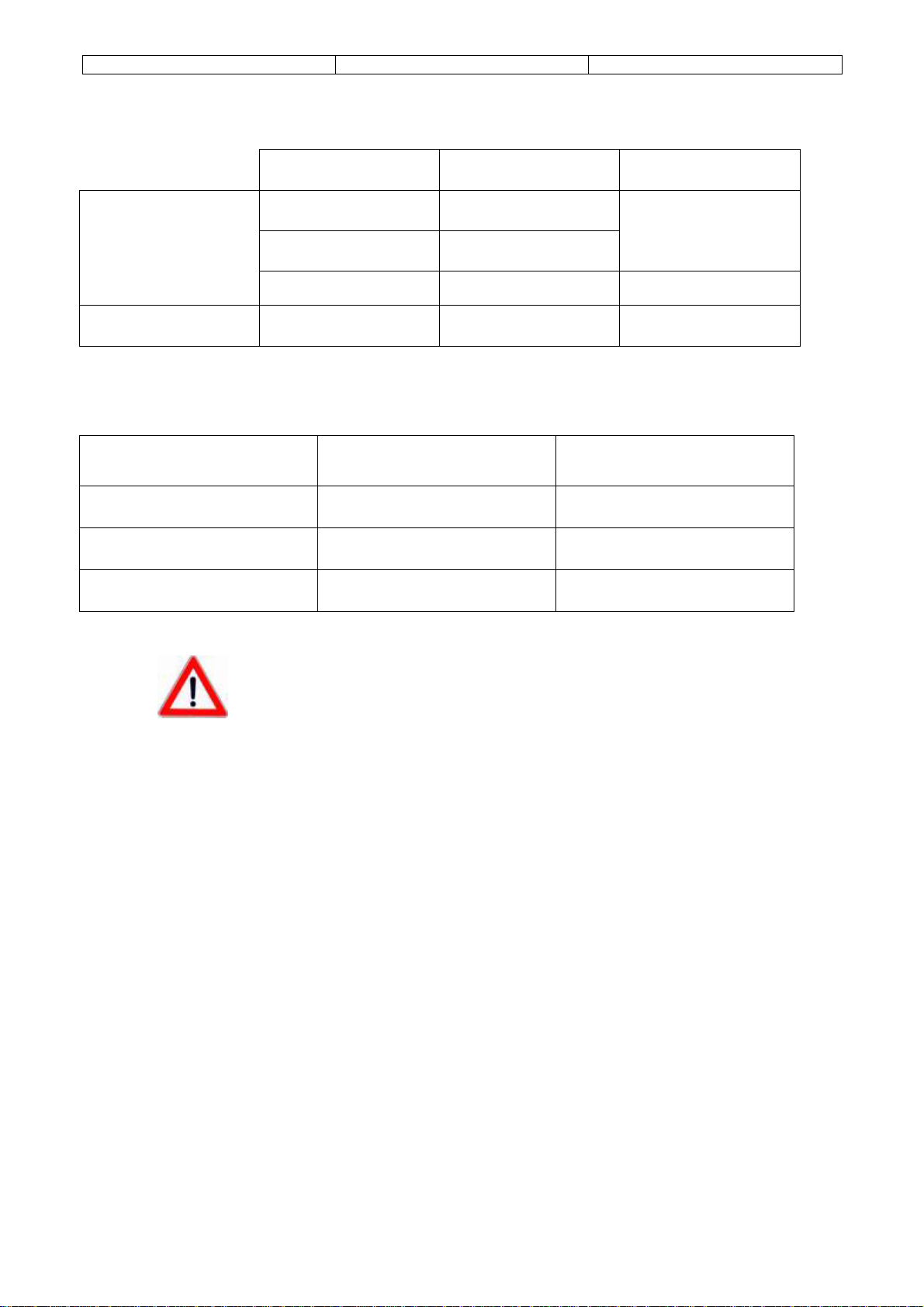

LUBRIFICANTS

Model Quantity Type

CP 6-7-9 0,2 kg

CP 13-15-17 0,5 kg SAE 15 W 40

Exciter

CB1450 – CD1450 0,2 kg Pontonic FDL 75W90

Engine All models See engine

instructions SAE 15W40

ENGINE / EXCITER REVS

Model Engine Exciter

CP 6-7-9 3500 – 3550 5350 – 5400

CB1450 – CD1450 3400 – 3450 5350 – 5400

CP 13-15-17 3550 – 3600 5350 – 5400

WARNING

Set the rpm as per the above table. A different rpm will not make the

compactor working properly and could break it. If the set rpm is changed, the

warranty will not be recognized.

batmatic CB1450 June 2008 R03

- 12 -

TECHNICAL DATA

Item

CBR1450

CBH1450

Dimensions base plate (Width x Length) mm 500 x 580

Operating weight kg 90

Working speed m/min 25

Max climbing ability 20%

Frequency 90 Hz

Centrifugal force 15,99 kN

Transmission Centrifugal clutch / Belt

Air-cooled single-cylinder 4 stroke

Engine Subaru Robin EX17 Honda GX 160

Engine Power 5.7 Hp

4.2 kW 4.8 Hp

3.6 kW

Displacement 169 cm

3

163 cm

3

Fuel Petrol

Fuel consumption l/h 1,2 l/h 1,2

Fuel tank capacity l 3,6 l 3,6

SOUND MEASUREMENTS

The product has been produced in accordance with the standard 2000/14/CE, procedure I annex

VI.

Measured sound power level 104,2 [dB(A)] and guaranteed sound power level 108 [dB(A)] on a

significant equipment.

VIBRATION MEASUREMENTS

Products are tested for hand/arm vibration level in accordance with annex D prEN500-4:2001

The hand/harm vibration level is 12 m/s

2

The plate compactor has been tested on a “macadam” surface, produced with not cleaned stone

crusher grit, with 16 mm medium diameter (with components which have diameter that goes from

10 to 20 mm).

batmatic CB1450 June 2008 R03

- 13 -

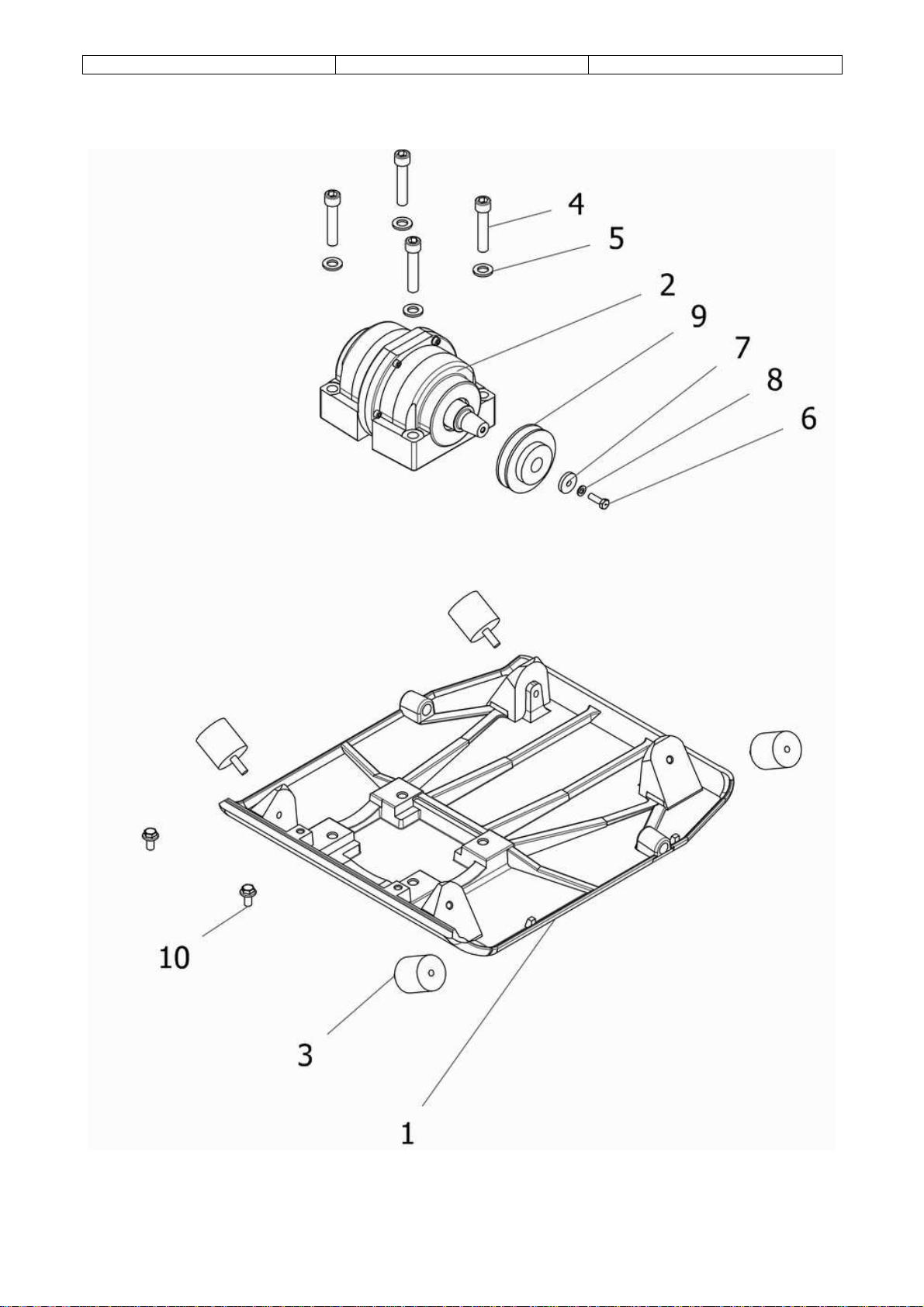

EXPLODED VIEW

EXCITER CB1450

POS CODE DESCRIPTION Q.TY

1 560428 EXCITER COVER CP6/7/9 1

2 560427 EXCITER COVER CP6/7/9 1

3 560432 EXCITER SHAFT CP7/9 - CDB1450 1

4 131760 DOUBLE LIP SEAL 40x62x7 1

5 151969 ROLLER BEARING NJ 208 E.TVP2.C4 2

6 151302 SCREW TCEI M 6x 30 8.8 UNI 5931 6

7 151198 WASHER M 6 UNI 6592 ZN 2

8 152273 TRIPPING PIN D6x16 1

--- 182126 OIL SAE 75W90 0,2 L

batmatic CB1450 June 2008 R03

- 14 -

BASE PLATE CB1450

batmatic CB1450 June 2008 R03

- 15 -

BASE PLATE CB1450

POS CODE DESCRIPTION Q.TY

1 560471 BASE PLATE CDB 1450 1

2 560472 EXCITER CP7/9 - CDB 1450 1

3 131998 SHOCKMOUNT MF D 50X50 M10X25 50-55 SH 4

4 151951 SCREW TCEI M14x 70 10.9 UNI 5931 4

5 151117 WASHER. M14 NORD LOCK 4

6 560239 SCREW 1

7 560267 CLUTCH WASHER. 28X8.5 SP.5 ZN 1

8 151207 GROWER WASHER M 8 UNI 1751 1

9 560446 EXCITER CLUTCH CBD 1450 1

10 152284 SCREW FLG D S/T M10X20 8.8 ZN 2

batmatic CB1450 June 2008 R03

- 16 -

ENGINE SUPPORT CB1450

batmatic CB1450 June 2008 R03

- 17 -

ENGINE SUPPORT CB1450

POS CODE DESCRIPTION Q.TY

1 560021 ENGINE SUPPORT CBD1450 1

2 152262 CENTRIFUGAL CLUTCH 19,05 X CBH1450 1

3 560442 CLUTCH COVER DISK D142 2

4 560443 CLUTCH GAGE D98 5

5 560468 SCREW 2

6 131999 SHOCKMOUNT MF D25X15 M6X18 60 SH 2

7 560333 SHOCKMOUNT D.43 60SH 2

8 181129 HONDA GX 160 K1 QX4 ENGINE 1

8 181217 ROBIN SUBARU EX 17OD50060 1

9 560502 CLUTCH AXEL BOX ZN 1

10 560051 HANDLE 1

11 152274 PIN mm4,5x35x23 2

12 131692 ON-OFF SWITCH 1

13 131711 DEFLECTOR BLACK 1

14 132255 ELECTRICAL CABLE 1

15 151301 SCREW TCEI M 6x 16 8.8 UNI 5931 ZN 6

16 152116 SCREW TCEI M 6x 50 8.8 UNI 5931 ZN 1

17 152278 SCREW TCEI M 8x 35 8.8 UNI 5931 ZN 2

18 151807 CONTACT WASHER 8(8.2x18x1.4)ZN 5

19 151311 SCREW TE M 8x35 8.8 UNI 5739 ZN 2

20 151309 SCREW TE 5/16-24x3/4" 8.8 UNF 1

21 151003 NUT M6 UNI 5588 ZN 2

22 152290 SCREW AUT.TCC 4,2x13 UNI 6954 - 7981 2

batmatic CB1450 June 2008 R03

- 18 -

VIBRATORY PLATE CB1450

batmatic CB1450 June 2008 R03

- 19 -

VIBRATORY PLATE CB1450

POS CODE DESCRIPTION Q.TY

1 ----- BASE PLATE WITH EXCITER FOR CBD1450 1

2 ----- SUPPORT OF ENGINE WITH ENGINE FOR CBH1450

1

2 ----- SUPPORT OF ENGINE WITH ENGINE FOR CBR1450

1

3 132055 V BELT HFX SEZ. XPA 832 1

4 151836 SCREW TE M10x20 8.8 UNI 5739 ZN 4

5 560477 ENGINE COVER CBH 1450 1

6 560441 ROLLBAR CBH 1450 1

7 151395 SCREW TCEI M 8x 16 8.8 UNI 5931 ZN 6

8 151207 GROWER WASHER M 8 UNI 1751 6

9 151814 CONTACT WASHER 10(10.2x22x1.6)ZN 4

10 151310 SCREW TE M 8x16 8.8 UNI 5739 ZN 2

11 151807 CONTACT WASHER 8(8.2x18x1.4)ZN 2

12 151856 SCREW TE M10x25 8.8 UNI 5739 ZN 2

13 132145 CE STEEL PLATE 55X70 1

14 132265 SMALL BATMATIC STICKER 2

15 132263 CB1450 STICKER 2

16 132260 PROTECTIVE HEAR STICKER 1

17 151791 CONTACT WASHER 10(10.2x22x1.6) 2

18 132189 HOOK STICKER 1

19 132285 108 db STICKER 1

20 132261 FUEL STICKER 1

21 530419 COMPLETE WHEEL CR 11-12 2

batmatic CB1450 June 2008 R03

- 20 -

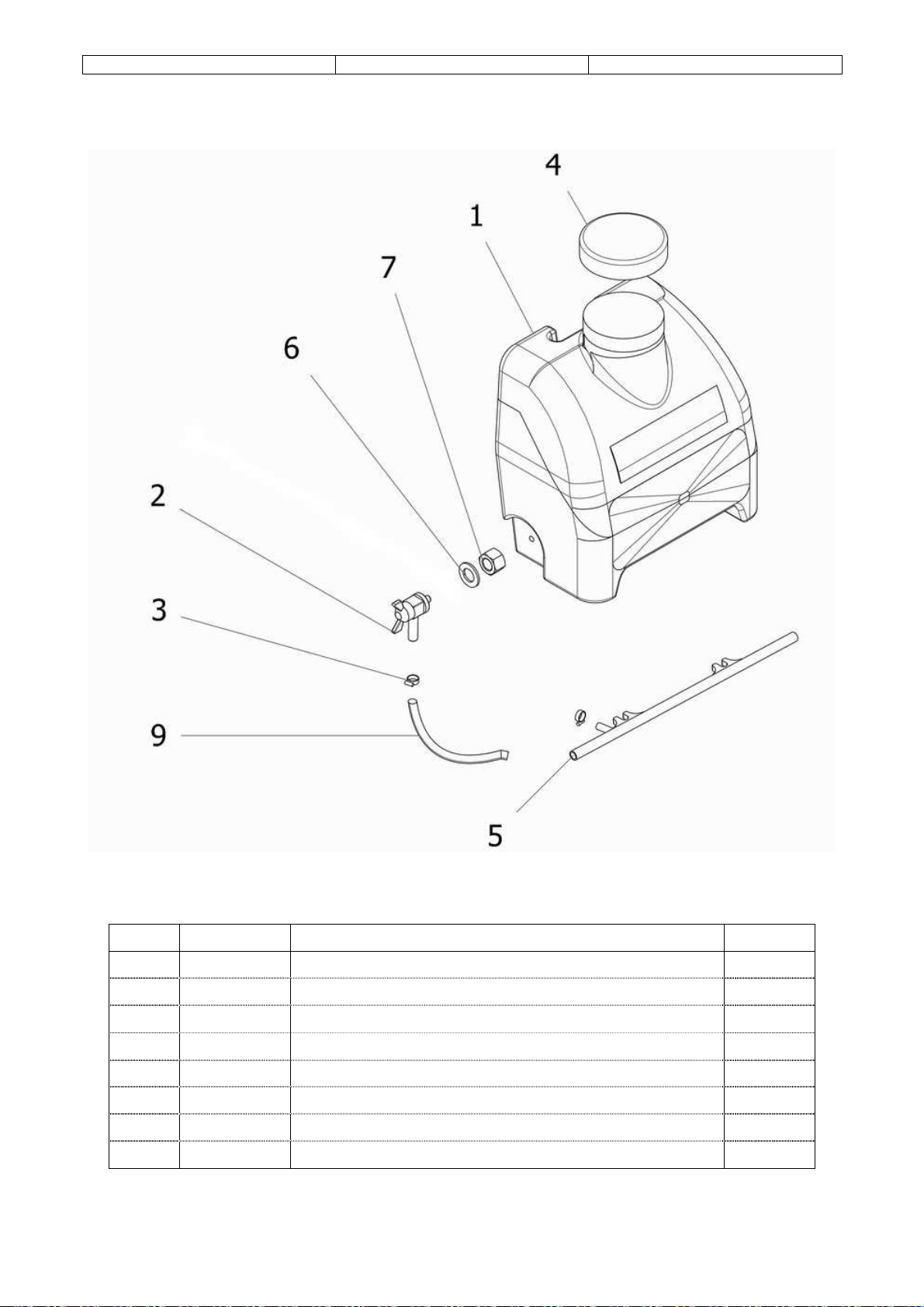

WATER TANK CB1450

POS CODE DESCRIPTION Q.TY

1 132250 WATER TANK 14 L. 1

2 152276 TAP 1

3 152114 CLAMP M12 D.12-20 ZNT 2

4 132254 WATER TANK 14 L. CAP 1

5 560481 PIPE CDB1450 1

6 151203 WASHER M20 UNI 6592 ZN 1

7 560175 NUT GAS 3/8 H15 CH 27 ZN 1

9 132205 PIPE D 10x14 0,25 ML

This manual suits for next models

1

Table of contents

Other Batmatic Power Tools manuals