Bauer Compressors MAXI VERTICUS Manual

BAUER

BAUER

COMPRESSORS

Instruction Manual and Replacement Parts List

BAUER Compressors, Inc. Phone: (757) 855-6006

1328 Azalea Garden Road Fax: (757) 855-6224

Norfolk, Virginia 23502-1944 www.bauercomp.com

MAXI VERTICUS

High Pressure Breathing Air Compressor

MVT26

October 2003 MNL- 0345

MVT26

October 2003 Section 1 Page 1

SECTION 1: INTRODUCTION

1.1 General

1.1.1 How To Use This Manual

This manual contains the operating and maintenance instructions for the Bauer Compressors, Inc. product

listed on the front cover.

All instructions in this manual should be observed and carried out as written to prevent damage or prema-

ture wear to the product or the equipment served by it.

If these operating instruction are not followed or changes are made to the product without prior written

authorization, including the use of parts not supplied by Bauer Compressors, Inc., any claims under war-

ranty shall be void. Please contact our customer service department at the number listed on the front of

this manual for assistance.

The instructions for installing this product are contained in Section A.4 of this manual. They must be

read, understood and complied with prior to operating the product.

The safety instructions applicable to this product are contained in Section A.2. They must be read, under-

stood and complied with prior to operating the product.

The instructions for long term storage (over 90 days) of this product are contained in Section A.3

Section A.5 is a set of forms which may be reproduced as needed to record operating hours, purification

cartridge adjusted operating hours, scheduled maintenance actions or suggested corrections to this man-

ual.

If your unit is equipped with nonstandard accessories and/or options, supplemental information is nor-

mally included in other documentation; i.e. OEM Manuals or additional Bauer Manuals.

Important instructions concerning the endangerment of personnel, technical safety or operator safety will

be specially emphasized in this manual by placing the information in the following types of safety notices

WARNING

Data contained in this notice must be adhered to exactly in order to avoid endangering personnel

CAUTION

Data contained in this notice must be complied with in order to avoid damage to or destruction of

the machine or its associated equipment.

NOTE

Data contained in this notice advises of technical requirements that require particular attention by

the operator or the maintenance technician

MNL- 0345

Page 2 Section 1 Base Edition

While every effort is made to ensure the accuracy of the information contained in this manual, Bauer

Compressors, Inc. will not, under any circumstances be held accountable for any inaccuracies or the con-

sequences thereof.

1.1.2 How to Use the Replacement Parts List

• The use of repair parts other than those included in the Bauer Replacement Parts Lists may create

unsafe conditions over which Bauer has no control. Such unsafe conditions can lead to accidents

that may be life-threatening, cause substantial bodily injury, and/or result in damage to the equip-

ment. Therefore, BAUER Compressors, Inc. can bear no responsibility for equipment in which

non-approved repair parts are installed.

• A lozenge ◊in the Item Number column indicates the part number for a complete assembly.

• a dagger (†) in the Qty column with or without an ellipis (…) in the Part Number column means

the part is illustrated for assembly purposes only and is not available for sale as an individual

component. This part can be obtained by ordering the complete assembly.

• AR in the Qty column means that the item is cut or manufactured to the size which the customer

specifies.

• A dash (—) in the Item Number column indicates that there is more than one part number appli-

cable to the preceding Item Number.

When placing an order for spare parts, please provide the following information to ensure delivery of the

correct parts.

Model Number Date of Manufacture

Serial Number Quantity required

Part Number Part Description

Example: Junior-E3; manufactured 1998; Serial number 32165; requiring 2 reed valves, p/n N04860.

The model number, date of manufacture and serial number can be found of the compressor unit identifi-

cation plate on the compressor unit’s frame.

Figure 1-1 Compressor Unit Identification Plate

BAUER

COMPRESSORS

BAUER COMPRESSORS, INC.

NORFOLK, VIRGINIA U.S.A

LBL-004

MODEL NO.

BLOCK NO.

CAPACITY

CFM

CHG. RATE

CFM

MOTOR HP

SPEED

RPM

SERIAL NO.

PRESSURE

PSIG

VOLTS

PH

HZ AMPS

DATE OF MANUFACTURE

DATE OF MANUFACTURE

MVT26

October 2003 Section 1 Page 3

1.1.3 Revisions and Changes

Ed.\Rev.\Change Date Notes Approval

1st Edition October 2003 JD

Ed\Rev\Change Effected Pages Ed\Rev\Change Effected Pages

MNL- 0345

Page 4 Section 1 Base Edition

1.2 Table of Contents

No. Title Page

SECTION 1: INTRODUCTION

1.1 General .......................................................................................................................................................................................1

1.1.1 How To Use This Manual......................................................................................................................................................1

1.1.2 How to Use the Replacement Parts List.................................................................................................................................2

1.1.3 Revisions and Changes ..........................................................................................................................................................3

1.2 Table of Contents .......................................................................................................................................................................4

1.3 List of Figures ............................................................................................................................................................................8

1.4 Description and Specifications.................................................................................................................................................12

1.4.1 Unit Description...................................................................................................................................................................12

1.4.2 Unit Specifications...............................................................................................................................................................13

1.4.2.1 MVT26-E3 .......................................................................................................................................................................13

1.4.2.1.1 Compressor Block, IK180II ..............................................................................................................................................13

1.4.2.1.2 Compressor Drive .............................................................................................................................................................13

1.4.2.1.3 Purification System Applicability .....................................................................................................................................13

No. Title Page

SECTION 2: OPERATIONS

2.5 Electric Motor Driven Units ....................................................................................................................................................14

2.5.1 Pre-start Checks ...................................................................................................................................................................14

2.5.2 Start-up Procedure................................................................................................................................................................14

2.5.3 Post Start Procedures ...........................................................................................................................................................14

2.5.4 Shutdown Procedures...........................................................................................................................................................14

No. Title Page

SECTION 3: MAINTENANCE AND PARTS

3.1 IK150 II and IK180 II Compressor Blocks..............................................................................................................................15

3.1.1 Description ...........................................................................................................................................................................15

3.1.1.1 Air Flow Diagram .............................................................................................................................................................15

3.1.1.2 Component Location.........................................................................................................................................................16

3.1.2 Lubrication System ..............................................................................................................................................................17

3.1.2.1 Description. .......................................................................................................................................................................17

3.1.2.2 Oil Level Check ................................................................................................................................................................18

3.1.2.3 Oil Change Interval ...........................................................................................................................................................18

3.1.2.4 Oil Capacity ......................................................................................................................................................................18

3.1.2.5 Oil Change ........................................................................................................................................................................18

3.1.2.6 Venting the Oil Pump........................................................................................................................................................19

3.1.3 Intake Filter ..........................................................................................................................................................................20

3.1.3.1 Description ........................................................................................................................................................................20

3.1.3.2 Maintenance ......................................................................................................................................................................20

3.1.4 Intermediate Separators........................................................................................................................................................22

3.1.4.1 Description ........................................................................................................................................................................22

3.1.4.2 Maintenance ......................................................................................................................................................................22

MVT26

October 2003 Section 1 Page 5

3.1.4.2.1 2nd Stage Intermediate Separator .................................................................................................................................... 22

3.1.4.2.2 3rd Stage Intermediate Separator..................................................................................................................................... 22

3.1.5 Compressor Valves and Valve Heads.................................................................................................................................. 23

3.1.5.1 Functional Description...................................................................................................................................................... 23

3.1.5.2 Initial Operational Check of the Valves............................................................................................................................ 23

3.1.5.3 General Instructions for Changing the Valves.................................................................................................................. 23

3.1.5.4 Changing the 1st Stage Valves. ........................................................................................................................................ 24

3.1.5.4.1 Removal Procedure........................................................................................................................................................... 24

3.1.5.4.2 Installation Procedure ....................................................................................................................................................... 24

3.1.5.5 Changing the 2nd and 3rd Stage Valves ........................................................................................................................... 25

3.1.5.5.1 Removal Procedure ........................................................................................................................................................... 25

3.1.5.5.2 Installation Procedure ....................................................................................................................................................... 25

3.1.5.6 Changing the 4th Stage Valves ......................................................................................................................................... 26

3.1.5.6.1 Discharge Valve Removal Procedure .............................................................................................................................. 26

3.1.5.6.2 Discharge Valve Installation Procedure........................................................................................................................... 26

3.1.5.6.3 Inlet Valve Removal and Installation .............................................................................................................................. 27

3.1.6 Repair and Troubleshooting................................................................................................................................................. 27

3.1.6.1 Repair ................................................................................................................................................................................ 27

3.1.6.2 Troubleshooting ................................................................................................................................................................ 28

3.1.7 Replacement Parts List ........................................................................................................................................................ 30

3.2 4 Stage Automatic Condensate Drain System ......................................................................................................................... 58

3.2.1 Description........................................................................................................................................................................... 58

3.2.1.1 Compressor Operating ...................................................................................................................................................... 59

3.2.1.2 Condensate Draining......................................................................................................................................................... 59

3.2.1.3 Start Unloading ................................................................................................................................................................. 60

3.2.1.4 Standstill Drainage............................................................................................................................................................ 60

3.2.1.5 Condensate Drain Piping .................................................................................................................................................. 60

3.2.1.6 Electrical Connections ...................................................................................................................................................... 60

3.2.1.7 ACD Timer ...................................................................................................................................................................... 60

3.2.1.8 Condensate Drain Separator ............................................................................................................................................. 61

3.2.1.9 ACD Maintenance ............................................................................................................................................................ 61

3.2.2 Replacement Parts List ........................................................................................................................................................ 62

3.2.3 Trouble shooting .................................................................................................................................................................. 68

No. Title Page

SECTION 4: SCHEDULING MAINTENANCE

4.1 Maintenance Schedules............................................................................................................................................................ 69

4.1.1 Initial start-up or after maintenance..................................................................................................................................... 69

4.1.2 Calendar intervals ................................................................................................................................................................ 69

4.1.3 Operating hours.................................................................................................................................................................... 70

4.1.4 Maintenance Records........................................................................................................................................................... 71

No. Title Page

SECTION 4: PURIFICATION SYSTEMS

4.1 General..................................................................................................................................................................................... 72

4.1.1 System Configurations......................................................................................................................................................... 72

4.1.2 General Purification System Procedures ............................................................................................................................. 72

4.1.3 Chamber Safety Bore........................................................................................................................................................... 73

MNL- 0345

Page 6 Section 1 Base Edition

4.1.4 Manual Condensate Drainage ..............................................................................................................................................73

4.1.5 Model, Serial Number and Part Number Identification.......................................................................................................73

4.1.5.1 Compressor Dataplate .......................................................................................................................................................73

4.1.5.2 Purification System Dataplate...........................................................................................................................................73

4.1.5.3 Cartridge Installation Dataplate ........................................................................................................................................74

4.1.6 Cartridge Operating Life......................................................................................................................................................74

4.1.6.1 Calculating the Maximum Cartridge Operating Hours.....................................................................................................75

4.1.6.2 Calculating the Adjusted Cartridge Operating Hours .......................................................................................................75

4.1.7 Air Purification Cartridge Operating Hours.........................................................................................................................77

4.2 P5 Purification System............................................................................................................................................................78

4.2.1 Component Description .......................................................................................................................................................78

4.2.1.1 Chamber ............................................................................................................................................................................78

4.2.1.2 Cartridge............................................................................................................................................................................79

4.2.1.2.1 Cartridge Construction .....................................................................................................................................................79

4.2.1.2.2 Cartridge Handling............................................................................................................................................................79

4.2.1.3 Coalescing Oil/Water Separator........................................................................................................................................79

4.2.1.4 Condensate Drain Valve ...................................................................................................................................................79

4.2.1.5 Check Valves ....................................................................................................................................................................79

4.2.1.6 Bleed Valve.......................................................................................................................................................................79

4.2.1.7 Pressure Maintaining Valve ..............................................................................................................................................79

4.2.1.8 Safety Valve ......................................................................................................................................................................80

4.2.1.9 Securus®Electronic Air Purification Monitoring System................................................................................................80

4.2.1.9.1 Securus®Cartridge ............................................................................................................................................................80

4.2.1.9.2 Securus®Indicator ............................................................................................................................................................80

4.2.2 Maintenance .........................................................................................................................................................................80

4.2.2.1 Coalescing Oil/Water Separator........................................................................................................................................80

4.2.2.2 Cartridge Replacement......................................................................................................................................................82

4.2.2.3 Leaking at the Safety Bore................................................................................................................................................82

No. Title Page

SECTION 5: COMPRESSOR UNIT DRIVE

5.1 Vertical Compressor Drive ......................................................................................................................................................88

5.1.1 Maintenance of the V-belt and Sheaves...............................................................................................................................89

5.1.1.1 Check The Sheaves. ..........................................................................................................................................................89

5.1.1.2 Check the V-belt ...............................................................................................................................................................89

No. Title Page

SECTION 6: MISCELLANEOUS

6.1 Pneumatic Valves and Controls ...............................................................................................................................................90

6.1.1 Nonadjustable Valves ..........................................................................................................................................................90

6.1.2 Pressure Maintaining Valve .................................................................................................................................................90

6.1.3 Safety Valves .......................................................................................................................................................................91

6.2 Electrical Controls and Indicators............................................................................................................................................92

6.2.1 Pressure Switch ....................................................................................................................................................................92

6.2.1.1 Operating Set Point Adjustment........................................................................................................................................92

6.2.1.1.1 Switch characteristics........................................................................................................................................................92

6.2.1.2 Indicators...........................................................................................................................................................................93

6.2.1.3 Replacement Parts List......................................................................................................................................................94

MVT26

October 2003 Section 1 Page 7

6.2.1.3.1 Electrical Parts .................................................................................................................................................................. 94

6.2.1.3.2 Indicators........................................................................................................................................................................... 95

No. Title Page

SECTION A: APPENDICES

A.1 Reference Data......................................................................................................................................................................... 96

A.1.1 Tightening Torque Values.................................................................................................................................. 96

A.1.2 Torque Sequence Diagrams ............................................................................................................................... 96

A.1.3 Conversion Formulas ......................................................................................................................................... 96

A.1.4 Approved Lubricants Chart................................................................................................................................ 97

A.1.5 Glossary of Abbreviations and Acronyms ......................................................................................................... 97

A.2 Safety ....................................................................................................................................................................................... 98

A.2.1 General Safety Precautions ................................................................................................................................ 98

A.2.2 Safety Warning Labels..................................................................................................................................... 100

A.3 Long Term Storage ................................................................................................................................................................ 101

A.3.1 General ............................................................................................................................................................. 101

A.3.2 Preparations...................................................................................................................................................... 101

A.3.2.1 Units Equipped with a Filter System ................................................................................................................................. 101

A.3.3 Preserving the Compressor .............................................................................................................................. 101

A.3.4 Preventive Maintenance During Storage ......................................................................................................... 101

A.3.5 Lubrication Oils for Preservation..................................................................................................................... 102

A.3.6 Reactivating the Compressor Unit ................................................................................................................... 102

A.4 Unpacking, Handling and Installation ................................................................................................................................... 103

A.4.1 Unpacking and Handling.................................................................................................................................. 103

A.4.2 Installation of the Compressor Unit ................................................................................................................. 103

A.4.2.1 General............................................................................................................................................................................... 103

A.4.2.2 Ventilation ......................................................................................................................................................................... 104

A.4.2.2.1Outdoor Installation......................................................................................................................................................... 104

A.4.2.2.2Indoor Installation............................................................................................................................................................ 104

A.4.2.2.3Natural Ventilation .......................................................................................................................................................... 104

A.4.2.2.4Forced Ventilation ........................................................................................................................................................... 105

A.4.2.3 Electrical Installation ......................................................................................................................................................... 106

A.4.2.3.1Electric Drive................................................................................................................................................................... 106

A.4.2.3.2Electrical Supply.............................................................................................................................................................. 106

A.5 Reproducible Forms............................................................................................................................................................... 108

A.5.1 Scheduled Maintenance Form ......................................................................................................................... 108

A.5.2 Record of Operating Hours ............................................................................................................................. 111

A.5.3 Purifier Cartridge Adjusted Operating Hours. ................................................................................................. 112

A.6 Additional Documents ........................................................................................................................................................... 113

A.6.1 Diagrams and Drawings................................................................................................................................... 113

A.6.2 Other Documents ............................................................................................................................................. 113

MNL- 0345

Page 8 Section 1 Base Edition

1.3 List of Figures

No. Title Page

Section 1: Introduction

Figure 1-1 Compressor Unit Identification Plate ....................................................................................................................2

No. Title Page

Section 2: Operations

There are no Figures in this Section

No. Title Page

Section 3: Maintenance and Parts

Figure 3.1-1 Four Stage Compressor Air Flow ........................................................................................................................15

Figure 3.1-2 Compressor Block (Front View)..........................................................................................................................16

Figure 3.1-3 Lubrication Oil System ........................................................................................................................................17

Figure 3.1-4 Oil Filler Sight Gauge..........................................................................................................................................18

Figure 3.1-5 Removing the Oil Filter Cover ............................................................................................................................19

Figure 3.1-6 Replacing the Oil Filter........................................................................................................................................19

Figure 3.1-7 Intake Filter..........................................................................................................................................................20

Figure 3.1-8 2nd Stage Intermediate Separator ........................................................................................................................21

Figure 3.1-9 3rd Stage Intermediate Separator.........................................................................................................................21

Figure 3.1-10 Valve Function.....................................................................................................................................................23

Figure 3.1-11 1st Stage Valve and Head ....................................................................................................................................24

Figure 3.1-12 2nd and 3rd Stages Valve Heads and Valves .....................................................................................................25

Figure 3.1-13 4th Stage Valve and Head....................................................................................................................................26

Figure 3.1-14 4th Stage Discharge Valve Removal ...................................................................................................................26

Figure 3.1-15 Assembly Tool.....................................................................................................................................................27

Figure 3.1-16 Using Special Tool...............................................................................................................................................27

Figure 3.1-17 Crankcase Assembly............................................................................................................................................30

Figure 3.1-18 Complete Crankshaft Assembly ..........................................................................................................................32

Figure 3.1-19 K150II 1st Stage Piston and Cylinder..................................................................................................................33

Figure 3.1-20 K180II 1st Stage Piston and Cylinder..................................................................................................................34

Figure 3.1-21 2nd Stage Piston and Cylinder Assembly............................................................................................................36

Figure 3.1-22 3rd Stage Piston and Cylinder .............................................................................................................................38

Figure 3.1-23 4th Stage Piston and Cylinder Assembly.............................................................................................................40

Figure 3.1-24 4th Stage Piston and Sleeve Assembly ................................................................................................................41

Figure 3.1-25 K180 1st Stage Valve Head .................................................................................................................................42

Figure 3.1-26 2nd Stage Valve Head..........................................................................................................................................43

Figure 3.1-27 3rd Stage Valve Head Assembly .........................................................................................................................44

Figure 3.1-28 4th Stage Valve Head Assembly .........................................................................................................................45

Figure 3.1-29 Flywheel Drive Assembly ...................................................................................................................................46

Figure 3.1-30 Intake Filter Assembly.........................................................................................................................................47

Figure 3.1-31 2nd Stage Interfilter Assembly ............................................................................................................................48

Figure 3.1-32 3rd Stage Interfilter Assembly.............................................................................................................................49

Figure 3.1-33 K150-180 II Cooling System Assembly ..............................................................................................................50

Figure 3.1-34 2nd Stage Intercooler ...........................................................................................................................................53

Figure 3.1-35 3rd Stage Intercooler............................................................................................................................................54

MVT26

October 2003 Section 1 Page 9

Figure 3.1-36 K180 1st Stage Auxiliary Cooler......................................................................................................................... 55

Figure 3.1-37 Lubricating System Assembly............................................................................................................................. 56

Figure 3.1-38 Lubricating System.............................................................................................................................................. 57

Figure 3.2-1 4 Stage Automatic Condensate Drain System..................................................................................................... 58

Figure 3.2-2 ACD Operation Diagrams ................................................................................................................................... 59

Figure 3.2-3 ACD Timer .......................................................................................................................................................... 61

Figure 3.2-4 4 Stage ACD System ........................................................................................................................................... 62

Figure 3.2-5 ACD Manifold and Valves .................................................................................................................................. 63

Figure 3.2-6 3rd Stage Condensate Drain Valve...................................................................................................................... 64

Figure 3.2-7 Oil and Water Separator Condensate Drain Valve.............................................................................................. 66

No. Title Page

Section 4: Scheduling Maintenance

There are no Figures in this Section

No. Title Page

Section 4: Purification Systems

Figure 4.1-1 Cartridge Safety Venting ..................................................................................................................................... 73

Figure 4.1-2 Compressor Unit Identification Plate .................................................................................................................. 73

Figure 4.1-3 Purification System Dataplate (typical)............................................................................................................... 74

Figure 4.1-4 Cartridge Installation Dataplate (typical) ............................................................................................................ 74

Figure 4.1-5 Correction Factor for Cartridge Operating Hours ............................................................................................... 76

Figure 4.1-6 Example Record of Adjusted Operating Hours................................................................................................... 76

Figure 4.2-1 P5 Purification System ........................................................................................................................................ 78

Figure 4.2-2 Oil and Water Separator ...................................................................................................................................... 81

Figure 4.2-3 Cartridge Replacement ....................................................................................................................................... 82

Figure 4.2-4 Oil and Water Separator ..................................................................................................................................... 83

Figure 4.2-5 27” Chamber Assembly....................................................................................................................................... 84

Figure 4.2-6 Securus®Electronic Air Purification Monitoring System ..................................................................................86

No. Title Page

Section 5: Compressor Unit Drive

Figure 5.1-1 Vertical Motor Mount (typical) ........................................................................................................................... 88

No. Title Page

Section 6: Miscellaneous

Figure 6.1-1 Pressure Maintaining Valve................................................................................................................................. 90

Figure 6.1-2 Safety Valves ....................................................................................................................................................... 91

Figure 6.2-1 Pressure Switch.................................................................................................................................................... 92

Figure 6.2-2 Electrical Parts ..................................................................................................................................................... 94

Figure 6.2-3 Indicators ............................................................................................................................................................. 95

MNL- 0345

Page 10 Section 1 Base Edition

No. Title Page

Section A: Appendices

Figure A.1-1 6 Bolt and 4 Bolt Torque Sequence .....................................................................................................................96

Figure A.1-2 Lifting Devices ..................................................................................................................................................103

MNL- 0345

Page 12 Section 1 Base Edition

1.4 Description and Specifications

1.4.1 Unit Description

The BAUER MVT26 model has an electric motor drive as the prime mover.

Standard features - 6000 psig

• BAUER Breathing Air Purification System

• Securus®Electronic Moisture Monitoring System

• Air Storage System

• Containment Fill Station

• Air Control Panel

• Carbon Monoxide Monitor

• Air-cooled Interstage Coolers and Aftercooler

• Interstage and Final Separator with Manual Drains

• Interstage and Final Relief Valves

• Belt Guard designed to meet OSHA guidelines

• Inlet Filter

• High Temperature Switch with Indicating Light

• Hourmeter

• Low Oil Pressure Switch with Indicating Light

MVT26

October 2003 Section 1 Page 13

1.4.2 Unit Specifications

All specifications are subject to change without prior notice.

1.4.2.1 MVT26-E3

Medium air

Charging Rate 25.1 scfm1

Free Air Delivery 21.0 scfm2

Inlet pressure atmospheric

Operating pressure, max. 6,000 psig

Ambient temperature range 32° to 105° F

Weight Approximately 6950 lb.

1.4.2.1.1 Compressor Block, IK180II

No. of stages 4

No. of cylinders 4

Cylinder bore, 1st stage 5.07 in. (130mm)

Cylinder bore, 2nd stage 2.367 in. (60mm)

Cylinder bore, 3rd stage 1.26 in. (32mm)

Cylinder bore, 4th stage 0.55 in. (14mm)

Piston Stroke 1.97 in.(50mm)

Intermediate pressure, 1st stage 30 - 45 psig(2 - 3 bar)

Safety valve setting, 1st stage 80 psig (5.5 bar)

Intermediate pressure, 2nd stage 200 - 230 psig (14 - 16 bar)

Safety valve setting, 2nd stage 260 psig (18 bar)

Intermediate pressure, 3rd stage 950 - 1,000 psig (65 - 70 bar)

Safety valve setting, 3rd stage 1,160 psig (80 bar)

Direction of rotation when facing flywheel CCW

Compressor speed 900 - 1350 RPM

Oil capacity 4.25 qts.(4l)

Oil Pressure 870 psig (60 bar)

Recommended oil BAUER OIL-0024

Maximum Inclination 20° in all directions

1.4.2.1.2 Compressor Drive

1.4.2.1.3 Purification System Applicability

The MVT26 is equipped with the Bauer P5 Purification System with Securus®Electronic Moisture Mon-

itoring System.

1. Based on recharging an 80 cubic foot tank from 500 to 3000 PSIG

2. Referenced to standard inlet conditions of 68°F and 36% humidity at 14.70 psia.

Voltage Frequency Phase Power RPM Type

-E3 208 - 460 VAC 60Hz 3 Φ20 Hp 3600 ODP

MNL- 0345

Page 14 Section 2 Base Edition

SECTION 2: OPERATIONS

2.5 Electric Motor Driven Units

The safety instructions applicable to this product are contained in Appendix A.2. They must be read,

understood and complied with prior to operating the product.

2.5.1 Pre-start Checks

1. Ensure that all scheduled maintenance is completed.

2. Check compressor oil level. Refer to Section 3.1.

2.5.2 Start-up Procedure

1. Complete all Pre-start checks.

2. Verify that all connections downstream of the compressor are secure.

3. Open the condensate drain valves to relieve any remaining pressure.

4. Close the condensate drain valves.

5. Apply electric power to the unit.

6. Immediately check the direction of motor rotation (CCW when viewed from the flywheel side}.

7. If rotation is incorrect, remove electrical power and refer to the Troubleshooting Section.

2.5.3 Post Start Procedures

1. Allow the compressor to build up pressure. Monitor the pressure gauge.

2. Listen to the unit as it operates. If excessive knocking or vibrations are observed shut down the unit.

3. Allow the compressor to reach full pressure.

4. Attach regulating/filling device to the fill hose assembly. Use only devices approved for the intended

service.

5. Adjust the fill pressure regulator to the proper fill pressure.

2.5.4 Shutdown Procedures

1. Verify all bottle valves and fill valves are closed.

2. Remove electrical power.

3. After the compressor drive stops, open the condensate drain valves to relieve any remaining pressure

and drain any moisture from the intermediate separators and the oil and water separator.

4. Close the condensate valves.

5. If the compressor is to remain idle for six months or longer, refer to the Appendix titled, Long Term

Storage for preservation instructions.

CAUTION

Minimum bend radius for the fill hose is 1½ inches. Less than this will cause damage to or failure

of the fill hose. Place the bottle so that the bend radius of the hose is greater than 1½ inches.

MVT26

October 2003 Section 3 Page 15

SECTION 3: MAINTENANCE AND PARTS

3.1 IK150 II and IK180 II Compressor Blocks

3.1.1 Description

The IK150 II and IK180 II compressors are used to compress air up to 5000 psi.

Both compressors are four cylinder, four stage air cooled, oil lubricated reciprocating compressors. The

4th stage cylinder is lubricated by means of the forced feed lubrication system, while the other cylinders

are splash lubricated. The cylinders are arranged 90° apart, with the 1st and 2nd stage, and the 3rd and 4th

stage opposite each other. These compressor blocks are particularly suitable for continuous operation

because of their rugged design and corrosion resistant intermediate filter and cooler assemblies.

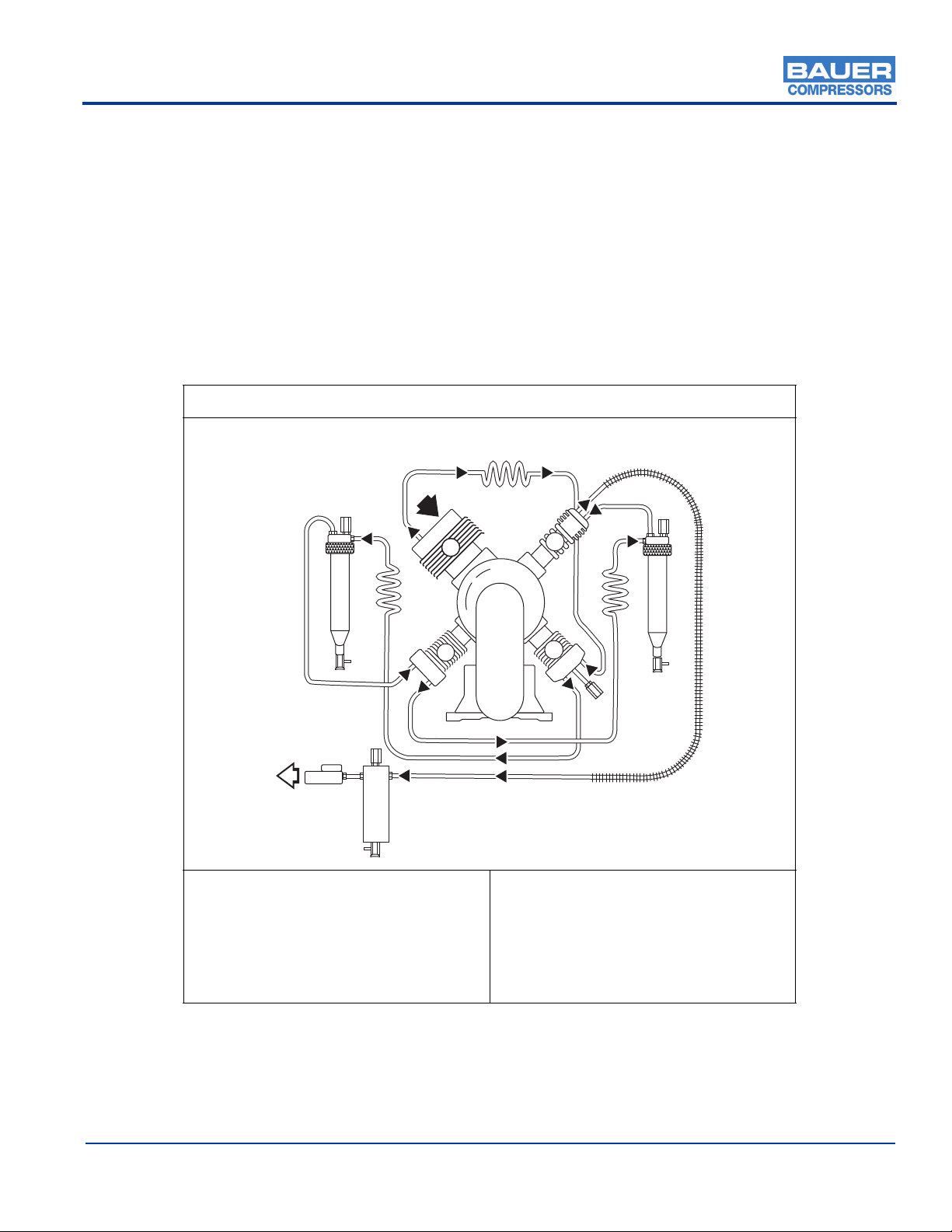

3.1.1.1 Air Flow Diagram

Figure 3.1-1 Four Stage Compressor Air Flow

1. Intake Manifold

2. 1st Stage Cooler

3. 2nd Stage Cooler

4. 3rd Stage Cooler

5. Aftercooler

6. 2nd Stage Separator

7. 3rd Stage Separator

8. Final Separator

9. Manual Condensate Drain Valve

10. Safety Valves

11. Pressure Maintaining Valve (PMV)

12. Compressed Air Outlet

I

III

IV

II

1

2

34

10

6

9

1011

1

28

9

5

7

10

9

10

MNL- 0345

Page 16 Section 3 Base Edition

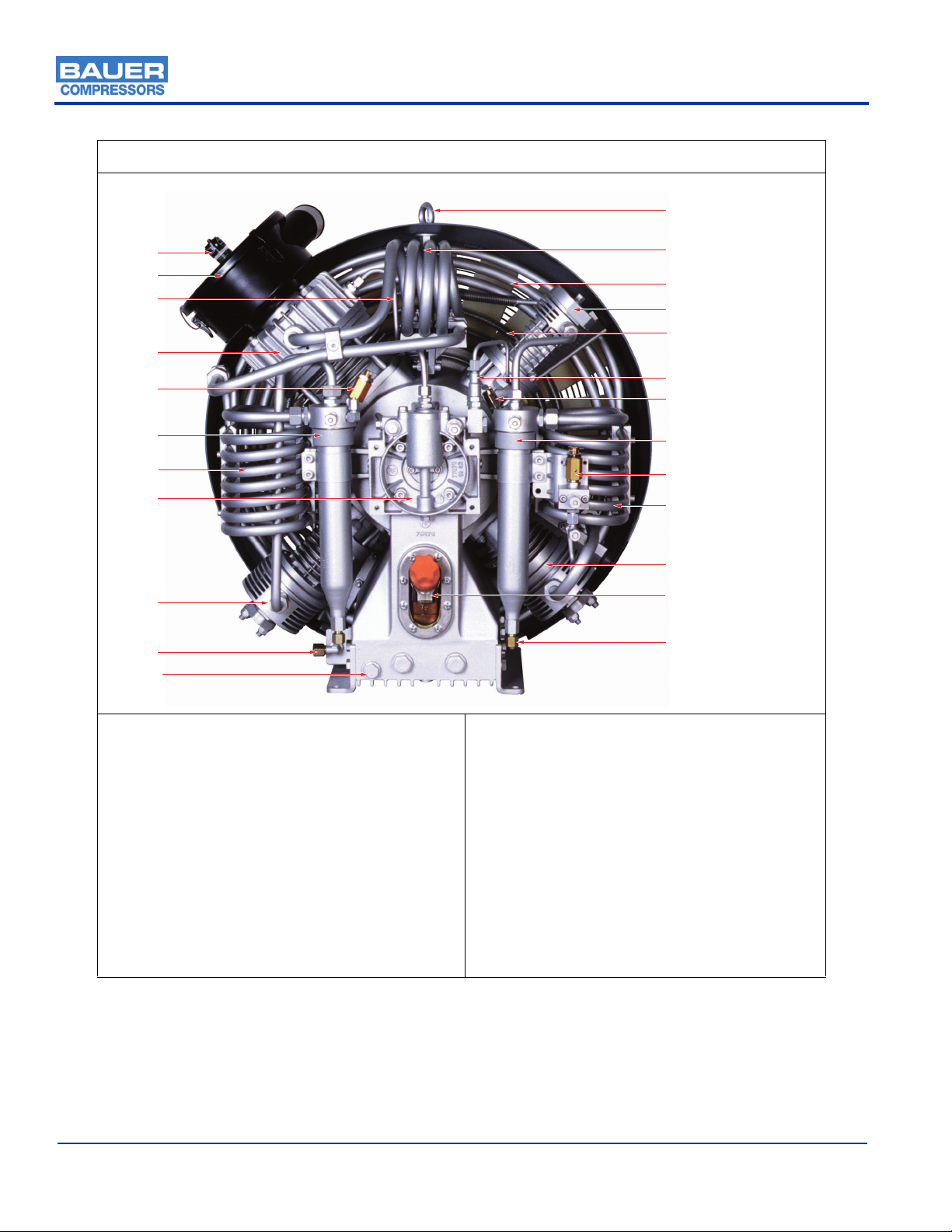

3.1.1.2 Component Location

Figure 3.1-2 Compressor Block (Front View)

1. Service Indicator

2. Intake Filter

3. Crankcase Vent Feedback Line

4. 1st Stage Cylinder

5. 2nd/3rd Inter Stage Pressure Valve

6. 2nd Stage Separator

7. 2nd Stage Cooler

8. Oil Pump Housing

9. 3rd Stage Cylinder

10. Compressed Air Outlet

11. Oil Drain Plug

12. Lifting Eyebolt

13. 1st Stage Auxiliary Cooler (IK180II Only)

14. 1st Stage Inter Cooler

15. 4th Stage Cylinder

16. 4th Stage After Cooler

17. Oil Pressure Regulating Valve

18. 3rd/4th Inter Stage Pressure Valve

19. 3rd Stage Separator

20. 1st/2nd Inter Stage Pressure Valve

21. 3rd Stage Cooler

22. 2nd Stage Cylinder

23. Oil Filler with Sight Glass

24. Condensate Outlet

1

2

3

4

5

6

7

8

9

10

12

11

13 (IK180II Only)

14

15

16

17

18

19

20

21

22

23

24

MVT26

October 2003 Section 3 Page 17

3.1.2 Lubrication System

3.1.2.1 Description.

The compressor is provided with forced-feed lubrication. The oil pressure is produced by a low revving

gear pump. The oil pressure is between 44 psi and 87 psi (3 to 6 bar).

(See Figure 3.1-3). The oil pump (1) is coupled to and driven by the crankshaft. It pumps oil from the

crankcase through an oil filter (2) and the oil pressure regulating valve (3) to the 4th stage cylinder. The

oil is then distributed by the guide piston of the 4th stage and lubricates all the moving parts of the com-

pressor block. The oil pressure sensor (5) allows mounting for an optional oil pressure gauge or electronic

pressure monitoring.

CAUTION

This oil pump must be operated in the correct direction of rotation, other wise no oil pressure will

be built up and the compressor may be damaged.

Figure 3.1-3 Lubrication Oil System

1. Oil Pump

2. Oil Filter

3. Oil Pressure Regulating Valve

4. Injection Line to 4th Stage

5. Oil Pressure Sensor

1

2

3

4

5

MNL- 0345

Page 18 Section 3 Base Edition

3.1.2.2 Oil Level Check

(See 3.1-4). Check the oil level at the oil filler sight gauge on the compressor block every day before put-

ting the compressor into operation. Oil level must never be below the minimum mark molded into the

sight gauge as this will cause severe damage due to lack of lubrication.Overfilling is prevented by the

design of the filler neck; i.e. oil should be filled right to the edge of the opening

3.1.2.3 Oil Change Interval

The synthetic oil should be changed every 2,000 operating hours or biennially, whichever is reached first.

3.1.2.4 Oil Capacity

The oil capacity is approximately 6.5 quarts (6.0 liters). The amount of oil between the minimum and

maximum marks is approximately 1.7 quarts (1.6 liters).

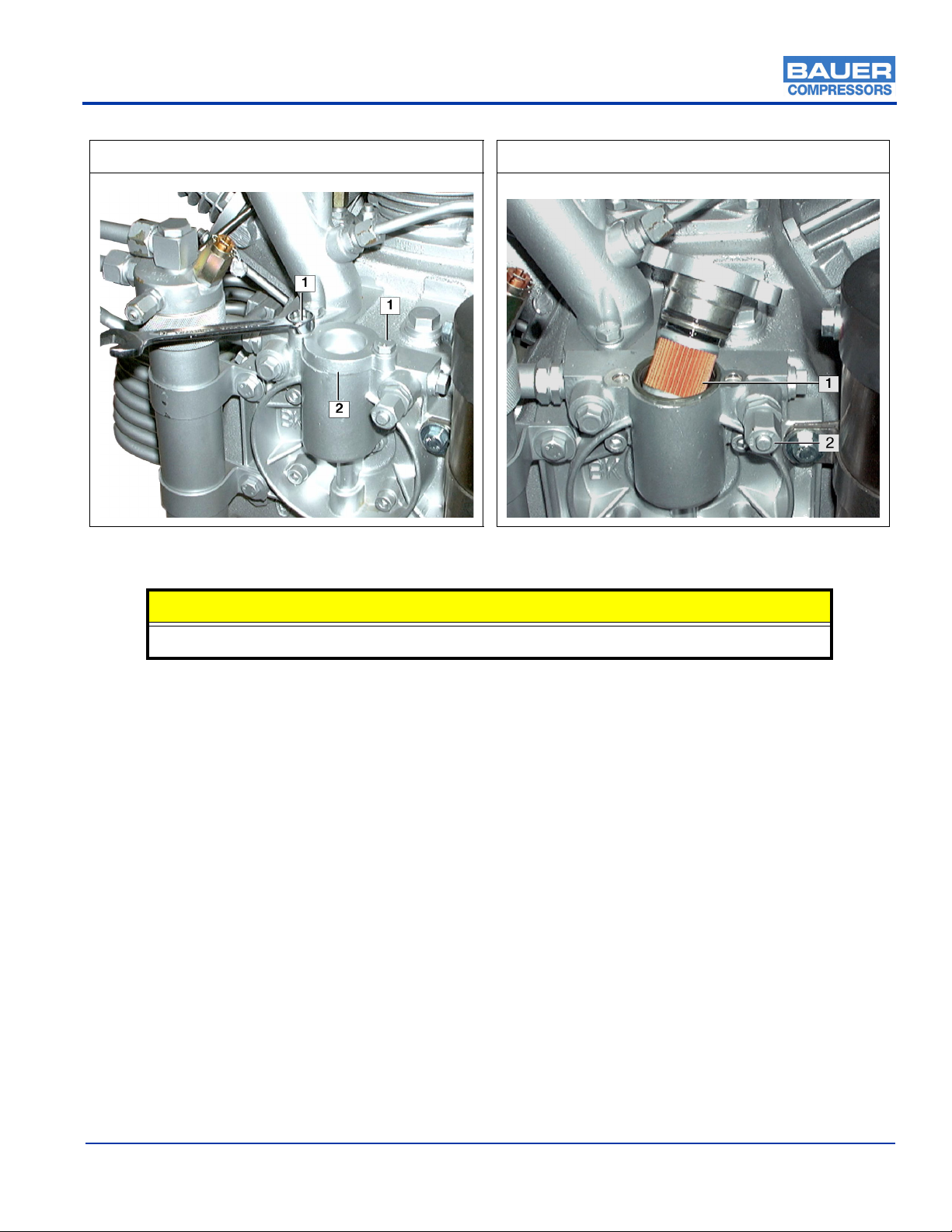

3.1.2.5 Oil Change

1. Run the compressor until it is warm.

2. Remove cap from Oil Filler Sight Gauge.

3. (See 3.1-2) Open the Oil Drain Plug. (11)

4. (See Figure 3.1-5). Remove two bolts (1) with a 13mm wrench. Remove cover (2).

5. (See Figure 3.1-6). Remove the Oil Filter (1) from the rubber gasket at the cover.

6. Mount a new filter element and replace and fasten cover.

7. Fill new oil through filler neck to the Maximum mark on the Oil Fill Sight Gauge.

8. Pour oil in slowly, wait a few minutes until the level settles then replace cap in the Oil fill Sight

Gauge.

9. Return the unit to operation.

Figure 3.1-4 Oil Filler Sight Gauge

CAUTION

Replace the oil filter at every oil change, otherwise when the filter becomes clogged a bypass valve

opens and the oil circulates without being filtered.

Ma

x

Min

MVT26

October 2003 Section 3 Page 19

3.1.2.6 Venting the Oil Pump

(See 3.1-6). If after the start of the compressor no oil pressure builds up, venting the oil pump may be

necessary, especially after maintenance and repair work. It may also be necessary if the unit has been

operated in the wrong direction of rotation.

1. With the unit running, open the condensate drain valves.

2. Open Oil Pump Vent Plug (2) and wait until oil comes out bubble free.

3. Replace Oil Vent Plug.

Figure 3.1-5 Removing the Oil Filter Cover Figure 3.1-6 Replacing the Oil Filter

CAUTION

To avoid damage after maintenance the following measures should be strictly adhered to.

This manual suits for next models

1

Table of contents

Other Bauer Compressors Air Compressor manuals

Popular Air Compressor manuals by other brands

DeWalt

DeWalt D55270-1 instruction manual

Parkside

Parkside PKZ 180 B2 Translation of the original instructions

Hitachi

Hitachi WHP09500AEDPC9EQ instruction manual

Champion

Champion CCE10 Operation maintenance manual & parts list

Mangar

Mangar Airflo 12 User instructions

GreenWorks

GreenWorks 4101302 user manual