Bauer Kompressoren B-SAFE 300 Guide

Operating manual and

Spare parts list

Fail-safe Filling Ramp

Operating Manual wB-SAFE 300

i

INTRODUCTION

This manual contains information and instructions for the service

and maintenance of the following type of fail-safe filling ramps:

In order to avoid damage or premature wear and tear of the

machine, strictly follow the prescribed operating instructions.

The defects and damages caused by the failure to follow these

instructions are not covered by the guarantee.

WARNING

! Pneumatic high pressure system !

Edition January 2012

W2012 BAUER Kompressoren GmbH, München

All rights reserved.

B-SAFE 300

Operating Manual wB-SAFE 300

ii

TABLE OF CONTENTS

1. DESCRIPTION 1................................................................................

2. COMPOSITION 1...............................................................................

2.1. FILLING CHAMBER 1..............................................................................

2.2. FILLING ACCESSORIES 2...........................................................................

2.3. PROPORTIONAL/SOLENOID VALVE 2.................................................................

2.4. AUTOMATIC DEPRESSURISATION SYSTEM 2...........................................................

2.5. EMERGENCY STOP 2.............................................................................

2.6. ELECTRONIC CONTROL FOR FILLING 2...............................................................

3. OPERATING PRINCIPLE 10........................................................................

3.1. B-SAFE 300 WITH PROPORTIONAL VALVE, 10..........................................................

3.2. B-SAFE 300 WITH SOLENOID VALVE AND TWO PRESSURE RANGES 11......................................

4. TECHNICAL CHARACTERISTICS 12.................................................................

5. INSTALLATION 13...............................................................................

5.1. INSTALLATION ROOM 13...........................................................................

5.2. FITTING 13......................................................................................

5.3. CONNECTIONS 13.................................................................................

5.4. SECURE FILLING STATION, MODEL 14.................................................................

6. SAFETY MEASURES 15...........................................................................

6.1. WARNING NOTICES AND SIGNS 15...................................................................

6.2. SIGNS FOR SAFETY INSTRUCTIONS 15.................................................................

6.3. BASIC SAFETY INSTRUCTIONS 15.....................................................................

6.4. SAFETY REGULATIONS (VALID IN FRANCE) 16..........................................................

7. ACTIVATION/OPERATION 19......................................................................

7.1. ACTIVATION 19..................................................................................

7.2. FILLING 19......................................................................................

7.3. USING THE TRACEABILITY OPTION 21.................................................................

8. MAINTENANCE 23...............................................................................

8.1. PROOF OF MAINTENANCE 23.......................................................................

8.2. INSTRUCTIONS 23.................................................................................

8.3. MAINTENANCE WORKS 23.........................................................................

9. TRANSPORT 23..................................................................................

10. STORAGE 23....................................................................................

11. ANNEXE 25.....................................................................................

11.1. QUICK START 25..................................................................................

11.2. PROGRAMME STRUCTURE 26.......................................................................

11.3. PROGRAMME STRUCTURE – TRACEABILITY 27..........................................................

11.4. LISTS 29........................................................................................

11.5. PNEUMATIC DIAGRAMS 31.........................................................................

11.6. WIRING DIAGRAM 35..............................................................................

Operating Manual wB-SAFE 300

iii

TABLE OF FIGURES

Fig. 1 B-SAFE 300 with integrated filling ramp (optional) 1....................................................

Fig. 2 Screen 2.......................................................................................

Fig. 3 Navigation keys 3................................................................................

Fig. 4 Main page 3....................................................................................

Fig. 5 Main page: filling not allowed (1/2) 3................................................................

Fig. 6 Main page: filling not allowed (2/2) 3................................................................

Fig. 8 MAINTENANCE page 4............................................................................

Fig. 9 PASSWORD page 4...............................................................................

Fig. 10 Alphanumeric keyboard 5.........................................................................

Fig. 11 SETTINGS page 5................................................................................

Fig. 12 ACTIVE ALARM LIST page 6........................................................................

Fig. 13 Alarms HISTORY page 6...........................................................................

Fig. 14 Main page – traceability 7.........................................................................

Fig. 15 PASSWORD page – traceability 7....................................................................

Fig. 16 LOGIN CHANGE page – traceability 7................................................................

Fig. 17 SETTINGS page – traceability 8.....................................................................

Fig. 18 SCAN CYLINDERS page 8..........................................................................

Fig. 19 SCAN CYLINDERS – EXAMPLE page 8................................................................

Fig. 20 2D code reader 8................................................................................

Fig. 21 ACTIVE ALARM LIST page 9........................................................................

Fig. 22 LAST FILLING page 9.............................................................................

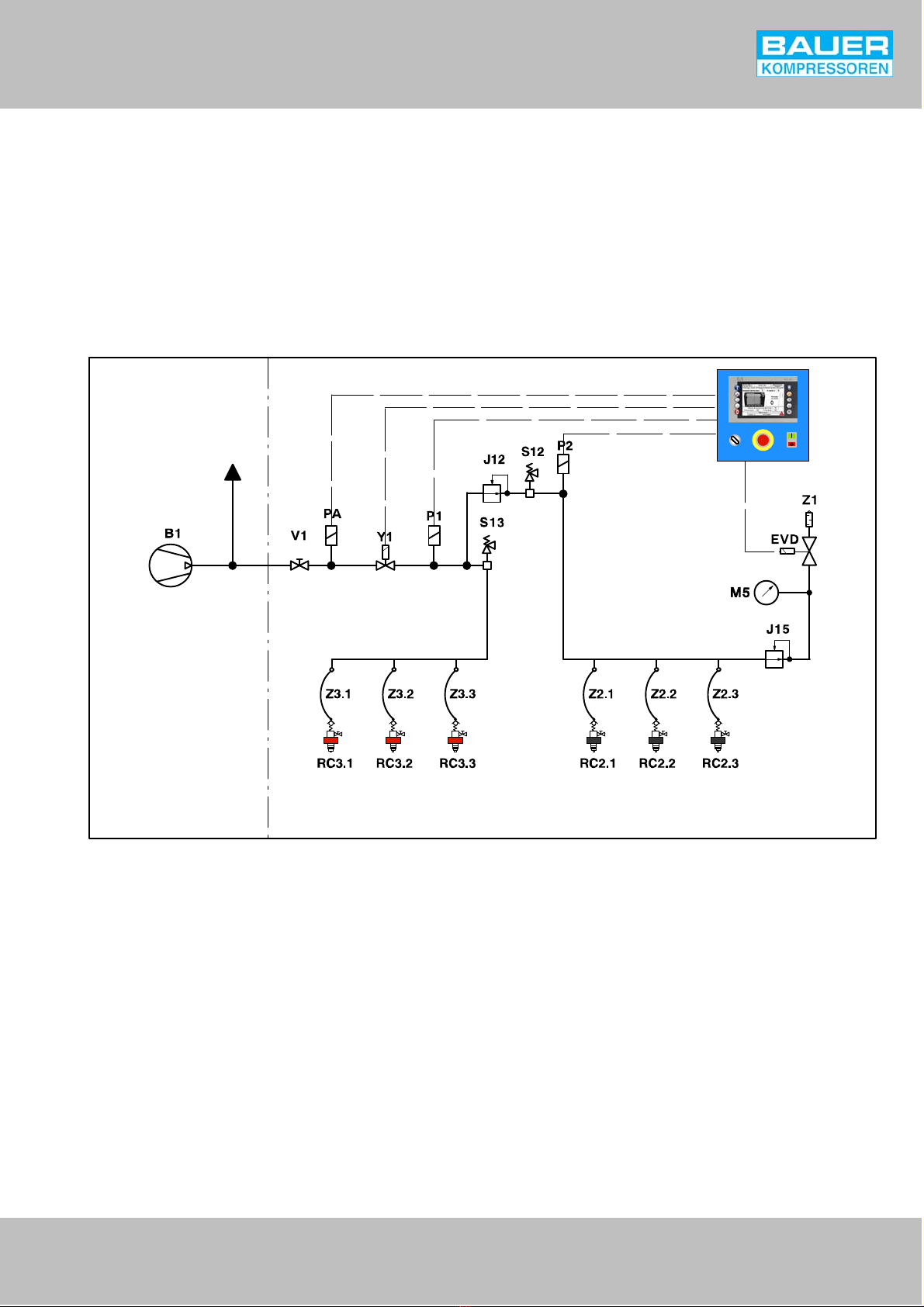

Fig. 23 Pneumatic diagram, B-SAFE 300 with proportional valve and 2 pressure ranges. 10............................

Fig. 24 Pneumatic diagram, B-SAFE 300 with solenoid valve and two pressure ranges. 11.............................

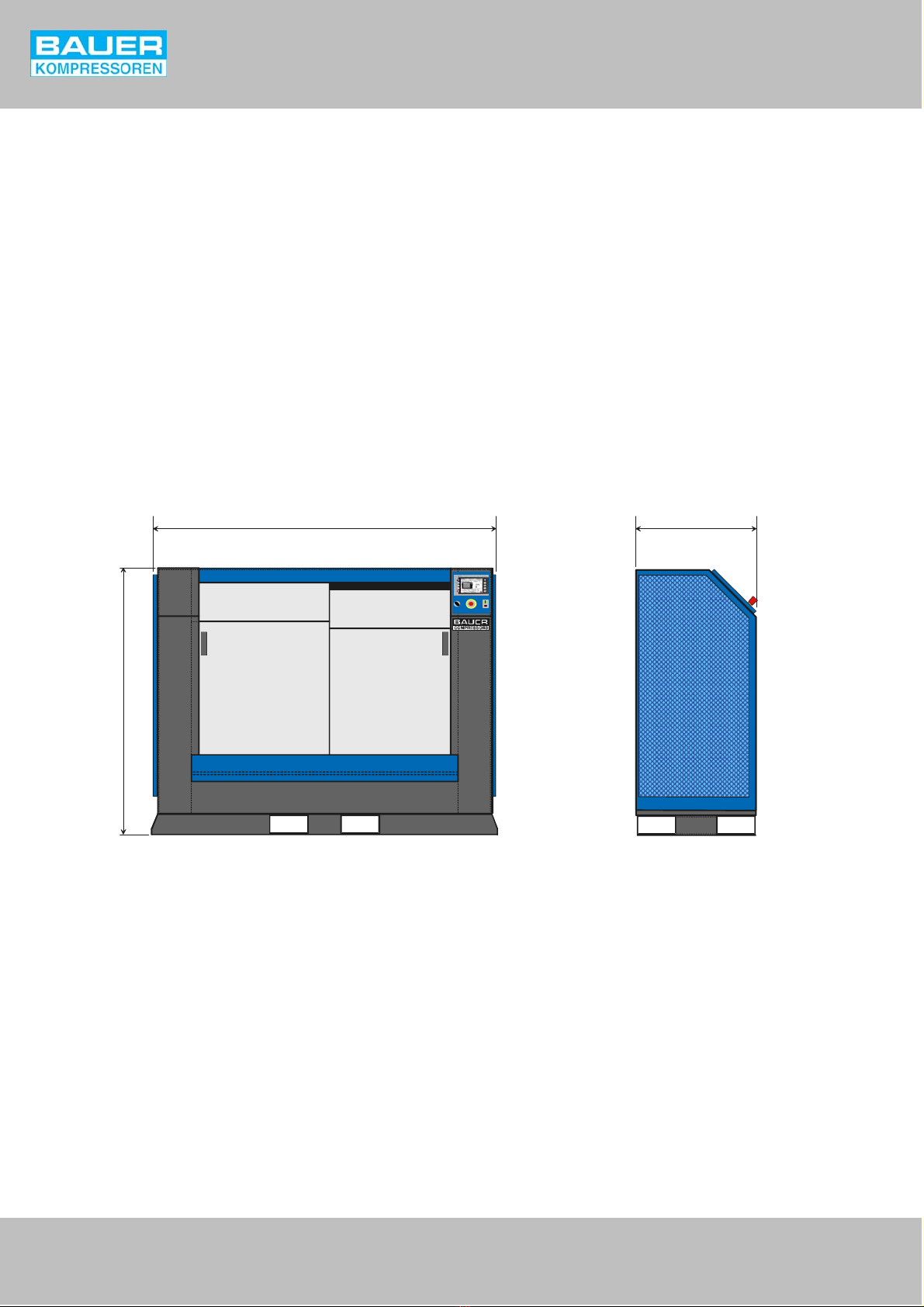

Fig. 25 Dimensions (in mm) 12.............................................................................

Fig. 26 Minimum distances and hazardous areas 13............................................................

Fig. 27 Secure filling station 14............................................................................

Fig. 28 Control panel 19..................................................................................

Fig. 29 Connecting the compressed air cylinders 20............................................................

Fig. 30 International fitting 20.............................................................................

Fig. 31 Filling the compressed air cylinders 20................................................................

Fig. 32 Removing the compressed air cylinders 21.............................................................

Fig. 33 2D code reader 21................................................................................

Fig. 34 Scanned labels _ example 21........................................................................

Operating Manual wB-SAFE 300

iv

INDEX

A

Activation, 19

Alarms, 6

Annexe, 25

Automatic depressurisation, 2

C

Connections, 13

D

Dimensions (in mm), 12

E

Electronic control, 2

Active alarm list, 6

History, 6

Last filling page, 9

Machine references, 4

Main page, 3

Maintenance page , 4

Password, 4

Settings, 5

Emergency stop, 2

F

Filling, 19

Filling accessories, 2

Filling chamber, 1

Fillingvalves, 2

Fitting, 13

H

Hazardous areas, 13

History, 6

I

Installation, 13

L

Labels, 8

Lists, 29

Alarms, 29

Filling statuses, 29

Messages on the bottom of the screen, 29

Save example, 29

M

Maintenance, 4, 23

Flexible hoses for filling, 23

Maintenance works, 23

Proof of maintenance, 23

Regulator, 23

Safety valves, 23

Minimum distances, 13

O

Operation, 10

P

Pneumatic diagram, 10, 11

Pneumatic diagrams, 31

Proportional valve, 2

Q

Quick start, 25

R

Regulation, 16

Operating Manual wB-SAFE 300

v

INDEX

S

Safety, 15

Save, 22

Scanner, 8

Secure filling station, 14

Settings, 5

Traceability option, 8

Solenoid valve, 2

Start-up, 19

Storage, 23

T

Technical characteristics, 12

Traceability, 7

Filling the cylinders, 21

Login, 7

Settings, 8

Transport, 23

U

USB, 9

USB Key, 9

W

Wiring diagram, 35

Operating Manual wB-SAFE 300

vi

Diagrams: Code

Pneumatic diagram, B-SAFE with solenoid valve, flexible hoses and two pressure ranges ISP 0175-A

Pneumatic diagram, B-SAFE with solenoid valve for integrating a filling panel ISP 0176-A

Pneumatic diagram, B-SAFE with proportional valve, flexible hoses and two pressure ranges ISP 0173-A

Wiring diagram, B-SAFE with proportional valve for integrating a filling panel ISP 0174-A

Wiring diagram, B-SAFE ISE 0236

Spare parts catalogue: Code

B-SAFE 300 G71.2

Modification notice

The modifications with respect to the previous edition are shown to the right of a vertical line.

Modification no. Modification date

0January 2012, first edition

Operating Manual wB-SAFE 300

1

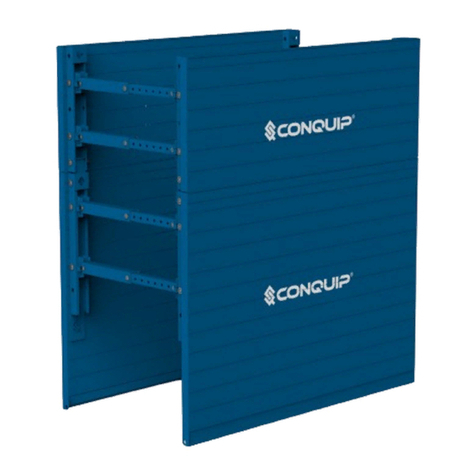

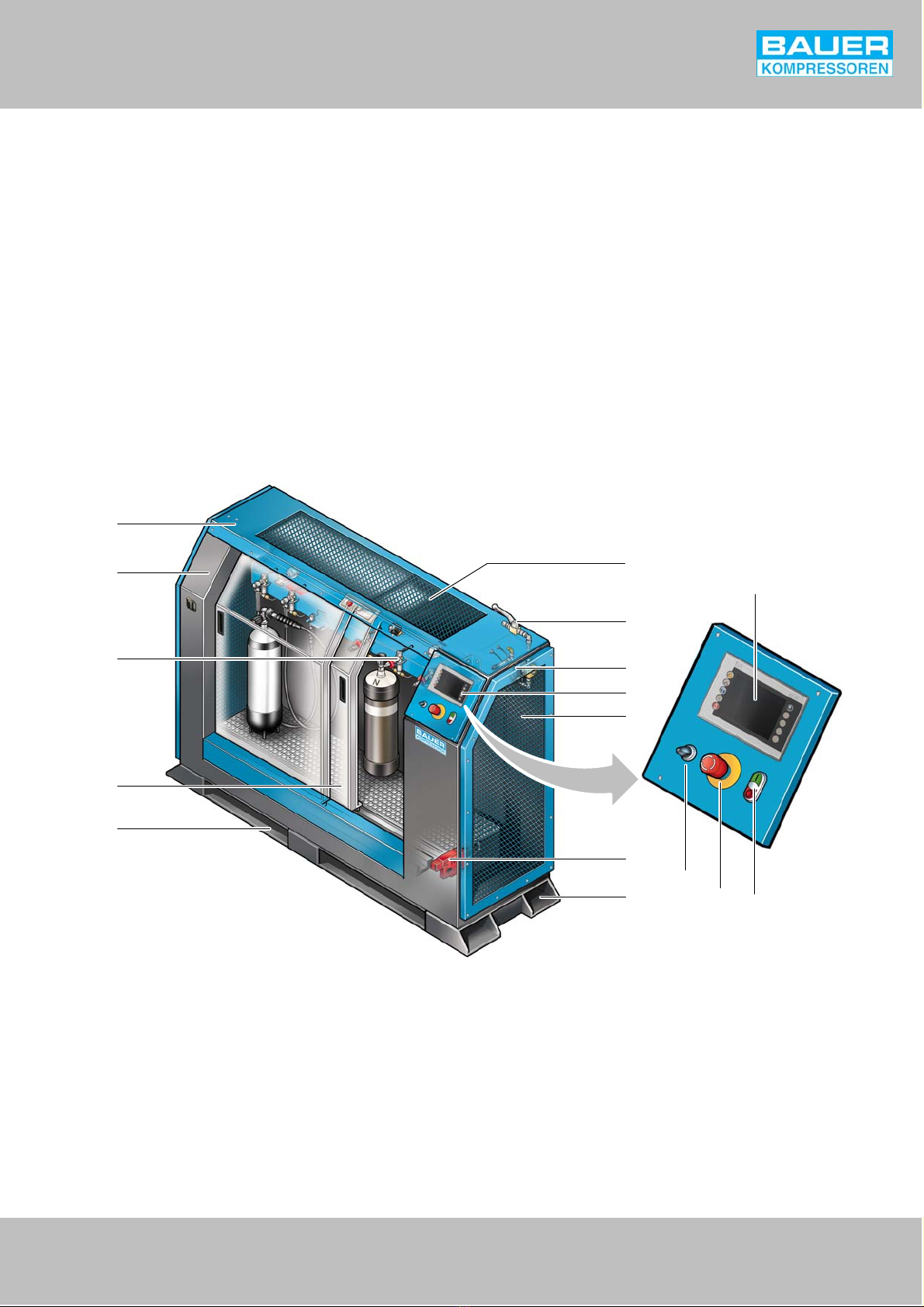

1. DESCRIPTION

The B-SAFE 300 fail-safe fill ramp can be used, with any type of

breathing air compressor, for the purpose of safe and controlled

filling of breathing air cylinders.

An enclosed filling chamber protects the operator from cylinder or

flexible hose explosions during the filling process. In addition,

electronic control allows precise configuration of the filling.

2. COMPOSITION

The B-SAFE 300 ramp consists of the following main components:

wExplosion-proof filling chamber

wFilling accessories

wProportional/solenoid valvea)

wAutomatic depressurisation system

wElectronic control for filling

2.1. FILLING CHAMBER

The body of the enclosed safety chamber, built using steel sheets,

is extremely stable:

wTwo explosion-proof sliding doors protect the filling chamber

where the cylinders are connected.

wThe automatic locking system of the doors prevents the doors

from opening during the filling of cylinders. At the same time,

it prevents the filling of cylinders while the doors are open.

wOpenings on the sides and top of the ramp allow a controlled

release of compressed air in case of an explosion of a cylinder or

a flexible hose.

Openings for handling are provided on all sides to facilitate the

transport.

1

2

4

5

7

6

8

9

512 13

14

11

10

6

3

Fig. 1 B-SAFE 300 with integrated filling ramp (optional)

1 Body

2 Name plate

3 Filling valves

4 Sliding door

5 Openings for handling

6 Openings for air release

7 Manual inlet valve

8 Proportional valve

9 Control panel

10 Door locking system

11 Main switch

12 Emergency stop

13 On/Off switch with light indicator

14 Touch screen

a) Option

Operating Manual wB-SAFE 300

2

2.2. FILLING ACCESSORIES

In its standard configuration, the B-SAFE filling ramp is equipped

with flexible hoses and filling valves.

The B-SAFE ramp is available without any accessories or with an

integrated BAUER external filling ramp upon request. All the BAUER

external filling ramps that are available for the B-SAFE are equipped

with filling valves and direct filling valves.

The B-SAFE ramp is available with:

wpressure range (PN200 or PN300), or

wtwo pressure ranges (PN200 and PN300).

The second pressure range is obtained using a regulator which

allows you to fill two cylinders with different pressures

simultaneously.

The B-SAFE 300 ramp allows simultaneous filling of a maximum of:

w6 diving cylinders, or

w10 HP cylindersa) .

The number of connections must be determined according to the

output of the compressor as the time taken to fill the cylinders

depends on the latter.

2.3. PROPORTIONAL/SOLENOID VALVE

The B-SAFE filling ramp is available with:

wa proportional valve (can be used only with a storage bench), or

wa solenoid valve.

2.3.1. Proportional valve

The proportional valve helps regulate the speed used to fill the

cylinders between 20 and 50 bar/min. This reduced filling speed

limits the risk of explosion and wear and tear of the cylinders,

particularly of those made of composite materials.

The filling speed is adjusted using electronic controls. Refer to

Fig. 11, page 5.

2.3.2. Solenoid valve

The solenoid valve is used to open or isolate the internal pneumatic

circuit. Thus, it only allows direct filling of cylinders i.e. the time

required for filling depends directly on the output of the compressor.

2.4. AUTOMATIC DEPRESSURISATION SYSTEM

The B-SAFE ramp can be equipped with a depressurisation system

which automatically aerates the internal pneumatic circuit when

adoor is opened or emergency stop function is activated.

The compressed air in the cylinders does not escape into the

atmosphere during the depressurisation as the filling valves are

fitted with a non-return valve. In order to be able to disconnect the

cylinders with minimum risk, the valves are also provided with an air

valve that opens when the valve is loosened.

2.5. EMERGENCY STOP

In case of danger, it is possible to stop filling the cylinders

immediately by pressing the emergency switch (12, Fig. 1). It

interrupts the electric supply and:

wthe proportional valve or solenoid valve shuts down and the

internal pneumatic circuit is depressurised,

wthe doors remain locked,

wthe indicator light flashes and the message “Emergency stop” is

displayed at the bottom of the screen.

To restart the B-SAFE ramp, rotate the emergency switch (12, Fig. 1)

by a quarter turn to the left and then press the “0” key (13).

Theindicator light stops flashing and the message “EMERGENCY

STOP” disappears from the screen. The filling of cylinders can start

again.

2.6. ELECTRONIC CONTROL FOR FILLING

The electronic control system has a 6-inch touch screen (Fig. 2) for

displaying and regulating filling parameters.

Fig. 2 Screen

5

1

23 4

1 Stand by button

2 Double status bar

3 Touch screen

4 Alarm indication

5 Navigation keys

2.6.1. Communication with the compressor

The electronic control system of the B-SAFE ramp can be connected

to that of the compressor. This allows remote start or shut down of

the compressor (only possible with direct filling i.e. without storage

or proportional valves).

In addition, the B-SAFE control panel can display a compressor

breakdown message. In such a case, the Alarm sign is displayed and

the message “Cycle interrupted: Comp. error” is displayed to

indicate that the compressor has shut down. The filling process is

stopped. After the repair work, the error must be acknowledged by

pressing the red button “0”. The flashing stops and the error

message disappears. The filling process can start again.

a) Only if combined with the standard filling accessories (maximum diameter of cylinders = 18 cm, maximum height = 60 cm)

Alarms

Settings

Machine

references

Password

ON-OFF and

Logout

Main

page

Export

files

Scanner

Option:

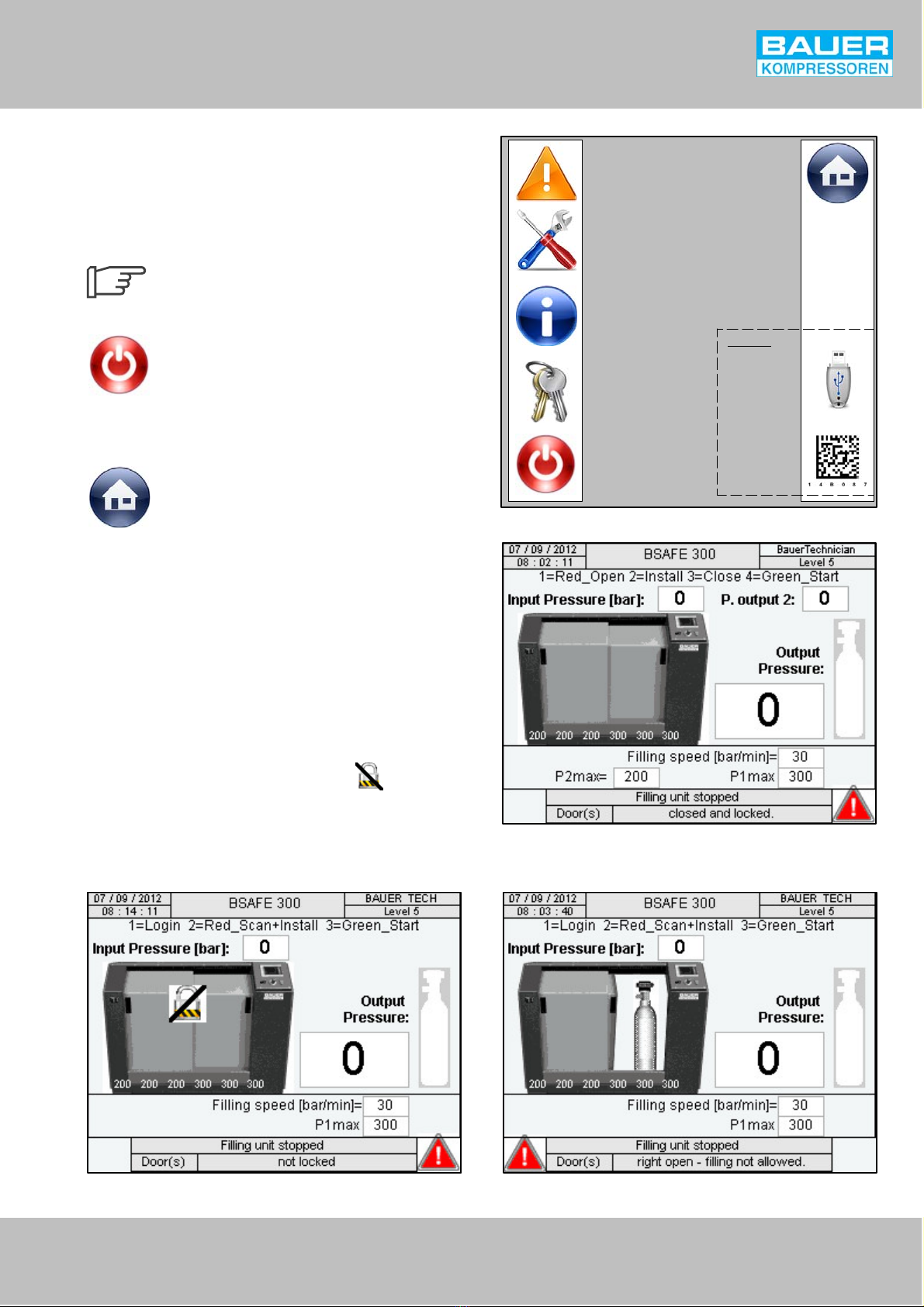

Fig. 3 Navigation keys

Fig. 4 Main page

Operating Manual wB-SAFE 300

3

2.6.2. Navigation

The electronic control panel has 6 to 8 navigation keys (Fig. 3)

depending on the version installed; the “Export files” and “Scan”

keys are available only with the Traceability option (see page 8).

Also refer to chapters 11.2. “Program structure” and 11.3. “Program

structure – Traceability” provided in the annexe.

On the entire screen, the active fields (values, text,

arrows, buttons, etc.) are black and the inactive or

inaccessible fields are grey.

ON / OFF

Unlike other navigation keys, the function of the ON/OFF switch is

not to open a window but to switch on or switch off the screen and

exit the current access level.

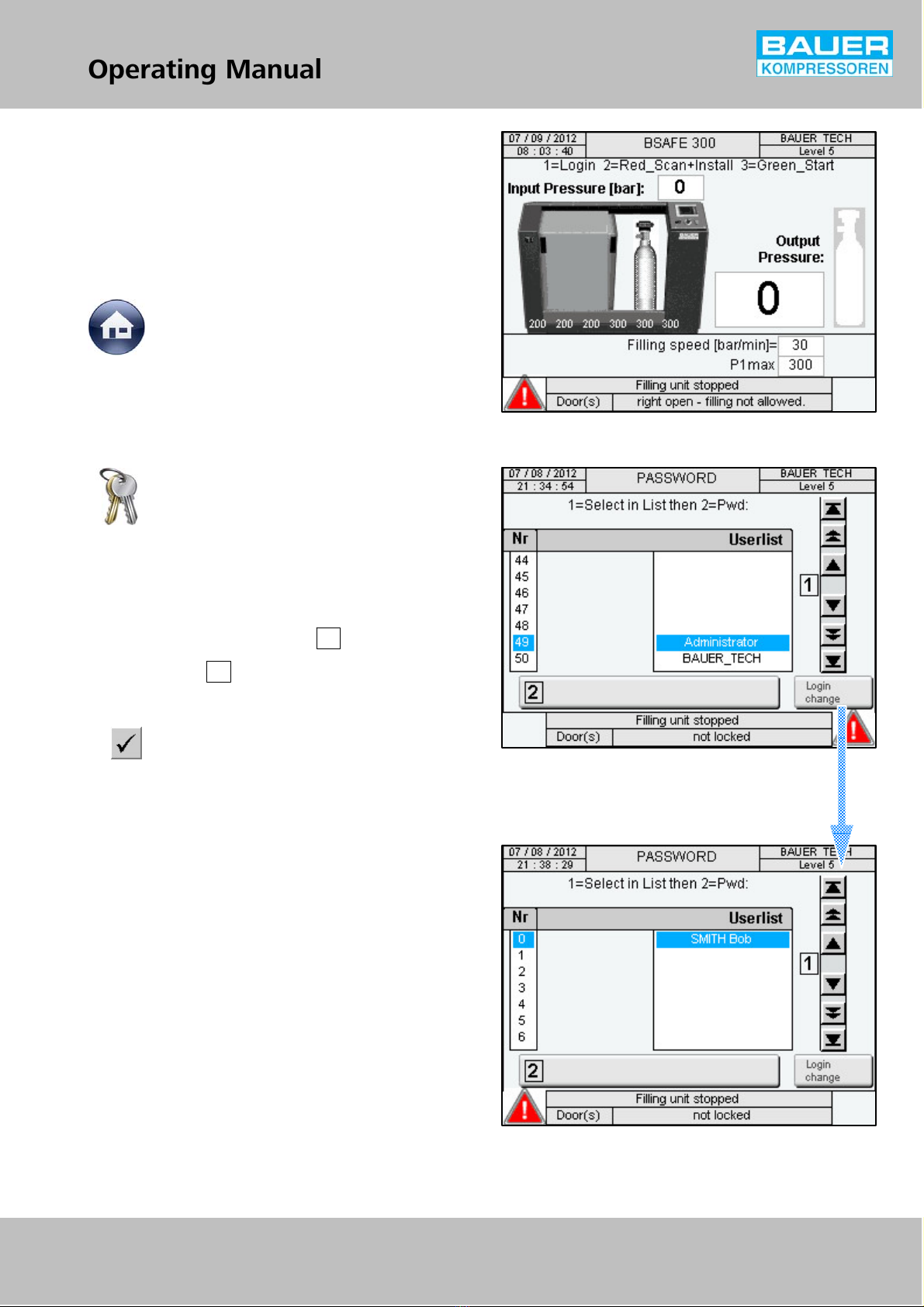

Main page

The main page (Fig. 4) comprising the basic information related to

the status of B-SAFE 300 ramp is displayed during every start-up.

This information includes the supply pressure (input pressure), filling

pressure(s) and filling speed (only for proportional valves) as well

asthe doors status.

– The output pressure (P1) is regulated through the software.

– The output pressure 2 (P2, option) is mechanically regulated

using a regulator.

Filling not allowed

In case the filling is not allowed the doors and locks can be regulated

from the main page. Example of Filling not allowed:

– Doors closed and unlocked – icon flashing (Fig. 5)

– Doors open – message at the bottom of the screen “Right open

- filling not allowed” (Fig. 6 )

Fig. 5 Main page: filling not allowed (1/2) Fig. 6 Main page: filling not allowed (2/2)

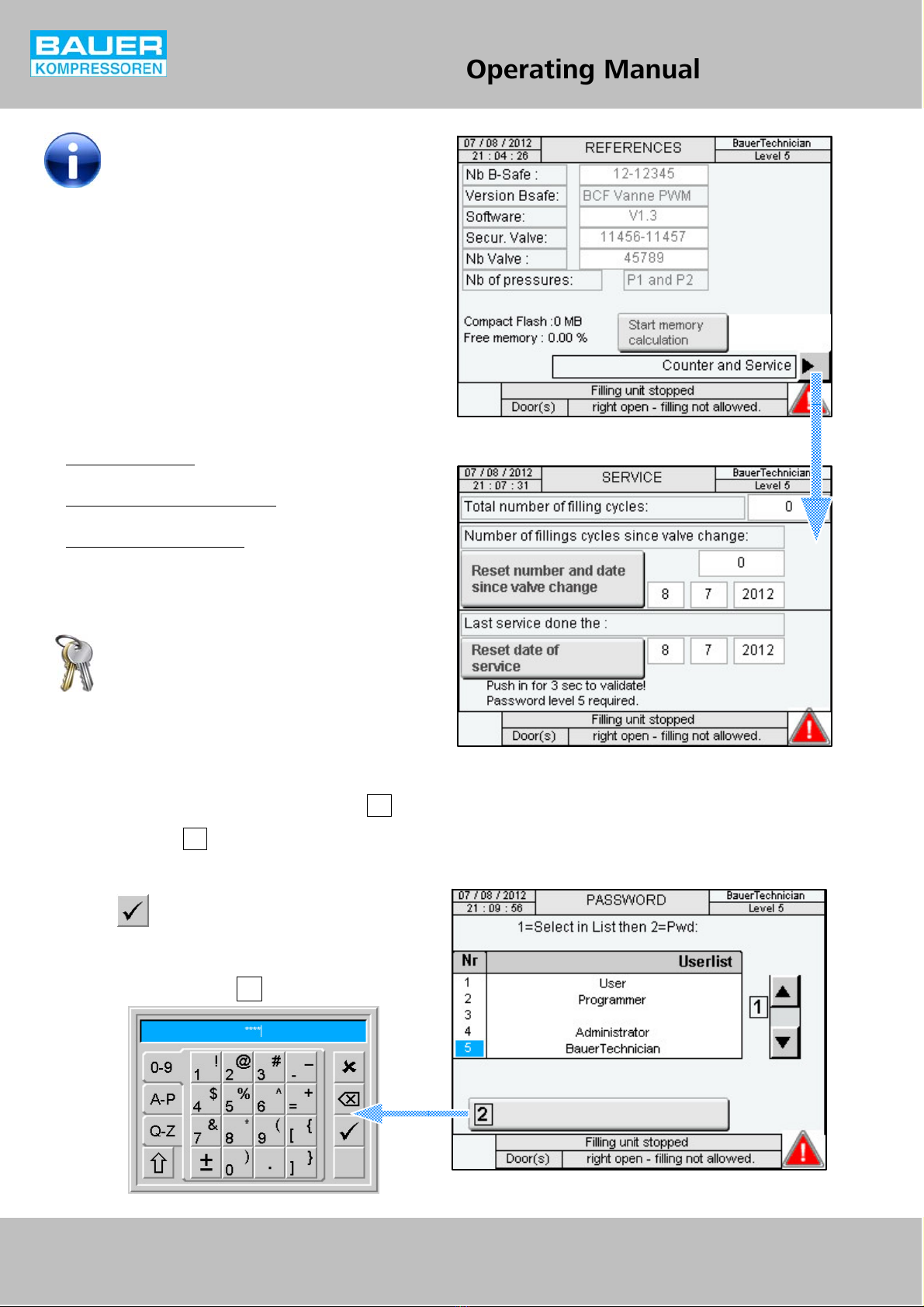

Fig. 7 MACHINE REFERENCES page

Fig. 8 MAINTENANCE page

TT

TT

TT

TT

TT

TT

TT

TT

Operating Manual wB-SAFE 300

4

MACHINE REFERENCES page

This page (Fig. 7) contains the information for quality control of the

BSAFE 300 and its main components.

Press the “Counters and Maintenance” arrow to open the

“Maintenance” page (Fig. 8). See below.

MAINTENANCE page

This page (Fig. 8) contains the counters and date of change of the

solenoid or proportional valve and the date of the last maintenance

work carried out:

wTotal number of cycles: counts the number of fillings since the

BSAFE 300 was activated.

wNumber of cycles since valve change: indicates the number of

fillings since the valve was replaced and the replacement date.

wLast maintenance carried out on: indicates the date on which the

last maintenance was carried out.

The counter-reset and modification of the maintenance date can be

done only by a SAV BAUER technician using a factory password (level

5 required).

PASSWORD page

To access certain functions of the automatic controller, the operator

must first open the corresponding access level (see “Password and

access levels”, page 5). The desired accesslevel is selected from the

password page (Fig. 9) and then opened by entering the

corresponding password :

–1 Selecting the level (1, 2, 4 or 5) using the arrows: 1

–2 Press the button: 2

–3 Enter the password corresponding to the level using

thealphanumeric keyboard present below and validate by

pressing .

Fig. 9 PASSWORD page

TTTTTT

TTTTTT

3

Fig. 10 Alphanumeric keyboard

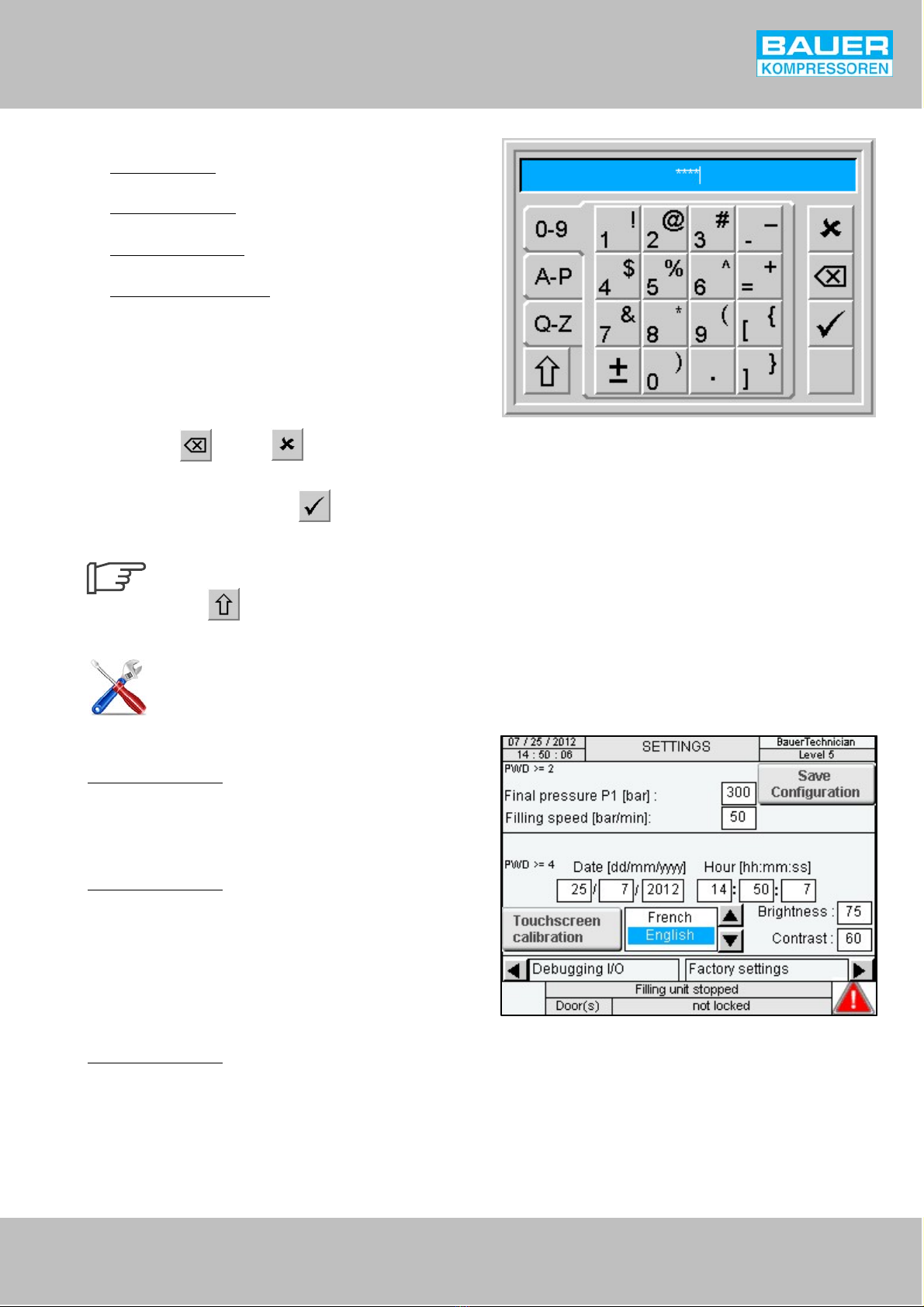

Fig. 11 SETTINGS page

Operating Manual wB-SAFE 300

5

PASSWORD AND ACCESS LEVELS:

wLevel 1 “Operator”: default level,to carry out the filling process.

PWD (password) = “0”

wLevel 2 “Programmer”: to regulate the final pressure and filling

speed. PWD (password) = “1000”.

wLevel 4 “Administrator”: to regulate the screen settings. PWD

(password) = “0100”.

wLevel 5 “Factory settings”: access reserved for personnel

authorised by BAUER.

Entering the password

After selecting the desired level, an alphanumeric keyboard is

displayed on the screen (Fig. 10) where the access code can be

entered.

In case of a typing error, the last character can be deleted with the

help of the key . The key cancels the password entry

operation and returns to the “Password” screen.

After entering the password, press to access the selected

level.

The keyboard letters are useful only for the

TRACEABILITY function (AP and QZ). The

key can be used to enter symbols and

capital letters.

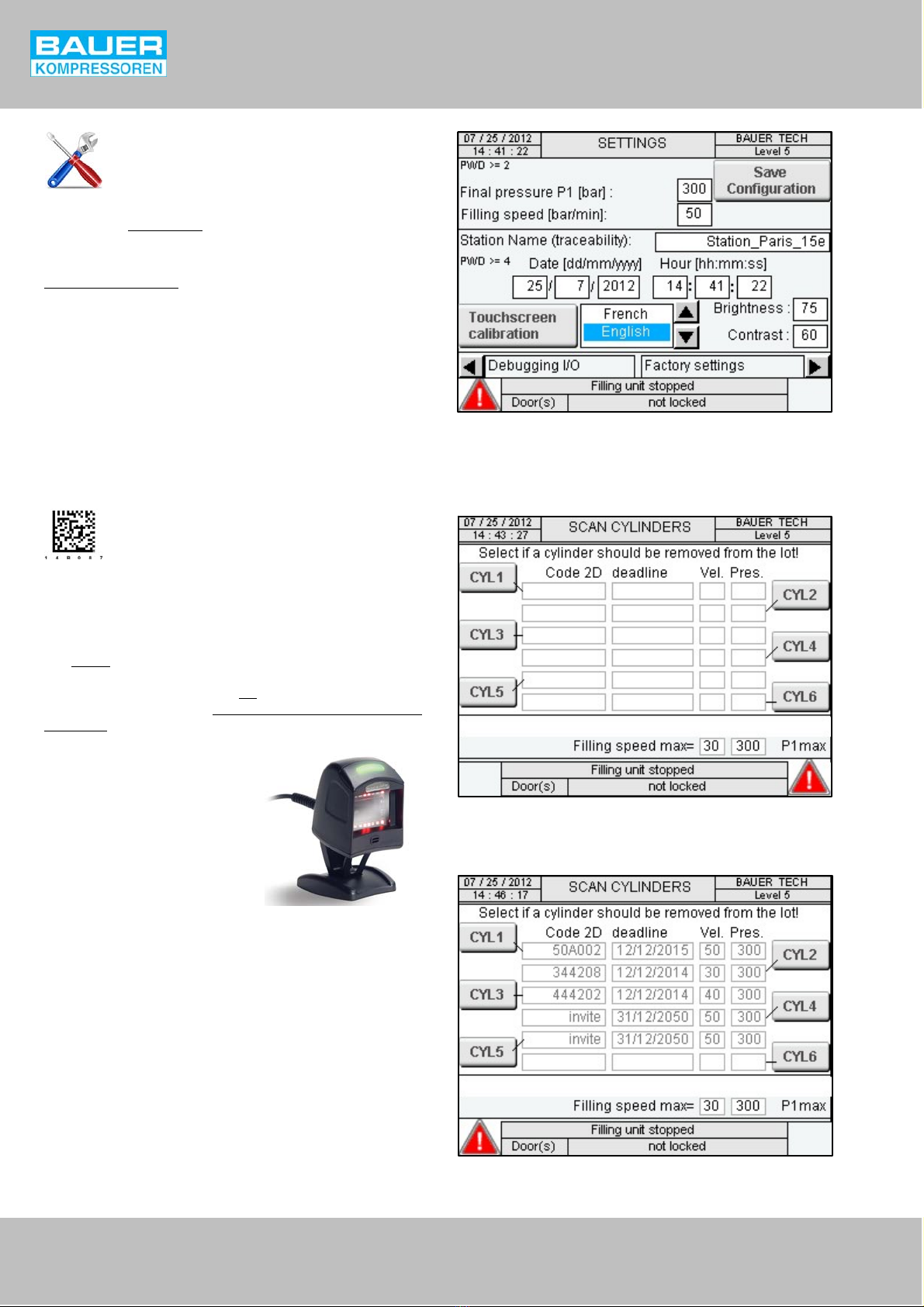

SETTINGS page (level 2, 4 and 5)

This page (Fig. 11) allows the operator to change the following

parameters:

Level 2 access required:

wFINAL PRESSURE P1: Select the value to change it.

wFILLING SPEEDa) : Select the value to change it. Enter the desired

speed (between 20 and 50 bar/min) using the keyboard

displayed on the screen.

Level 4 access required:

wDATE AND TIME: Select the value to change it.

wLANGUAGE: Select the desired language from the drop-down

menu.

wBRIGHTNESS AND CONTRAST OF THE SCREEN: Select the values

to change them.

wTOUCHSCREEN CALIBRATION: Select the targets in the order in

which they appear to re-align the touch detection.

Level 5 access required:

wI/O DEBUGGING and FACTORY SETTINGS: Access reserved for

personnel authorised by BAUER.

Once the modifications are complete, press “Save Configuration” to

save it.

a) Option available only with a proportional valve

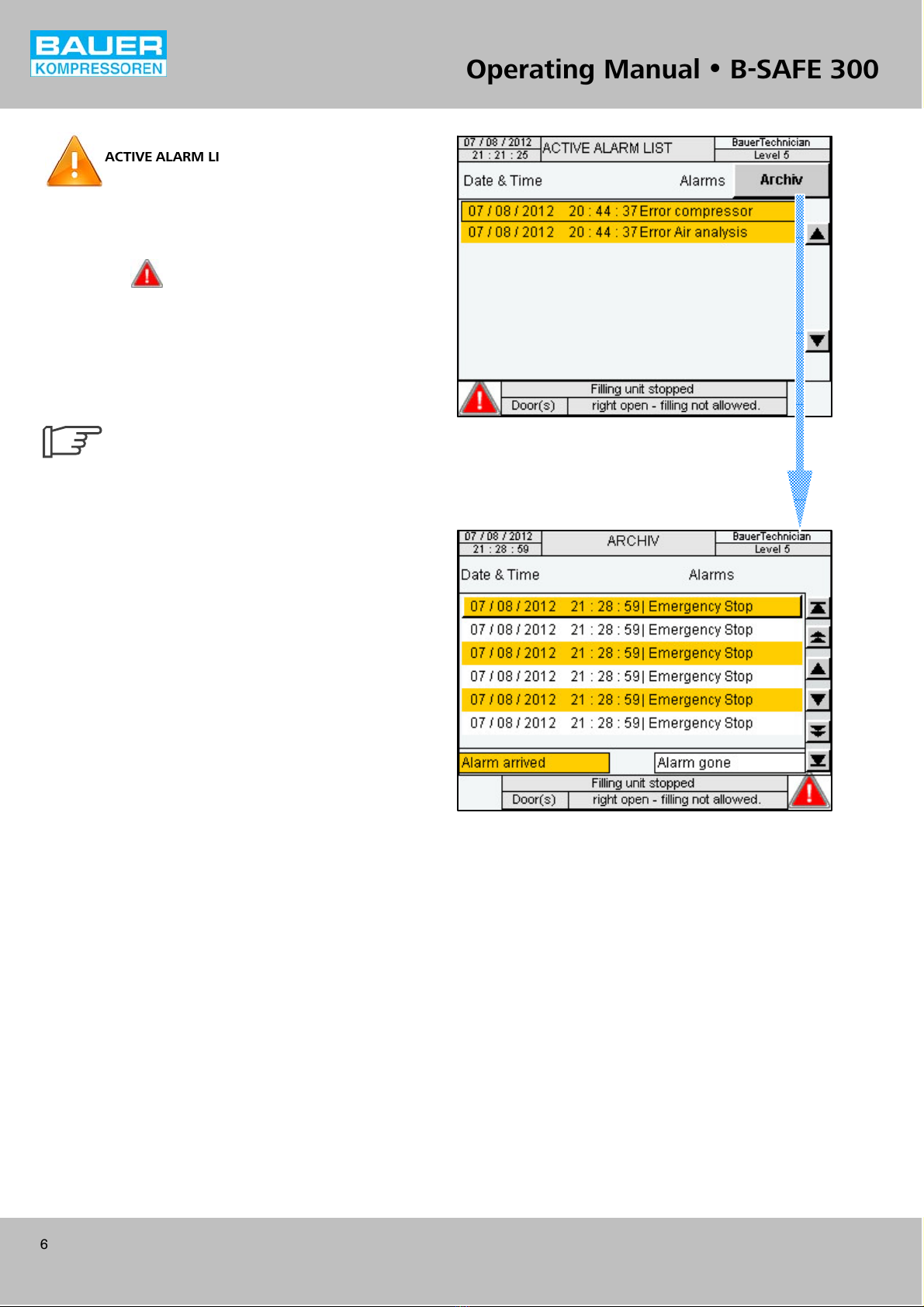

Fig. 12 ACTIVE ALARM LIST page

Fig. 13 Alarms HISTORY page

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

TTT

Operating Manual wB-SAFE 300

6

ACTIVE ALARM LIST page

This page (Fig. 12) allows the operator to view the active alarms of

the B-SAFE 300.

In case an alarm is active, the filling stops automatically and two

warning signs ( ) flash at the bottom of the screen.

Once the cause of activation of the alarm is identified and the

problem is resolved, all the alarms must be reset to return to normal

functioning. Press the red stop switch “0” (13, Fig. 1) to reset the

alarm and then press the green start switch “I” to restart the filling

of cylinders.

Also see the list of alarms in annexe, chap.11.4.3.

An alarm cannot be reset until the correspond

ing fault is repaired.

Press the “History” button to display the chronological list of alarms

(Fig. 13). See below.

HISTORY page

On the“HISTORY” page (Fig. 13), all the alarms displayed during the

operation of the ramp are automatically saved in a file of 1,000 lines.

Use the vertical arrows to scroll through the history. The bottom

arrow allows the user to view previous records.

Fig. 14 Main page – traceability

Fig. 15 PASSWORD page – traceability

Fig. 16 LOGIN CHANGE page – traceability

TT

TT

TT

TT

TT

TT

TT

TT

Operating Manual wB-SAFE 300

7

TRACEABILITY OPTION

The traceability option allows a simple and effective check of the

cylinders. For this, the cylinders must have a label with a 2D code

containing the filling information of every cylinder. Once the label

is scanned, the B-SAFE 300 displays the characteristics of the

cylinders, thus allowing a quick check of the filling data. In addition,

after filling the cylinders, the B-SAFE 300 saves the filling parameters

of each cylinder. This data can then be saved on a USB key and

exported to an operating file.

Main page – traceability

If the BSAFE 300 is configured and has the option “TRACEABILITY”,

with the 2D code included, the main page is displayed as shown in

the image (Fig. 14).

To access the “Scan Cylinders” screen, the user must first identify

himself by accessing the “Password” screen. See below.

PASSWORD – LOGIN CHANGE page

On the machines that have the “TRACEABILITY” option, access to

the screens is limited, i.e., the operator must select the pre-saved

user that corresponds to him. It is the responsibility of the person in

charge of operating the station to save and manage the users, see

“Login change” below.

–1 Select the user using the arrows: 1, Fig. 15.

–2 Press the bar: 2.

–3 Enter the password corresponding to the level using the

alphanumeric keyboard present below and validate by pressing

.

User no. 50 is reserved for BAUER Compressor (level 5).

User Number 49 is pre-saved as Administrator in order to give the

operator in-charge access to login change. The operator in-charge

is advised to change and customise his password.

LOGIN CHANGE page

On this page (Fig. 16), the station administrator may:

– Create a user (name, password, level: min. 2)

– Change password

– Delete a user

– Logout: exit from the administrator level.

The station administrator can create 50 users (049) having different

levels: level 2 for a regular operator, level 3 for an operator

authorised to load the data on the USB key, level 4 for the station

administrator

Each user created must have a different password.

Fig. 17 SETTINGS page - traceability

Fig. 18 SCAN CYLINDERS page

Fig. 19 SCAN CYLINDERS – EXAMPLE page

Operating Manual wB-SAFE 300

8

SETTINGS page – traceability

With the traceability option, this page (Fig. 17) allows the operator

to change the station name as well as the pressure settings, filling

speed, date, time, brightness, contrast and realignment of the touch

detection (also see SETTINGS, page 5).

Level 4 access required:

– Station name (traceability): Press the box to enter the station

name using the alphanumeric keyboard, then press “Save

Configuration”.

SCAN CYLINDERS page

This page (Fig. 18) allows the operator to scan the cylinder labels in

order to save and check each cylinder before filling it.

In order to fill the values in the table, just scan the labels of the

cylinders that are to be filled using the 2D code reader.

If an ERROR message is displayed upon scanning a cylinder, it means

that the label was rejected due to inappropriate format or because

the expiry date has passed. Press OK to remove the message and

cancel the saving operation. Do not fill the cylinder and verify its

expiry date!

Fig. 20 2D code reader

SCAN CYLINDERS – EXAMPLE page

This page (Fig. 19) shows the results of the 5 cylinders in the B-SAFE

scanned before starting the secure filling.

Before starting the filling process, it is possible, to remove a scanned

cylinder. For this, press the corresponding CYLx button; the line is

thus erased.

w“Filling speed max” = the lowest filling speed authorised among

the scanned cylinders.

w“P1max” = final pressure set on the Settings page. The scanned

information related to the pressure of the cylinders is for

information purposes only.

Fig. 21 ACTIVE ALARM LIST page

Fig. 22 LAST FILLING page

TT

TT

TT

TT

TT

TT

TT

TT

Operating Manual wB-SAFE 300

9

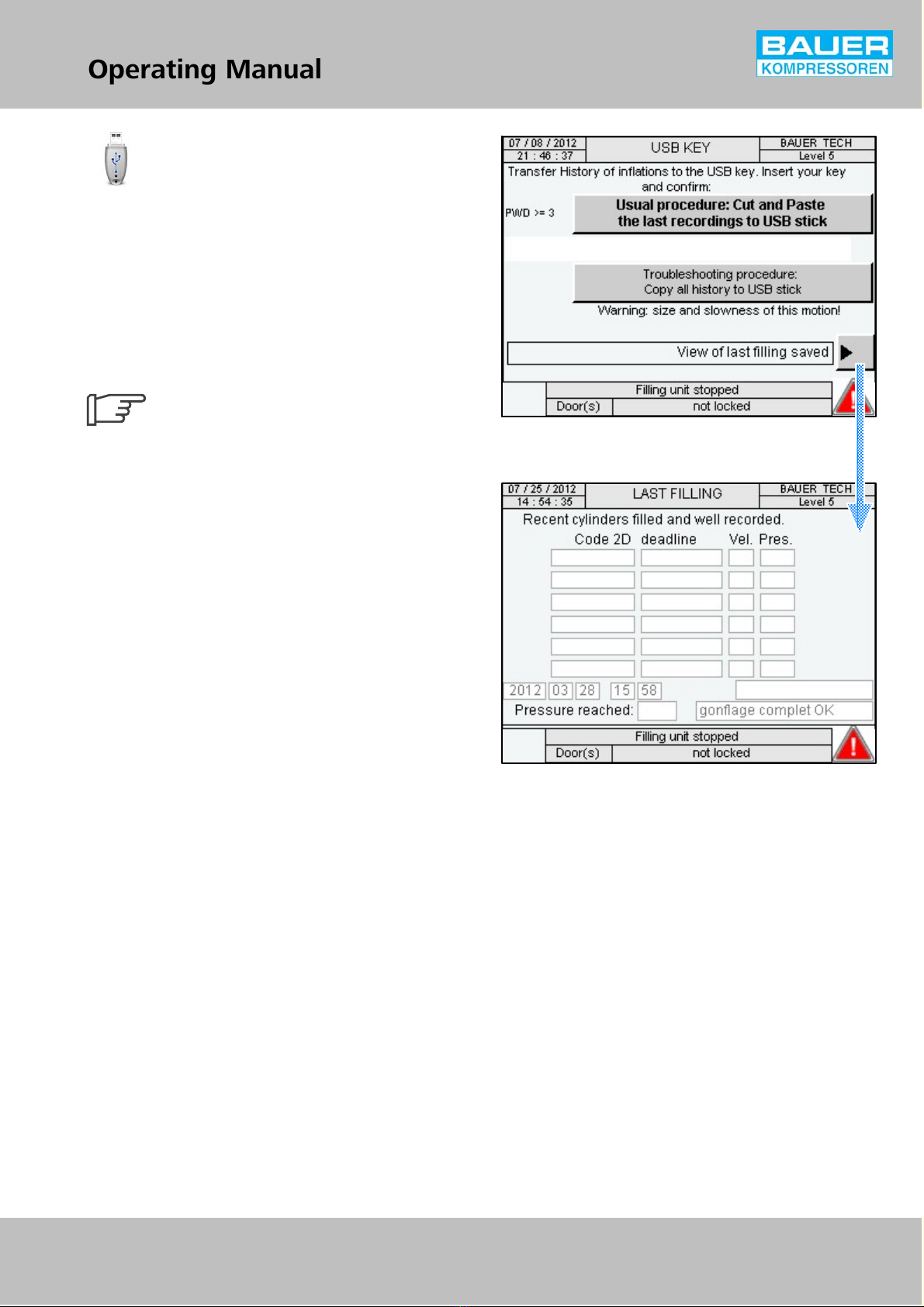

USB KEY page

This page (Fig. 21) allows the operator to transfer the following files

on a USB key:

– the history of the previous fillings by pressing the button: “Usual

procedure: Cut and Paste the last recordings to USB stick”,

– a backup of the entire history of the traceability since the BSAFE

300 was activated by pressing the button: “Troubleshooting

procedure: Copy all history to USB stick”

Only a registered user with the appropriate access level may carry

out this data transfer. See the “LOGIN CHANGE” page 7.

The USB port for inserting the key is located on

the top-right inside the B-SAFE 300.

Pressing the “View of last filling saved” arrow key displays the LAST

FILLING page (Fig. 22).

LAST FILLING page

The operator can view the last filling carried out once it is complete

and the doors are open. It remains open till the next filling.

Operating Manual wB-SAFE 300

10

3. OPERATING PRINCIPLE

The operating principle of the B-SAFE 300 ramp is described below

with the help of two examples:

wB-SAFE 300 with proportional valve and two pressure ranges,

wB-SAFE 300 with solenoid valve and two pressure ranges.

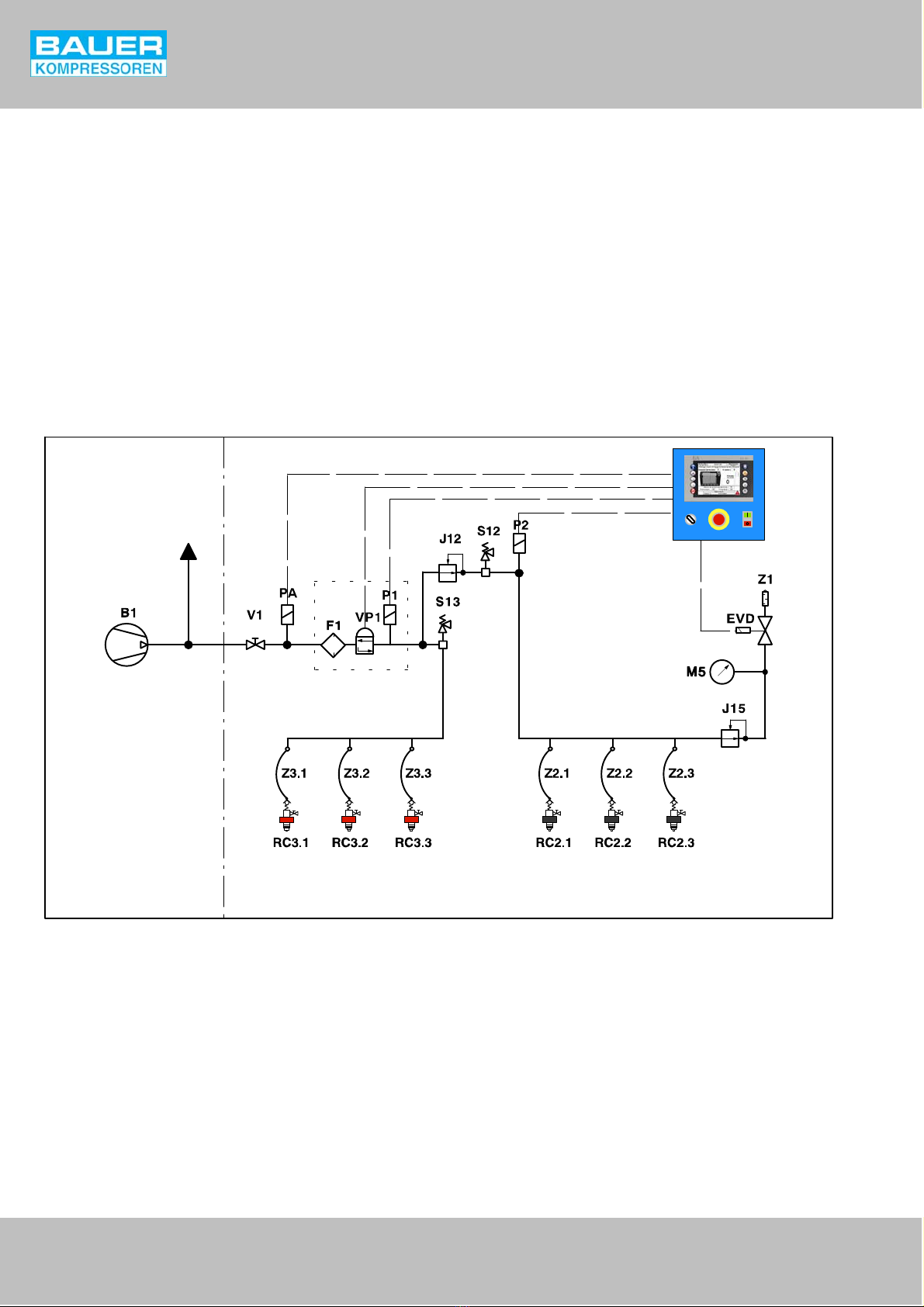

3.1. B-SAFE 300 WITH PROPORTIONAL VALVE,

The references indicated below refer to the positions of the

pneumatic diagram (Fig. 23).

The compressed air supplied by the compressor and storage enters

through the V1 manual shut-off valve.

The supply pressure and residual pressures of the cylinders are

measured by pressure sensors PA, P1 and P2 respectively. The

proportional valve F1-VP1 regulates the filling pressure according to

the values measured by the sensors. In addition, the proportional

valve opens and automatically isolates the internal pneumatic circuit

while starting and stopping the filling process.

The secondary pressure is obtained by reducing the primary pressure

with the help of the J12 regulator.

The primary and secondary pressures are pneumatically limited by

the S13 and S12 safety valves respectively.

The compressed air is transferred to the cylinders through flexible

hoses Z3 and Z2 and the filling valves RC3 and RC2.

The depressurisation system consists of J15 regulators, an EVD

solenoid valve and a Z1 silencer. The EVD solenoid valve opens

automatically when a door of the machine is open (or when the

emergency stop option is activated), thus depressurising the internal

pneumatic circuit.

COMPRESSOR B-SAFE 300

TO

STORAGE

Fig. 23 Pneumatic diagram, B-SAFE 300 with proportional valve and 2 pressure ranges.

B1 HP compressor

EVD Solenoid valve, depressurisation

F1-VP1 Proportional valve (VP1) with filter (F1)

J12 Regulator

J15 Regulator

M5 Pressure gauge, depressurisation

PA Pressure sensor, input

P1 Pressure sensor, primary filling pressure

P2 Pressure sensor, secondary filling pressure

RC2 Filling valves, secondary pressure

RC3 Filling valves, primary pressure

S12 Safety valve, secondary pressure

S13 Safety valve, primary pressure

V1 Manual inlet valve

Z1 Silencer

Z2 Flexible filling hoses, secondary pressure

Z3 Flexible filling hoses, primary pressure

Operating Manual wB-SAFE 300

11

3.2. B-SAFE 300 WITH SOLENOID VALVE AND TWO

PRESSURE RANGES

The references indicated below refer to the positions of the

pneumatic diagram (Fig. 24).

The compressed air supplied by the compressor enters through the

V1 manual shut-off valve.

Compressed air directly enters (i.e. without being regulated) the

cylinders. The only function of the Y1 solenoid valve is to allow or

stop the supply of compressed air while starting or stopping the

filling process.

The secondary pressure is obtained by reducing the primary pressure

with the help of the J12 regulator.

The primary and secondary pressures are pneumatically limited by

the S13 and S12 safety valves respectively.

The compressed air is supplied to the cylinders through the flexible

hoses Z2 and Z3 and the filling valves RC2 and RC3.

The depressurisation system consists of J15 regulators, an EVD

solenoid valve and a Z1 silencer. The EVD solenoid valve opens

automatically when a door of the machine is open (or when the

emergency stop option is activated), thus depressurising the internal

pneumatic circuit.

COMPRESSOR B-SAFE 300

TO

STORAGE

Fig. 24 Pneumatic diagram, B-SAFE 300 with solenoid valve and two pressure ranges.

B1 HP compressor

EVD Solenoid valve, depressurisation

J12 Regulator

J15 Regulator

M5 Pressure gauge, depressurisation

PA Pressure sensor, entry

P1 Pressure sensor, primary filling pressure

P2 Pressure sensor, secondary filling pressure

RC2 Filling valves, secondary pressure

RC3 Filling valves, primary pressure

S12 Safety valve, secondary pressure

S13 Safety valve, primary pressure

V1 Manual inlet valve

Y1 Solenoid valve

Z1 Silencer

Z2 Flexible filling hoses, secondary pressure

Z3 Flexible filling hoses, secondary pressure

Operating Manual wB-SAFE 300

12

4. TECHNICAL CHARACTERISTICS

Fluid Breathable air in conformity with EN 12021........................................................................

Operating pressure Max. 410 bar.............................................................

Filling pressure (max. 2) PN200/PN300 bar.........................................................

Standard setting, final safety valve PN200 225 bar..........................................

Standard setting, final safety valve PN300 330 bar..........................................

Standard setting, final safety valve for operating with proportional valve 320 bar..................

Control range of the filling speed 20 to 50 bar/min.................................................

Number of filling items Max. 6 diving cylinders (max. 10 optiona) ).........................................................

Max. temperature permitted +5 to +45°C.....................................................

Dimensions See Fig. 25...................................................................

Internal dimensions of the filling chamber 1300 x 400 x 700 mm..........................................

Weight (standard version) About 350 kg.......................................................

Supply voltage 240 V, 50 Hz................................................................

Power consumption 100 W............................................................

Inlet connector for the compressed air 8S.............................................

1750 600

1350

Fig. 25 Dimensions (in mm)

a) Only if combined with the standard filling accessories (max diameter of cylinders = 18 cm, max height = 60 cm)

Table of contents

Popular Industrial Equipment manuals by other brands

PPI

PPI FLOREX Operation manual

Afag

Afag PEL20 Assembly and operating instructions

Festo

Festo EAMM-U Series Assembly instructions

Pepperl+Fuchs

Pepperl+Fuchs 6500 Series instruction manual

Vantage Hearth

Vantage Hearth Hollister-Whitney GLV-40D2 instruction manual

COREMO OCMEA

COREMO OCMEA D-M User and maintenance manual