Thiele TWN 0850/1 User manual

OPERATING INSTRUCTIONS

WELD-ON HOOKS TWN 0850/1

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07332-C B07332-B

© All rights reserved EN 04.2021 1 | 5

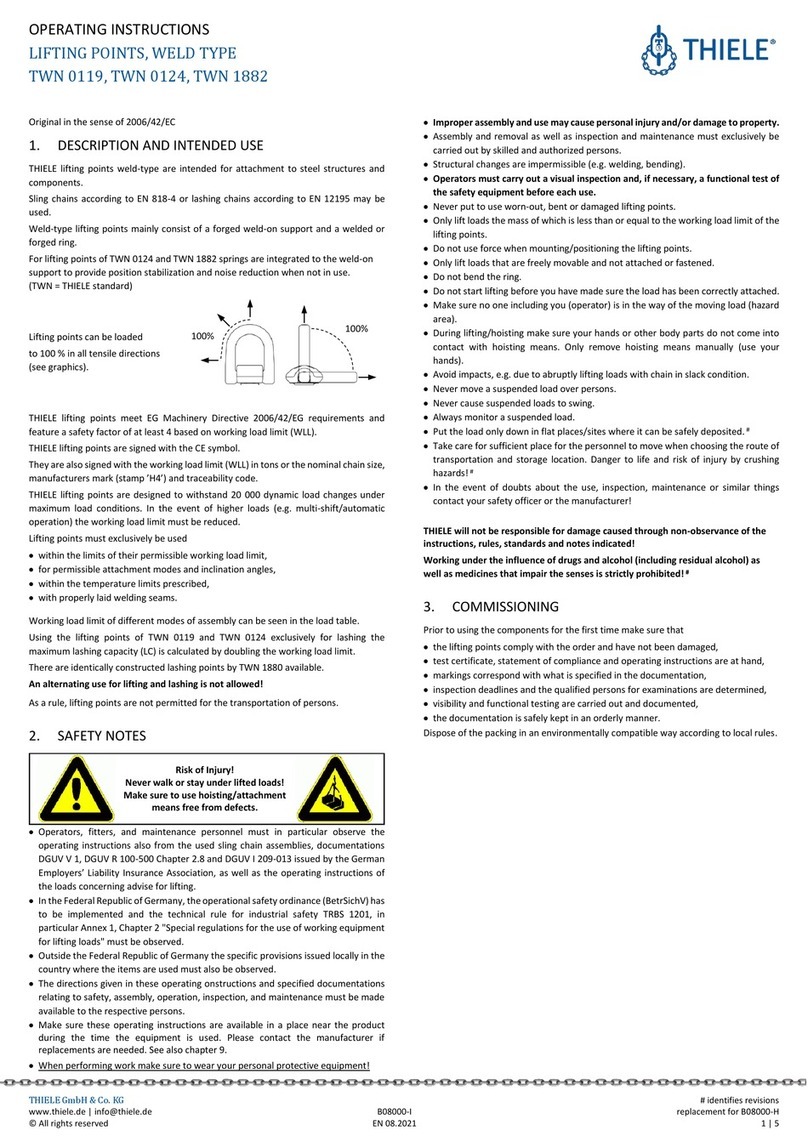

1DESCRIPTIONAND INTENDED USE

Weld-on hooks according to this THIELE company standard (TWN) are intended

for lifting and handling loads and are primarily welded onto earth-moving

machinery, e.g. shovels.

They are firmly connected to the load-bearing component by welding.

The weld-on hooks consist of a forged body and a spring-loaded safety latch.

The weld-on hooks are marked with working load limit, manufacturer's mark, CE

mark and traceability code and are not painted.

They are certified by the German Employer's Liability Insurance Association for

Wood and Metal in accordance with the "Principles for the testing and

certification of attachment hooks for earth-moving machinery in lifting

applications" (GS-OA 15-03).

Weld-on hooks may only be used

•within the permissible working load limit and attachment angle,

•within the permissible temperature limits,

•by trained and authorised persons,

•with mounted and functioning securing systems,

•with properly executed weld seams.

Weld-on hooks meet the requirements of Machinery Directive 2006/42/EC and

have a design factor of 4 in relation to their working load limt (WLL).

THIELE weld-on hooks are designed to withstand 20 000 dynamic load cycles at

maximum loading capacity. For higher workloads (e.g. multi-shift and automated

operations) the loading capacity is to be reduced accordingly.

Eine Verwendung zum Zurren oder für den Personentransport ist nicht zulässig!

2SAFETY NOTES

Risk of Injury!

Never walk or stay under lifted loads!

Make sure to use weld-on hooks and

hoisting means free from defects

.

•Operators, fitters, and maintenance personnel must in particular observe the

Operating Instructions of the used vehicle, vehicle assembly and hoisting

means, documentations DGUV V 1, DGUV R 100-500 Chapter 2.8 and DGUV I

209-013 issued by the German Employers’ Liability Insurance Association, as

well as the standard specification DIN 15429.

•In the Federal Republic of Germany, the Operational Safety Ordinance

(BetrSichV) has to be implemented and the Technical Rule for Industrial Safety

TRBS 1201, in particular Annex 1, Chapter 2 "Special regulations for the use of

working equipment for lifting loads" must be observed.

•Outside the Federal Republic of Germany the specific provisions issued locally

in the country where the items are used must also be observed.

•Outside the Federal Republic of Germany the specific provisions issued locally

in the country where the items are used must also be observed.

•The directions given in these Operating Instructions and specified

documentations relating to safety, assembly, operation, inspection, and

maintenance must be made available to the respective persons.

•Make sure these Operating Instructions are available in a place near the product

during the time the equipment is used.

•Please contact the manufacturer if replacements are needed.

•When performing work make sure to wear your personal protective equipment!

•Improper assembly and use may cause personal injury and/or damage to

property.

•Assembly and removal as well as inspection and maintenance must exclusively

be carried out by skilled and authorized persons.

•Structural changes (e.g. bending, detachment of parts, drilling) are not

permitted.

•Carry out a visual inspection before each use.

•Operators must carry out a visual inspection and, if necessary, a functional

test of the safety equipment before each use.

•Never put to use worn-out, bent or damaged weld-on hooks or hoisting means.

•Only lift loads the mass of which is less than or equal to the working load limit

of the weld-on hooks.

•Never expose weld-on hooks to loads exceeding the specified working load

limits!

•Do not use force when mounting/positioning the weld-on hooks or hoisting

means.

•Check that the load can withstand the forces including proof forces to be

applied without deformation.

•Do not twist or knot the chains together.

•Avoid sharp edges. Use edge protectors or reduce the working load limit by 20

%.

•Only lift loads that are free to move and are not fastened or anchored.

•Do not apply bending stress to chain links and components.

•Shortening of chain sling legs is only permitted with approved shortening

elements.

•Do not start lifting before you have made sure the load has been correctly

attached.

•Make sure no one including you (operator) is in the way of the moving load

(hazard area).

•During lifting/hoisting make sure your hands or other body parts do not come

into contact with hoisting means.

•Remove hoisting means only by hand.

•Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in places/sites where it can be safely deposited.

•Do not catch hoisting means under the load.

•Operation without functioning safety devices is not permitted.

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer!

THIELE will not be responsible for damage caused through non-observance of

the instructions, rules, standards and notes indicated!

Working under the influence of drugs, medications impairing the sense and/or

alcohol (including residual alcohol) is strictly forbidden!

3COMMISSIONING

Prior to using the components for the first time make sure that

•the components comply with the order and have not been damaged,

•test certificate, declaration of conformity and operating instructions are at

hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are

determined,

•visibility and functional testing are carried out and documented,

•documentations are safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local

rules.

OPERATING INSTRUCTIONS

WELD-ON HOOKS TWN 0850/1

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07332-C B07332-B

© All rights reserved EN 04.2021 2 | 5

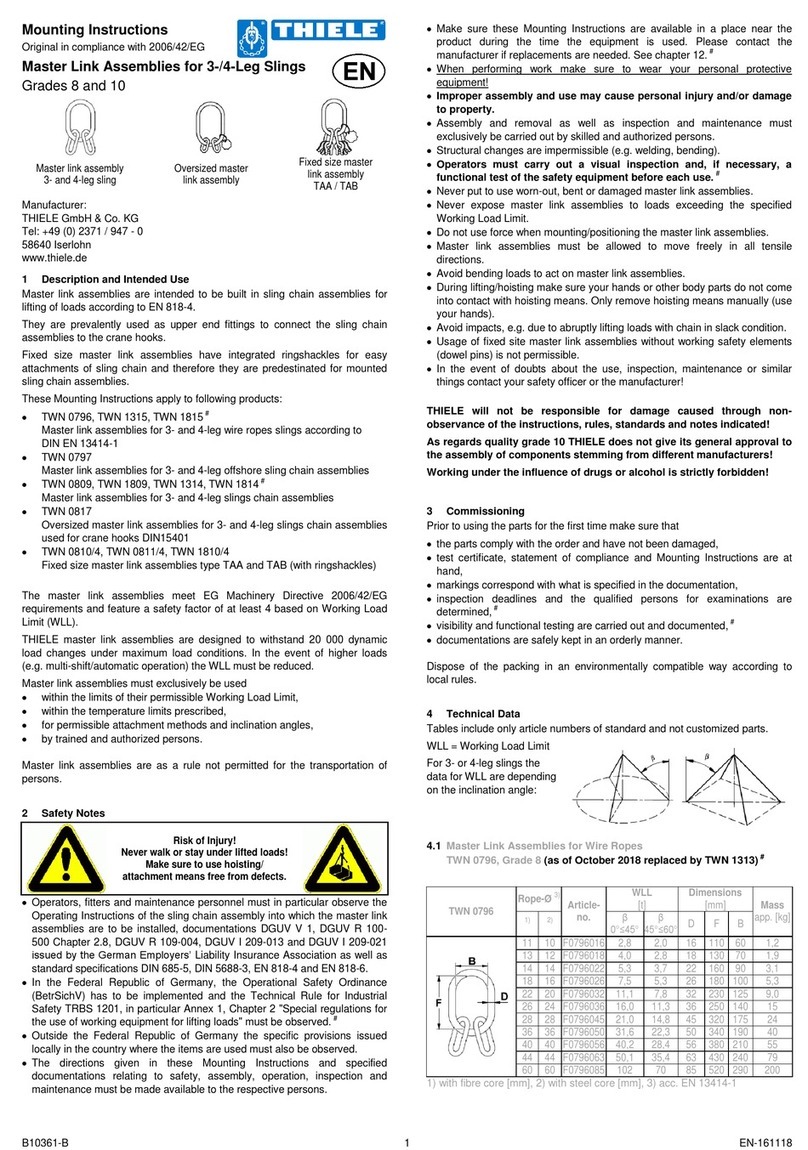

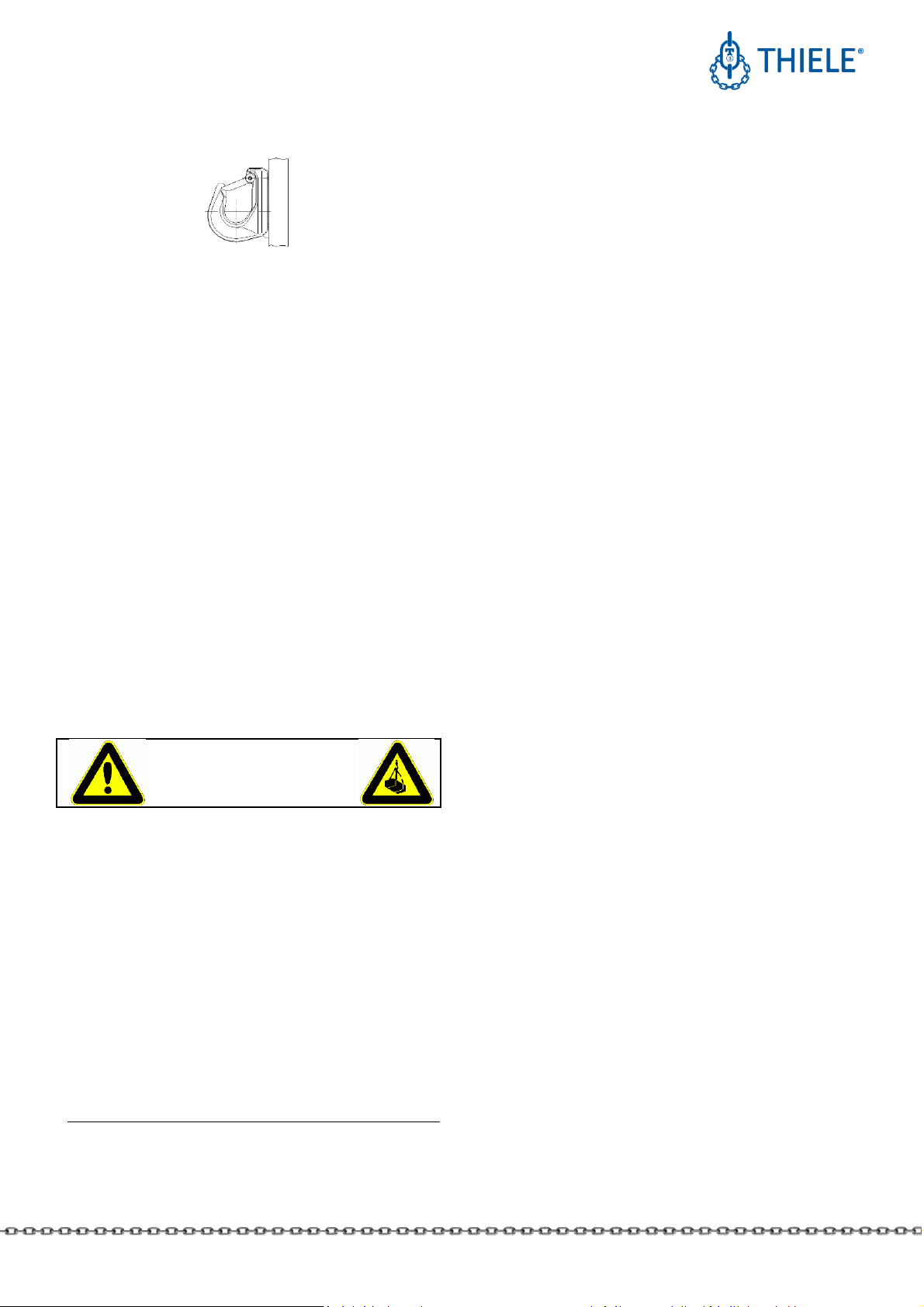

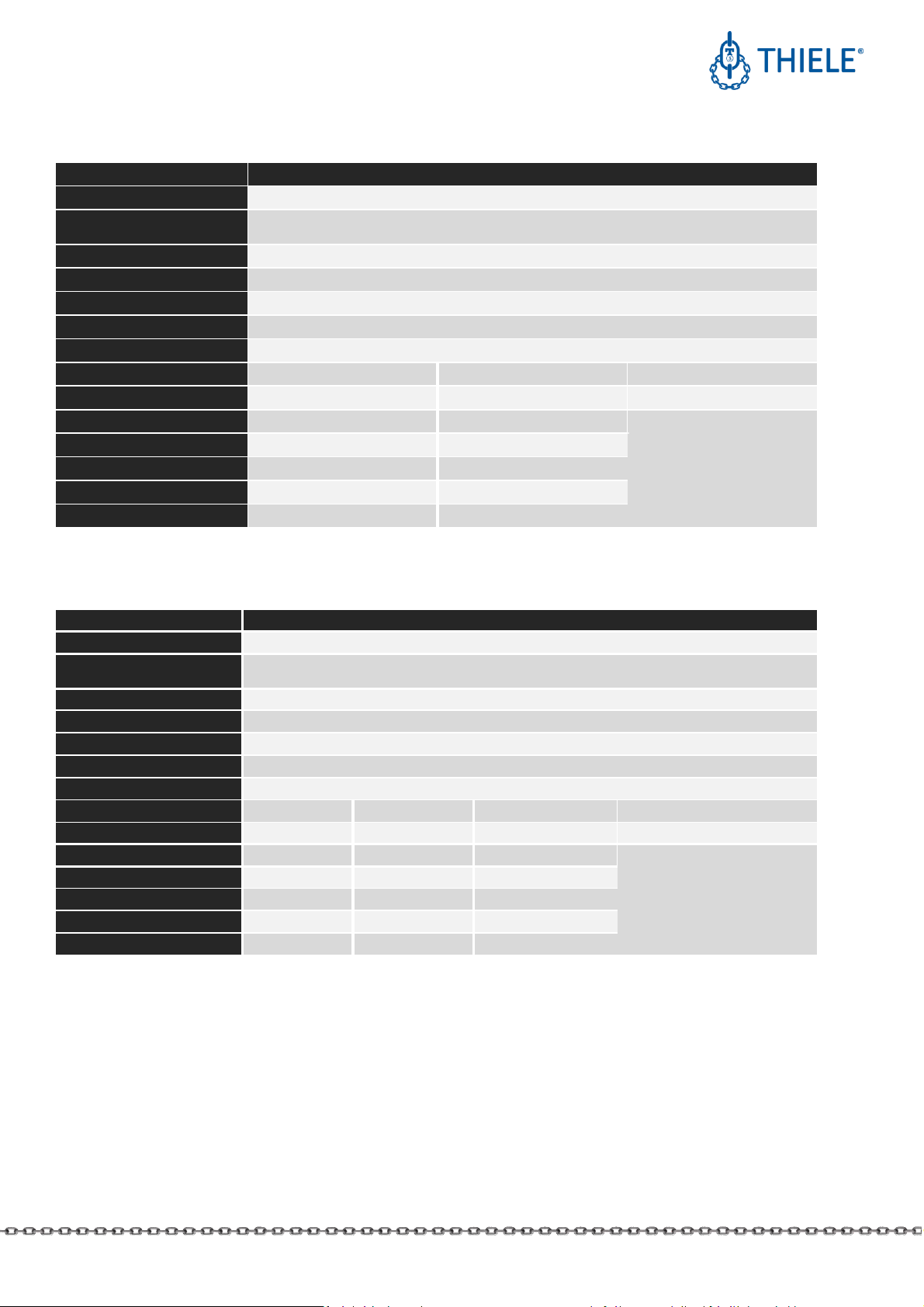

4TECHNICAL DATA

Nominal size /

WLL

Article no.

Dimensions

[mm]

Mass

[t]

A

B

C

E

F

G

H

app.

[kg]

1,12

F32751

94

77

24

85

51

26

24

0,5

2,0

F32752

120

97

30

107

65

33

28

1,0

The hook bodies are forged from the material S355.

5WELDING INSTRUCTIONS

5.1 General

Material of weld-on hooks: S355

Material of weld-on joint: C22, S235, S355 or similar

The following general welding instructions must be observed:

•EN ISO 2560 Welding consumables –Covered electrodes for manual arc

Welding of non-alloy and fine grain steel

•EN ISO 14341 Welding consumables –Wire electrodes and weld

deposits for gas shield metal arc welding of non-alloy

and fine grain steel

•ISO 3834-2 Quality requirements for fusion welding of metallic

materials

•EN 1011-1, 2 Welding –recommendations for welding of metallic

materials

•EN ISO 9606-1 Qualification testing of welders –fusion welding

•DVS 0702-1 / 0711 Factsheet - Requirements for operation and personnel

Welding is only permitted by trained and authorised personnel in accordance with

the qualification according to EN ISO 9606.

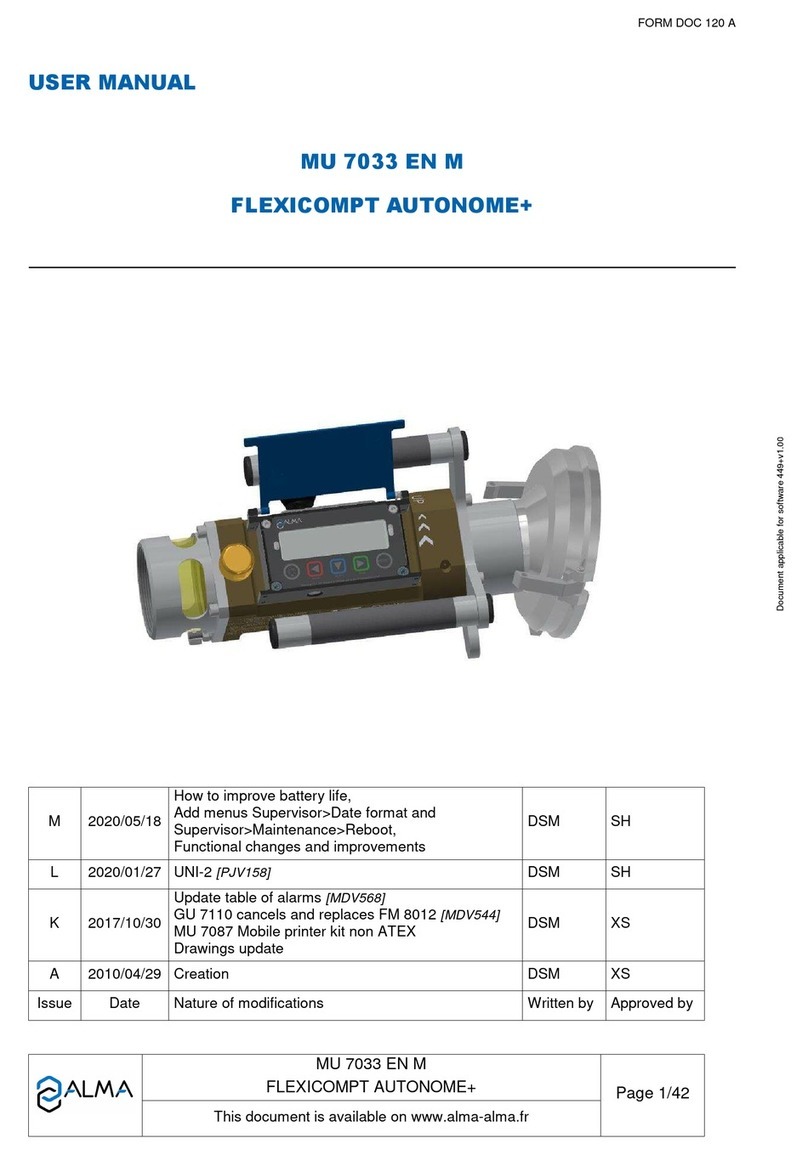

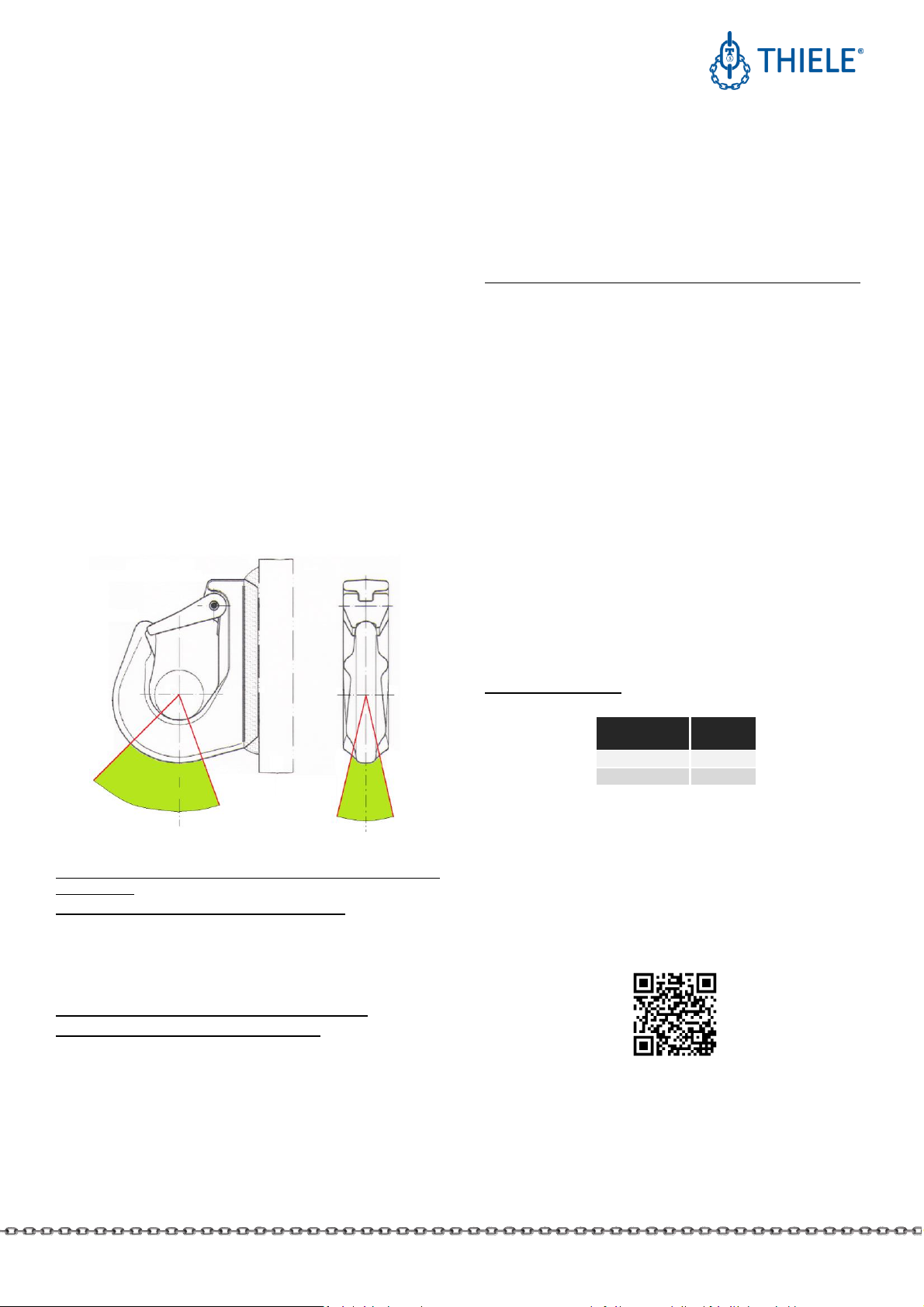

Sketch:

5.2 Preparation activities

Make sure that the welding surface is even, dry, free of rust, paint and impurities

and suitable for welding (C-content ≤ 0.30 %). Select the welding location in such

a way that the forces to be applied can be absorbed by the component with

sufficient safety and without deformations.

5.3 Mounting conditions

Position the weld-on hooks in a way,

•that no danger areas (crushing points, shearing points, rotating parts) are

created,

•that the forces to be applied can be absorbed by the component without

deformations and that inadmissible stresses, e.g. due to off-centre load

application, are avoided,

•that the forces to be applied can be absorbed with sufficient safety (at least 4

times in the major load direction, at least 2.5 times perpendicularly thereto) by

the welding location for all intended load directions,

•that the hoisting means to be suspended in the weld-on hooks are not deflected

by other components during subsequent operation,

•that the load is applied in the bottom of the hook and that the direction of

loading is as parallel as possible to the longitudinal axis of the hook,

•that damage to hoisting means, e.g. by sharp edges, is avoided,

•that the weld-on hooks can be reached easily and without obstruction for

attaching and detaching, even when set down,

•that an unintentional loosening of the hoisting means is avoided,

•that there are no obstructions caused by hooking or getting stuck, both during

excavator and hoist operations.

Observe the welding instructions given.

The weld-on hooks must be inspected by a competent person after welding and

before first use. This inspection must be documented.

5.4 Welding seam dimensions

Nominal size /

WLL

Proof force

MPF

Breaking force

BF

[t]

[kN]

[kN]

1,12

27,5

43,9

2,0

49,0

78,5

Nominal size /

WLL

Min. welding seam

thickness a

Welding seam

cross-section

[t]

[mm]

[mm²]

1,12

4

808

2,0

5

1 270

Temper pass

Stringer

pass

Weld-on hook

Weld-on joint

OPERATING INSTRUCTIONS

WELD-ON HOOKS TWN 0850/1

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07332-C B07332-B

© All rights reserved EN 04.2021 3 | 5

5.5 Welding process MAG

5.6 Manual welding process MMA

Welding process

Metal active gas welding (MAG) EN ISO 9606-1; No. 135

Welding groove

see sketch

Quality grade

Root run: EN ISO 5817 - C

Final run: EN ISO 5817 - C

Wire electrode

EN ISO 14341-A:2011: ISO 14341-A-G 46 4 M21 3Si1

Welding position

EN ISO 9606-1: PA, PB, PF

Preheating of parent metal

max. 150 °C

Interpass temperature

≤ 400 °C

Postweld heat treatment

400 °C - 20 °C tempering and / or apply quenching and tempering layer technology

Pass

Root run

Final run

Temper pass

Wire electrode diameter

1 mm

1,2 mm

1 or 1,2 mm

Welding current (=)

130 - 200 A

135 - 290 A

See root run or stringer pass

Note: The quench and temper

layer must only be applied to the

weld metal. Contact with the base

metal must be avoided.

Electrode polarity

(= +)

(= +)

Voltage

19 –25 V

19 –32 V

Shlied gas ISO 14175; M21

10 –12 l/min

12 –14 l/min

Kind of pass

Stringer pass

Stringer pass

Welding process

Manual metal arc welding (MMA) EN ISO 9606-1; No. 111

Welding groove

see sketch

Quality grade

Root run: EN ISO 5817 - C

Final run: EN ISO 5817 - C

Wire electrode

EN ISO 2560 A:2010: min. ISO 2560-A-E 38 4 B 42 H5

Welding position

EN ISO 9606-1: PA, PB, PF

Preheating of parent metal

max. 150 °C

Interpass temperature

≤ 400 °C

Postweld heat treatment

400 °C - 20 °C tempering and / or apply quenching and tempering layer technology

Pass

Root run

Final run

Alternative final run

Temper pass

Wire electrode diameter

2,5 mm

3,2 mm

4,0 mm

1 or 1,2 mm

Welding current (=)

80 - 110 A

100 - 140 A

130 –180 A

See root run or stringer pass

Note: The quench and temper layer

must only be applied to the weld

metal. Contact with the base metal

must be avoided.

Electrode polarity

(= +)

(= +)

(= +)

Voltage

-

-

-

Shlied gas ISO 14175; M21

-

-

-

Kind of pass

Stringer pass

Stringer pass

Stringer pass

OPERATING INSTRUCTIONS

WELD-ON HOOKS TWN 0850/1

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07332-C B07332-B

© All rights reserved EN 04.2021 4 | 5

5.7 Others

•Minimum notched-bar impact strength values of ISO-V specimens KV = 27 J at -

40 °C (z.B. S355J4G3 or S355NL, EN 10025).

•When selecting material grades other than those listed above please contact

the base material and filler metal manufacturers for information.

•The responsible welding supervisor must make sure the welding current is

correctly adjusted to suit the given welding position. The qualification must be

in accordance with EN ISO 14731.

•Check the weld for cracks, inclusions and blowholes.

6OPERATING

6.1 General

The safety latch must always engage form-fittingly with the tip of the hook to

ensure a stable fit. Removal of the safety latch is not permitted.

Hoisting means must always be able to move freely in the hook jaw.

6.2 Temperature influence

The operating temperature range is -40 °C to +200 °C.

After heating above the maximum temperature for use, the weld-on hooks must

no longer be put into operation.

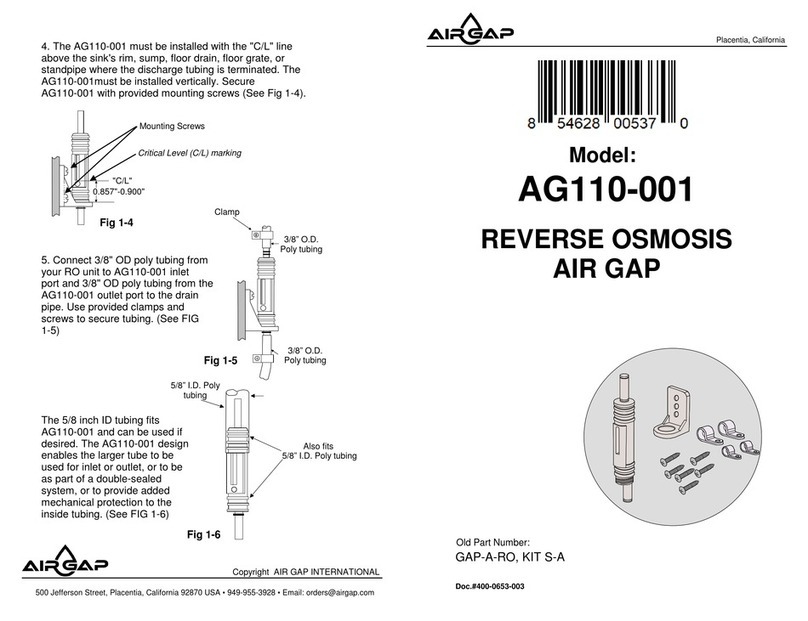

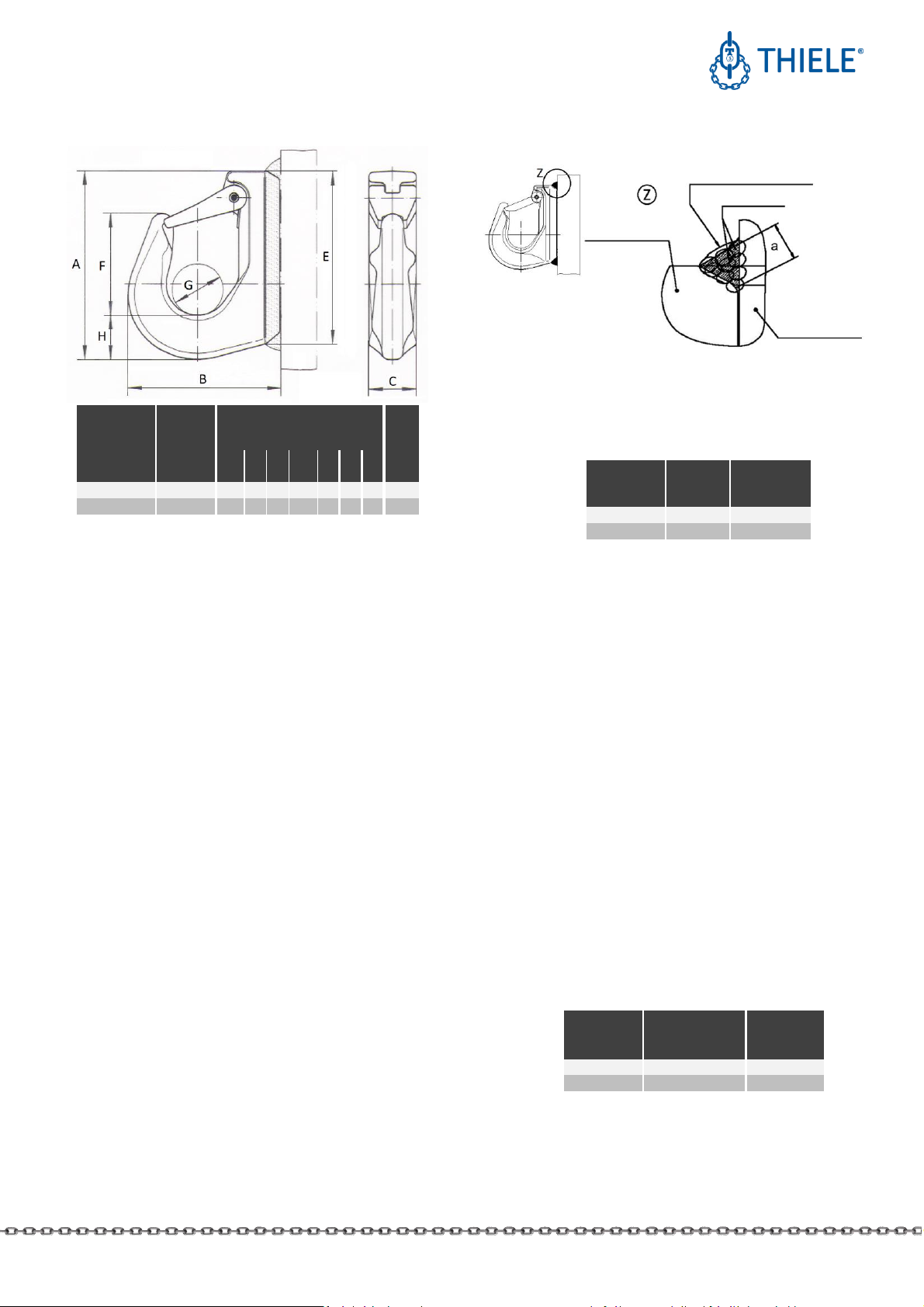

6.3 Load directions

Permissible load directions are shown in the following sketches:

6.4 Environmental influence

Use in environments with acids, aggressive or corrosive chemicals or their fumes

is not permitted.

Hot-dip galvanising or galvanic treatments are not permitted.

7TESTING, MAINTENANCE,DISPOSAL

7.1 General

Inspections and maintenance must be arranged for by the Owner!

Inspection deadlines shall be determined by the Owner!

Inspections must be carried out and documented by competent persons regularly

but at least once a year, or more frequently if the weld-on hooks are in heavy-duty

service. After three years at the latest they must additionally be examined for

cracks. A load test shall never be considered a substitute for this examination.

The results of the inspection shall be entered into a register (DGUV I 209-062 or

DGUV I 209-063) to be prepared at first use. The register will show characteristic

data as well as identity details.

Immediately stop using weld-on hooks that show the following defects:

•deformation, elogation or fracture,

•cuts, notches, cracks, incipient cracks, pinching,

•heavy wear in the hook jaw,

•missing or jamming safety latch,

•severe corrosion,

•missing or illegible identification/marking.

7.2 Maintenace

Maintenance work may only be carried out by trained and competent persons!

Minor cracks and notches can be removed by careful grinding, observing the

maximum cross-section reduction of 10 % as well as the avoidance of notches.

Document all maintenance activities.

7.3 Changing the safety latch

Disassembly is carried out by driving out the dowel pin.

The assembly is done by positioning the spring and the safety latch and

hammering in the thicker dowel pin. The thin dowel pin is then mounted. Make

sure that its slot is positioned opposite the slot position of the thicker dowel pin.

Check the proper function of the safety latch.

7.4 Inspection service

THIELE offers inspection, maintenance and repair services by trained and

competent personnel.

7.5 Disposal

All components and accessories of steel taken out of service are to be scrapped in

line with local regulations and provisions.

8SPARE PARTS

Only use original spare parts.

Spare parts sets include safety latch, spring and dowel pin.

Nominal size /

WLL [t]

Article no.

set

1,12

F48730

2,0

F48732

9STORAGE

Store weld-on hooks dry and protected against corrosion at temperatures

between 0 °C and +40 °C.

10 THIELE OPERATING AND MOUNTING

INSTRUCTIONS

Current operating and assembly instructions are available as a PDF download on

the THIELE homepage.

11 IMPRINT

THIELE GmbH & Co. KG

Werkstraße 3

58640 Iserlohn, Germany

Tel.: +49(0)2371/947-0

45° 20°

15° 15°

OPERATING INSTRUCTIONS

WELD-ON HOOKS TWN 0850/1

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07332-C B07332-B

© All rights reserved EN 04.2021 5 | 5

12 DECLARATIONOFCONFORMITY

EC Declaration of conformity

acc. to Machinery Directive 2006/42/EG, Annex II A for a machine

THIELE GmbH & Co. KG herewith declares as manufacturer that

Weld-on hooks TWN 0850/1

are in compliance with the applicable provisions of the EU Machinery Directive

2006/42/EG.

The following harmonized standards have been observed:

•EN 12100 Safety of machinery –General principles for design –

Risk assessment and risk reduction

•EN 1677-1 Components for lings - Safety

The following test principle of the employers' liability insurance association was

applied:

•GS-OA 15-03 Principles for the testing and certification of attachment

hooks for earth-moving machinery in lifting applications

This declaration/statement is not meant to warrant any product properties.

Safety notes and instructions pertinent to the products must be observed.

Responsible for documentation

Rene Völz (Head of QA and EP), Tel.: +49(0)2371/947-541

Iserlohn, 6 April 2021

Dr. Michael Hartmann

(Managing director)

Table of contents

Other Thiele Industrial Equipment manuals

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele TWN 1472 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele TWN 0835/1 User manual

Thiele

Thiele TWN 1450 User manual

Thiele

Thiele TWN 0861 User manual

Thiele

Thiele TWN 0119 User manual

Thiele

Thiele Streamfeeder Value Series User manual

Thiele

Thiele TWN 0812 User manual

Thiele

Thiele TWN 1340/1 User manual