EAMM-U-...-T...-...A/P/R-2

Parallel kit

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Assembly instructions

8133030

2021-08c

[8133032]

Translation of the original instructions

© 2021 all rights reserved to Festo SE & Co. KG

1Applicable documents

All available documents for the product è www.festo.com/sp.

Observe further applicable documents:

–Operating instructions, motor

–Operating instructions, axis

2 Safety

2.1 Safety instructions

–Only mount the product on components that are in a condition to be safely

operated.

–Clean the shafts. The coupling hub [17] will grip without slipping only on a drive

shaft which is dry and free of grease.

–Maintain the alignment of the coupling hub [17].

–If the motor is loosened or turned, homing must be carried out on the axis.

–Select required mounting components. The kit contains all the mounting com-

ponents that may be required.

–Observe tightening torques. Unless otherwise specified, the tolerance is

± 20 %.

2.2 Intended use

2.2.1 Use

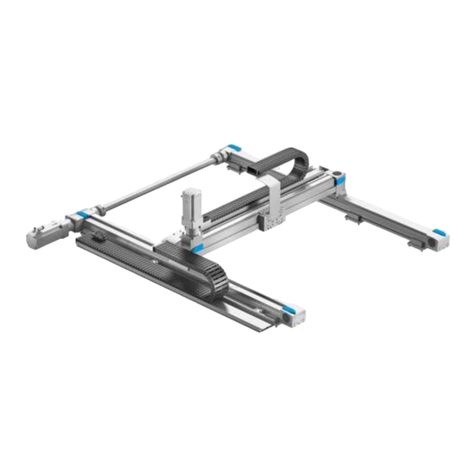

The parallel kit connects an axis to a motor in a parallel configuration.

2.2.2 Permissible axes and motors

NOTICE

Overloading can cause malfunction and material damage.

The motor’s output variables must not exceed the permissible values of the

components used.

Permissible values è www.festo.com/catalogue.

• Limit the motor’s output variables accordingly.

•Derive the axis and motor from the interface codes.

Example: EAMM-U-...-T42-60P

T42: axis interface

60P: motor interface

Axis interface Axis1)

T42 EGSC-BS-60, ELGC-BS-60, EPCC-BS-60

T46 ELGC-BS-80, ELGT-BS-90, ELGT-120, ELGT-160

1) Mini slide EGSC-BS, spindle axis ELGC-BS, spindle axis ELGT-BS, electric cylinder EPCC-BS

Tab. 1: Permissible axes

Motor interface Motor1)

57A EMCS-/EMMS-ST-57, third-party motor

60P EMMB-/EMME-/EMMT-AS-60, Fremdmotor

67A EMCA-EC-67

1) Servo motor EMM...-AS/third-party motor, stepper motor EMM...-ST/third-party motor, integrated drive

EMC...

Tab. 2: Permissible motors

It is the responsibility of users to qualify third-party motors with the matching

mechanical interface for the combination.

To find out which third-party motors are suitable, contact your regional Festo

contact or call è www.festo.com/sp.

2.3 Training of qualified personnel

Work on the product may only be carried out by qualified personnel who can eval-

uate the work and detect dangers. Personnel must have the relevant mechanical

training.

3 Additional Information

–Accessories è www.festo.com/catalogue.

4 Product Range Overview

4.1 Scope of delivery

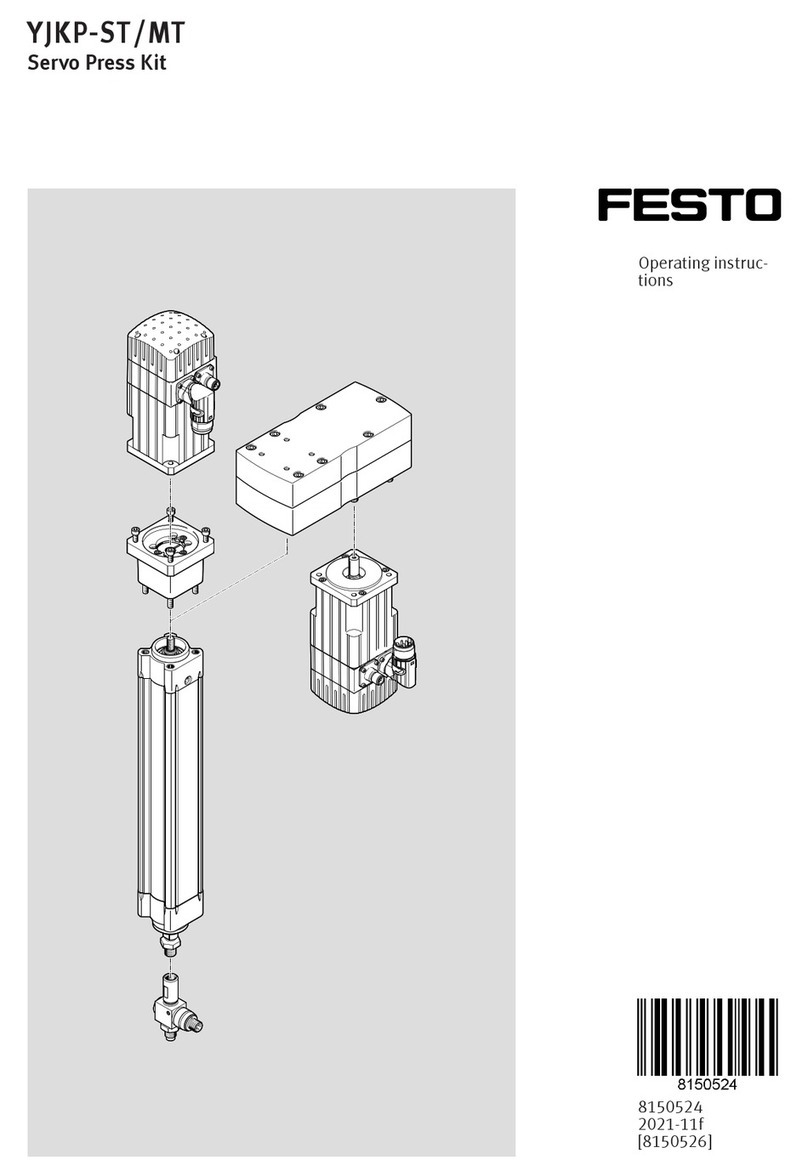

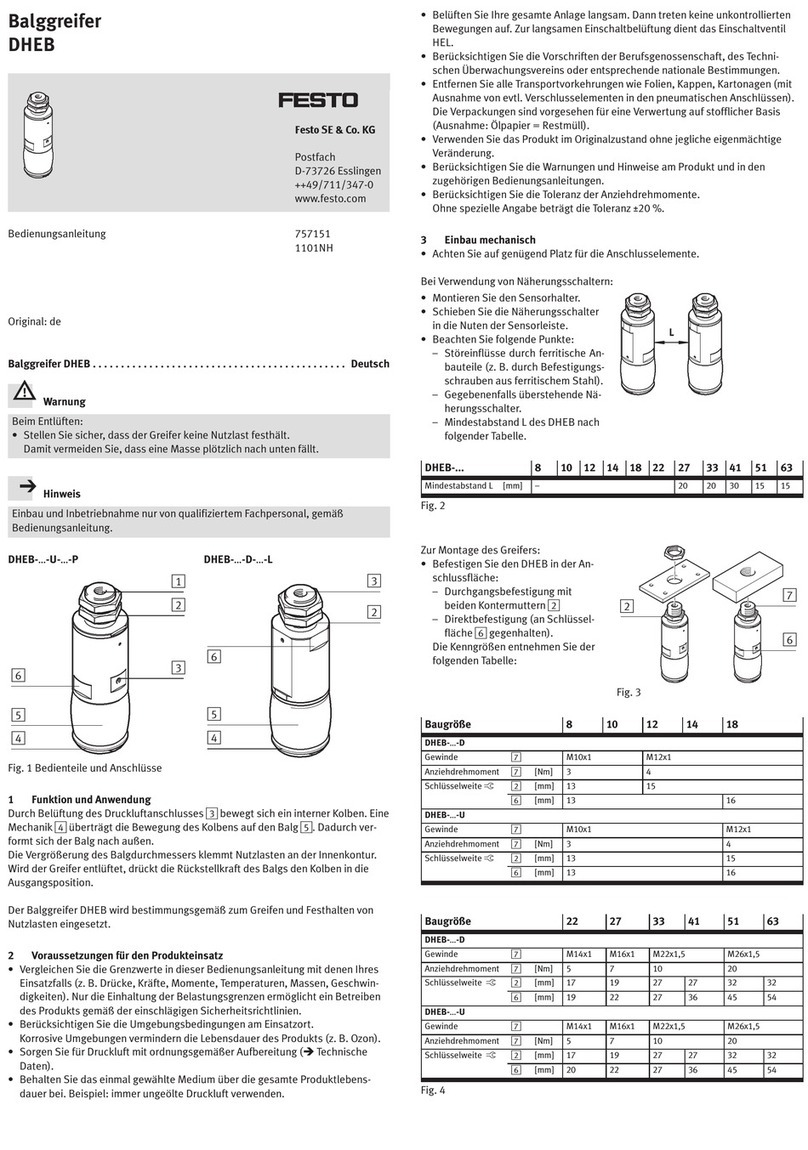

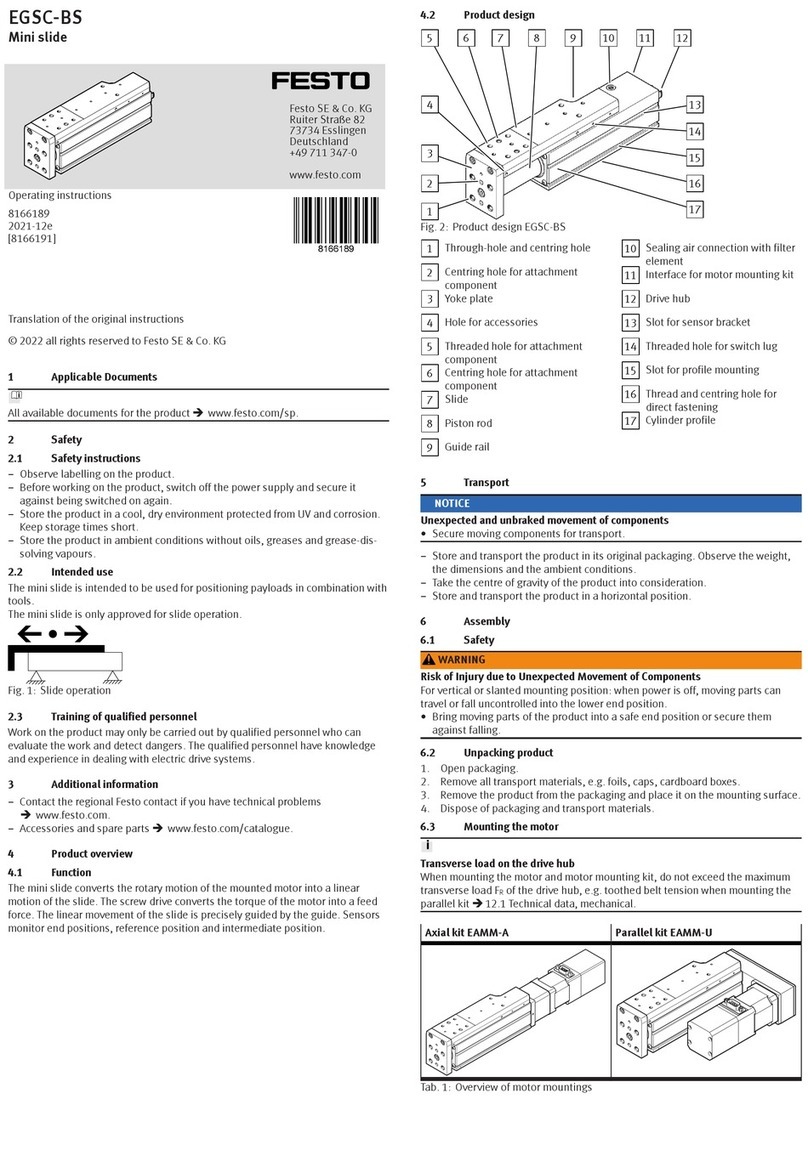

Fig. 1: Basic scope of delivery

1Housing (1x)

2Screw (4x)

5Toothed belt (1x)

6Toothed belt pulley axis (1x)

7Cover (1x)

8Screw (3x)

9Square nut (4x)

10 Screw (4x)

15 Toothed belt pulley motor (1x)

16 Clamping screw (1x)

17 Coupling hub (1x)

18 Retaining ring (2x)

19 Elastomer star (2x)

20 Slip ring (2x)

The square nut [9] is not included with EAMM-U-...-67A.

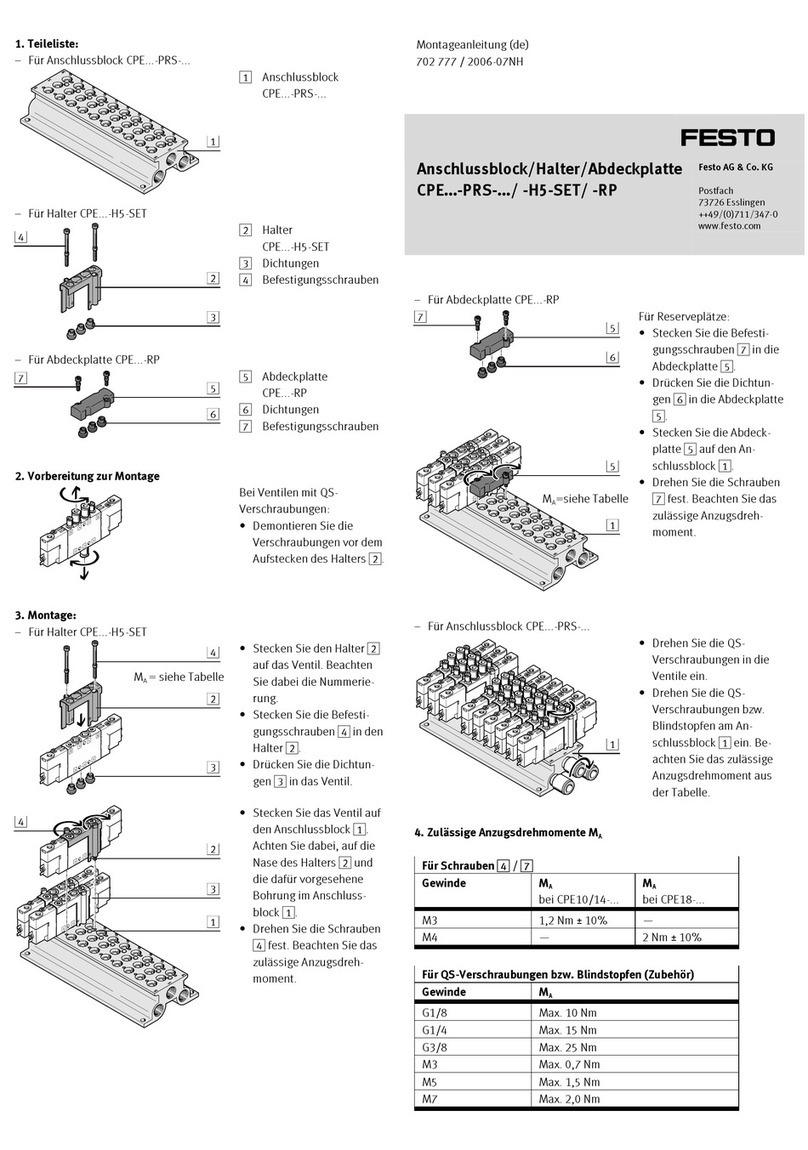

Fig. 2: Addendum with EAMM-U-...-67A

40 Adapter plate (1x) 41 Screw (4x)

5 Assembly

5.1 Assembly

5.1.1 Preassembly of adapter plate (with EAMM-U-...-67A)

Fig. 3: Mount adapter plate

•Fasten the adapter plate [40] to the motor with the screws [2].