TABLE OF CONTENTS

What You Can Do With This Machine ............................................................................... 9

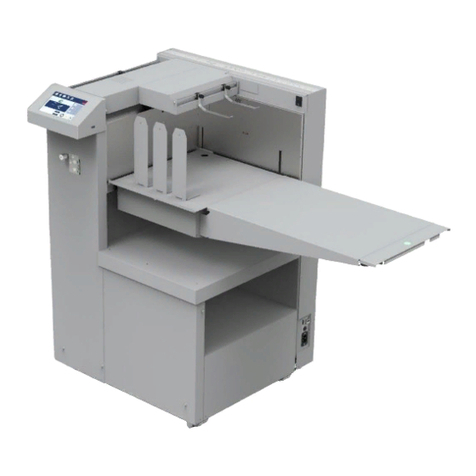

Guide To Components ..................................................................................................... 10

1. Basics............................................................................................... 13

Turning On / O the Stacker Power ................................................................................ 13

Undocking the Stacker..................................................................................................... 14

Docking the Stacker......................................................................................................... 14

Setting the Paper Support ............................................................................................... 15

2. Control Panel ................................................................................... 17

Control Panel .................................................................................................................... 17

Table positioning lever ................................................................................................................ 17

Pause / Resume button .............................................................................................................. 17

LED bar....................................................................................................................................... 17

Fan speed adjustment ................................................................................................................ 18

Software version ......................................................................................................................... 18

Status LED.................................................................................................................................. 19

Sheet counter ............................................................................................................................. 19

3. Jobs .................................................................................................. 21

Handling jobs.................................................................................................................... 21

Table position.............................................................................................................................. 21

Setting Sheet Guide & End Stop ................................................................................................ 22

Setting Long Sheet Guide & Long Sheet End Stop .................................................................... 26

4. Maximum Stack Height ................................................................... 31

Stack Limit ........................................................................................................................ 31

5. Troubleshooting .............................................................................. 33

Fault codes........................................................................................................................ 33

General ....................................................................................................................................... 33

Fault codes list............................................................................................................................ 34

6. Remarks ........................................................................................... 35

Do’s And Don’ts................................................................................................................ 35

Safety Features................................................................................................................. 36

Infeed Unit / Stacker Table Interlock Switch .......................................................................................... 36

Infeed Side Guides / Stacker Table Interlock Switch............................................................................. 37

Where to put Your Stacker............................................................................................... 38

Machine environment ................................................................................................................. 38

Power connection ....................................................................................................................... 38

Maintaining Your Stacker................................................................................................. 39

Cleaning the sensors.............................................................................................................................39

Stacker Operational Best Practices................................................................................ 40

Stacker Limitations .......................................................................................................... 40

7. Specication ................................................................................... 41

Machine Specications.................................................................................................... 41

Stacker Stack Quality Specication ............................................................................... 42