Pag. 2di 14

TABLE OF CONTENTS

1. Introduction............................................................................................................................................... 3

2. Manufacturer............................................................................................................................................. 3

3. General information .................................................................................................................................. 3

4. Warnings.................................................................................................................................................... 4

5. Technical data............................................................................................................................................ 5

5.1. Product performance ................................................................................................................................ 5

5.2. Brake lining wear....................................................................................................................................... 6

5.3. Special note ............................................................................................................................................... 6

6. Transport and storage ............................................................................................................................... 7

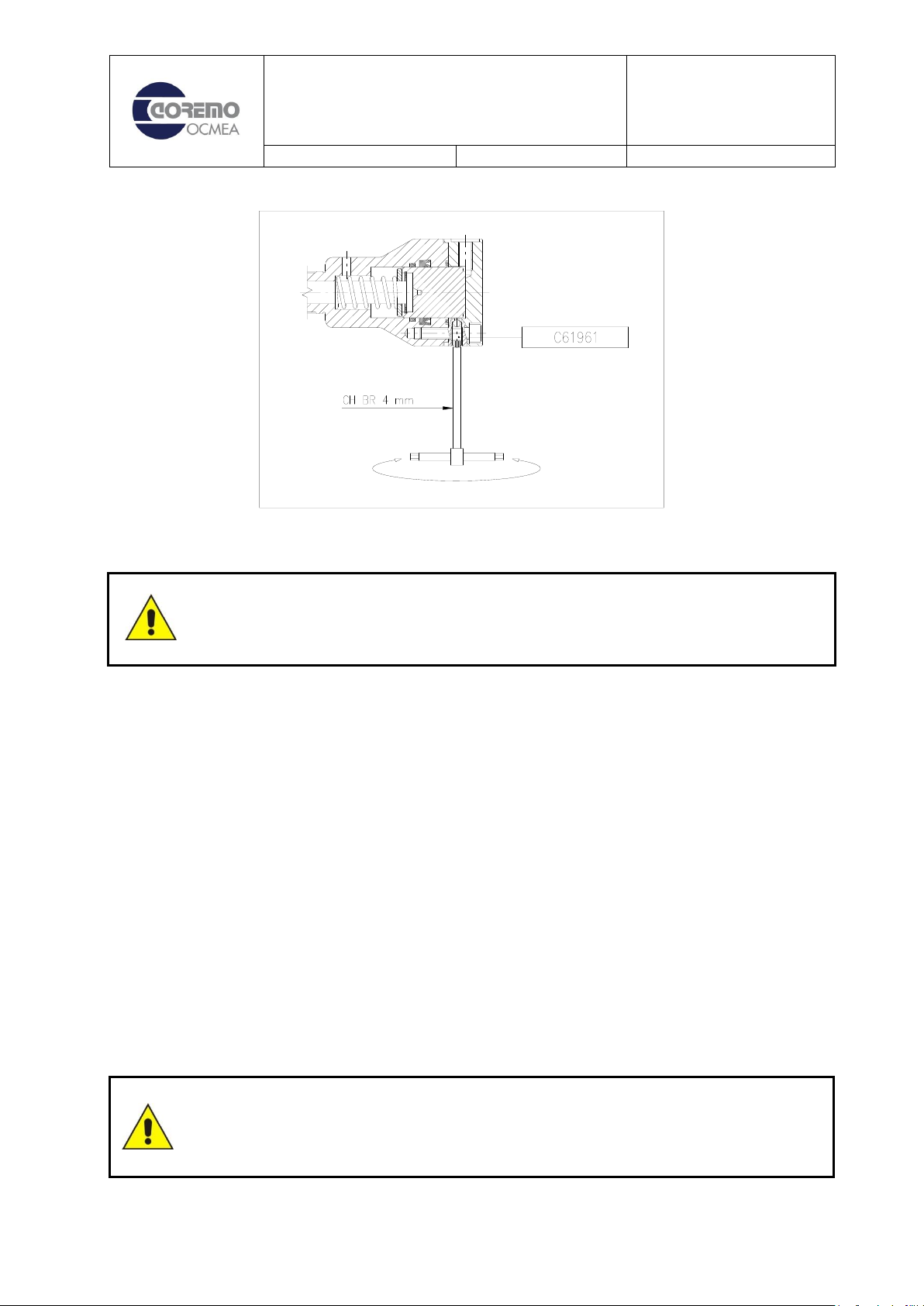

7. Installation................................................................................................................................................. 7

8. Operation................................................................................................................................................. 10

8.1. Power supply of the product................................................................................................................... 10

8.2. Improper use ........................................................................................................................................... 11

9. Maintenance and cleaning ...................................................................................................................... 11

9.1. Readjusting the play ................................................................................................................................ 11

9.2. Changing the lining pads and cleaning the friction surfaces................................................................... 11

9.3. Changing the thruster spring (brakes D05 , D1 , D2 , D3 e D3-ID)........................................................... 12

9.4. Changing the thruster spring (brake D–M).............................................................................................. 12

9.5. Changing the diaphragm and the gaskets ............................................................................................... 12

9.6. Changing the brake shoe alignment springs ........................................................................................... 13

9.7. Periodic maintenance.............................................................................................................................. 13

10. Spare parts list......................................................................................................................................... 14