Baumalight CP560 User manual

CP560 and CP572 BRUSH CUTTER

OPERATOR’S MANUAL

Issue Date: July 2021

TABLE OF CONTENTS

1 INTRODUCTION����������������������������������������������������������������������������������������������������������������������������������� 1

1�1 Overview�������������������������������������������������������������������������������������������������������������������������������� 1

1�2 Intended Use And Foreseeable Misuse ������������������������������������������������������������������������������ 2

2 SAFETY ������������������������������������������������������������������������������������������������������������������������������������������������ 3

2�1 Safety Alert Symbol And Safety Words ������������������������������������������������������������������������������ 3

2�2 Operational Hazards������������������������������������������������������������������������������������������������������������� 3

Prepare for Emergencies ����������������������������������������������������������������������������������������������������������������� 4

Replace Safety Signs ����������������������������������������������������������������������������������������������������������������������� 4

Do Not Allow Riders ������������������������������������������������������������������������������������������������������������������������� 4

Lower Operating Speed ������������������������������������������������������������������������������������������������������������������� 5

Avoid Rollover ���������������������������������������������������������������������������������������������������������������������������������� 5

Avoid Powerlines & Underground Utilities ������������������������������������������������������������������������������������ 5

Detach Cutter Safely ������������������������������������������������������������������������������������������������������������������������ 5

Hazards From Modifying Equipment ���������������������������������������������������������������������������������������������� 5

2�3 Maintenance Hazards����������������������������������������������������������������������������������������������������������� 7

3 SAFETY SIGNS ������������������������������������������������������������������������������������������������������������������������������������ 8

4 OPERATION ��������������������������������������������������������������������������������������������������������������������������������������� 10

4�1 Preparation For Use ����������������������������������������������������������������������������������������������������������� 10

4�2 Remove Skid ����������������������������������������������������������������������������������������������������������������������� 10

4�3 Driveshaft Dimension����������������������������������������������������������������������������������������������������������11

4�4 Machine Components �������������������������������������������������������������������������������������������������������� 12

4�5 Attach To Tractor ���������������������������������������������������������������������������������������������������������������� 12

4�6 Transporting������������������������������������������������������������������������������������������������������������������������ 13

4�7 First Time User Tips ����������������������������������������������������������������������������������������������������������� 13

4�8 Field Operation ������������������������������������������������������������������������������������������������������������������� 13

4�9 Detach From Tractor����������������������������������������������������������������������������������������������������������� 15

5 SERVICE AND MAINTENANCE��������������������������������������������������������������������������������������������������������� 16

5�1 Every Two Hours����������������������������������������������������������������������������������������������������������������� 16

5�2 Every Eight Hours��������������������������������������������������������������������������������������������������������������� 16

5�3 Replace Blades ������������������������������������������������������������������������������������������������������������������� 17

5�4 Squaring Blades ����������������������������������������������������������������������������������������������������������������� 17

5�5 Slip Clutch Tension ������������������������������������������������������������������������������������������������������������ 18

6 TROUBLESHOOTING������������������������������������������������������������������������������������������������������������������������ 19

7 STORAGE������������������������������������������������������������������������������������������������������������������������������������������� 20

7�1 Storing Brush Cutter ���������������������������������������������������������������������������������������������������������� 20

7�2 Removing Brush Cutter From Storage����������������������������������������������������������������������������� 20

7.2.1 Slip Clutch.................................................................................................................. 20

8 WARRANTY���������������������������������������������������������������������������������������������������������������������������������������� 21

ii

1 INTRODUCTION

Congratulations on your choice of a Baumalight

3-Point Brush Cutt to complement your brush

cutting operation. This equipment has been

designed and manufactured to meet the needs of

a discriminating buyer for efcient brush cutting.

The unique blade design reduces the brush

to mulch. Controlling the brush cutter is done

completely from the tractor providing the ability for

precise control and all day operator comfort.

Tractor must have suitable safety equipment

properly installed.

Safe, efcient and trouble free operation of your

Brush Cutt requires that you and anyone else

who will be operating or maintaining the Brush

Cutt, read and understand the Safety, Operation,

Maintenance and Troubleshooting information

contained within the Operator’s Manual.

This manual covers the Baumalight PTO Brush

Cutt. Use the Table of Contents as a guide to

locate required information.

Keep this manual handy for frequent reference

and to pass on to new operators or owners. Call

your Baumalight dealer, distributor or the factory

if you need assistance, information or additional

copies of the manuals.

OPERATOR ORIENTATION - The directions left,

right, front and rear, as mentioned throughout this

manual, are as seen from the tractor driver’s seat

and facing in the direction of travel.

1�1 Overview

1

The cutter is designed to be used by an

experienced operator. Operator must be trained in

the safe operation of a tractor and hazards related

to using the brush cutter and the safe use of the

brush cutter for the intended purpose. Operators

will require personal protective equipment to

reduce the risk from some hazards that cannot be

completely eliminated or controlled by the design

of the cutter.

Care is required to ensure that the brush cutter will

not come in contact with metallic objects, stones or

other materials.

Brush cutters are not designed for use in

hazardous atmospheres where there is a risk

of re or explosion due to ammable gases or

vapors. Use in hazardous, explosive atmospheres

is prohibited. Serious injury or death of the operator

or bystanders may be caused if cutter is misused.

Misuse may also cause damage to the machine

carrying the cutter.

1�2 Intended Use And Foreseeable

Misuse

2

2 SAFETY

You must read, understand and follow the

instructions given by the operating unit

manufacturers, as well as the instructions in this

manual.

The safety information in this manual is denoted

by the safety alert symbol:

^

This symbol means ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED!

The level of risk is indicated by the following signal

words:

^^ DANGER

DANGER - Indicates a hazardous

situation, which, if not avoided, WILL

result in death or serious injury�

^ WARNING

WARNING - Indicates a hazardous

situation, which, if not avoided, could

result in death or serious injury�

^ CAUTION

CAUTION - Indicates a hazardous

situation, which, if not avoided, could

result in minor or moderate injury�

NOTICE

NOTICE - Indicates a situation that could

result in damage to the equipment or

other property.

2�1 Safety Alert Symbol And Safety

Words

2�2 Operational Hazards

^ WARNING

Prevent death or serious injury�

Read and understand this manual before

operating cutter�

Always stop engine and remove key

before leaving operators seat�

Never allow anyone near the cutter

during operation�

Travel at a safe speed�

^ WARNING

Prevent death or serious injury from

moving parts�

Moving parts can crush and dismember�

Do not operate without guards and

shields in place�

Disconnect and lockout power source

before adjusting or servicing�

^ WARNING

Use cutter only for the designed

applications�

Any other use may result in personal

injury, damage to equipment and may

void the warranty�

3

^ WARNING

Prevent death or serious injury�

Verify cutter is locked to tractor hitch

before operation or transport�

^ WARNING

Protect from ying debris.

Wear proper safety glasses, goggles,

or a face shield to protect from ying

debris�

Carefully read all safety messages in this manual

and on equipment safety signs. Keep safety signs

in good condition and replace missing or damaged

safety signs.

New equipment components and repair parts must

include the current safety decal.

Learn how to properly operate equipment.

NEVER operate or work around this equipment

without proper instruction, while fatigued or under

the inuence of alcohol, prescription or non-

prescription medication or if feeling ill.

Keep your equipment in proper working condition.

Know the regulations and laws that apply to you

and your industry. This manual is not to replace

any regulations or laws. Additional information

may be found at: www.asae.org or www.osha.gov.

If you do not understand any part of this manual,

contact Baumalight at 866-820-7603.

Prepare for Emergencies

• Be prepared in case of emergencies.

• Keep a re extinguisher and rst aid kit close

to the machine.

• Keep emergency phone numbers close to

your phone.

• Know your address so emergency services

can locate you if an emergency arises.

Replace Safety Signs

• Replace missing or damaged safety signs.

• Safety signs are identied in Section 3 of this

manual.

• Replacement safety signs are available from

your Baumalight dealer.

Do Not Allow Riders

• NEVER lift or carry anyone on cutter.

• NEVER use cutter as a work platform.

• NEVER allow passengers on cutter.

4

Lower Operating Speed

Keep cutter low and move at slow speeds on rough

or uneven terrain.

Lower operating speed while operating in heavy

conditions.

Avoid Rollover

The equipment may rollover, resulting in death or

serious injury. To help prevent rollover:

• Travel at a slow speed.

• Avoid sharp turns & sudden movement on

slopes.

• Carry cutter close to the ground.

• Avoid holes, ditches and other obstructions

which may cause equipment to rollover.

• Balance load so weight is evenly distributed

and load is stable.

• Use caution when operating on slopes and do

not operate on excessively steep slopes.

• Do not exceed load capacity of equipment.

Avoid Powerlines & Underground

Utilities

^ DANGER

Prevent electrocution�

Death or serious injury can result if

equipment comes near or contacts

power lines�

Electrocution can occur without direct

contact�

• Check clearance before raising equipment.

• Have local utilities locate and mark under

ground wires, cables, pipelines and other

hazards before operation.

DO NOT leave the operator’s seat if any part of the

equipment contacts electric lines or cables.

Detach Cutter Safely

Detach cutter on a rm and level surface. Be sure

people, livestock and pets are clear of machinery.

Raised Attachment

^ WARNING

Crushing hazard�

Raised, unsupported cutter can fall,

resulting in death or serious injury�

Never enter the area under a raised

cutter�

A raised cutter can lower unexpectedly, resulting in

death or serious injury.

NEVER enter area under a raised cutter.

Lower cutter to ground, engage parking brake,

shut off engine and remove key before servicing.

Hazards From Modifying Equipment

Do not make any alterations to your cutter. Altering

may cause your equipment to be unsafe and may

void the manufacturers’ warranty.

5

Avoid Loud Noise

^ WARNING

Prolonged exposure to loud noise can

cause impairment or loss of hearing�

Wear a suitable hearing protective device

such as earmuffs or earplugs to protect

against objectionable or uncomfortable

loud noises�

Stay Clear Of Rotating Driveshaft

^ WARNING

Entanglement in a rotating driveshaft

can cause serious injury or death�

Keep tractor shields and driveshaft

shields in place at all times� DO NOT

operate without driveshaft shields�

DO NOT wear loose tting clothing.

Avoid Wood Dust Inhalation

^WARNING

Drilling, sawing, sanding or machining

wood products can expose you to wood

dust, a substance known to the State of

California to cause cancer�

Avoid inhaling wood dust or use a dust

mask or other safeguards for personal

protection� For more information go to

www�P65Warnings�ca�gov/wood�

^WARNING

Wear an approved dust mask or

respirator�

Follow local, state and federal

regulations�

6

2�3 Maintenance Hazards

Before servicing, park machine on a rm and

level surface, set parking brake and place a “Do

Not Operate” tag on control panel. Read and

understand this manual. If you do not understand

any part of the manual, contact Baumalight at 866-

820-7603.

Always wear face and/or eye protection, safety

shoes, and other protective equipment appropriate

for the job.

Do not make unauthorized modications. Contact

Baumalight at 866-820-7603. Before you weld,

cut/drill holes, or make any other modications.

Always use Baumalight replacement parts.

^ WARNING

Moving parts can crush and cut�

Keep clear of moving components�

Follow lockout procedure before

servicing�

^ WARNING

Crushing hazard�

Before performing inspections, service

or maintenance:

Park machine on rm, level surface.

Engage parking brake�

Turn engine off and remove key�

Place “Do Not Operate” tag on control

panel�

^ WARNING

Entanglement hazard�

Keep clear of moving components�

Wear proper protective equipment

appropriate for the job�

7

A. D005255 ^WARNING - Rotating blade

hazard. Keep back 75 m while machine

is operating. Wait for blade to stop before

approaching machine.

D005365

B. D005252 ^WARNING - Read and understand

safety signs on the machine and operating

instructions in this manual before operating

machine.

D005125

3 SAFETY SIGNS

The two and four panel safety decals are pictorial

and have a yellow background. The panel with a

triangle indicates the potential hazard. The panel

without a triangle indicates how to avoid the

hazard.

If any of the decals are missing, are damaged, or

if you do not understand the decal, please contact

your dealer.

A

D

B

A

E

C

8

C. D005521 ^WARNING - Remove key before

servicing.

D005522

D. D005262 ^WARNING - P65 warning

information.

WARNING: This product can expose you to chemicals

including 1,3-Butadiene and lead, which are known to the state of

California to cause cancer and birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov.

D005262

E. D005336 ^WARNING - Rotating driveshaft.

Entanglement hazard. Keep away from

driveshaft while it is rotating.

D005224

9

Although the cutter has been carefully inspected

and checked prior to shipment from manufacturer,

it is recommended that the unit be thoroughly

inspected.

Check all bolts for tightness and remove all

shipping tags, bags, skids, and blocking.

Remove any masking materials afxed during

painting. Inspect equipment to verify that

nameplates and all safety warning, caution signs

and decals provided with the equipment are in

place and clearly visible.

Visually inspect the cutter before each start up.

Check for loose or missing parts and any damage

that may have occurred during moving or shipping.

Review all tractor pre-start instructions, and ensure

that all recommended steps and procedures have

been followed.

4 OPERATION

4�1 Preparation For Use 4�2 Remove Skid

If cutter is shipped on a skid, it will be in a vertical

position and must be lowered to horizontal position

before use.

^ WARNING

Crushing hazard�

Use adequate lifting devices to lower

cutter to working position�

Never enter the area under a raised

cutter�

Always keep the weight of the cutter in mind.

Never position body in line of impact or under

cutter.

10

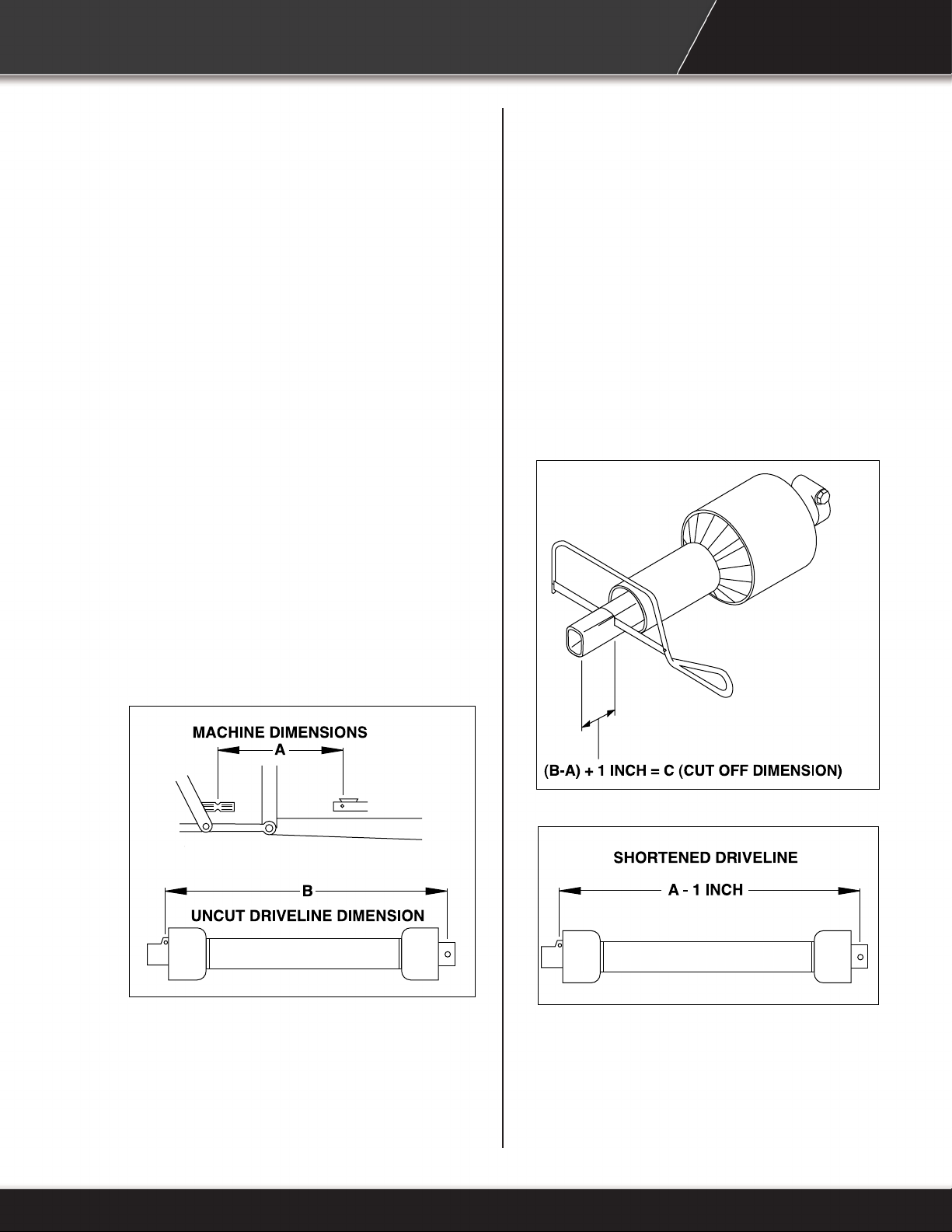

4�3 Driveshaft Dimension

To accompany the variety of 3 point hitch geometry

available today, the driveshaft can be too long for

most machines or too short for others. It is very

important that the driveshaft be free to telescope

but not to bottom out when going through its

working range. If the driveshaft bottoms out, the

bearings on both the machine and tractor PTO

shaft will be overloaded and fail in a short time.

To determine the proper length of the driveshaft,

follow this procedure:

1. Attach brush cutter to tractor but do not attach

driveshaft.

2. Raise cutter until the input shaft is level with

tractor PTO shaft.

3. Measure dimension (A) between locking

grooves on tractor PTO shaft and cutter input

shaft.

4. Measure same dimension (B) on compressed

driveshaft.

5. If compressed driveshaft dimension (B)

exceeds the machine dimension (A), driveshaft

must be cut.

When cutting driveshaft, follow this procedure:

1. Subtract machine dimension (A) from uncut

driveshaft dimension (B). This dimension

determines how much too long the driveshaft

is.

2. Add 1 inch (25 mm) to the dimension to be

sure it doesn’t bottom out, to determine cut off

dimension (C).

3. Use a hacksaw to cut dimension (C) from both

ends. Cut both plastic tubes and metal cores.

4. Use a le to remove burrs from cut edges.

5. Assemble shaft.

6. Make sure shaft can telescope freely. If it does

not, separate and inspect for burrs or cuttings

on shaft ends. Be sure it telescopes freely

before installing.

11

^ WARNING

To prevent injury or machine damage

put transmission in “Park”�

Check the full range of hitch for

interference, binding or PTO separation�

Never position yourself between tractor

and cutter�

Only experienced and properly trained

operator may operate tractor and cutter�

1. Read and follow all safety instructions.

2. Back up tractor to brush cutter with hitch points

approximately in alignment.

3. Engage tractor park brake and/or place

transmission in park.

4. Shut off engine and remove key.

5. Attach lower links to cutter and retain using

lock pins.

6. Align top link with hole in top of frame and

retain with pin and lock pin.

7. Pull PTO shaft collar back toward cutter.

8. Align splines and push drive shaft onto tractor

PTO shaft until it snaps into place. Pull back on

shaft to make sure it is locked in place.

9. Attach safety shield chain.

10. Adjust top link so brush cutter lower frame is

vertical to ground.

11. Move to a clear open area to test functions.

4�5 Attach To Tractor

A. Brush Guard

B. 3-Point Top Link

C. 3-Point Lift Points

D. Debris Guard

E. Gearbox

F. Blades

A

D

E

B

C

F

4�4 Machine Components

12

1. Verify all reectors and Slow Moving Vehicle

(SMV) sign are visible.

2. Verify PTO is disengaged.

3. Raise cutter to fully raised position.

4. Travel at a reasonable and safe speed.

4�7 First Time User Tips

Operate all functions in a clear area with tractor at

low speed to get a good feel for the controls before

you actually move into any brush.

Choose low density brush and move into it slowly,

do not expect to get the rst area done fast.

Operate with cutter slightly raised until you have a

better feel how much the unit can take.

Use push bar to push brush or small trees over

and allow cutter teeth to contact lower portion of

brush and mulch it or cut it off. The rest of the plant

will be mulched as the machine moves through the

working area.

Each operator must experiment to nd a technique

that works for them in their application.

Although it is best to mulch when it is dry, the

machine works well in wet conditions. However,

you must travel slower to do the same quality

mulching. It will also be necessary to clean the

machine more frequently to prevent clogging.

^ WARNING

Always stop engine and remove key

before leaving operators seat�

4�6 Transporting 4�8 Field Operation

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park tractor on a level surface�

2� Lower cutter to ground�

3� Engage tractor parking brake�

4� Shut off engine and remove key�

^ WARNING

Entanglement in a rotating driveshaft

can cause serious injury or death�

Keep tractor shields and driveshaft

shields in place at all times� DO NOT

operate without shields and guards�

DO NOT wear loose tting clothing.

^ WARNING

Never operate brush cutter when other

people are in the vicinity�

Debris can be thrown from cutting area�

Keep all shields and guards in place�

Do not allow riders on tractor�

13

^WARNING

Drilling, sawing, sanding or machining

wood products can expose you to wood

dust, a substance known to the State of

California to cause cancer�

Avoid inhaling wood dust or use a dust

mask or other safeguards for personal

protection� For more information go to

www�P65Warnings�ca�gov/wood�

^WARNING

Wear an approved dust mask or

respirator�

Follow local, state and federal

regulations�

1. Inspect work area to verify there are no rocks,

metal or other debris before cutting.

2. Attach cutter to tractor. See Attaching/

Detaching in this section.

^ WARNING

Prevent serious injury or death�

Operating unit must be equipped with a

forestry guard to protect the operator�

1. Lower cutter so skid plates are on ground.

2. Set engine speed to low idle and engage cutter.

3. Slowly increase engine speed to high idle.

4. Verify cutter is operating smoothly and start

travel.

5. If cutter stalls, stop movement, slightly raise

cutter and allow rotor to regain speed. Slow

ground speed to prevent further stalling.

^ WARNING

Moving parts can crush and cut�

Keep clear of moving components�

Lockout operating unit before clearing

jams�

^ WARNING

Moving parts can crush and cut�

Keep clear of moving components�

Lockout operating unit before clearing

jams�

14

4�9 Detach From Tractor

^ WARNING

Prevent death or serious injury caused

by unexpected movement:

1� Park tractor on a level surface�

2� Lower cutter to ground�

3� Engage tractor parking brake�

4� Shut off engine and remove key�

1. Park tractor on a level surface.

2. Lower cutter to the ground.

3. Shut off engine and remove key.

4. Disconnect driveshaft safety chain.

5. Support driveshaft and pull collar back toward

cutter. Slide driveshaft off of shaft.

6. Remove lock pin and pin.

7. Place top link in storage position.

8. Remove lock pins and pins from both lower

links.

15

5 SERVICE AND

MAINTENANCE

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park tractor on a level surface�

2� Lower cutter to ground�

3� Engage tractor parking brake�

4� Shut off engine and remove key�

1. Inspect blades for wear and damage. Replace

blades when worn to 3 in. (76 mm) minimum

width (A). As an option, blades can be re-

squared with a grinder. See section 5.4 for

blade sharpening procedure.

If blades need replacing, see section 5.3 for blade

replacement procedure.

Operating with dull or worn blades may result in:

• Slip clutch failure.

• Extreme blade bolt wear.

• Blade bar fatigue, cracking and total failure.

• Blade fatigue, cracking and total failure.

• Deck fatigue and cracking.

• Increased amount of discharge or debris.

• Poor cutting.

A

2. Inspect blade attachment hardware for worn,

damaged or missing hardware. Install new

blade hardware as needed.

5�1 Every Two Hours 5�2 Every Eight Hours

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park tractor on a level surface�

2� Lower cutter to ground�

3� Engage tractor parking brake�

4� Shut off engine and remove key�

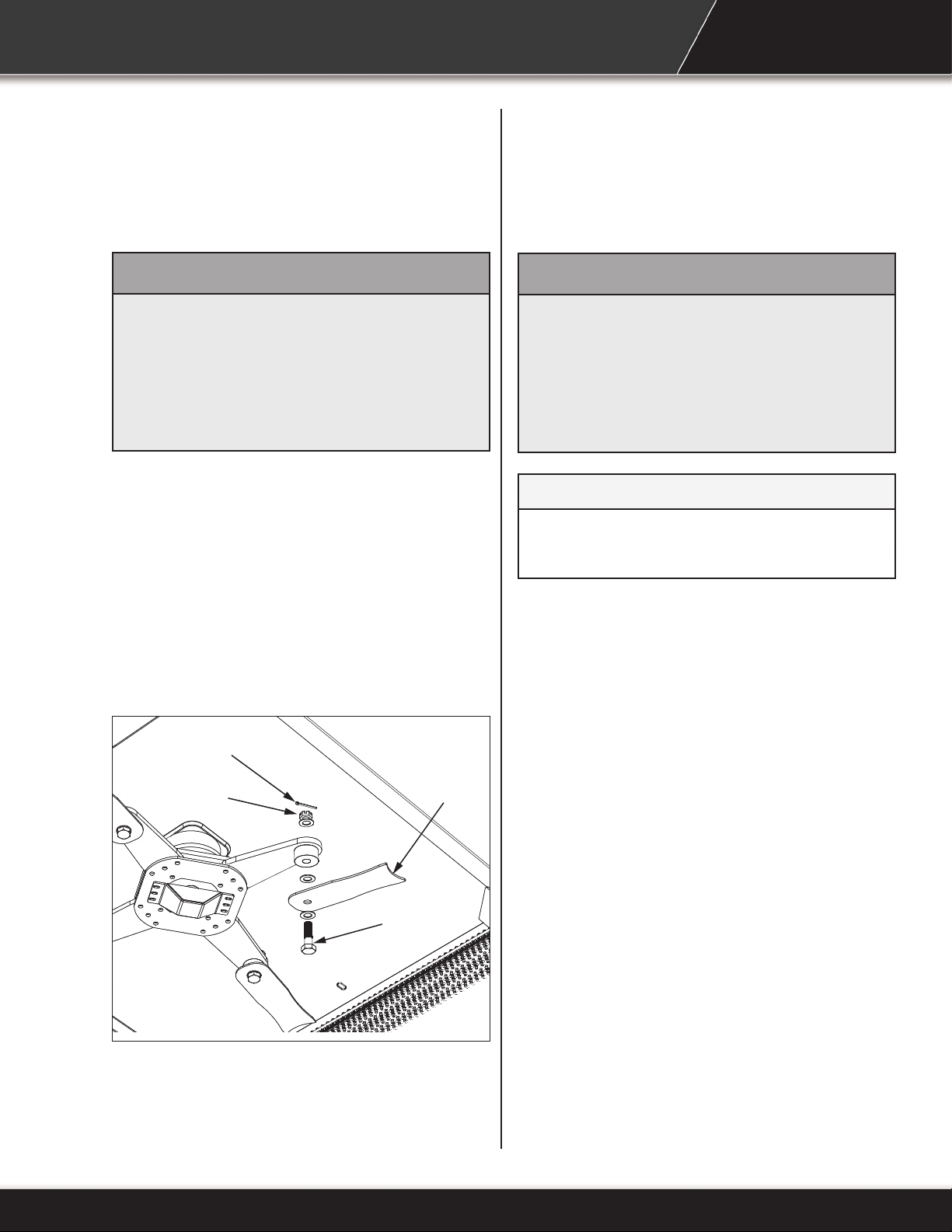

1. Pump grease into driveshaft ttings until

adequately lubricated.

2. Remove gearbox plug (A). Gearbox oil level

should be up to bottom of hole. Add 90W

synthetic oil if low. Install plug (A).

A

16

5�3 Replace Blades

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park tractor on a level surface�

2� Lower cutter to ground�

3� Engage tractor parking brake�

4� Shut off engine and remove key�

1. Inspect blades for damage.

2. Replace blades in pairs. Replacing only one

blade can cause cutter to be out of balance.

3. Remove cotter pin (A), nut (B), bolt (C) and

blade (D).

4. Install new blade (D), bolt (C), washers and nut

(B).

5. Tighten nut (B) until snug, but blade swings

freely.

6. Install cotter pin (A) through nut (B) and bolt

(C). Bend cotter pin ends over to secure.

A

BD

C

5�4 Squaring Blades

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1� Park tractor on a level surface�

2� Lower cutter to ground�

3� Engage tractor parking brake�

4� Shut off engine and remove key�

NOTICE

Prevent equipment damage.

Do not overheat blade when grinding.

Do not overheat blade. Allowing grinder to stop or

rest in one spot will cause the material to overheat.

Blade will turn blue if overheated. An overheated

blade must be replaced.

The outer 1.5 in. (38 mm) of the blade is where all

cutting takes place. This point of contact and the

blade bevel must be maintained.

Always remove equal amount of blade material

from the paired blades.

Blades must be kept within 2 oz. (57 g) of each

other or cutter may vibrate. Always keep blades in

the same pairs as removed from the cutter.

17

^ WARNING

Entanglement in a rotating driveshaft

can cause serious injury or death�

Disconnect and lockout power source

before adjusting or servicing�

^ CAUTION

Slip clutch may be hot� Wait for clutch to

cool before adjusting or servicing�

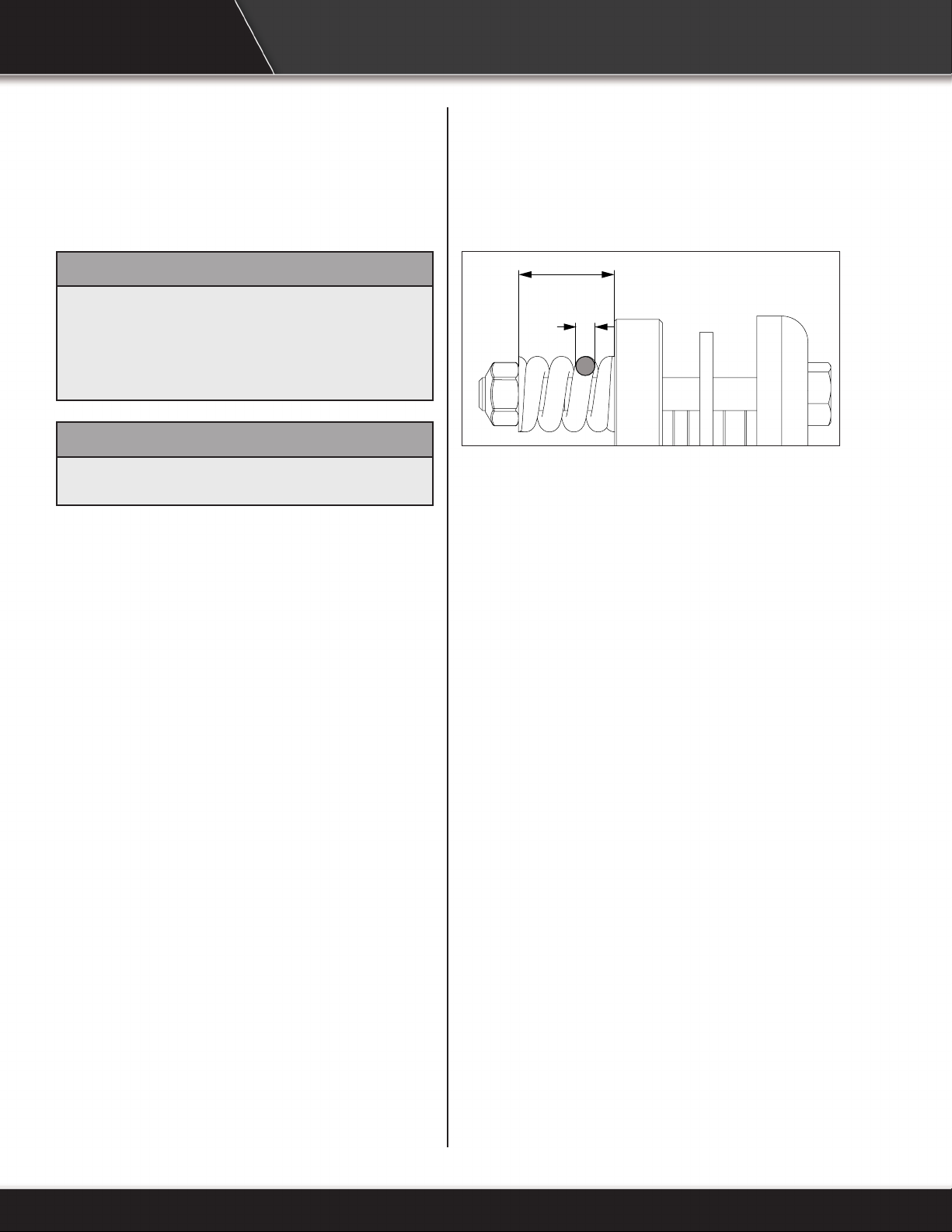

Bondioli Driveshafts

4-Disk 120 Hp 1,000 rpm

• OEM Part Number

• 71R8121UCKR80V6

• Dimension A - 0.236 in. (6 mm)

• Dimension B - 1.12 in. (28.5 mm)

4-Disk 165 Hp 1,000 rpm

• OEM Part Number

• CSHN086U2R100W8

• Dimension A - 0.275 in. (7 mm)

• Dimension B - 1.14 in. (29 mm)

Binacchi Drivehafts

2-Disk 68 Hp 540 rpm

• OEM Part Number

• B6140EA60255

• B6N121USA60255

• Dimension A - 0.236 in. (6 mm)

• Dimension B - 1.1 in. (28 mm)

4-Disk 80 Hp 540 rpm

• OEM Part Number

• B8N111USA60307

• B8#140EA60307

• Dimension A - 0.275 in. (7 mm)

• Dimension B - 1.15 in. (29 mm)

5�5 Slip Clutch Tension

B

A

18

This manual suits for next models

1

Table of contents

Other Baumalight Brush Cutter manuals